Last Updated on 2026-02-04 by SolenoidFactory

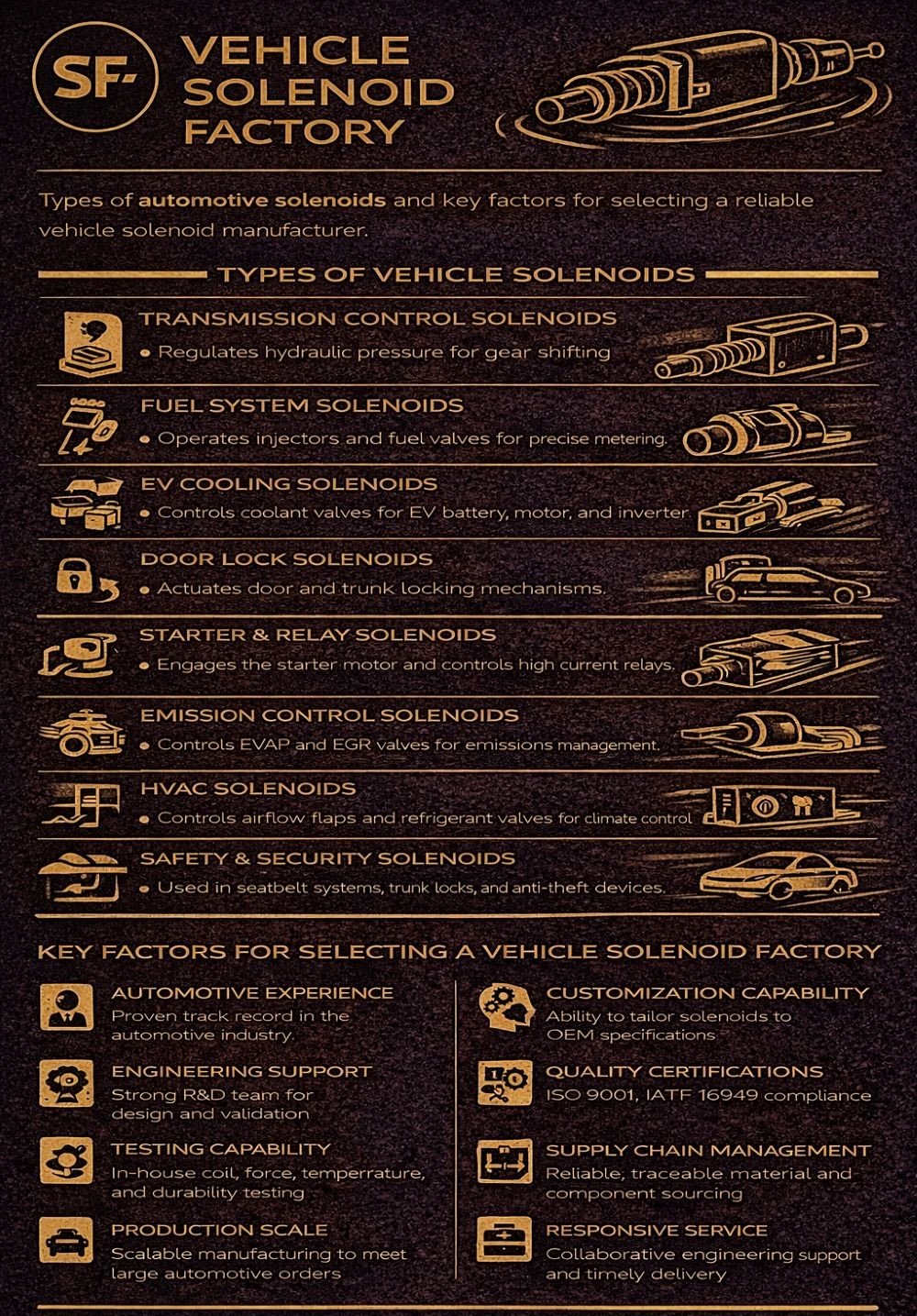

In today’s automotive industry, electromechanical precision is critical. Modern vehicles rely on dozens of electromagnetic actuators to manage motion, control fluids, improve safety, and enhance user comfort. At the heart of many of these systems is a highly engineered component supplied by a specialized vehicle solenoid factory.

From transmission control to door locking, and from fuel systems to thermal management, solenoids are indispensable. This article provides a comprehensive technical overview of automotive solenoids, their functions, value in vehicle design, and how to select a reliable vehicle solenoid factory for long-term supply and innovation. We will also introduce SF, a professional custom solenoid manufacturer with more than 10 years of experience in solenoid electromagnet production.

What Does a Vehicle Solenoid Factory Produce?

A professional vehicle solenoid factory designs and manufactures electromagnetic actuators that convert electrical energy into controlled linear or rotary motion. These solenoids operate in harsh automotive environments involving vibration, temperature extremes, moisture, and long duty cycles.

Core production capabilities typically include:

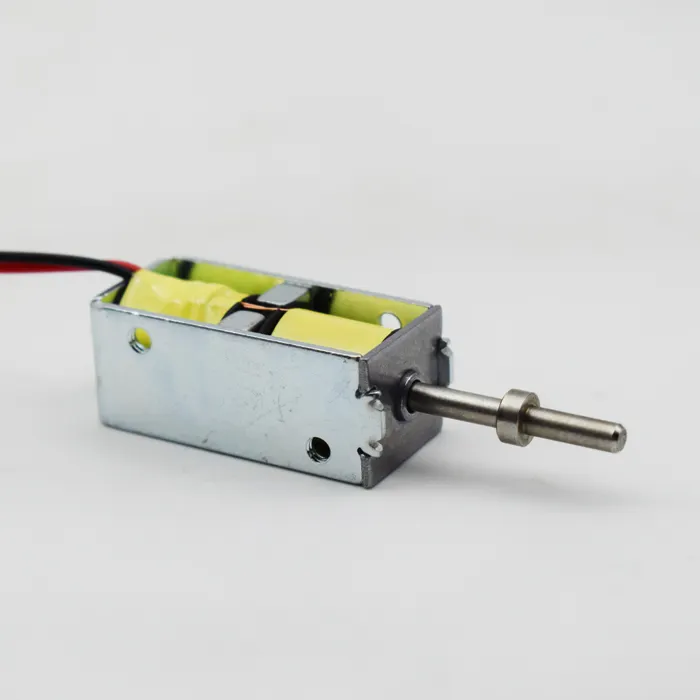

Push-pull solenoids

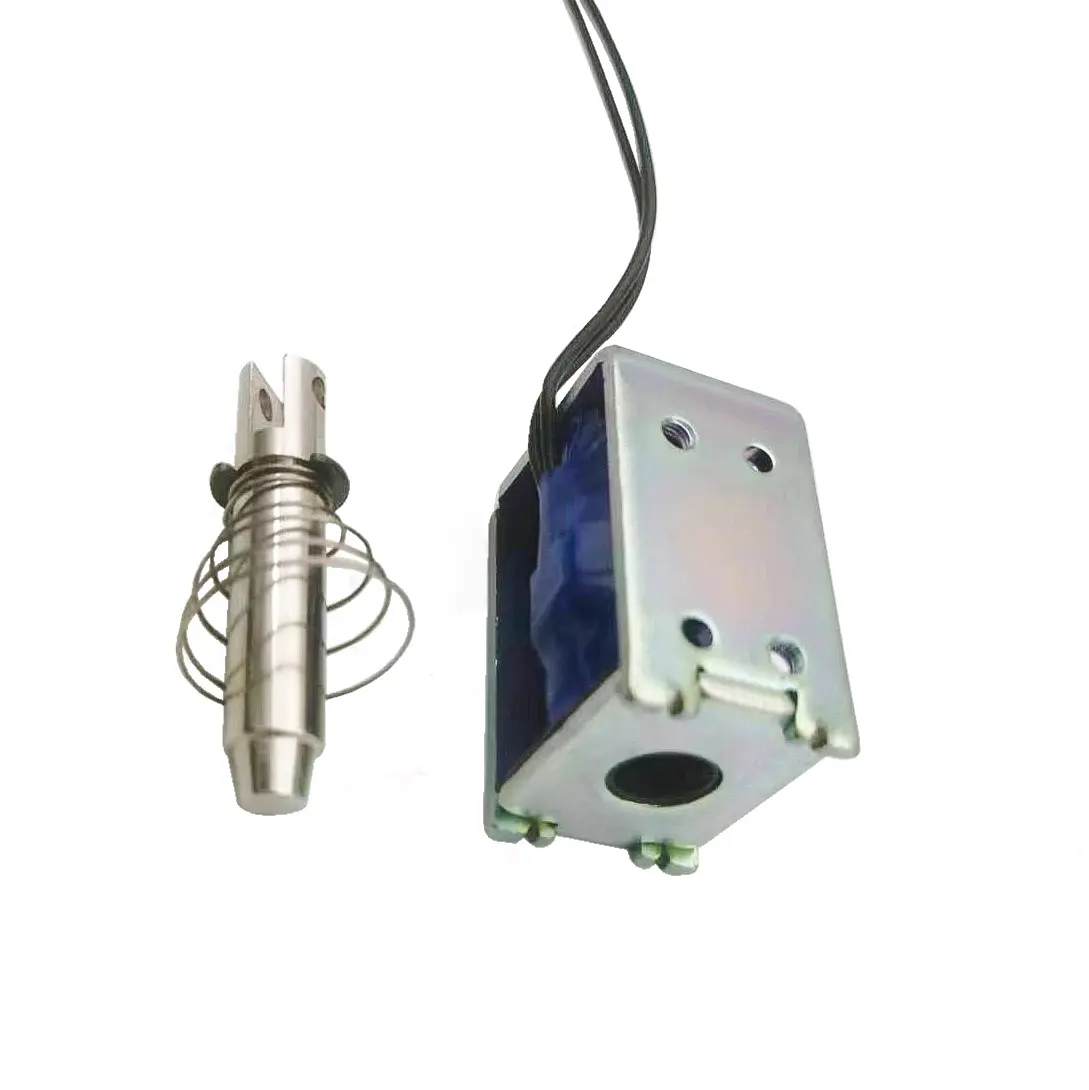

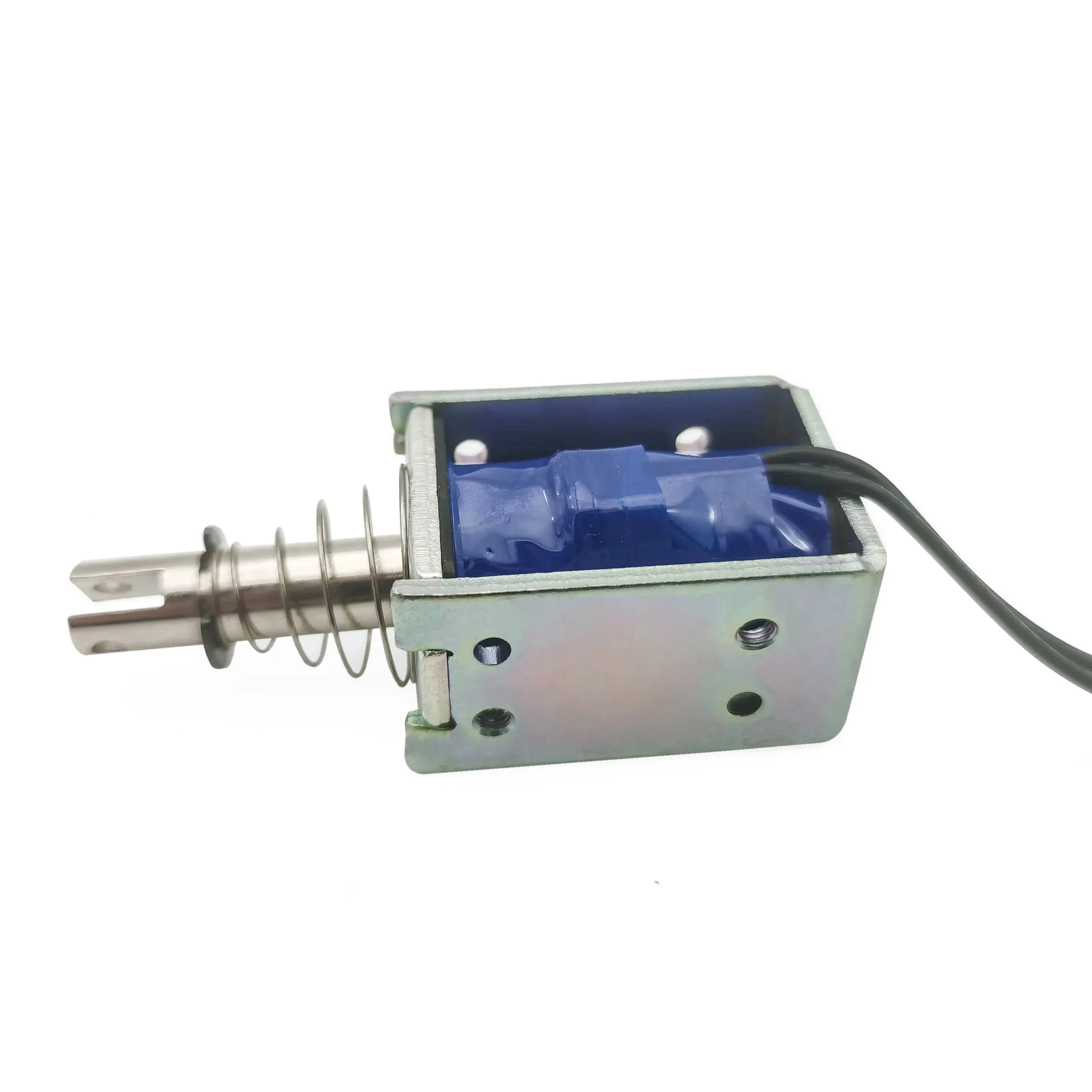

Latching solenoids

Rotary solenoids

Tubular solenoids

Valve solenoids

Custom electromagnets for locking, positioning, and fluid control

An experienced vehicle solenoid factory must combine electromagnetic design, mechanical precision, materials science, and automotive reliability standards.

Major Types of Solenoids a Vehicle Solenoid Factory Supplies

Different automotive systems require different solenoid architectures. A qualified vehicle solenoid factory provides multiple technical solutions.

1. Transmission Control Solenoids from a Vehicle Solenoid Factory

These solenoids regulate hydraulic pressure in automatic transmissions. They control gear shifting timing, clutch engagement, and torque converter lockup.

Technical requirements:

Fast response time

Oil resistance

High cycle durability

Stable force output under temperature variation

A reliable vehicle solenoid factory must design coils and plungers to maintain performance in ATF fluid environments.

2. Fuel System Solenoids by a Vehicle Solenoid Factory

Fuel injectors and fuel shutoff valves rely on precision electromagnetic control. These solenoids must deliver repeatable motion in milliseconds.

Value provided:

Precise fuel metering

Improved combustion efficiency

Reduced emissions

A specialized vehicle solenoid factory uses high-precision winding and magnetic circuit optimization to meet strict fuel system tolerances.

3. EV and Hybrid Thermal Management Solenoids from a Vehicle Solenoid Factory

Electric vehicles use solenoid valves to manage coolant flow for batteries, motors, and inverters.

Why this matters:

Battery life depends on thermal stability

Cooling efficiency impacts driving range

An advanced vehicle solenoid factory develops low-power, long-life solenoids that support continuous duty cycles in EV cooling loops.

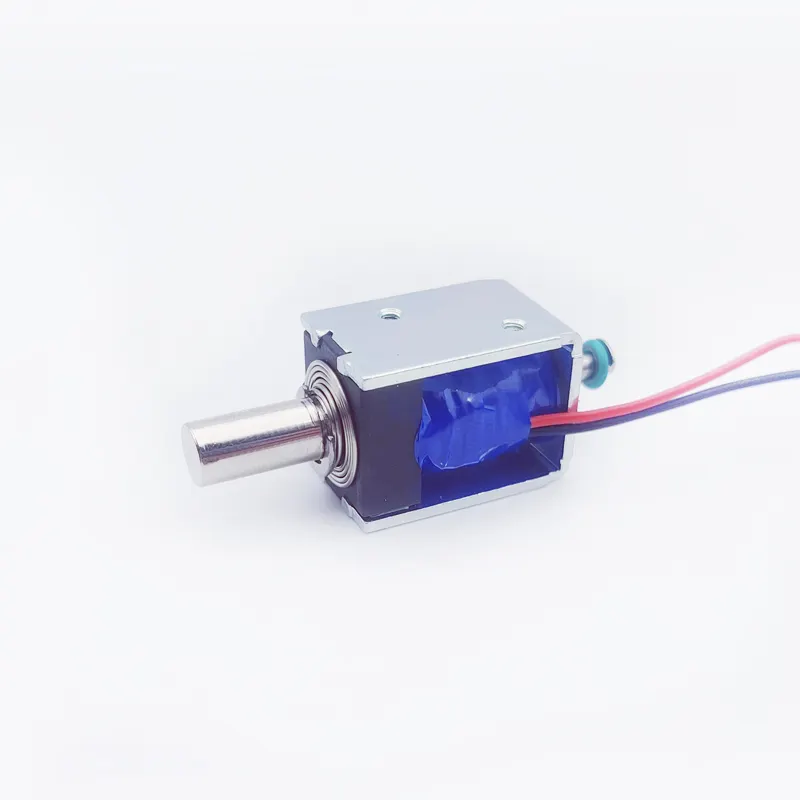

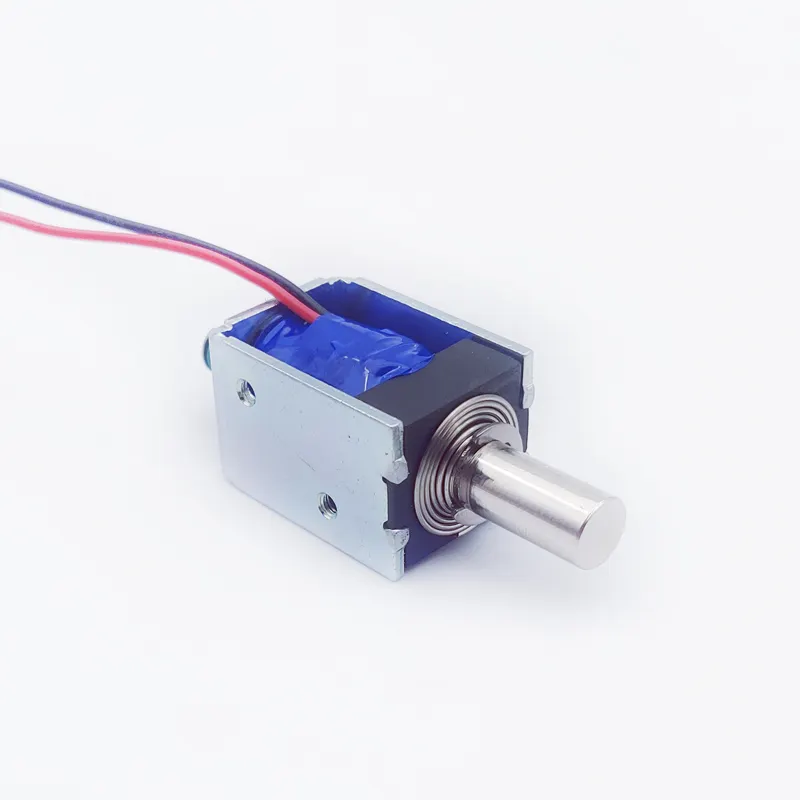

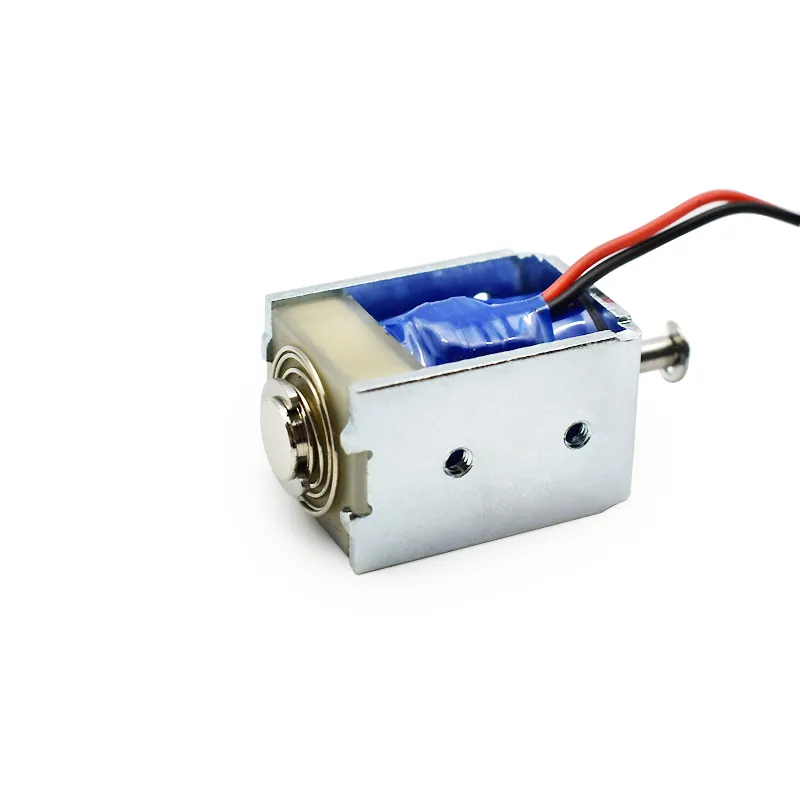

4. Door Lock & Smart Access Systems from a Vehicle Solenoid Factory

Automotive door locks use compact push-pull solenoids for actuation. These must be quiet, fast, and durable.

Key performance targets:

Low noise

Compact design

Long mechanical life

A precision vehicle solenoid factory ensures stable force even after millions of cycles.

5. Starter and Relay Solenoids by a Vehicle Solenoid Factory

Starter solenoids engage the motor with the engine flywheel. These are high-force devices operating under high current.

Critical characteristics:

High impact resistance

Strong magnetic force

Heat dissipation

A qualified vehicle solenoid factory must design robust housings and contact systems.

6. Emission Control Solenoids from a Vehicle Solenoid Factory

EVAP purge valves and EGR control valves rely on solenoid actuation to manage emissions.

Contribution to compliance:

Accurate vapor flow control

Reduced hydrocarbon emissions

An experienced vehicle solenoid factory helps OEMs meet global environmental regulations.

7. HVAC and Airflow Control Solenoids from a Vehicle Solenoid Factory

Vehicle climate systems use solenoids to control air direction, vent positions, and refrigerant flow.

Benefits:

Improved cabin comfort

Efficient airflow management

A capable vehicle solenoid factory ensures silent operation for passenger comfort.

8. Safety and Security Solenoids from a Vehicle Solenoid Factory

Solenoids are also used in seatbelt systems, trunk release, steering locks, and anti-theft mechanisms.

Design priorities:

Fail-safe operation

High reliability

Quick response in emergency scenarios

A professional vehicle solenoid factory designs redundant and durable systems for safety applications.

Why Automotive OEMs Depend on a Professional Vehicle Solenoid Factory

Automotive design requires suppliers that can deliver both innovation and reliability. A strong vehicle solenoid factory provides:

Custom electromagnetic design

Automotive-grade materials

High-volume production capacity

Strict quality control systems

PPAP and traceability support

Without a dependable vehicle solenoid factory, OEM performance and safety cannot be guaranteed.

Engineering Advantages Offered by a Leading Vehicle Solenoid Factory

Magnetic Circuit Optimization

Advanced simulation ensures efficient flux paths, reducing power consumption.

Thermal Management Design

Automotive solenoids often operate in 125°C+ environments. A capable vehicle solenoid factory selects insulation classes and materials accordingly.

Mechanical Life Testing

Top manufacturers perform lifecycle tests exceeding millions of cycles.

Sealing & Environmental Protection

Ingress protection against dust, oil, and moisture is essential.

Production Strength of a Reliable Vehicle Solenoid Factory

A competitive vehicle solenoid factory should have:

Automated coil winding lines

Precision CNC machining

In-house stamping and assembly

Coil resistance and force testing stations

End-of-line durability testing

These capabilities ensure consistency across large automotive orders.

How to Choose the Right Vehicle Solenoid Factory

Selecting a long-term vehicle solenoid factory partner requires evaluation across multiple dimensions.

1. Automotive Experience

Years of automotive project history reduce development risk.

2. Customization Capability

Each vehicle platform requires unique specifications.

3. Engineering Support

A strong R&D team accelerates validation.

4. Quality Certifications

Look for ISO 9001, IATF 16949 readiness.

5. Testing Capability

Force curves, temperature tests, and vibration tests must be available.

6. Supply Chain Stability

A dependable vehicle solenoid factory maintains material consistency.

7. Production Capacity

Scalability is vital for mass vehicle production.

8. Communication & Project Management

Responsive engineering support shortens development cycles.

Industry Case Examples Supported by a Vehicle Solenoid Factory

Case 1: EV Cooling Valve Program

A global EV manufacturer required compact low-power solenoids for battery cooling loops. A specialized vehicle solenoid factory optimized coil design to reduce energy consumption by 18%.

Case 2: Smart Door Lock System

A car brand upgraded to silent smart locks. The chosen vehicle solenoid factory developed a low-noise plunger structure.

Case 3: Transmission Shift Control

An automatic transmission supplier partnered with a high-precision vehicle solenoid factory to improve shift timing accuracy.

SF — A Professional Vehicle Solenoid Factory with 10+ Years of Experience

SF is a custom electromagnet and solenoid manufacturer with over a decade of production expertise. As a growing vehicle solenoid factory, SF provides:

Custom push-pull solenoids

Rotary solenoids

Valve solenoids

Latching solenoids

Tubular electromagnets

SF Vehicle Solenoid Factory Advantages

Engineering Strength

SF engineers support magnetic simulation, structural optimization, and rapid prototyping.

Customization Capability

SF provides voltage, stroke, force, and mounting customization.

Quality Focus

Strict in-process inspections ensure performance consistency.

Production Capacity

SF supports both low-volume development and high-volume automotive supply.

Future Trends Shaping the Vehicle Solenoid Factory Industry

The role of the vehicle solenoid factory continues expanding with vehicle electrification and automation.

Emerging trends include:

Low-power solenoids for EV systems

Compact designs for ADAS modules

Smart feedback-enabled actuators

Lightweight materials for efficiency

A forward-looking vehicle solenoid factory must invest in R&D and advanced manufacturing.

Why Choosing the Right Vehicle Solenoid Factory Matters

Automotive performance, safety, and comfort depend heavily on electromagnetic actuators. Partnering with an experienced vehicle solenoid factory ensures:

Reliable system performance

Long service life

Efficient energy use

Compliance with automotive standards

With more than 10 years of solenoid manufacturing experience, SF continues to support global customers as a trusted vehicle solenoid factory, delivering custom electromagnetic solutions for next-generation vehicles.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680