Last Updated on 2025-09-04 by SolenoidFactory

In the high-stakes world of medical technology, where precision and reliability can mean the difference between life and death, electromagnets have emerged as indispensable components in life-support systems. Ventilators and infusion pumps, two cornerstones of modern critical care, rely heavily on electromagnetic valve technology to deliver oxygen and medications with exacting accuracy. As a professional electromagnet manufacturer, we explore how these devices work, their life-saving applications, and the innovations driving their evolution in healthcare.

1. The Science of Electromagnetic Valve Control

1.1 How Electromagnetic Valves Operate

Electromagnetic valves use a solenoid—a coil of wire wound around a ferromagnetic core—to convert electrical energy into mechanical motion. When energized, the coil generates a magnetic field that moves a plunger or diaphragm, opening or closing the valve to regulate fluid or gas flow. Key advantages include:

- Rapid response times (millisecond-level actuation).

- Precise flow control (adjustable via current modulation).

- Fail-safe operation (spring-assisted closure during power loss).

1.2 Key Components in Medical Valves

- Solenoid Coil: Designed for low power consumption and heat generation.

- Plunger/Seal Assembly: Medical-grade materials (e.g., PTFE, silicone) ensure biocompatibility and chemical resistance.

- Spring Mechanism: Ensures valve closure in emergencies.

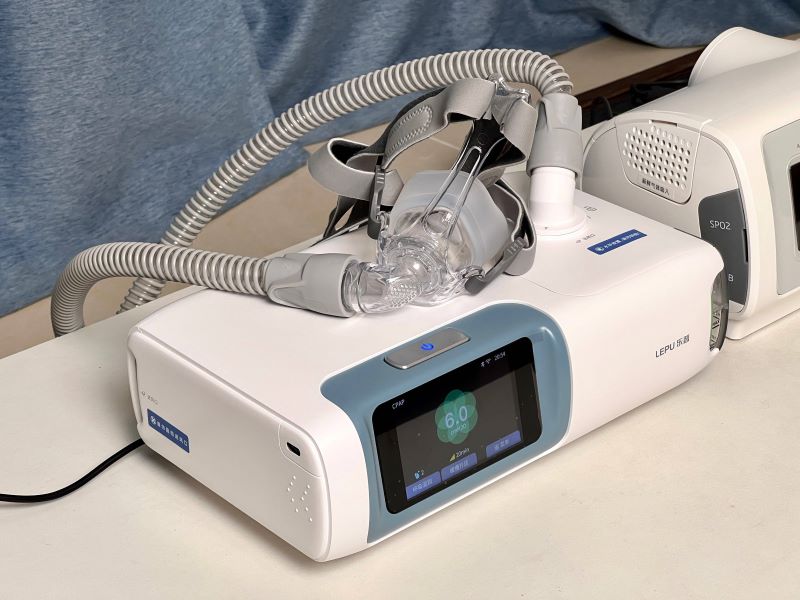

2. Electromagnets in Ventilator Valves: Breathing Life into Critical Care

2.1 Role in Ventilator Systems

Ventilators use electromagnetic valves to control the flow of oxygen and air mixtures into a patient’s lungs. These valves must operate with split-second precision to synchronize with breathing cycles, adjust tidal volumes, and maintain positive end-expiratory pressure (PEEP).

Key Applications:

- Inspiratory/Expiratory Valve Control: Electromagnets switch between inhalation (valve open) and exhalation (valve closed) phases.

- Pressure Regulation: Proportional valves adjust gas flow to maintain airway pressure within safe limits.

- Emergency Shut-Off: Instant valve closure prevents barotrauma during system faults.

2.2 Case Study: Rapid Ventilator Production During COVID-19

During the COVID-19 pandemic, a medical device manufacturer faced surging demand for ventilators. By integrating latching solenoid valves—which require power only during state changes—they reduced energy consumption by 40% and accelerated production. The valves’ fail-safe design also ensured compliance with FDA emergency use guidelines, enabling the company to deliver 10,000 ventilators to overwhelmed hospitals within three months.

2.3 Technical Challenges and Solutions

- Challenge: Condensation in oxygen lines causes valve sticking.

Solution: Hydrophobic coatings on valve seals and heated solenoid assemblies. - Challenge: Continuous operation leads to coil overheating.

Solution: High-efficiency coils with Class H insulation (withstand 180°C).

3. Electromagnets in Infusion Pump Valves: Precision Drug Delivery

3.1 Role in Infusion Systems

Infusion pumps use electromagnetic valves to regulate the flow of medications, nutrients, or fluids. These valves ensure microliter-level accuracy, critical for administering potent drugs like insulin, chemotherapy agents, or vasopressors.

Key Applications:

- Dosing Control: Proportional solenoids adjust flow rates dynamically based on patient vitals.

- Anti-Free-Flow Mechanisms: Valves prevent gravity-driven overdosing during setup or power outages.

- Multi-Channel Delivery: Compact solenoid arrays manage concurrent infusions (e.g., IV fluids + antibiotics).

3.2 Case Study: Neonatal ICU Infusion System

A hospital neonatal ICU sought to minimize dosing errors in premature infants. By adopting infusion pumps with piezoelectric-assisted solenoid valves, they achieved a 99.9% dosing accuracy rate. The hybrid design combined the precision of piezoelectric actuators (for micro-adjustments) with the force of electromagnets (for rapid shut-off), reducing hypoglycemia incidents by 60%.

3.3 Technical Challenges and Solutions

- Challenge: Drug crystallization clogs valve seats.

Solution: Ultrasonic cleaning cycles and diamond-like carbon (DLC) coatings on seal surfaces. - Challenge: EMI from nearby devices disrupts valve timing.

Solution: Shielded solenoid coils and twisted-pair wiring to reduce noise.

4. Innovations in Electromagnetic Valve Technology

4.1 Smart Valves with IoT Integration

Modern valves embed sensors to monitor parameters like flow rate, pressure, and coil temperature. Data is transmitted to hospital networks for predictive maintenance.

Example: A smart ventilator valve detects a 5% drop in flow efficiency, triggering an alert for seal replacement before a failure occurs.

4.2 Energy-Efficient Designs

- Latching Solenoids: Consume power only during state changes, ideal for battery-powered infusion pumps.

- Energy Recovery Circuits: Capture and reuse inductive energy from coil deactivation.

4.3 Miniaturization for Portable Devices

Micro-solenoids (e.g., 3mm diameter) enable wearable infusion pumps for diabetes management or ambulatory chemotherapy.

4.4 3D-Printed Valves

Additive manufacturing creates valves with complex internal geometries, optimizing fluid dynamics and reducing part counts.

5. Technical Challenges in Medical Electromagnetic Valves

5.1 Biocompatibility and Sterilization

Challenge: Repeated autoclaving degrades coil insulation.

Solution: Medical-grade epoxy resins and stainless steel housings withstand 1,000+ sterilization cycles.

5.2 Long-Term Reliability

Challenge: 24/7 operation in ICUs demands valves with 10+ year lifespans.

Solution: Redundant coil designs and self-lubricating plunger materials (e.g., PTFE-impregnated stainless steel).

5.3 Regulatory Compliance

Challenge: Meeting FDA, ISO 13485, and IEC 60601 standards.

Solution: Rigorous testing protocols, including:

- EMC Testing: Ensure EMI/EMC compliance in dense hospital environments.

- Cyclic Endurance: 1 million+ actuation cycles without performance drift.

6. electromagnets Case Studies: Real-World Impact

6.1 Case Study 1: Emergency Ventilator for Rural Clinics

A humanitarian organization deployed portable ventilators with battery-operated solenoid valves in Sub-Saharan Africa. The valves’ low power draw (2W) enabled 72-hour operation on solar-charged batteries, saving lives in off-grid regions.

6.2 Case Study 2: Chemotherapy Infusion Breakthrough

A cancer center reduced medication waste by 30% using infusion pumps with adaptive solenoid valves. The valves adjusted flow rates in real time based on patient biometrics, minimizing side effects.

7. Future Trends in Medical Electromagnetic Valves

7.1 AI-Driven Adaptive Control

Machine learning algorithms analyze patient data to optimize valve timing and dosing, enabling personalized therapies.

7.2 Magnetic Nanoparticle Valves

Experimental systems use magnetic nanoparticles as “smart fluids,” guided by electromagnets for targeted drug delivery.

7.3 Sustainable Manufacturing

Recyclable coils and biodegradable seals align with the healthcare sector’s push toward net-zero emissions.

Electromagnets—The Pulse of Modern Medical Innovation

Electromagnetic valves are the unsung heroes of ventilators and infusion pumps, combining precision engineering with life-saving reliability. From pandemic-ready ventilators to smart infusion systems, their role in healthcare is both transformative and expanding.

For medical device manufacturers, partnering with an experienced electromagnet provider is critical to navigating technical challenges, regulatory landscapes, and the demand for miniaturized, energy-efficient solutions. As technology advances, electromagnetic valves will continue to push the boundaries of what’s possible—ensuring that every breath and every drop of medication counts.

In the delicate balance of critical care, electromagnets prove that even the smallest controlled force can have an outsized impact on human life.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact WhatsApp +86 18902611680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.