Last Updated on 2025-09-03 by SolenoidFactory

In the realm of electromagnetic devices, sucker electromagnet occupy a unique niche. These devices leverage the principles of electromagnetism to create an adhesive force, allowing them to lift and hold objects against a surface. This blog aims to explore the working principle of sucker electromagnets, shedding light on their unique mechanics and the applications they serve.

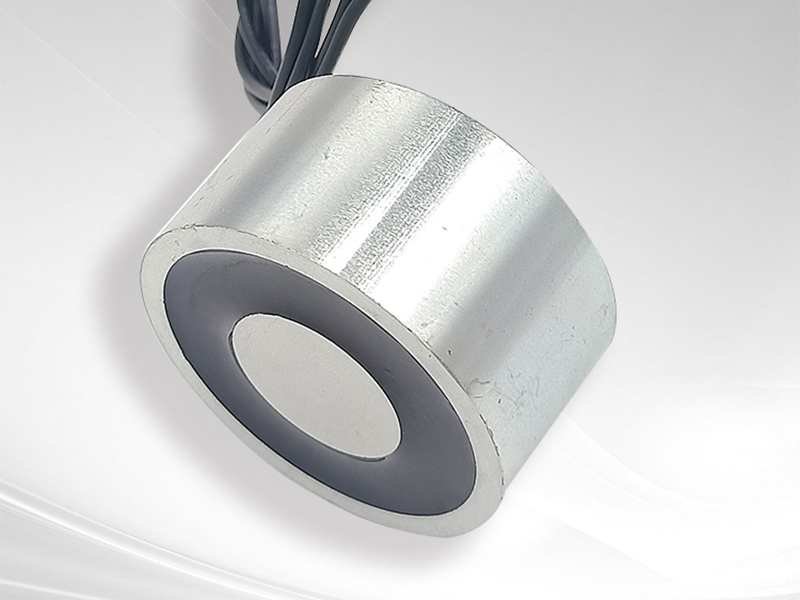

Understanding the Sucker Electromagnet Structure

A sucker electromagnet typically consists of a ferromagnetic core, an electromagnetic coil wound around this core, and a flat or slightly concave suction cup attached to the core’s end. When an electric current flows through the coil, it generates a magnetic field that magnetizes the core and enhances its adhesive capabilities.

Sucker Electromagnet: Working Principle

The operational mechanics of a sucker electromagnet are rooted in the principles of electromagnetism and magnetic attraction. Here’s a closer look at how it works:

Coil Energization: When an electric current is applied to the coil, it generates a magnetic field that magnetizes the ferromagnetic core. The strength of this magnetic field increases with the current’s magnitude.

Magnetic Flux and Attraction: The magnetized core creates a magnetic flux that extends into the suction cup. This magnetic flux interacts with any ferromagnetic material or metallic surface in close proximity, exerting an attractive force.

Suction and Adhesion: As the attractive force increases, the sucker electromagnet adheres to the surface. The suction cup’s design, often made of flexible material, enhances the seal and ensures a strong adhesive force.

De-Energization and Release: When the coil is de-energized, the magnetic field collapses, and the sucker electromagnet loses its adhesive force. This allows the device to be easily released from the surface, making it versatile for cyclic applications.

Benefits of Sucker Electromagnet

The unique mechanics of sucker electromagnets offer several benefits, making them ideal for various applications:

- Versatility: Sucker electromagnets can adhere to a wide range of surfaces, including metal, steel, and some non-ferromagnetic materials with appropriate adaptations.

- Strong Adhesive Force: The magnetic attraction generated by the sucker electromagnet can provide a strong holding force, making it suitable for lifting and holding heavy objects.

- Compact Design: The sucker electromagnet’s design can be compact, making it suitable for space-constrained applications.

- Ease of Control: The adhesive force can be easily controlled by regulating the electric current flowing through the coil, providing precise control over the sucker electromagnet’s operation.

Applications of Sucker Electromagnet

Sucker electromagnets find applications across numerous industries, including automotive, aerospace, and industrial automation. In automotive systems, they may be used in assembly lines for lifting and positioning components. In aerospace, they contribute to the reliability of robotic arms and automated tools for precise assembly tasks. In industrial automation, they are employed in material handling systems, where precise control over lifting and moving objects is crucial. Additionally, sucker electromagnets are used in various research and experimental setups where non-contact manipulation of objects is required.

The working principle of sucker electromagnet

The working principle of sucker electromagnets, based on the principles of electromagnetism and magnetic attraction, underscores their versatility and reliability in various applications. By understanding how they operate—from coil energization to magnetic flux creation and suction cup adhesion—we can appreciate their benefits and the contributions they make to various industries. As technology advances, sucker electromagnets will continue to evolve, driving innovation and enhancing system performance across diverse applications.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.