Last Updated on 2025-09-04 by SolenoidFactory

The automotive industry has undergone a paradigm shift over the past few decades, driven by stringent emission regulations, demand for fuel efficiency, and the pursuit of superior engine performance. At the core of this transformation lies the fuel injection system—a critical component responsible for delivering the precise amount of fuel into an engine’s combustion chamber. While mechanical and hydraulic systems dominated early designs, electromagnets have become indispensable in modern fuel injection technologies. Their ability to enable ultra-precise, rapid, and adaptive control has revolutionized engine performance, emissions, and reliability.

As a leading electromagnet manufacturer, we explore the pivotal role of electromagnets in fuel injection systems, their technical underpinnings, and how they are shaping the future of automotive engineering.

1. electromagnet and Electromagnetic Fuel Injection

1.1 How Electromagnets Power Fuel Injectors

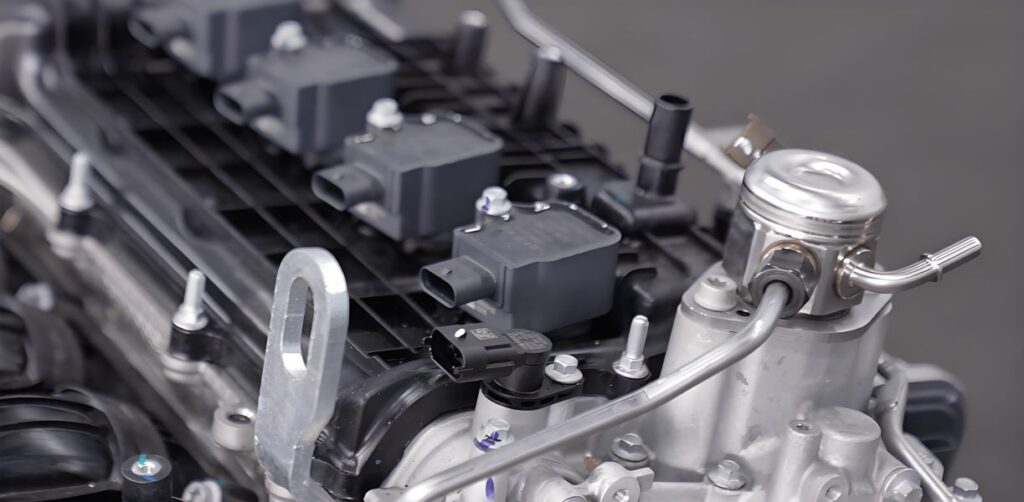

Electromagnets are the driving force behind electronically controlled fuel injectors. When an electric current flows through a coil wrapped around a ferromagnetic core, it generates a magnetic field. This field pulls a plunger or armature, which opens the injector nozzle to spray fuel into the combustion chamber. De-energizing the coil collapses the magnetic field, allowing a spring or hydraulic pressure to close the nozzle. This process occurs in milliseconds, enabling precise control over fuel delivery timing, duration, and quantity.

1.2 Key Components of an Electromagnetic Fuel Injector

- Coil: The electromagnet’s core, typically made of copper wire, generates the magnetic force.

- Armature/Plunger: Moves under magnetic force to open the injector.

- Nozzle: Atomizes fuel into a fine spray for efficient combustion.

- Spring: Returns the plunger to its closed position when de-energized.

- Control Unit: Sends electrical pulses to the coil to regulate injection timing and duration.

1.3 Types of Electromagnetic Fuel Injection Systems

- Gasoline Direct Injection (GDI): High-pressure injectors spray fuel directly into the combustion chamber.

- Common Rail Diesel Injection: Uses electromagnets to control high-pressure fuel delivery in diesel engines.

- Port Fuel Injection (PFI): Injects fuel into the intake port, controlled by electromagnetic valves.

2. Advantages of Electromagnetic Fuel Injection

2.1 Unmatched Precision in Fuel Delivery

Electromagnetic injectors can adjust fuel delivery in real time, with injection durations as short as 1 millisecond. This precision ensures optimal air-fuel ratios under varying engine loads, improving combustion efficiency and reducing emissions.

2.2 Faster Response Times

Electromagnets activate and deactivate in milliseconds, enabling multiple injection events per combustion cycle (e.g., pilot, main, and post injections in diesel engines). This reduces noise, improves cold starts, and minimizes unburned hydrocarbons.

2.3 Adaptability to Engine Conditions

Modern engine control units (ECUs) use data from sensors (e.g., oxygen, throttle position, crankshaft speed) to dynamically adjust injector timing. Electromagnets enable this flexibility, ensuring optimal performance across RPM ranges, temperatures, and driving conditions.

2.4 Reduced Emissions and Improved Fuel Economy

Precise fuel metering minimizes over-fueling, a key contributor to CO2 and particulate emissions. For example, GDI systems reduce fuel consumption by up to 15% compared to traditional carburetors.

2.5 Durability in Harsh Environments

Electromagnetic injectors withstand extreme temperatures, vibrations, and fuel pressures (up to 3,000 bar in diesel systems). Advanced materials like stainless steel, nickel alloys, and high-temperature resins ensure long-term reliability.

3. electromagnets Applications in Modern Engines

3.1 Gasoline Direct Injection (GDI)

GDI systems use electromagnets to deliver fuel directly into the combustion chamber at high pressures. This technology enhances power output, reduces knock propensity, and improves thermal efficiency.

Case Study: A leading automotive brand achieved a 10% increase in torque and a 7% reduction in fuel consumption by adopting electromagnetic GDI injectors in its turbocharged engines.

3.2 Common Rail Diesel Injection

In diesel engines, common rail systems rely on electromagnets to control injectors fed by a high-pressure fuel reservoir. This allows for multiple injections per cycle, reducing NOx and particulate emissions while enhancing power delivery.

Example: Heavy-duty trucks using electromagnetic common rail systems meet Euro 6 and EPA Tier 4 emission standards without compromising performance.

3.3 Hybrid and Plug-in Hybrid Vehicles

Electromagnetic injectors play a dual role in hybrid engines: optimizing combustion during ICE operation and enabling seamless transitions between electric and combustion modes.

3.4 High-Performance and Racing Engines

In motorsports, electromagnetic injectors provide the rapid response and precise control needed for engines operating at 10,000+ RPM. Tuners adjust injection maps to maximize power output under race conditions.

4. Technical Challenges and Solutions of electromagnets

4.1 High-Pressure Tolerance

Challenge: Diesel common rail systems operate at pressures exceeding 2,500 bar, risking injector wear or leakage.

Solution: Use hardened materials (e.g., tungsten carbide nozzles) and precision machining to maintain seal integrity.

4.2 Temperature Extremes

Challenge: Prolonged exposure to combustion heat degrades coil insulation and magnetic properties.

Solution: High-temperature epoxy coatings and advanced cooling designs (e.g., fuel-cooled injectors) protect critical components.

4.3 Wear and Clogging

Challenge: Fuel contaminants or deposits can clog injector nozzles, disrupting spray patterns.

Solution: Incorporate self-cleaning cycles, ultra-fine fuel filters, and detergent additives in fuels.

4.4 Electromagnetic Interference (EMI)

Challenge: High-frequency operation generates EMI, disrupting onboard electronics.

Solution: Shield coils with ferrite cores and optimize ECU grounding and shielding.

5. electromagnets Innovations Driving the Future

5.1 Piezoelectric vs. Electromagnetic Injectors

While piezoelectric injectors offer faster response times, electromagnets remain dominant due to their cost-effectiveness and durability. Hybrid designs combine piezoelectric crystals with electromagnetic actuators for enhanced performance.

5.2 AI-Optimized Injection Strategies

Machine learning algorithms analyze real-time engine data to predict optimal injection timings, adapting to driving styles, fuel quality, and environmental conditions.

Example: An AI-driven ECU reduces fuel consumption by 5% in urban driving by optimizing injection pulses during stop-and-go traffic.

5.3 Hydrogen Fuel Injection

As the automotive industry shifts toward hydrogen combustion engines, electromagnets are being adapted to handle hydrogen’s low viscosity and high diffusivity. Specialized injectors prevent leakage and ensure precise metering of hydrogen fuel.

5.4 Additive Manufacturing

3D-printed injectors with complex internal geometries improve fuel atomization and reduce weight. Electromagnetic coils are integrated into these designs using conductive printing materials.

5.5 Smart Diagnostics and Predictive Maintenance

Embedded sensors monitor injector health, detecting issues like coil degradation or nozzle clogging. Data is relayed to drivers or service centers for proactive maintenance.

6. Choosing the Right Electromagnetic Fuel Injector

6.1 Key Selection Criteria

- Fuel Type: Gasoline, diesel, hydrogen, or alternative fuels.

- Pressure Rating: Match injector capability to engine requirements.

- Response Time: Critical for high-RPM or hybrid applications.

- Environmental Compliance: Ensure adherence to emission standards (e.g., Euro 7, CARB).

6.2 Customization for Engine Demands

As a manufacturer, we offer tailored solutions, including:

- High-Frequency Injectors: For racing or hybrid engines requiring ultra-fast cycling.

- Low-Heat Designs: For turbocharged engines with elevated under-hood temperatures.

- Corrosion-Resistant Coatings: For compatibility with ethanol-blended or hydrogen fuels.

Electromagnets—Powering the Future of Fuel Injection

Electromagnetic fuel injection systems represent the pinnacle of precision engineering, enabling automakers to meet the dual challenges of emission reduction and performance enhancement. From daily commuters to high-octane racing engines, electromagnets ensure that every drop of fuel is utilized efficiently, cleanly, and powerfully.

As the automotive industry pivots toward electrification and alternative fuels, electromagnets will continue to play a vital role in hybrid systems and hydrogen combustion engines. For manufacturers seeking to innovate, partnering with an experienced electromagnet provider is key to unlocking next-generation fuel injection technologies.

By embracing advancements in materials, AI, and additive manufacturing, the future of electromagnetic fuel injection promises even greater efficiency, sustainability, and adaptability—driving us toward a cleaner, high-performance automotive era.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact us +86 189 0261 1680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.