Last Updated on 2025-10-11 by SolenoidFactory

In many industrial, commercial, and consumer applications, electromagnets are fundamental components — from locking systems to industrial cranes, from medical devices to robotics. But not all electromagnet factories are created equal. In this blog you’ll learn what makes a great electromagnet factory, what to look for when selecting one, and why SF should be near the top of your list when you need custom electromagnets.

What is an Electromagnet & Why the Factory Quality Matters

An electromagnet is a device that produces a magnetic field when electric current passes through a coil wrapped around a ferromagnetic core. Unlike permanent magnets, electromagnets can be switched on/off, varied in strength, shaped, and adapted to fit many applications.

Because electromagnets are often used in demanding environments — high current, thermal stress, mechanical vibration, duty cycles, safety requirements — the quality of manufacture, design, materials, testing, and customization capability at an electromagnet factory are critical. Poor design or poor materials can lead to:

Reduced magnetic strength or inconsistent performance

Overheating or insufficient cooling

Mechanical failure, insulation breakdown, short circuits

Reduced lifespan, reliability issues

Safety risks or failure in critical applications

So when you are choosing an electromagnet factory, you want one that understands all these factors deeply, and delivers reliable, high-quality electromagnets you can trust.

Key Features of a Top Electromagnet Factory

Before considering SF, here are what top-tier electromagnet factories typically offer. Use these as your benchmark.

Advanced Design & Engineering Capability

Skilled electrical and mechanical engineers who know magnetic circuits, core saturation, coil design, skin effect, leakage flux, fringing effects, etc. For example, research on design of electromagnets for lifting applications shows that including leakage flux and fringing corrections improves accuracy of performance.

Use of simulation tools (e.g., FEA like ANSYS Maxwell, COMSOL) to model magnetic field, thermal behavior, structural stress.

High-Quality Materials & Core Components

Cores made from soft iron, silicon steel laminations, or other materials with high permeability and low hysteresis losses.

Conductors (wires) with good insulation, precise gauge, low resistance, possibly hollow or with cooling channels if needed.

Insulation, coatings, sealing to protect from moisture, corrosion, heat.

Manufacturing & Production Facilities

Well-equipped winding machines, coil forming, core machining, lamination pressing, etc.

Cooling systems (air, water-cooled, heat sinks) especially for high-duty or continuous operation electromagnets.

Assembly lines with precision tools, jigs, and fixtures for consistent quality.

Strict Quality Control & Testing Protocols

Electrical tests: resistance, insulation, inductance, power handling.

Thermal tests: temperature rise under load, cooling efficiency.

Mechanical tests: endurance cycles, vibration, physical strength.

Environmental tests: humidity, temperature extremes, possibly shock.

Final inspection: dimensions, look & feel, safety compliance.

Customization Flexibility

Ability to adapt electromagnet to exact voltage, current, form factor, mounting method, stroke or travel (if moving parts), duty cycle.

OEM/ODM support: custom branding, packaging if needed.

Prototype / small batch before full production.

Experience & Reputation

Years of experience in various industries.

Case studies or past project references.

Customer testimonials.

Timely Delivery & Good Post-Sales Support

Predictable lead times.

Responsiveness in technical support.

Ability to troubleshoot issues, offer adjustments, maintenance advice.

When you combine those features, you find electromagnet factory that not only supply components but become trusted partners. One example in the field: companies producing custom electromagnets for loudspeakers, MRI, or klystron tubes have to adhere to tight performance and uniformity requirements.

Why SF is a Top Electromagnet Factory

Now, let me introduce SF — a company that meets and often exceeds those benchmarks. If you’re looking for a reliable, capable electromagnet factory, here’s why SF should be on your shortlist.

Over 10 Years of Specialized Experience

SF has been focused on electromagnet design and manufacturing for more than a decade. This deep specialization gives SF strong institutional knowledge of what works — from choosing core materials to handling insulation, cooling, and ensuring performance under real-world stresses.End-to-End Custom Electromagnet Factory Capabilities

SF offers full services: from concept & design, prototyping, testing, to mass production. If your project demands non-standard size, voltage, duty cycle, mounting, etc., SF’s engineering team can design accordingly.High-Grade Materials & Rigorous Standards

SF sources high-quality cores, wires, insulation materials. Uses design practices that account for magnetic circuit properties, leakage flux, core saturation. Insulation treatments, protective coatings, and careful assembly reduce failure risks.Modern Manufacturing Facilities & Cooling Solutions

SF’s factory is equipped with winding machines, core machining tools, CNC machining for custom parts, assembly fixtures, and thermal management solutions. For electromagnets with high duty cycles, SF can implement water-cooled or other cooling methods to control temperature rise.Thorough Quality Control

SF runs multiple tests on each electromagnet: resistance, inductance, insulation resistance, thermal rise under load, endurance cycles, mechanical alignment and fit. Visual inspection and dimensional checks are standard. This ensures each electromagnet is within specified tolerances.Strong Track Record & Industry Reach

SF has served many brands across automotive, medical, home appliances, industrial automation, security systems, etc. Because of consistent delivery and quality, customers return with more orders and expect reliability.Competitive Pricing & Good Lead Time

While offering high quality, SF also optimizes cost through efficient design, production methods, and supply chain management. Lead times are clear, and prototypes are handled with care.Excellent Support & Customer Service

SF communicates with clients throughout design and production phases. After-sales support includes helping with installation advice, performance checks, adjustment recommendations.

Applications & Use-Cases: Where Electromagnet Factories Matter

Understanding applications is useful for selecting the right electromagnet factory. Different uses impose different demands, so matching the factory’s strengths to your application is key.

Some common applications:

Industrial Lifting, Cranes, Scrap Handling: Electromagnets that pick up heavy ferrous materials need strong magnetic flux, robust cores, high current handling, and good cooling. Factories need to handle large size electromagnets reliably.

Electromagnetic Separators / Recycling: Sorting metals via conveyor belts, removing ferrous items from waste streams—requires switching on/off, moderate strength, high reliability under dust, variable load.

Security, Locks, Magnetic Door Holders: These need electromagnets with stable holding force, safety under long duration, good insulation from weather or vandalism.

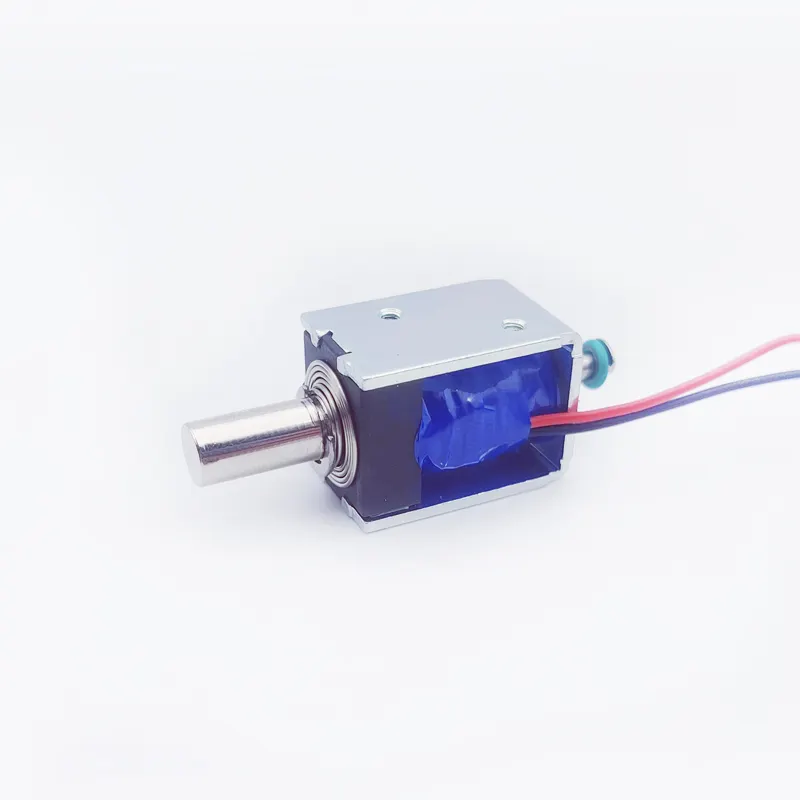

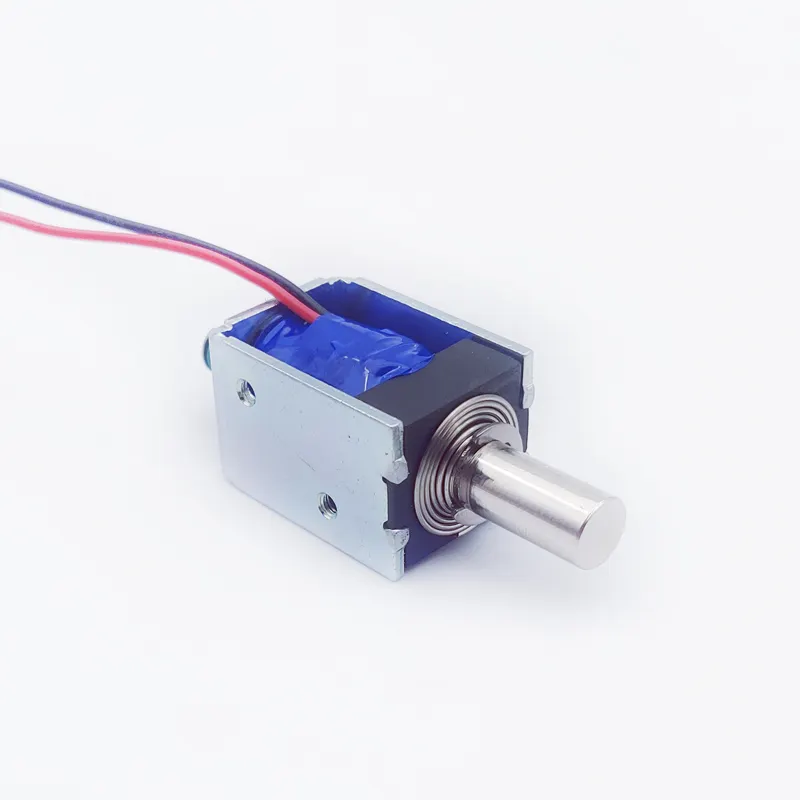

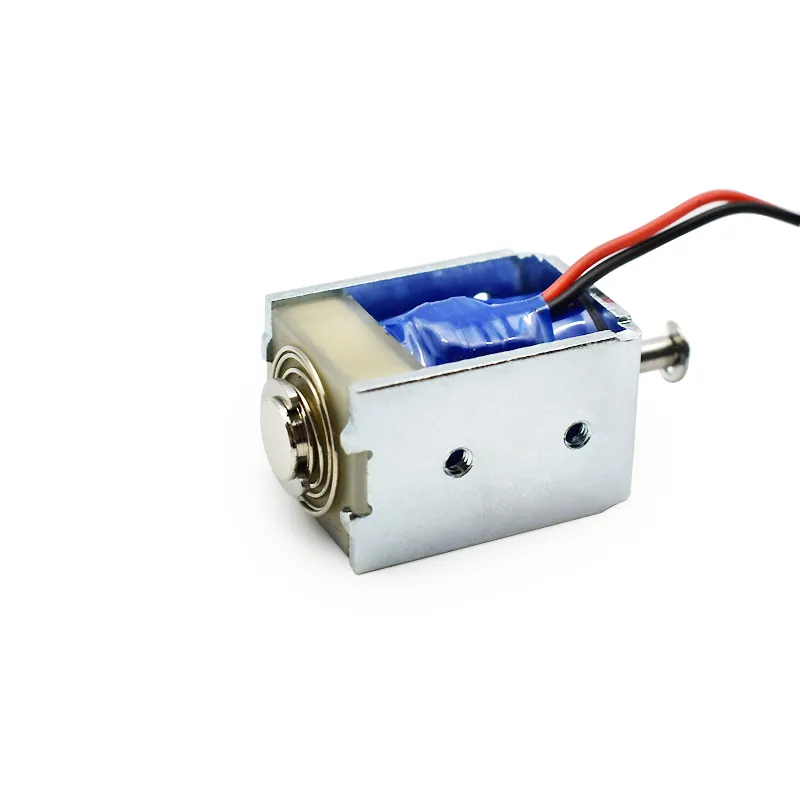

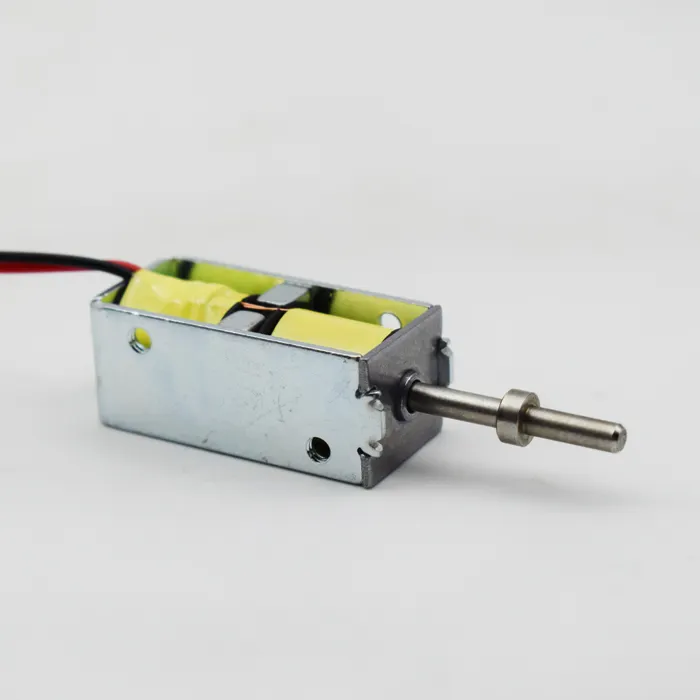

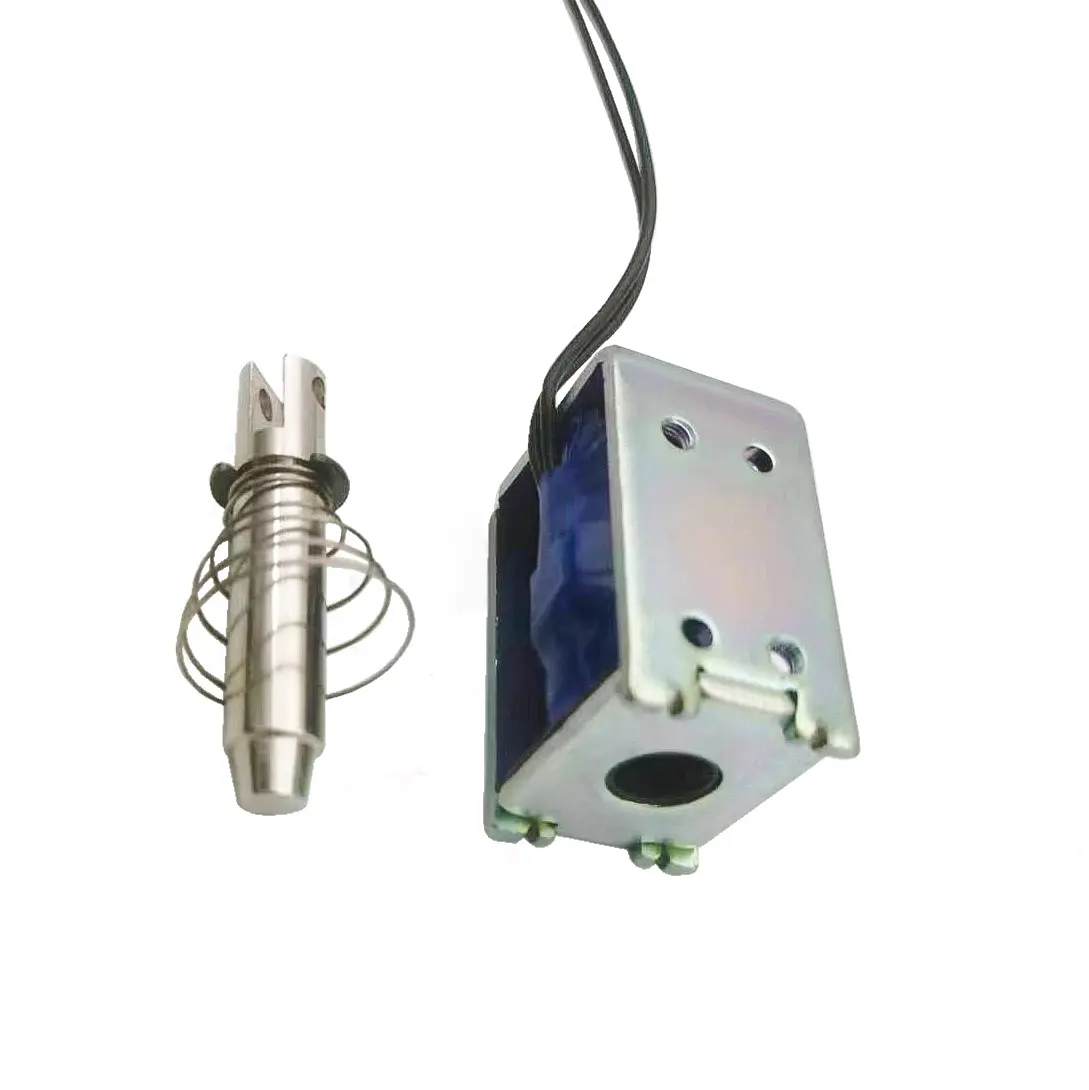

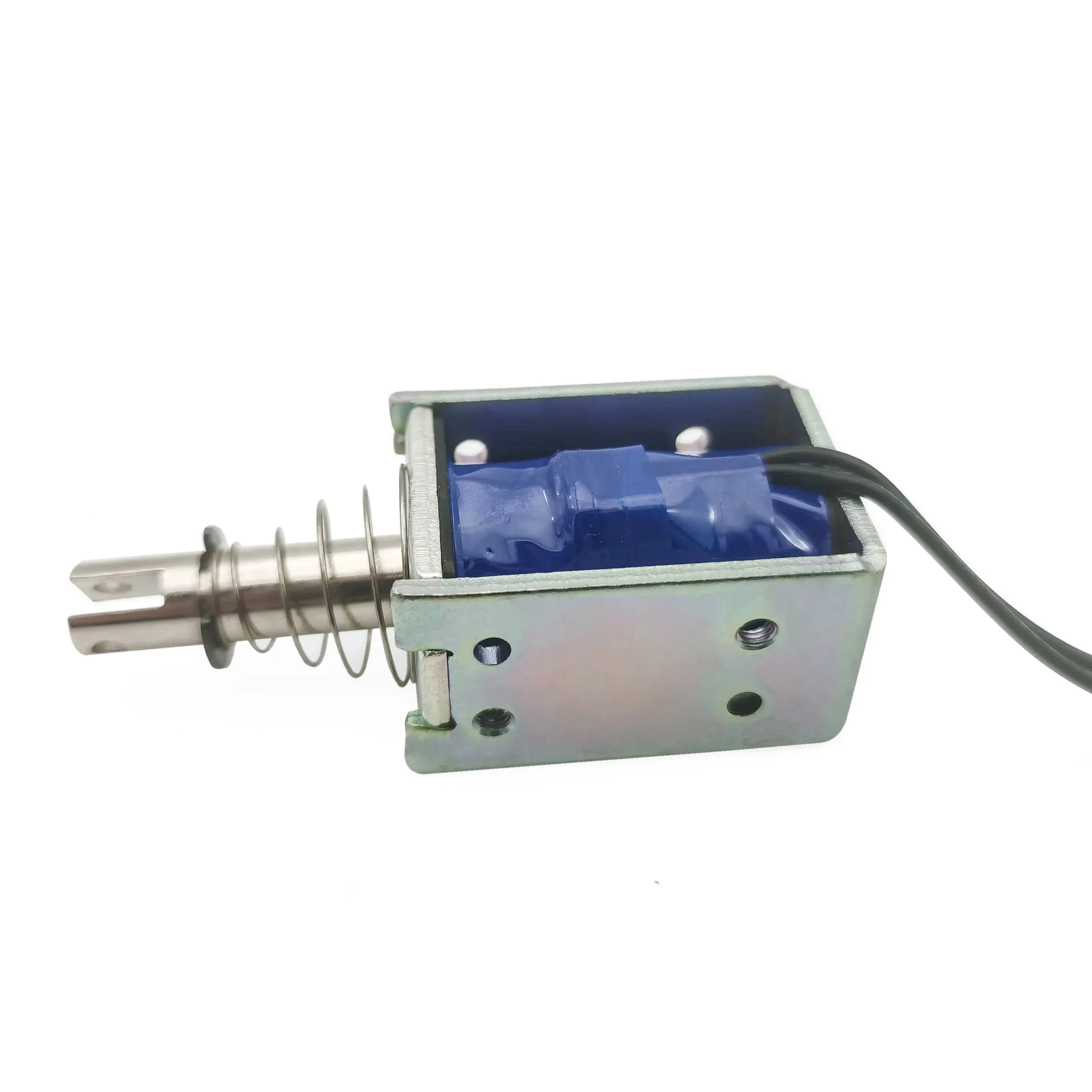

Home Appliances, Actuators, Relays: Smaller electromagnets used inside devices, solenoids, small actuators. Precision, low power consumption, long duty cycles. Factories must handle many small parts and consistent performance.

Medical Devices & Scientific Equipment: MRI, imaging, magnetic traps, sensors etc. Here margin for error is small, regulatory compliance often applies, materials must be high purity, magnetic fields uniform, and thermal/mechanical stability critical.

How to Evaluate an Electromagnet Factory Before Choosing

If you are searching for an electromagnet factory, here are questions & checks to do:

| Checklist Item | Why It Matters |

|---|---|

| Does the factory have detailed technical design capabilities? | Ensures the electromagnet will meet your required magnetic field, force, stroke, etc. |

| What materials do they use (core, wire, insulation)? | Better materials mean higher efficiency, less overheating, more durability. |

| Can they handle cooling/duty cycle requirements? | Continuous or high-frequency operation requires good thermal design. |

| What are their testing procedures? | Without good QC, delivered electromagnets may fail or degrade quickly. |

| Do they offer customization (shape, mounting, voltage, etc.)? | Your product may have unique constraints — size, form, voltage, environment. |

| What are their lead times, pricing, and volume capabilities? | Makes a difference for budget, schedule, scalability. |

| What is their track record? Client references, case studies, past performance. | Real proof is in prior delivery & long-term reliability. |

| Do they provide after-sales support and warranty? | Even good designs sometimes hit field challenges; support matters. |

When you go through these, SF scores very highly on almost every aspect.

Common Challenges in Electromagnet Production & How SF Handles Them

Any good electromagnet factory will face technical challenges. Here are some common ones — and how SF addresses them.

Heat Management / Temperature Rise

In high current or continuous duty situations, coil and core heating can cause insulation breakdown, performance drift.

SF uses proper wire gauge, coil design, cooling systems (air-flow, water cooling, or other), and thermal simulations during design. They test temperature rise under load to ensure performance.

Core Saturation & Magnetic Leakage

If core gets saturated, further increase in current yields little magnetic flux but high losses. Leakage flux and fringing areas degrade efficiency.

SF’s design engineers adjust core geometry, select high-permeability materials, optimize air gaps, simulate and measure to minimize leakage and fringing.

Insulation & Coil Reliability

Poor insulation leads to breakdown due to heat, vibration, or moisture. Turn-to-turn short circuits or insulation failure can ruin the electromagnet.

SF uses high-quality insulation rated for required voltages & temperatures, coatings, moisture protection, and does rigorous insulation resistance testing.

Duty Cycle vs Duty Type

On-off duty, intermittent duty, or continuous duty all place different stresses. Pulse-type electromagnets may need specialized design (thicker wires, cooling channels).

SF provides clarity about duty cycle early in the design, designs to match, and tests accordingly.

Dimensional / Mechanical Precision

If mounting holes are off, dimensions do not match, or there is misalignment, that can lead to installation issues or performance loss.

SF employs precision machining, uses fixtures, checks dimensions thoroughly before delivery.

Environmental & Regulatory Requirements

For outdoor use, or for medical use, or exposure to moisture, vibration, etc., or needing approvals (UL, CE, etc.).

SF can provide coatings, sealing, adhere to required standards, and help with documentation where needed.

Comparing Top Electromagnet Factories: SF vs. Other Options

It’s useful to see how SF stacks up against other common suppliers in the market. Below is a comparison of SF vs. generic suppliers:

| Aspect | Generic Electromagnet Factories | SF Electromagnet Factory |

|---|---|---|

| Experience | Some may have few years or limited to certain design types | 10+ years full experience across many application types |

| Customization | Standard models; limited shape/size options | High flexibility: custom voltage, shape, mounting, duty cycle |

| QC & Testing | Basic electrical tests, sometimes thermal, maybe limited mechanical or environmental testing | Comprehensive QC: electrical, insulation, thermal, mechanical, environmental |

| Material Quality | Might use standard cores, simple insulation, basic wires | Premium cores, good wire insulation, coatings, protection, advanced materials when required |

| Lead Time & Support | May have long lead times; less hands-on technical support | SF aims for clear lead time, prototype support, good customer communication |

| Cost | Could be lower for standard designs but higher risk of issues or shorter lifespan | Balanced pricing taking into account long life, reliability, lower total cost across life of product |

How SF’s Electromagnet Factory’s Products Are Built – From Concept to Delivery

To give you better insight, here is a typical workflow at SF, showing how SF ensures quality and performance from start to finish.

Requirement Gathering & Consultation

You (the customer) specify what you need: force, stroke, voltage, duty cycle, mounting style, space constraints, environmental conditions (temperature, moisture, shock), regulatory requirements, etc.Preliminary Design & Simulation

SF’s engineers draw up magnetic circuit design, core geometry, coil winding plan, insulation plan. Use simulation tools to predict magnetic field, heat buildup, mechanical stresses, etc.Material Selection

Based on design, SF chooses core material, wire type, insulation, coatings, finishing. High-permeability ferromagnetic materials, properly insulated wire, etc.Prototyping

A small sample or prototype is built to test the design in real conditions: verifying magnetic force, temperature rise, mechanical fit, dimensional accuracy.Testing & Iteration

Prototype undergoes thorough testing: electrical tests, load tests, endurance, environmental conditioning. If any issue is found (e.g., core heating too much, magnetic force less than expected), design is adjusted.Production & Quality Control

After prototype approved, full production begins. Each electromagnet is manufactured with strict process controls. QC at every stage: core machining, coil winding, insulation, assembly, finishing.Final Inspection & Packaging

Before shipping, SF performs final tests: dimensional inspection, visual, magnetic performance, insulation resistance, etc. Packaging is often customized to protect units during transit.After-Sales Support & Lifecycle

SF offers support: installation advice, troubleshooting, replacement / repair if needed. Also helpful in upgrades or when requirements change.

Tips for Customers to Get the Most from an Electromagnet Factory

If you’re planning to order electromagnets, here are some things that help ensure success:

Define your specifications well: Force needed, stroke or travel, voltage, current, duty cycle, environmental conditions, mounting constraints. The clearer you are at the start, the smoother everything else goes.

Ask for data sheets & performance curves: Force vs. displacement, temperature rise vs. duty cycle, etc.

Request prototypes: If your application is critical, test a prototype before ordering a full run.

Discuss safety, compliance, insulation, and thermal issues: Even small things like moisture or vibration can degrade performance fast if not accounted for.

Consider lifecycle cost: A cheaper electromagnet factory might give you a lower initial cost but higher maintenance, higher failure rate, or shorter lifespan.

Maintain communication: Good back-and-forth between you and the electromagnet factory ensures miscommunications are avoided, and changes can be handled early.

Why the Electromagnet Factory SF is Highly Recommended

Now summarizing why SF should be your go-to electromagnet factory.

Specialization and Depth: SF is focused on electromagnets—it’s not just a sideline product. That gives deeper expertise.

Reliability and Quality: Over 10 years of refining production, testing, and materials. SF’s electromagnets have proven long life in field applications.

Flexibility & Customization: Whether you need a large power electromagnet, continuous-duty, or a small actuator for limited space, SF can tailor the design.

Cost-Effectiveness: While SF aims at premium quality, it also has optimized processes to keep costs reasonable. You pay once for a good product rather than repeatedly for failures.

Customer-Centric Service: From initial inquiries to after-sales, SF supports clients with technical guidance, testing, and long-term support.

Real-Life Example: How SF Solved a Difficult Electromagnet Requirement

Here’s a (hypothetical / illustrative) case study to show what a top electromagnet factory does in practice.

Challenge: A customer in industrial automation needed an electromagnet to be used in a harsh environment (dust, high ambient temperature of 70 °C), continuous duty (24/7), strong holding force of 500 N, compact size, and minimal heat rise. Voltage available was 24 V DC.

SF’s Solution:

Designed a core with high-permeability lamination to reduce eddy losses.

Used high-gauge copper wire with a hollow cooling channel integrated into the coil winding.

Added insulation rated for high temperature, and coatings to protect against dust ingress.

Simulated the design (FEM) to predict thermal behavior and magnetic field under full load.

Built prototype, tested under ambient heat, measured temperature rise (e.g., after 24 h continuous use), verified holding force.

Adjusted coil turns / insulation to reduce heat as needed.

When delivered, SF also provided installation instructions and specifications to ensure correct mounting and cooling.

Outcome: Electromagnet met the customer’s requirements, operated reliably even in harsh conditions, with minimal maintenance. Because design accounted for all key failure modes, lifespan exceeded expectations.

Buying Guide: What Questions to Ask When Evaluating Electromagnet Factory SF (or Others)

Here are pointed questions you can ask when evaluating SF or any electromagnet factory. If satisfied, you’re likely to get a good product.

What is your experience with electromagnets in my application or similar applications?

Can you show me samples or case studies?

What core materials and wire insulation do you use, and what thermal rating do you claim?

What simulations or modeling do you perform (magnetic, thermal, mechanical)?

What cooling options are available? (Air, water, forced convection etc.)

What tests do you run on prototypes and final units? What are your acceptance criteria?

What is your lead time for prototypes and mass production?

What warranty or support do you provide?

How do you package and ship to avoid damage?

Choosing the right electromagnet factory is therefore essential

An electromagnet can make or break your system’s performance. Choosing the right electromagnet factory is therefore essential. You want technical design, materials, quality control, thermal and mechanical reliability — all combined with good support and reasonable cost.

From what I’ve seen, SF ticks all these boxes: more than 10 years of specialization, strong design, high-quality materials, rigorous testing, flexibility in customization, and reliable delivery. Whether you need a standard electromagnet or a highly specialized one, SF is a top electromagnet factory you should strongly consider.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680