Last Updated on 2025-11-02 by SolenoidFactory

Surgical robots have transformed the medical landscape, enabling minimally invasive procedures with unparalleled accuracy, reduced recovery times, and improved patient outcomes. At the heart of these advanced systems lies a critical technology: electromagnets. These devices provide the precise force control, haptic feedback, and reliability required for delicate surgical tasks. As a professional electromagnet manufacturer, we explore how electromagnets empower surgical robots, the technical challenges they overcome, and the future innovations poised to redefine robotic-assisted surgery.

1. The Science of Electromagnetic Control in Surgical Robots

1.1 How Electromagnets Enable Precision Motion

Electromagnets convert electrical energy into controlled mechanical force through magnetic fields. In surgical robots, they actuate joints, adjust tools, and simulate tactile feedback. By modulating current flow, surgeons can achieve micron-level precision in movements—essential for procedures like microsurgery or tissue manipulation.

1.2 Key Components in Robotic Systems

- Linear Actuators: Electromagnetic solenoids control linear motion for instrument positioning.

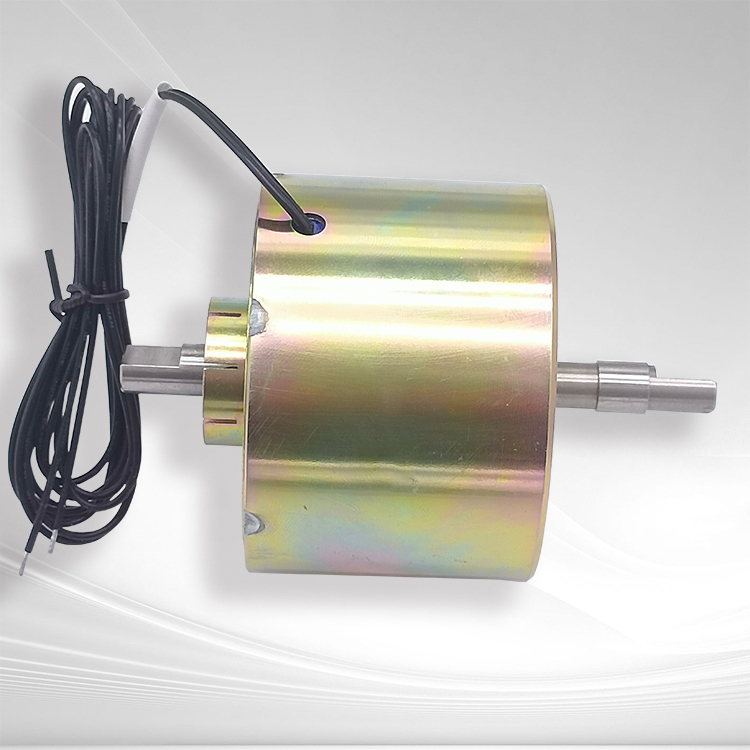

- Torque Motors: Generate rotational force for robotic arms, combining high torque with compact size.

- Haptic Feedback Systems: Use electromagnets to simulate resistance and texture, giving surgeons a “sense of touch” during operations.

- Latching Mechanisms: Secure tools or adjust tension without continuous power consumption.

1.3 Types of Electromagnets in Surgical Robotics

- Voice Coil Actuators (VCAs): Provide direct, frictionless motion for high-speed tool adjustments.

- Solenoid Valves: Regulate fluid or air flow in pneumatic/hydraulic end-effectors.

- Magnetic Levitation Systems: Enable contactless movement of tools, reducing wear and contamination risks.

2. Advantages of Electromagnets in Surgical Robotics

2.1 Sub-Millimeter Precision

Electromagnetic actuators achieve positional accuracy down to 10 microns, critical for procedures like corneal surgery or nerve repair. This precision minimizes collateral damage to healthy tissues.

2.2 Rapid Response Times

Electromagnets operate in milliseconds, allowing real-time adjustments during dynamic tasks such as beating-heart surgery or laser ablation.

2.3 Enhanced Safety and Reliability

- Fail-Safe Mechanisms: Spring-loaded or redundant electromagnets ensure tools retract or lock during power failures.

- Sterility: Non-contact magnetic systems reduce particulate generation, maintaining sterile fields.

2.4 Compact and Lightweight Design

Miniaturized electromagnets enable slim, articulated robotic arms that navigate tight anatomical spaces, such as the brain or thoracic cavity.

2.5 Energy Efficiency

Latching electromagnets and energy-recovery circuits minimize power draw, crucial for portable or battery-powered surgical systems.

3. Applications of Electromagnets in Surgical Robots

3.1 Minimally Invasive Surgery (MIS)

Electromagnets drive the wristed instruments of robots like the Da Vinci Surgical System, enabling seven degrees of freedom (DOF) for suturing, cutting, and dissection through tiny incisions.

Case Study: A hospital reduced post-op complications by 30% using electromagnetic-driven robots for prostatectomies, leveraging precise vessel sealing and reduced blood loss.

3.2 Neurosurgery

- Biopsy and Tumor Resection: Magnetic-guided catheters navigate brain vasculature with sub-millimeter accuracy.

- Deep Brain Stimulation (DBS): Electromagnetic actuators position electrodes for Parkinson’s treatment, avoiding critical neural structures.

3.3 Ophthalmology

- Retinal Surgery: Voice coil actuators adjust laser focus and instrument position in procedures requiring 5-micron precision.

- Cataract Removal: Electromagnetic phacoemulsification probes fragment lenses with controlled vibration.

3.4 Orthopedics

- Bone Cutting and Drilling: Electromagnetic torque motors ensure precise osteotomy angles in knee/hip replacements.

- Spinal Fusion: Robots use magnetic feedback to position screws without damaging spinal nerves.

3.5 Endoscopy and Cardiology

- Magnetic Steering: Electromagnets guide endoscopic capsules through the gastrointestinal tract.

- Catheter Ablation: Magnetic navigation systems direct catheters to arrhythmia sites in the heart.

4. Technical Challenges and Solutions of electromagnets

4.1 Heat Generation

Challenge: Prolonged use heats coils, causing thermal expansion and calibration drift.

Solution: Liquid-cooled actuators and high-temperature materials (e.g., ceramic-insulated coils).

4.2 Electromagnetic Interference (EMI)

Challenge: EMI from imaging systems (MRI, CT) disrupts robotic control.

Solution: Shielding with mu-metal enclosures and frequency-filtered circuits.

4.3 Sterility and Biocompatibility

Challenge: Ensuring materials withstand autoclaving and resist biofilm formation.

Solution: Medical-grade stainless steel, titanium coatings, and disposable magnetic tool tips.

4.4 Force Sensitivity

Challenge: Balancing high force for cutting with delicate touch for soft tissues.

Solution: Hybrid systems combining electromagnets and piezoelectric sensors for adaptive force feedback.

5.electromagnets Innovations Shaping the Future

5.1 AI-Integrated Electromagnetic Control

Machine learning algorithms analyze surgical video and sensor data to predict optimal tool trajectories, adjusting electromagnetic actuators in real time.

Example: An AI-driven robot autonomously sutures blood vessels by learning from thousands of expert-surgeon demonstrations.

5.2 Nanoscale Magnetic Actuators

Nano-electromagnets enable microbots for targeted drug delivery or plaque removal in arteries, controlled externally via MRI-guided magnetic fields.

5.3 Magnetic Particle Imaging (MPI)

Emerging MPI systems use electromagnets to track injected nanoparticles in real time, enhancing surgical navigation without radiation.

5.4 Self-Powered Systems

Energy-harvesting electromagnets capture kinetic energy from robotic movements, reducing reliance on external power sources.

5.5 Collaborative Robotics (Cobots)

Surgeons and robots share control via electromagnetic haptic interfaces, blending human intuition with machine precision.

6. Selecting Electromagnetic Solutions for Surgical Robots

6.1 Key Considerations

- Precision Requirements: Match actuator resolution to surgical tasks (e.g., 10 µm for microsurgery).

- Sterility Compliance: Ensure materials meet ISO 13485 and FDA biocompatibility standards.

- EMC Certification: Validate EMI/EMC performance to avoid interference with medical devices.

- Customization: Tailor force profiles, sizes, and control interfaces to OEM specifications.

6.2 Custom Solutions for Medical OEMs

As a manufacturer, we offer:

- Hermetic Sealing: For implants or in-body robotic tools.

- MRI-Compatible Actuators: Non-ferromagnetic designs for intraoperative MRI environments.

- Ultra-Compact VCAs: For handheld robotic scalpels or endoscopic tools.

Electromagnets—The Precision Partners of Surgical Innovation

Electromagnets are indispensable in the evolution of surgical robotics, bridging the gap between human skill and machine accuracy. From enabling life-saving minimally invasive procedures to paving the way for autonomous nanobots, their role in medicine is both transformative and expanding.

As surgical robots advance toward greater autonomy and accessibility, the demand for smarter, smaller, and safer electromagnetic solutions will grow. For medical device manufacturers, partnering with an experienced electromagnet provider is critical to staying at the forefront of this revolution.

In the delicate dance of surgery, where every micron matters, electromagnets provide the perfect balance of power and precision—proving that even the smallest magnetic force can have an outsized impact on human health.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact WhatsApp +86 18902611680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.