Last Updated on 2025-09-04 by SolenoidFactory

Electromagnets are indispensable in industries ranging from automotive manufacturing to renewable energy. However, like all electromechanical devices, they are prone to specific issues that can affect performance, safety, and longevity. As a professional electromagnet manufacturer, we’ve compiled this comprehensive guide to help users identify, troubleshoot, and prevent the most common electromagnet problems. With real-world case studies and actionable solutions, this blog equips you to maximize uptime and optimize operations.s leo.

1. electromagnet problems--Overheating: The Silent Killer of Electromagnet

1.1 Causes of Overheating

- Excessive Duty Cycle: Continuous operation beyond rated ON/OFF times.

- High Ambient Temperatures: Poor ventilation or hot environments.

- Voltage Fluctuations: Overvoltage increases current, accelerating heat buildup.

Case Study 1:

A factory’s conveyor system electromagnets overheated after 12 hours of non-stop use. Thermal imaging revealed coil temperatures reaching 120°C—50% above the 80°C limit.

1.2 Solutions

- Install Cooling Systems: Add fans, heat sinks, or liquid cooling jackets.

- Use PWM Controllers: Reduce hold current after activation (e.g., from 100% to 30%).

- Upgrade Insulation: Switch to Class H (180°C-rated) insulation materials.

Result: The factory reduced coil temperatures to 75°C by adding fans and implementing a 60% duty cycle.

2. electromagnet problems--Coil Burnout: From Sparks to System Failures

2.1 Causes of Coil Burnout

- Insulation Breakdown: Due to moisture, chemical exposure, or aging.

- Short Circuits: Damaged wires or contaminants bridging terminals.

- Inrush Current Surges: Uncontrolled startup currents exceeding coil ratings.

Case Study 2:

A hospital elevator’s electromagnetic brake failed abruptly, trapping passengers. Diagnosis revealed a short circuit caused by corroded wiring in a humid shaft.

2.2 Solutions

- Regular Megohmmeter Tests: Check insulation resistance (>100MΩ).

- Surge Suppressors: Install inrush current limiters or NTC thermistors.

- Environmental Sealing: Use epoxy-encapsulated coils in damp areas.

Result: Post-repair, the hospital adopted IP67-rated coils and quarterly insulation tests—no failures in 3 years.

3. electromagnet problems--Reduced Holding Force: When Electromagnets Lose Their Grip

3.1 Causes of Force Loss

- Air Gap Changes: Misalignment or worn armature plates.

- Demagnetization: Excessive heat or mechanical shock.

- Power Supply Issues: Undervoltage or unstable current.

Case Study 3:

A robotic welding cell dropped components due to a 40% force reduction in its gripper electromagnets. Inspection found a 0.5mm air gap deviation from the ideal 0.2mm.

3.2 Solutions

- Laser Alignment Tools: Ensure air gaps within ±0.1mm.

- Armature Resurfacing: Machine worn plates to restore flatness.

- Current Stabilization: Use regulated power supplies with ±2% accuracy.

Result: Realigning the gap and upgrading to a stabilized 24V DC supply restored full holding force.

4. electromagnet problems--Mechanical Wear and Tear: The Cost of Friction

4.1 Common Mechanical Failures

- Worn Bushings/Bearings: Leading to misalignment and noise.

- Fatigue in Springs: Reduced return force in latching systems.

- Corroded Fasteners: Compromising structural integrity.

Case Study 4:

A steel mill’s electromagnetic crane dropped a 5-ton load due to a fractured mounting bracket. Root cause: stress corrosion cracking from acidic fumes.

4.2 Solutions

- Lubrication Schedules: Apply high-temperature grease every 500 cycles.

- Corrosion-Resistant Materials: Use stainless steel (A4-80) or titanium fasteners.

- Vibration Monitoring: Detect imbalance before catastrophic failure.

Result: The mill switched to galvanized brackets and implemented biweekly lubrication—zero incidents in 18 months.

5. electromagnet problems--Electrical Noise and EMI: Disrupting Sensitive Systems

5.1 Causes of Electromagnetic Interference (EMI)

- Arcing Contacts: During rapid ON/OFF switching.

- Unshielded Cables: Acting as antennas for radiated noise.

- Poor Grounding: Creating ground loops.

Case Study 5:

A semiconductor fab’s MRI-compatible robot malfunctioned due to EMI from nearby electromagnets. Oscilloscope traces showed noise spikes disrupting control signals.

5.2 Solutions

- Ferrite Chokes: Install on power and signal cables.

- Twisted Pair Wiring: Reduces magnetic field coupling.

- Shielded Enclosures: Use mu-metal or conductive coatings.

Result: Adding ferrite beads and shielded conduits eliminated EMI, restoring nanoscale positioning accuracy.

6. electromagnet problems--Armature Sticking: When Release Becomes a Problem

6.1 Causes of Sticking

- Residual Magnetism: Common in DC electromagnets.

- Contaminated Surfaces: Oil, grease, or debris on armatures.

- Weak Return Springs: Fatigue or incorrect sizing.

Case Study 6:

A packaging machine’s electromagnet failed to release, causing jams. Residual magnetism of 0.3 Tesla was detected post-power-off.

6.2 Solutions

- Degaussing Circuits: Apply reverse polarity pulses to neutralize residual fields.

- Non-Stick Coatings: Use PTFE or ceramic coatings on armatures.

- Spring Upgrades: Replace with high-cycle-life springs (e.g., 1 million+ cycles).

Result: Installing a degaussing module and coated armatures eliminated sticking.

7. electromagnet problems--Power Supply Issues: The Root of Many Problems

7.1 Common Power-Related Failures

- Voltage Drops: From undersized wiring or long cable runs.

- Ripple Current: Causing coil vibration and noise.

- Phase Imbalance: In 3-phase systems, leading to uneven forces.

Case Study 7:

A wind turbine’s pitch control electromagnet overheated due to 20% voltage drop in 100-meter cables.

7.2 Solutions

- Cable Sizing: Use 125% of rated current capacity (e.g., 10A load → 12.5A cable).

- Active Power Factor Correction (PFC): Reduce reactive power losses.

- Voltage Boosters: Compensate for line drops in long-distance applications.

Result: Upgrading to 16 AWG cables and adding a 28V booster stabilized the system.

8. electromagnet problems--Corrosion and Environmental Damage

8.1 High-Risk Environments

- Marine/Saltwater Exposure: Accelerating galvanic corrosion.

- Chemical Plants: Acidic/alkaline fumes attacking metals.

- Food Processing: Moisture and organic residues.

Case Study 8:

A fish processing plant’s stainless steel electromagnets corroded within 6 months due to chlorine-based sanitizers.

8.2 Solutions

- Material Selection: Use titanium, Hastelloy, or nickel-plated components.

- Protective Coatings: Apply epoxy or DLC (Diamond-Like Carbon) layers.

- Routine Cleaning: Neutralize chemicals with pH-balanced cleaners.

Result: Switching to titanium armatures and daily rinses extended lifespan to 5+ years.

9. Case Studies: Lessons from the Field

9.1 Case Study 9: Aerospace Actuator Failure

Problem: An aircraft’s landing gear electromagnet jammed at -50°C due to lubricant freezing.

Solution:

- Low-Temperature Grease: Switched to perfluorinated polyether (PFPE) lubricant.

- Cold Testing: Validated performance at -65°C.

Result: Zero failures in Arctic operations.

9.2 Case Study 10: Automotive Assembly Line Downtime

Problem: Robotic welders’ electromagnets failed weekly due to welding spatter.

Solution:

- Install Protective Shields: Made of boron carbide-coated steel.

- Air Blast Cleaning: Removed spatter after each cycle.

Result: Maintenance intervals extended from 7 to 90 days.

9.3 Case Study 11: Renewable Energy Storage

Problem: A battery recycling plant’s electromagnets lost 50% force due to rare-earth magnet demagnetization.

Solution:

- Upgrade to AlNiCo Magnets: Higher Curie temperature (800°C vs. 310°C for NdFeB).

- Thermal Shields: Reduced operating temperatures by 100°C.

Result: Demagnetization rate dropped to <1% per year.

10. Preventive Maintenance Checklist

10.1 Daily/Weekly Tasks

- Inspect for debris, corrosion, and loose connections.

- Measure coil temperature with an IR thermometer.

- Verify air gaps with feeler gauges.

10.2 Monthly/Quarterly Tasks

- Test insulation resistance (>100MΩ).

- Lubricate moving parts with approved grease.

- Degauss coils if residual magnetism exceeds 0.1 Tesla.

10.3 Annual Tasks

- Perform vibration analysis to detect mechanical wear.

- Replace consumables (springs, bushings, seals).

- Recalibrate control systems for voltage/current.

Proactive Solutions for Reliable Performance

Understanding and addressing common electromagnet problems is key to minimizing downtime and maximizing ROI. By combining regular maintenance, robust design choices, and lessons from real-world failures, users can ensure their systems operate safely and efficiently for years.

As your trusted electromagnet partner, we offer customized solutions tailored to your operational environment. From corrosion-resistant materials to advanced cooling systems, we’re here to help you conquer every challenge—one magnetic field at a time.

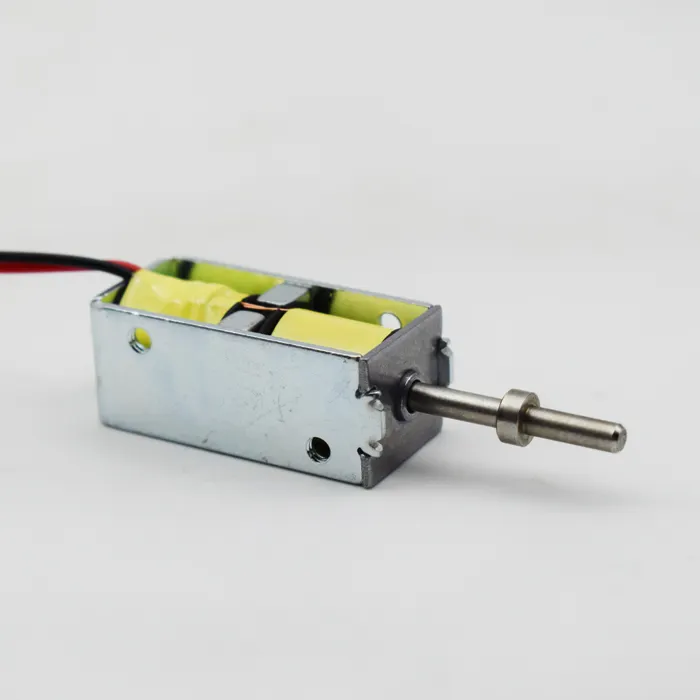

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact WhatsApp +86 18902611680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.