Last Updated on 2025-09-03 by SolenoidFactory

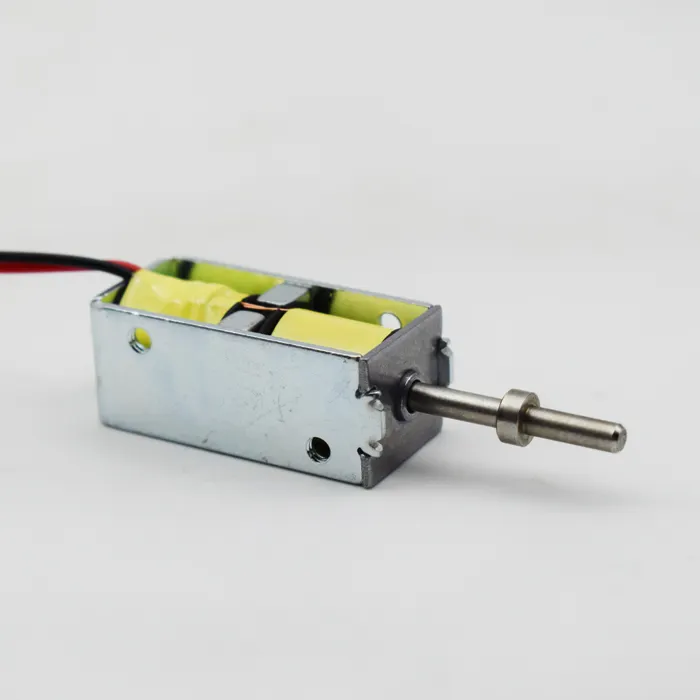

In the vast landscape of electromagnetic devices, latching solenoid occupy a niche position due to their ability to maintain a stable state without continuous power input. This unique feature makes them ideal for applications requiring reliable positioning and minimal energy consumption. This blog aims to explore the composition structure of latching solenoids, shedding light on their intricate mechanics and the benefits they offer.

Understanding the Latching Solenoid Composition

A latching solenoid is a sophisticated electromagnetic device comprising several key components that collectively contribute to its latching mechanism. These components include:

Electromagnetic Coil: This is the heart of the latching solenoid. When energized, the coil generates a magnetic field that interacts with the ferromagnetic components within the solenoid.

Core and Armature Assembly: Made of ferromagnetic material, the core and armature form the mechanical backbone of the latching solenoid. Their interaction with the magnetic field drives the latching action.

Spring Mechanism: A spring, typically placed around the armature, provides the restoring force necessary to switch the latching solenoid between its two stable states. This spring ensures smooth and reliable transitions.

Latching Mechanism: This is a unique feature of latching solenoids. It consists of a mechanical or magnetic latch that holds the armature in place once it has moved to one of its stable positions, allowing the coil to be de-energized without losing the armature’s position.

Housing and Seals: The housing encapsulates all internal components, protecting them from environmental factors and ensuring long-term durability. Seals prevent fluid or gas leakage, making latching solenoids suitable for harsh environments.

Latching Solenoid Structure: How It Works

The operational mechanics of a latching solenoid are intricate and rely on the interplay between the electromagnetic coil, core, armature, spring, and latching mechanism. Here’s a closer look at how it all works:

Initial State: In its unpowered state, the latching solenoid rests in one of its two stable positions. The spring and latching mechanism work together to keep the armature in this position.

Energization and Switching: When an electric current of sufficient magnitude and polarity flows through the coil, it generates a magnetic field that interacts with the core and armature, causing them to move. This movement engages the latching mechanism, holding the armature in its new stable position.

De-Energization and Maintenance: Once the coil is de-energized, the magnetic field collapses. However, the latching mechanism holds the armature in place, maintaining the solenoid in its new stable state without requiring continuous power input.

Switching Back: To switch the latching solenoid back to its original stable state, an opposite polarity current must be applied to overcome the latching mechanism and move the armature back. This process engages the spring, which aids in the smooth transition to the original position.

Benefits of Latching Solenoid

The unique composition structure of latching solenoids offers several benefits, making them ideal for various applications:

- Energy Efficiency: The ability to maintain a stable state without continuous power input significantly reduces energy consumption.

- Reliability: The robust design and minimal moving parts contribute to their reliability and durability, even in harsh environments.

- Compact Design: The compact footprint allows for integration into space-constrained systems.

- Bi-Stability: The latching mechanism enables the solenoid to maintain two stable states, providing versatile positioning options.

Applications of Latching Solenoid

Latching solenoids find applications across numerous industries:

- Automotive: In transmission systems, seat adjusters, and other positioning mechanisms requiring reliable and energy-efficient operation.

- Industrial Automation: In robotic arms, conveyors, and other automation systems needing precise positioning and minimal power consumption.

- Medical Devices: In infusion pumps, dialysis machines, and other medical equipment requiring reliable and low-power actuation mechanisms.

- Consumer Electronics: In smartphones, tablets, and other devices needing stable, low-power positioning mechanisms for user interface components.

The composition structure of latching solenoid

The composition structure of latching solenoids, with its intricate interplay of electromagnetic coil, core, armature, spring, and latching mechanism, underscores their unique ability to maintain stable states without continuous power input. By understanding how these components work together, we can appreciate the benefits that latching solenoids bring to industries requiring reliable positioning and minimal energy consumption. As technology advances, latching solenoids will continue to evolve, driving innovation and enhancing system performance across diverse applications.

Because space is limited, this article will discuss the above.Please refer to the following article for more information:

1:Whats Are Latching Solenoids-Electromagnet Technology

2:Solenoid (engineering) from Wikipedia

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.