Last Updated on 2025-09-03 by SolenoidFactory

In the fascinating world of electromagnetics, the choice of core materials plays a pivotal role in determining the performance and efficiency of an electromagnet. Electromagnet core materials influence magnetic flux density, energy loss, and overall cost, making their selection a critical decision in the design process. This blog aims to provide a comprehensive guide to electromagnet core materials, exploring their properties, benefits, drawbacks, and the factors to consider when making a selection. With “electromagnet core materials” as our focus, let’s dive into this intricate topic.

Understanding Electromagnet Core Materials

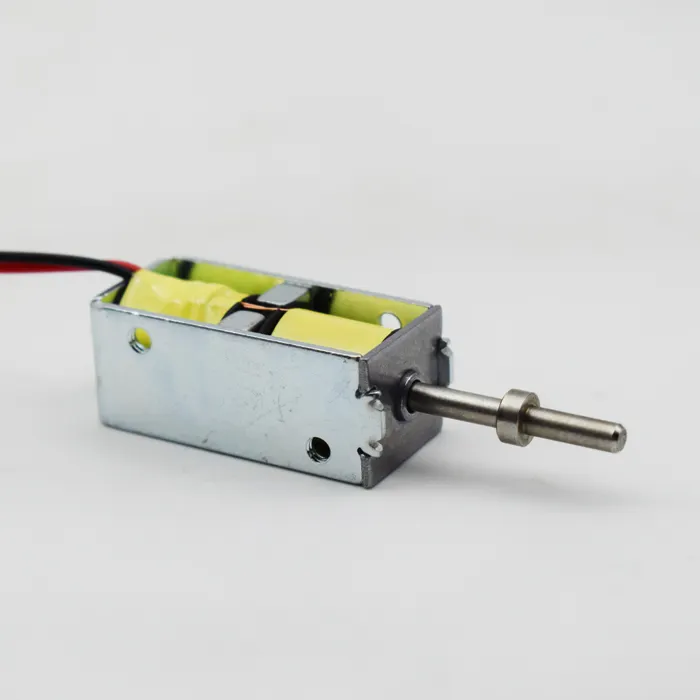

An electromagnet consists of several components, including a coil of wire, an insulating layer, and a core material. The core material serves as the path for the magnetic flux generated when current flows through the coil. It enhances the magnetic field strength and directs the flux, making it essential for the electromagnet’s functionality.

Types of Electromagnet Core Materials

Soft Ferrites:

- Properties: Soft ferrites are ceramic materials composed primarily of iron oxide combined with other metal oxides. They exhibit high electrical resistivity and low hysteresis loss.

- Benefits: Cost-effective, good temperature stability, and suitable for high-frequency applications.

- Drawbacks: Lower saturation induction compared to metallic materials.

Silicon Steel Laminations:

- Properties: Silicon steel is an alloy of iron with small amounts of silicon, typically used in thin laminated sheets to reduce eddy current losses.

- Benefits: High saturation induction, excellent for low-frequency applications, and widely available.

- Drawbacks: Heavier, prone to core losses at higher frequencies, and requires precision lamination to minimize eddy currents.

Nickel-Iron Alloys (Permalloy):

- Properties: Permalloy is a nickel-iron alloy known for its high permeability and low hysteresis loss.

- Benefits: Excellent for applications requiring high magnetic sensitivity and low power consumption.

- Drawbacks: More expensive than ferrites and silicon steel, and less common.

Cobalt-Iron Alloys (Amorphous Metals):

- Properties: Amorphous metals are rapidly solidified alloys with a disordered atomic structure, resulting in low core losses and high magnetic permeability.

- Benefits: High efficiency, low losses, and suitable for both low and medium-frequency applications.

- Drawbacks: Higher cost and more challenging to process compared to traditional materials.

Nanocrystalline Alloys:

- Properties: Nanocrystalline alloys are similar to amorphous metals but contain nanoscale crystalline structures, providing a balance between high permeability and low loss.

- Benefits: Superior performance in high-energy, low-loss applications.

- Drawbacks: Costly and specialized manufacturing processes are required.

Factors to Consider When Selecting Electromagnet Core Materials

When choosing electromagnet core materials, several factors must be taken into account:

Operating Frequency: The frequency at which the electromagnet operates influences core loss and material selection. For instance, soft ferrites are ideal for high-frequency applications due to their low hysteresis loss, while silicon steel is better suited for low frequencies.

Saturation Induction: The saturation induction level determines the maximum magnetic flux density the core can handle without significant loss of performance. Materials with higher saturation induction, like silicon steel and nickel-iron alloys, are preferred for applications requiring strong magnetic fields.

Cost: Cost is always a consideration, with soft ferrites being the most economical option and nanocrystalline alloys being the most expensive.

Temperature Stability: The core material’s ability to maintain its magnetic properties over a wide temperature range is crucial. Silicon steel and amorphous metals offer good temperature stability.

Weight and Size: The weight and size of the core material can affect the overall dimensions and handling of the electromagnet. Lighter materials, like ferrites, can be advantageous in weight-sensitive applications.

Environmental Factors: The core material’s resistance to corrosion, chemicals, and mechanical stress should be considered, especially in harsh operating environments.

the selection of electromagnet core materials is a critical decision

the selection of electromagnet core materials is a critical decision that significantly impacts the performance, efficiency, and cost of an electromagnet. By understanding the properties, benefits, and drawbacks of each material type and considering factors such as operating frequency, saturation induction, cost, temperature stability, and environmental factors, engineers can make informed choices that align with specific application requirements. With the right core material, electromagnet-based systems can achieve optimal performance, reliability, and cost-effectiveness, driving innovation and advancements across diverse industries.

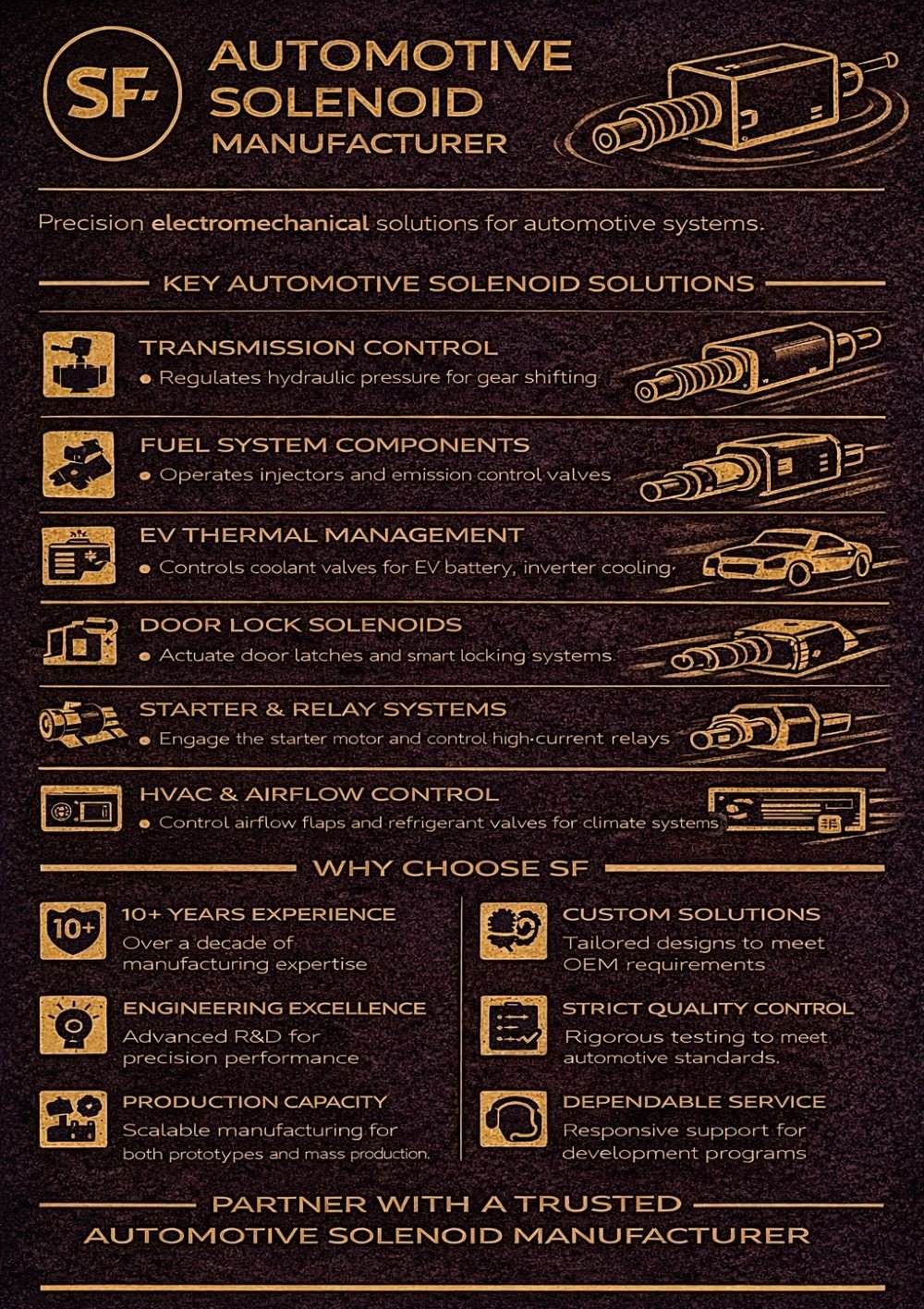

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.