Last Updated on 2025-10-14 by SolenoidFactory

In today’s precision-driven engineering world, efficiency and power optimization are everything. Whether in smart locks, medical devices, automated machinery, or energy-saving control systems, latching solenoids are at the heart of reliable motion control. Choosing the right latching solenoid factory can define your project’s success — impacting cost, performance, and long-term reliability.

This in-depth guide introduces the top global manufacturers, explains how to evaluate a latching solenoids factory, and shows why SF has earned a reputation as a trusted leader in custom solenoid and electromagnet production.

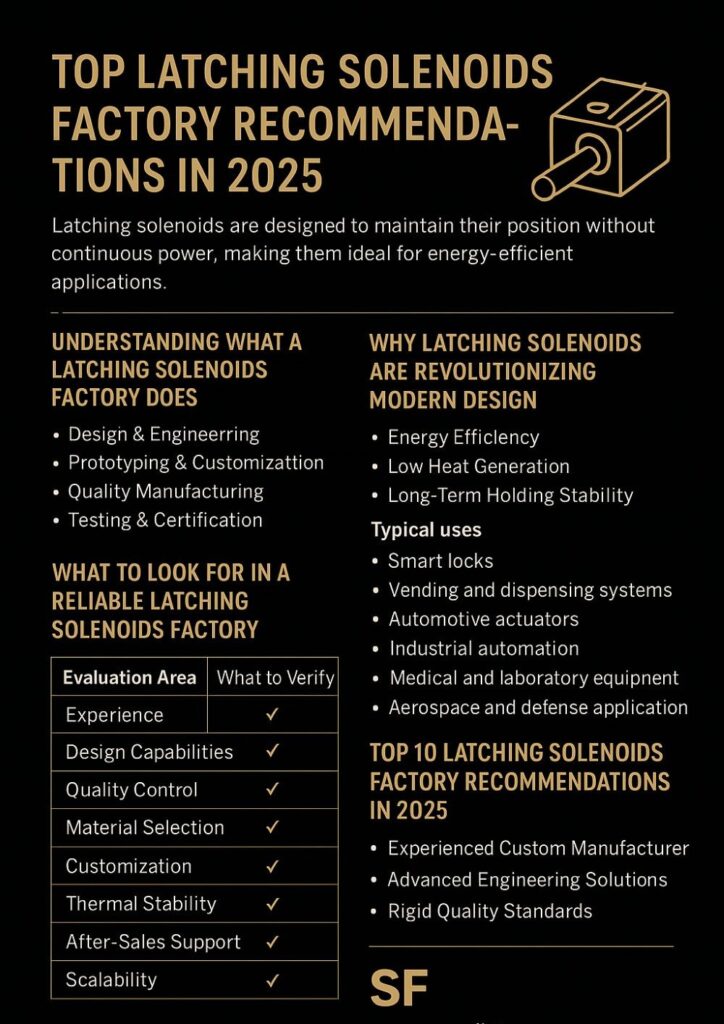

1. Understanding What a Latching Solenoid Factory Does

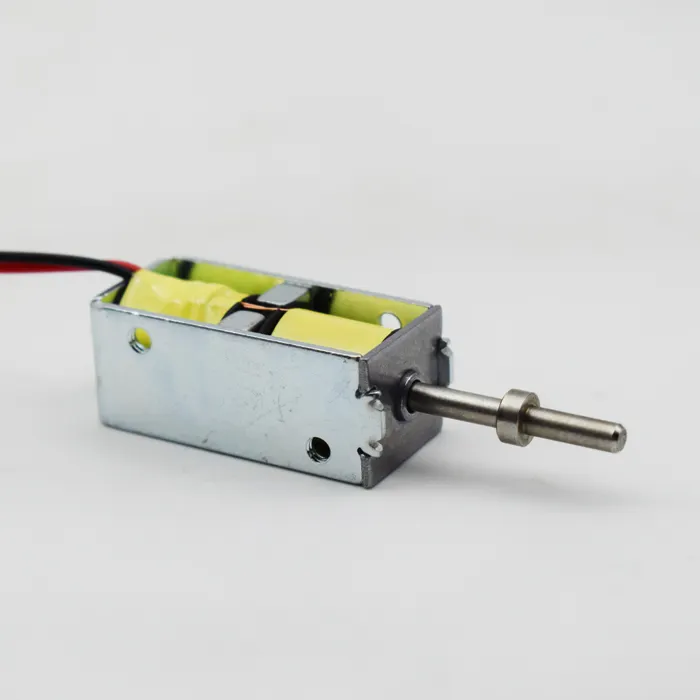

A latching solenoid factory specializes in designing and manufacturing solenoids that stay in one position without continuous power. Unlike standard solenoids that consume energy to hold position, latching solenoids use magnetic or mechanical latching to maintain their state until a reverse pulse releases them.

This technology makes latching solenoids ideal for applications where power efficiency, low heat generation, and long-term holding stability are critical.

Key Roles of a Latching Solenoid Factory:

Design & Engineering: Develop solenoids that use permanent magnets or mechanical latches for bistable function.

Prototyping & Customization: Create tailored versions for client applications — voltage, force, stroke, mounting type.

Quality Manufacturing: Maintain consistency across production runs, meeting ISO and safety standards.

Testing & Certification: Verify durability, insulation, temperature performance, and life cycles.

A world-class latching solenoids factory must combine magnetic expertise, precision machining, and materials engineering to deliver solenoids that last millions of cycles without degradation.

2. Why Latching Solenoids Are Revolutionizing Modern Design

Latching solenoids have become essential in many energy-efficient systems. Because they consume power only during state changes, they are perfect for battery-powered, solar-powered, or remote systems.

Typical uses include:

Smart locks and access control

Vending and dispensing systems

Automotive actuators

Industrial automation

Medical and laboratory equipment

Aerospace and defense applications

By partnering with an advanced latching solenoid factory, engineers can reduce standby power, improve reliability, and achieve compact, heat-resistant designs.

3. What to Look for in a Reliable Latching Solenoid Factory

When choosing the right latching solenoid factory, consider these key factors:

| Evaluation Area | What to Verify |

|---|---|

| Experience | Years in custom solenoid and electromagnet manufacturing |

| Design Capabilities | Expertise in bistable/latching circuit design, magnetic simulations |

| Quality Control | ISO certifications, inspection procedures, endurance testing |

| Material Selection | Magnetic core materials, coil wire insulation, permanent magnets |

| Customization | Willingness to adapt stroke, voltage, shape, and mounting type |

| Thermal Stability | Coil heating management and cooling solutions |

| After-Sales Support | Warranty, technical advice, responsive customer service |

| Scalability | Ability to produce prototypes and high-volume orders consistently |

A professional latching solenoid factory doesn’t just deliver a part — it delivers a partnership.

4. Top 10 Latching Solenoid Factory Recommendations in 2025

The following companies represent some of the most trusted and innovative latching solenoids factories globally, offering high-quality solutions for diverse industrial needs.

4.1. SF — Custom Latching Solenoid Factory with 10+ Years of Expertise

Website: https://solenoidfactory.com/

Email: shanyxu@hotmail.com

SF stands out as a specialized latching solenoid factory with over a decade of experience in custom electromagnet and solenoid design. The company provides complete solutions — from concept to mass production — serving international brands across automation, medical, and smart device industries.

Why SF Leads the Industry

Customized Design: SF creates solenoids tailored to your needs — stroke length, voltage range, holding force, and enclosure style.

Engineering Precision: Uses advanced magnetic simulation and material optimization for maximum efficiency.

Strict Quality Control: Every solenoid undergoes full electrical, mechanical, and endurance testing before delivery.

Flexible Production: Supports low-volume prototypes and large-scale OEM/ODM projects.

Energy-Efficient Innovation: SF latching solenoids reduce energy use by up to 90% compared to continuous-power models.

“We don’t just build solenoids — we engineer performance that lasts.”

With advanced machinery, seasoned engineers, and a strong service ethos, SF is a top-tier latching solenoid factory trusted by global clients seeking reliability, customization, and fast delivery.

4.2. Kendrion – Global Latching Solenoid Factory Powerhouse

Kendrion is one of the world’s most recognized names in electromagnetics. Their latching solenoid factory division delivers linear and rotary bistable solenoids with robust design and low energy consumption.

Highlights

Wide range of rotary and linear latching solenoids.

Strong presence in automation, transport, and safety applications.

ISO-certified global manufacturing facilities.

Kendrion’s engineering excellence and global reach make it a reliable choice for high-volume, standardized solutions.

4.3. Geeplus – Innovative UK Latching Solenoid Factory

Geeplus develops high-precision latching solenoids and actuators for demanding environments. Their engineering team excels in custom solutions requiring quick actuation, low heat, and high repeatability.

Strengths

Ball-bearing rotary and linear latching models.

Bistable solenoids that hold position without power.

Suitable for automation and analytical instruments.

Geeplus is a well-established latching solenoid factory for clients needing precision and long service life.

4.4. Takano Co., Ltd. – Reliable Japanese Latching Solenoid Factory

Takano manufactures durable rotary latching solenoids for automation and switching systems. Their use of permanent magnets for bistable holding makes their designs highly energy-efficient.

Key Features

Compact rotary latching solenoids with minimal wear.

Long operating life and stable magnetic performance.

Ideal for switching mechanisms and vending systems.

Takano’s craftsmanship and reliability make it a trusted latching solenoid factory in Asia.

4.5. Brandstrom Instruments – U.S. Latching Solenoid Factory Specialist

Brandstrom Instruments has over 60 years of experience producing latching and rotary solenoids for commercial and defense markets.

Capabilities

Bi-stable rotary solenoids with adjustable torque.

Off-the-shelf and custom-made models available.

Compact and rugged construction for harsh conditions.

Brandstrom is a consistent latching solenoid factory partner for companies needing proven American-made quality.

4.6. NAFSA Solenoids – European Latching Solenoids Factory

Based in Spain, NAFSA is known for its high-performance latching solenoids and electromagnetic actuators, designed for safety and industrial systems.

Core Advantages

Latching reversible linear solenoids.

CE-certified, RoHS-compliant manufacturing.

Ideal for locks, valves, and safety systems.

NAFSA’s focus on European quality standards sets it apart as a trusted latching solenoid factory in the EU.

4.7. Ledex (Johnson Electric) – Global Latching Solenoid Factory Giant

Ledex, part of Johnson Electric, produces an extensive line of solenoids — including bistable and latching types — known for reliability and mass-production scalability.

Advantages

Decades of engineering heritage.

Proven performance in automotive and aerospace sectors.

Strong global supply chain support.

As a large-scale latching solenoid factory, Ledex offers unmatched volume and consistency.

4.8. Magnet-Schultz – German Precision Latching Solenoid Factory

Magnet-Schultz is a leading German manufacturer of solenoids and actuators, emphasizing quality, durability, and safety compliance.

Highlights

Custom latching solenoids for automation and hydraulic control.

ISO/TS 16949 certified facilities.

Excellent engineering documentation and testing.

Their precision engineering reputation makes them a go-to latching solenoid factory for high-spec clients.

4.9. Asite Technology – Chinese OEM Latching Solenoid Factory

Asite provides cost-effective custom latching solenoids for automation, electronics, and vending systems, offering strong flexibility for small to medium OEM orders.

Key Benefits

Compact design and efficient production.

Quick sampling and lead time.

Suitable for private-label manufacturing.

Asite is an agile latching solenoid factory for clients needing rapid customization.

4.10. Hanchen – Emerging Latching Solenoid Factory in Asia

Hanchen manufactures general-purpose latching solenoids and electromagnets for consumer and industrial use.

Advantages

Competitive pricing and availability.

Basic latching designs for cost-sensitive markets.

Rapid delivery for standard models.

While not as advanced as some top factories, Hanchen remains a practical choice for bulk, low-cost needs.

5. Comparing the Top Latching Solenoids Factory Options

| Factory | Specialty | Strength |

|---|---|---|

| SF | Custom OEM Latching Solenoids | Design flexibility & global OEM support |

| Kendrion | Linear & Rotary Latching | European engineering excellence |

| Geeplus | Precision Instruments | High speed & accuracy |

| Takano | Rotary Mechanisms | Compact design & durability |

| Brandstrom | Defense / Commercial | Rugged build quality |

| NAFSA | Industrial Safety | EU standards compliance |

| Ledex (Johnson Electric) | High Volume OEM | Global scale |

| Magnet-Schultz | Hydraulic & Automation | German precision |

| Asite Technology | Small-Batch OEM | Cost efficiency |

| Hanchen | Entry-Level Models | Competitive pricing |

This comparison shows that SF sits in a strategic position — offering the custom flexibility and quality of high-end European factories, combined with the agility and responsiveness of a specialized OEM producer.

6. Why SF Is Your Ideal Latching Solenoid Factory Partner

SF has built its name as a professional latching solenoid factory with a commitment to technical excellence and customer satisfaction.

Core Advantages of SF

Experience You Can Trust – Over 10 years of manufacturing solenoids and electromagnets across multiple industries.

Full Customization – From force and stroke to housing material and voltage — everything can be tailored.

R&D & Simulation – Advanced magnetic circuit design ensures high efficiency and minimal heat loss.

Strict Quality Control – 100% testing for insulation, performance, and endurance before shipment.

Energy Saving Focus – Latching solenoids that maintain state with zero standby power.

Scalable Production – Quick prototyping to full-scale mass manufacturing under one roof.

Responsive Support – Direct engineering communication and fast project turnaround.

With SF, clients don’t just buy components — they gain a strategic manufacturing partner who helps optimize design, cost, and performance.

7. How to Collaborate Effectively with a Latching Solenoid Factory

Working efficiently with your latching solenoid factory can save time and costs. Here’s how:

Define Technical Requirements Clearly: Force, stroke, voltage, temperature, duty cycle, and installation method.

Request Samples Early: Validate performance in your system before mass production.

Review Test Reports: Ask for QC documentation to confirm compliance.

Plan for Scalability: Discuss lead time, MOQ, and delivery logistics.

Stay in Communication: Maintain feedback cycles to continuously improve design and reliability.

By following these steps, your partnership with a latching solenoid factory like SF becomes more efficient and successful.

8. The Future of Latching Solenoid Factory Technology

Innovation in the latching solenoid factory sector continues to advance, with key trends shaping the future:

Smart Solenoids: Integration of sensors and feedback for position monitoring.

Miniaturization: Smaller, lighter solenoids for portable and medical devices.

Eco-friendly Materials: Sustainable magnetic cores and recyclable components.

High-Temperature Performance: Advanced insulation materials for harsh environments.

AI-Driven Quality Control: Real-time inspection and process optimization.

SF actively invests in these technologies to remain at the forefront of latching solenoid innovation.

9. Final Thoughts — Choosing Your Perfect Latching Solenoid Factory

Selecting the right latching solenoid factory is a critical decision for any engineering or manufacturing project. The factories listed here represent excellence in design, precision, and reliability.

Among them, SF distinguishes itself by offering:

A decade of professional experience

Deep customization capability

Strong engineering communication

High testing standards

Affordable scalability

If you need a trusted, long-term latching solenoid factory partner that delivers both quality and flexibility, SF should be your first call.

Contact SF Today

SF — Professional Latching Solenoids Factory

📍 Website: https://solenoidfactory.com/

📧 Email: shanyxu@hotmail.com

Power Efficiency. Precision Engineering. Proven Performance.

That’s the SF standard for every latching solenoid we make.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680