Last Updated on 2025-09-03 by SolenoidFactory

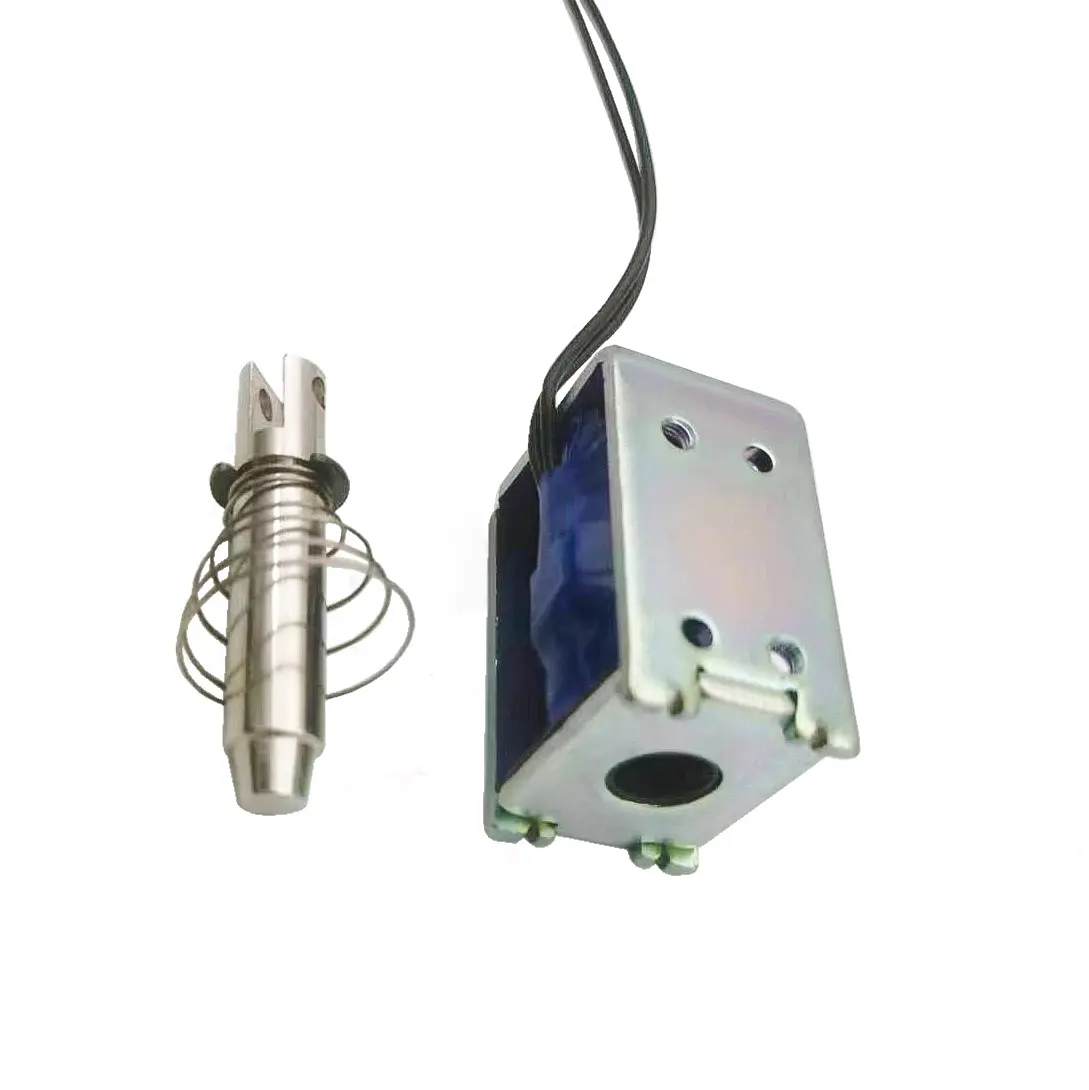

In the vast landscape of electromagnetic devices, open frame solenoid occupy a unique niche. Their design, characterized by an exposed coil assembly, offers versatility and flexibility in a range of applications. This blog delves into the working principle of open frame solenoids, exploring how their design contributes to their functionality and the benefits they bring to various industries.

Understanding the Open Frame Solenoid Design

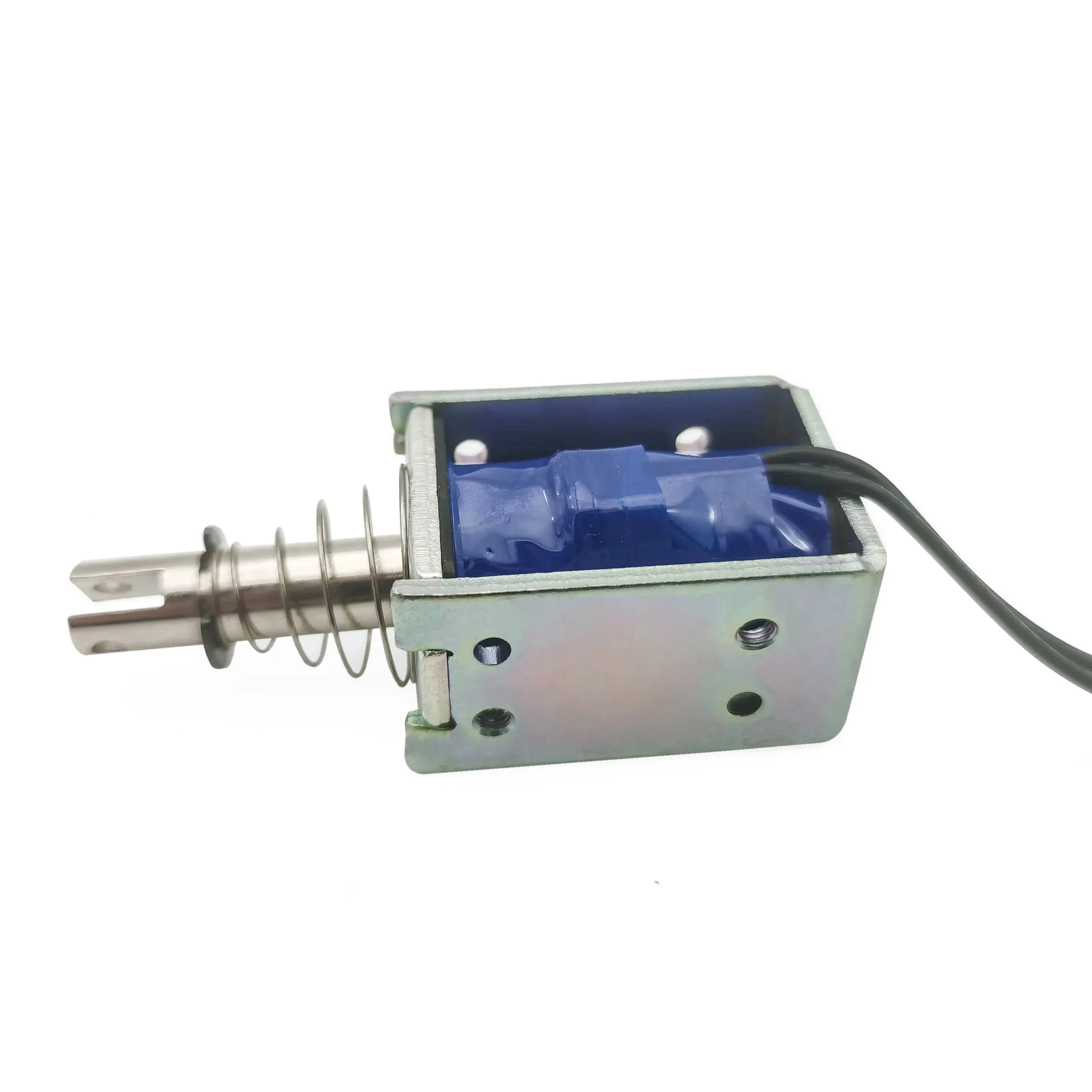

An open frame solenoid, as its name suggests, features an exposed or “open” coil assembly. This design allows for direct interaction with external components or materials, facilitating a broader range of applications. Unlike enclosed solenoids, which encapsulate the coil within a protective housing, open frame solenoids provide unrestricted access to the coil, enabling unique functionalities and integrations.

The Working Principle: Electromagnetic Induction at Play

At the core of an open frame solenoid’s operation lies the principle of electromagnetic induction. When an electric current flows through the coil, it generates a magnetic field. This magnetic field, in turn, exerts a force on a ferromagnetic plunger or armature, causing it to move. The direction and magnitude of this force depend on the polarity and strength of the current, respectively.

Here’s a closer look at the working process:

Current Flow: When an electric current is applied to the coil, it creates a magnetic field around the coil. The strength of this field increases with the current’s magnitude.

Magnetic Force Exertion: The generated magnetic field interacts with the ferromagnetic plunger, exerting an attractive or repulsive force depending on the plunger’s magnetization and the field’s polarity.

Plunger Movement: Under the influence of this magnetic force, the plunger moves linearly within the coil assembly. The distance and speed of this movement are determined by the current’s duration and amplitude.

Energy Conversion: The process converts electrical energy into mechanical energy, driving the plunger to perform work such as actuating a valve, moving a lever, or engaging a latch.

-

评分 0 / 5

Advantages and Applications of Open Frame Solenoid

The open frame design offers several advantages, making solenoids versatile and adaptable to various applications:

- Visibility and Accessibility: The exposed coil allows for easy visual inspection and access for maintenance or modifications.

- Cooling Efficiency: The open design enhances heat dissipation, preventing overheating and prolonging the solenoid’s lifespan.

- Customizability: The absence of a protective housing offers greater flexibility in designing and integrating solenoids into specific applications.

- Cost-Effectiveness: The simplified design can reduce manufacturing costs, making solenoids more affordable.

Open frame solenoids find applications across numerous industries, including automotive, aerospace, and industrial automation. In automotive systems, they may be used in door locks, seat adjusters, and transmission controls. In aerospace, they contribute to the reliability of flight control systems and landing gear mechanisms. In industrial automation, they are employed in assembly lines, packaging equipment, and material handling systems.

The working principle of open frame solenoid

The working principle of open frame solenoids, based on the fundamental concepts of electromagnetic induction, underscores their versatility and adaptability. By understanding how they operate, we can appreciate their contributions to various industries and the benefits they bring in terms of design flexibility, cooling efficiency, and cost-effectiveness. As technology advances, open frame solenoids will continue to evolve, driving innovation and enhancing system performance across diverse applications.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.