Last Updated on 2025-09-03 by SolenoidFactory

In the rapidly developing manufacturing industry, electromagnets, as a key electromechanical component, play an irreplaceable role in many fields with their unique electromagnetic conversion characteristics. From automated production lines to precision instruments, from automobile manufacturing to medical equipment, electromagnets are everywhere. This article will explore the wide application of electromagnets in the manufacturing industry, and through specific cases, demonstrate their important role in improving production efficiency, ensuring product quality, and realizing automated control.

1. Basic principles and classification of electromagnets

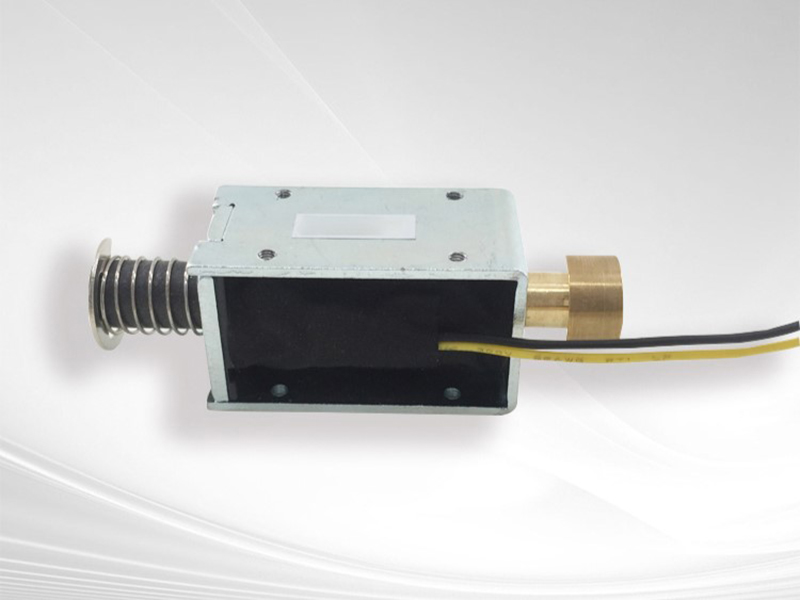

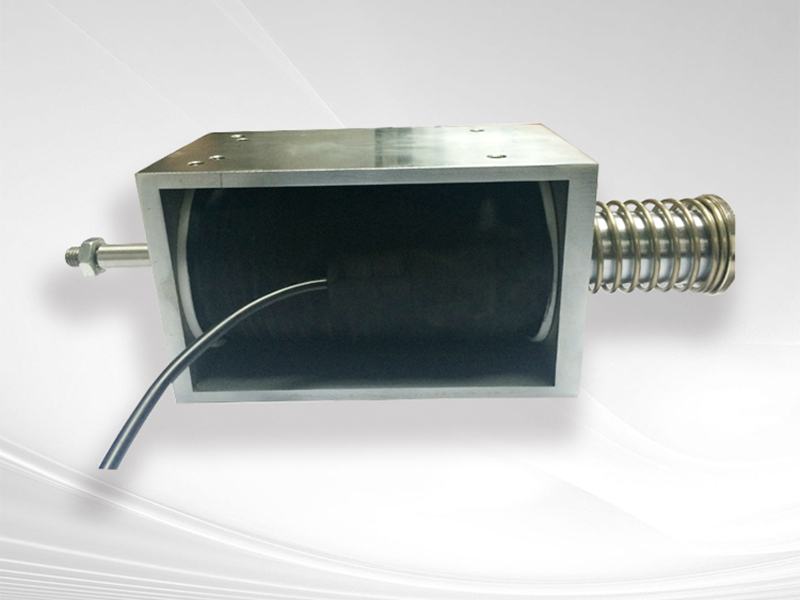

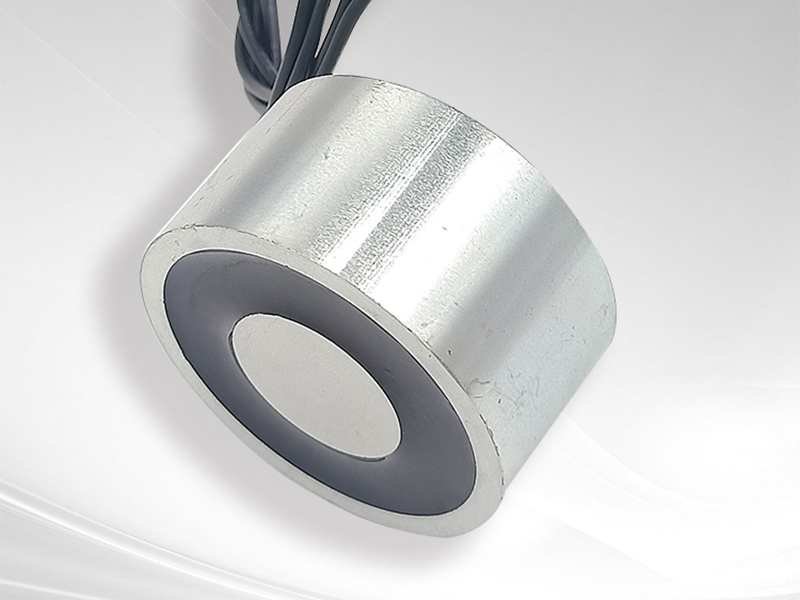

In short, an electromagnet is a device that uses current to pass through a wire to generate a magnetic field, thereby attracting ferromagnetic materials. Its core components include coils, cores, and armatures. When the coil is energized, the magnetic field generated magnetizes the core, which in turn attracts the armature to achieve mechanical movement or position control. Depending on the purpose and structure, electromagnets can be divided into many types, such as DC electromagnets, AC electromagnets, suction cup electromagnets, push-pull electromagnets, etc.

2. Application fields of electromagnets in the manufacturing industry

2.1 electromagnets for Automated production lines

In automated production lines, electromagnets are widely used in material handling, assembly, positioning, and other links. For example, electromagnetic suction cups use electromagnetic force to absorb workpieces for fast and accurate handling; electromagnetic clamps use electromagnetic force to fix workpieces to ensure stability and precision during assembly. In addition, electromagnets are often used in the sealing and labeling of automated packaging lines to improve production efficiency.

2.2 electromagnets for Automobile manufacturing

Automobile manufacturing is one of the important areas of electromagnet application. In the automobile production process, electromagnets are used in door locks, window lifters, seat adjustment, engine start and other aspects. For example, the electromagnet in the door lock controls the extension and retraction of the lock tongue to open and close the door; the window lifter uses the thrust of the electromagnet to drive the glass up and down. In addition, electromagnets also play an important role in key systems such as engine start and fuel injection.

2.3 electromagnets for Precision instruments and medical equipment

In precision instruments and medical equipment, the high precision and high stability characteristics of electromagnets are fully demonstrated. For example, in nuclear magnetic resonance (MRI) equipment, electromagnets generate a strong static magnetic field, which causes the hydrogen nuclei in the human body to resonate, thereby obtaining high-resolution medical images. In addition, electromagnets are also widely used in precision instruments such as electron microscopes and spectrometers, providing strong support for scientific research.

2.4 electromagnets for Home appliances and office equipment

Electromagnets also play an important role in home appliances and office equipment. For example, the electromagnet in the refrigerator door seal controls the magnetic switch to achieve a tight closure of the refrigerator door; the electromagnet in the printer is used to drive the print head to move to ensure the printing quality. In addition, electromagnets are also widely used in home appliances such as coffee machines and washing machines to improve user experience.

3.Introduction to electromagnet application cases

Case 1: Automobile automatic door lock system

In modern cars, the automatic door lock system has become a standard configuration. The system uses electromagnets to automatically lock and unlock the car door. When the driver presses the door lock button or the remote control, the electromagnet is energized to generate magnetic force, driving the lock tongue to retract and retract, thereby locking and unlocking the car door. This system not only improves driving safety, but also improves user convenience.

Case 2: Electromagnetic suction cups on automated production lines

On automated production lines, electromagnetic suction cups are widely used in material handling. Taking the steel plate processing production line as an example, the electromagnetic chuck absorbs the steel plate through electromagnetic force to achieve fast and accurate handling of the steel plate. The system can adjust the suction force according to production needs to ensure stable handling of the steel plate. At the same time, the electromagnetic chuck also has an automatic demagnetization function. When the steel plate reaches the specified position, the electromagnet is powered off and the steel plate automatically falls off to achieve efficient production.

Case 3: Magnetic resonance imaging in medical equipment

Magnetic resonance imaging (MRI) is an important tool for modern medical diagnosis. One of its core components is the superconducting magnet, which uses electromagnets to generate a strong static magnetic field. When the human body enters the magnetic field, the hydrogen nuclei in the body resonate under the excitation of radio frequency pulses, generating weak signals. These signals are received and amplified by the receiver, and then processed by the computer to form high-resolution medical images. The electromagnets in MRI equipment require not only high magnetic field strength and good uniformity, but also long-term stable operation to ensure the accuracy of diagnosis.

Case 4: Application of electromagnets in precision instruments

In precision instruments, the high precision and high stability characteristics of electromagnets have been fully utilized. Taking the electron microscope as an example, its sample stage achieves precise position control and movement through electromagnets. When a specific area of the sample needs to be observed, the electromagnet is energized to generate magnetic force, driving the sample stage to move to the specified position. This process requires the electromagnet to have extremely high control accuracy and response speed to ensure the accuracy and efficiency of observation.

4. Future development trend of electromagnets in manufacturing industry

With the continuous development of manufacturing industry and technological progress, the application field of electromagnets will be further expanded. In the future, electromagnets will pay more attention to the development direction of intelligence, integration and environmental protection.

4.1 Intelligence

With the rapid development of technologies such as the Internet of Things and artificial intelligence, electromagnets will pay more attention to integration with intelligent control systems. Through intelligent sensors and algorithm optimization, electromagnets will achieve more precise position control, force control and speed control, and improve the efficiency and accuracy of automated production lines.

4.2 Integration

In the future, electromagnets will pay more attention to the integrated design with other electromechanical components. For example, electromagnets are integrated with motors, sensors and other components to form an integrated actuator to achieve a more compact and efficient system design.

4.3 Environmental protection

With the continuous improvement of global environmental awareness, electromagnets will pay more attention to energy conservation and emission reduction and the application of environmentally friendly materials. For example, adopt low-energy electromagnet design, use recyclable or biodegradable materials to make electromagnet shells, etc., to reduce the impact on the environment.

electromagnets play an irreplaceable role in many fields

As an important component in the manufacturing industry, electromagnets play an irreplaceable role in many fields with their unique electromagnetic conversion characteristics. From automated production lines to automobile manufacturing, from precision instruments to medical equipment, the application cases of electromagnets are endless, showing their important role in improving production efficiency, ensuring product quality, and realizing automated control. In the future, with the continuous advancement of technology and the continuous expansion of application fields, electromagnets will play a more important role in the manufacturing industry, providing strong support for the transformation and upgrading of the manufacturing industry and sustainable development.

About SF electromagnet factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagne

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.