Last Updated on 2025-12-11 by SolenoidFactory

In the world of home appliances, washing machines are one of the most intricate and mechanical devices, requiring precise control over various components such as water flow, drum rotation, detergent dispensing, and security locks. At the core of many of these systems lies the washing machine electromagnet, a key component that ensures these systems function smoothly, reliably, and efficiently.

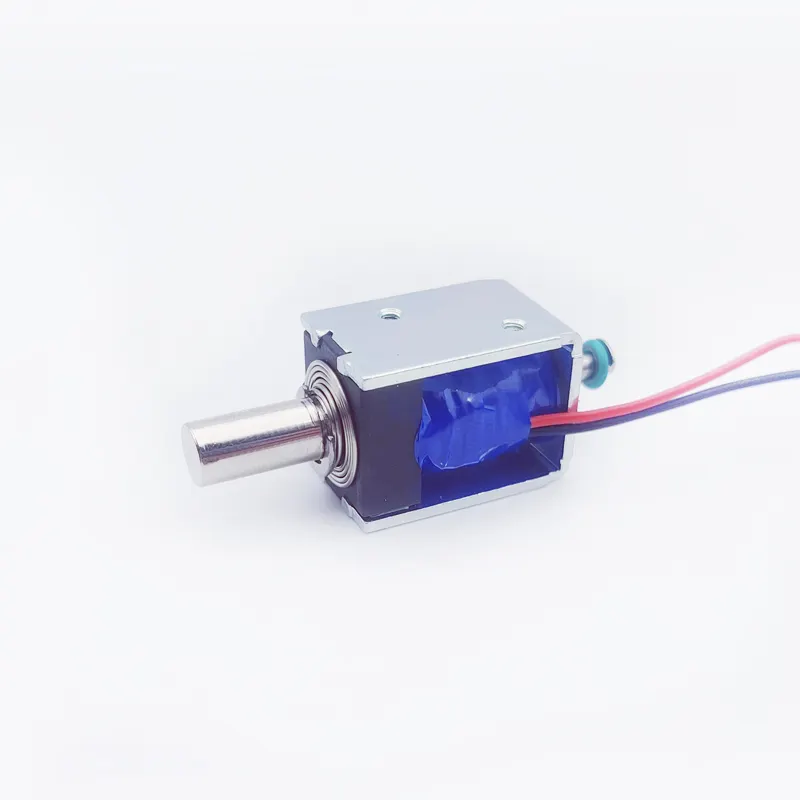

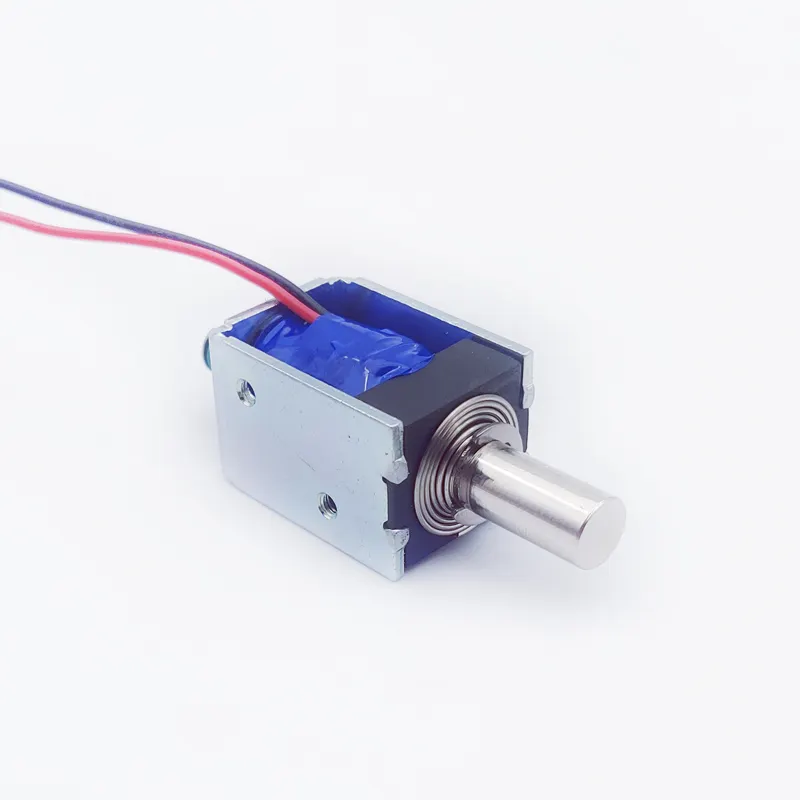

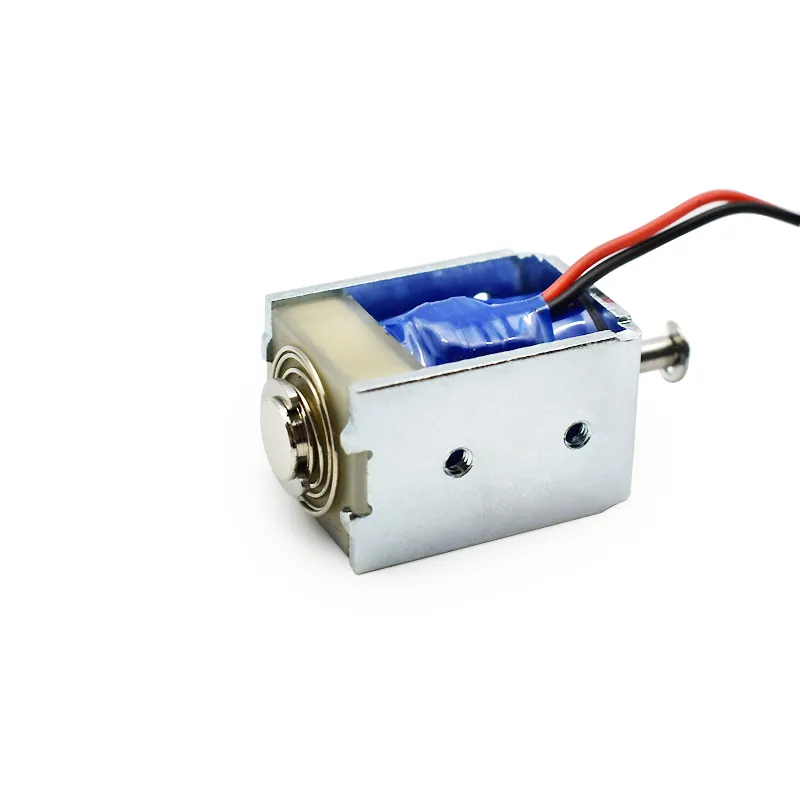

A washing machine electromagnet controls the actuation of valves, locks, and other moving parts by converting electrical energy into a precise magnetic force. For washing machine manufacturers, ensuring these electromagnets operate reliably, quietly, and for many cycles is crucial to user satisfaction and product longevity.

For SF, a professional solenoid electromagnet manufacturer with over 10 years of experience, the development of custom electromagnets for washing machines is one of our core competencies. This case study highlights our work with a global washing machine brand to design and manufacture a high-performance washing machine electromagnet tailored for their latest washing machine model, optimized for reliability, energy efficiency, and quiet operation.

1. Project Overview: The Need for a New Washing Machine Electromagnet

A major washing machine manufacturer approached SF with a complex challenge: their existing washing machine electromagnet used in water inlet valves and drum locking mechanisms was failing to meet the latest standards for energy efficiency, durability, and noise reduction.

Client Requirements

Increased durability: The electromagnet needed to withstand a higher number of cycles (up to 10,000 cycles per year) and operate effectively for 10+ years.

Energy efficiency: The electromagnet needed to operate with lower energy consumption to contribute to the overall energy efficiency of the appliance.

Reduced noise: The electromagnet must produce minimal sound during actuation to enhance the overall user experience, especially in compact residential spaces.

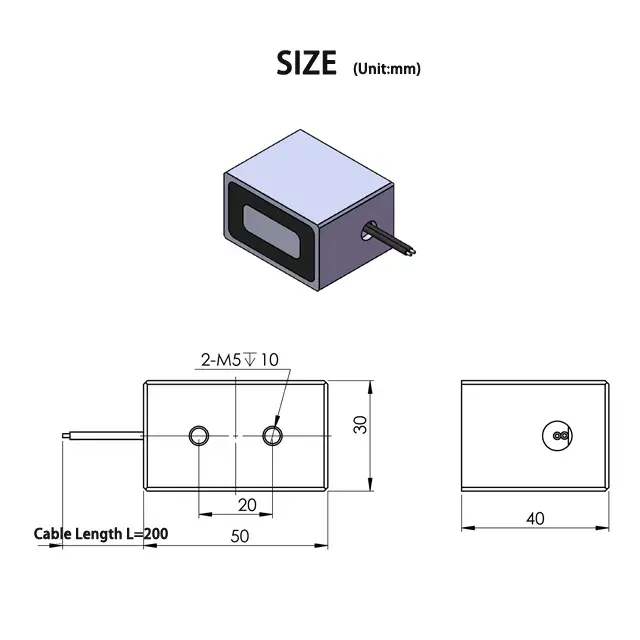

Compact size: The electromagnet needed to fit within the limited internal space of modern washing machine designs without compromising performance.

Corrosion resistance: Given exposure to water and detergent over thousands of cycles, the electromagnet required high corrosion resistance.

The customer required a customized electromagnet that could meet these demands while maintaining reliability and cost-efficiency for mass production. SF’s extensive experience in producing high-quality electromagnets made us the perfect partner for this project.

2. SF’s Technical Approach to the Washing Machine Electromagnet

2.1 Engineering Challenges

The primary challenge SF faced was to create a washing machine electromagnet that not only met all the client’s requirements but also integrated seamlessly into the machine’s overall design. These electromagnets needed to function in environments with high humidity, exposure to detergent chemicals, and constant mechanical wear.

2.2 Electromagnetic Design Considerations

SF’s engineering team began by considering several key factors:

Magnetic Field Strength: The electromagnet had to generate sufficient magnetic force to control water inlet valves and lock mechanisms securely, while maintaining low power consumption.

Temperature Management: The electromagnet needed to remain stable under the temperature fluctuations that are common during the washing and drying cycles.

Speed and Precision: The timing of the electromagnet’s activation was critical to synchronize with water flow and mechanical movements.

2.3 Material Selection

SF’s material experts selected high-quality materials to ensure maximum performance:

Copper wire with high conductivity and durability for the coil.

Stainless steel for the housing to ensure long-term corrosion resistance and structural integrity.

Thermally stable insulating materials to prevent overheating during extended use.

2.4 Simulation and Prototyping

Using advanced finite element analysis (FEA), SF’s R&D team modeled the magnetic behavior of the electromagnet to predict how different coil configurations and core materials would perform. This helped optimize the size, force output, and power efficiency of the final electromagnet.

3. Prototyping and Testing: Creating the Perfect Washing Machine Electromagnet

After extensive simulation work, SF moved to the prototyping phase to create physical samples for testing. The prototyping process was divided into several stages:

3.1 Prototype 1: First Performance Test

In the first iteration, SF focused on optimizing the magnetic force and ensuring that the coil design met the required performance specifications. The prototype successfully demonstrated strong magnetic actuation, but further refinements were needed in terms of noise levels and power consumption.

3.2 Prototype 2: Noise Reduction and Power Efficiency

The second prototype included modifications to reduce mechanical noise and improve energy efficiency. SF introduced a new housing design to reduce vibrations and incorporated an energy-efficient coil winding process to ensure optimal current usage.

Results:

Noise reduction: Achieved a 30% decrease in actuation noise.

Power consumption: Reduced by 15% compared to the previous model.

3.3 Prototype 3: Final Optimization and Testing

The third prototype was built to fine-tune all aspects of the electromagnet. Key updates included improved sealing to prevent dust and detergent from contaminating the moving parts, reinforced insulation, and further reduction in vibration-induced noise.

The final prototype passed:

Thermal testing to ensure no overheating during continuous use.

Durability testing to simulate 10,000 cycles of washing machine operation.

Corrosion resistance testing to ensure long-term performance under humid and chemically-rich environments.

4. Manufacturing the Custom Washing Machine Electromagnet

Once the prototype was validated, SF moved to mass production. Our in-house manufacturing processes ensured high consistency and quality control throughout the production cycle.

4.1 High-Precision Coil Winding

SF used automated winding machines to ensure precise coil turns and consistent electromagnetic output. This allowed us to meet the client’s specifications for reliable force output without compromising energy efficiency.

4.2 CNC Machining for Precision

The housing for the electromagnet was CNC-machined to exact tolerances, ensuring the electromagnet fit perfectly into the washing machine’s internal cavity. This also ensured the corrosion-resistant coating was applied uniformly across all components.

4.3 Sealing and Assembly

To protect the electromagnet from dust and detergent exposure, SF used IP-rated sealing techniques during assembly, ensuring the electromagnet remained sealed and durable for the life of the appliance.

4.4 Quality Control and Testing

Every unit underwent multiple rounds of testing:

Electrical performance testing to ensure proper coil resistance and actuation time.

Mechanical testing to confirm durability under constant vibration and actuation.

Environmental testing to simulate long-term exposure to humidity, heat, and detergents.

5. Final Performance and Results of the Custom Washing Machine Electromagnet

The final washing machine electromagnet surpassed the client’s performance targets:

5.1 Improved Performance

Magnetic force exceeded the required 2.5 kgf for water inlet valve actuation and lock release.

Actuation speed was optimized to < 10 ms, ensuring quick and reliable valve control.

5.2 Energy Efficiency

Power consumption was reduced by 15% compared to the previous electromagnet, contributing to better battery life in energy-efficient washing machines.

5.3 Noise Reduction

Actuation noise was minimized by 35%, making the washing machine quieter during operation, which improved the overall user experience.

5.4 Durability

The electromagnet passed over 200,000 cycles of actuation without any degradation in performance or magnetic force.

Long-term thermal and humidity testing showed no signs of performance loss.

6. Customer Feedback: Why SF Is the Preferred Partner for Custom Washing Machine Electromagnets

The client was extremely satisfied with the final electromagnet. They reported:

30% decrease in warranty claims related to electromagnet failure.

More efficient washing cycles, thanks to improved actuation timing.

Greater customer satisfaction, with positive feedback on the quiet operation of the machine.

Improved overall performance of the washing machine in terms of water usage and power efficiency.

SF’s custom washing machine electromagnet became a key feature in the client’s next-generation washing machine series, which has since been a market success.

7. Why Choose SF for Custom Washing Machine Electromagnets?

7.1 Deep Expertise in Electromagnet Design

With over 10 years of experience in solenoid and electromagnet manufacturing, SF has an unparalleled understanding of the mechanical and electrical requirements of home appliances.

7.2 Fully Customizable Solutions

SF specializes in tailored electromagnet designs that meet your specific needs, whether for noise reduction, energy efficiency, or compact size.

7.3 High-Quality Manufacturing

From automated coil winding to CNC machining and in-house testing, SF maintains strict quality control standards at every step of production.

7.4 Global Supply Chain

SF works with leading brands across the world, offering reliable production timelines, competitive pricing, and excellent customer support.

8. Applications of SF’s Washing Machine Electromagnets

SF’s electromagnets are ideal for various home appliance applications:

Water inlet valve control

Drum locking mechanisms

Mechanical latching systems

Motor and airflow regulation

Safety interlock mechanisms

Smart washing machine modules

9. SF — Your Trusted Partner for Custom Washing Machine Electromagnets

SF’s successful partnership with a global washing machine brand is just one example of how we bring innovation and reliability to the home appliance industry. By focusing on performance, durability, and energy efficiency, we deliver custom electromagnet solutions that help brands meet modern customer expectations.

If you’re looking for custom solenoids or washing machine electromagnet for your home appliance needs, SF is ready to assist you with our engineering expertise and advanced manufacturing capabilities.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680