Last Updated on 2025-09-04 by SolenoidFactory

The automotive industry is undergoing a technological renaissance, driven by the demand for smarter, safer, and more efficient vehicles. Among the unsung heroes of this transformation are electromagnets—devices that convert electrical energy into mechanical force with unmatched precision. In automatic transmissions and braking systems, electromagnets play a pivotal role in enabling seamless gear shifts, adaptive torque distribution, and fail-safe braking performance.

As a professional electromagnet manufacturer, we delve into the science, applications, and innovations of electromagnets in these critical automotive systems. This blog explores how electromagnetic technology is redefining vehicle dynamics, safety, and sustainability.

1. electromagnets and Electromagnetic Control in Automotive Systems

1.1 How Electromagnets Work

Electromagnets generate a magnetic field when an electric current flows through a coil of wire. This field attracts or repels ferromagnetic components, such as iron or steel, creating mechanical motion. By modulating the current, engineers can precisely control the timing, force, and duration of this motion—a capability that is indispensable in modern automotive systems.

1.2 Key Components in Automotive Applications

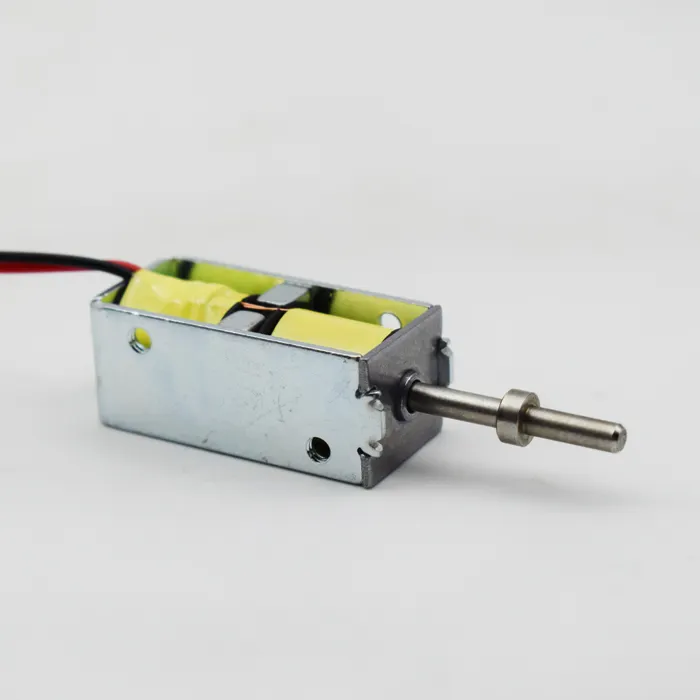

- Solenoids: Compact electromagnetic actuators used to control hydraulic valves, clutches, or brakes.

- Coils and Cores: Designed to withstand high temperatures, vibrations, and electromagnetic interference (EMI).

- Control Units: Integrated with sensors and algorithms to optimize electromagnetic responses in real time.

2. Electromagnets in Automatic Transmissions

2.1 The Evolution of Automatic Transmissions

Traditional automatic transmissions relied on hydraulic pressure and mechanical linkages for gear shifts. Modern systems, however, leverage electromagnetic solenoids to enable faster, smoother, and more efficient gear changes.

2.2 Role of Electromagnets in Transmission Control

- Shift Solenoids: Electromagnetic valves regulate hydraulic pressure to engage or disengage clutches and bands, facilitating gear shifts.

- Torque Converter Lockup Clutches: Electromagnets lock the torque converter to improve fuel efficiency at cruising speeds.

- Adaptive Control: Sensors monitor driving conditions (e.g., throttle position, vehicle speed) and adjust solenoid operation for optimal performance.

Case Study: A leading automaker reduced shift times by 30% and improved fuel economy by 8% by integrating high-response electromagnetic solenoids in its 10-speed automatic transmission.

2.3 Dual-Clutch Transmissions (DCTs)

In DCTs, electromagnets pre-select gears using two independent clutches. This eliminates torque interruption during shifts, delivering a sportier driving experience. Electromagnetic actuators ensure millisecond-level precision in clutch engagement.

2.4 Continuously Variable Transmissions (CVTs)

Electromagnetic systems adjust pulley widths in real time, optimizing the transmission ratio for engine efficiency. This technology is particularly effective in hybrid vehicles, where seamless power delivery is critical.

3. Electromagnets in Braking Systems

3.1 From Hydraulic to Electromechanical Braking

Traditional braking systems rely on hydraulic pressure generated by the driver’s pedal force. Modern systems, however, incorporate electromagnetic actuators to enhance safety, responsiveness, and energy recovery.

3.2 Electromagnetic Braking Technologies

- Anti-lock Braking Systems (ABS): Electromagnetic valves modulate brake pressure to prevent wheel lockup during emergency stops. By rapidly pulsating the brakes, ABS maintains traction and steering control.

- Electronic Stability Control (ESC): Electromagnets adjust braking force to individual wheels, counteracting skids or loss of control.

- Electric Parking Brakes (EPB): Replacing manual handbrakes, electromagnetic actuators engage and disengage rear brakes with a button press.

Case Study: A luxury car brand achieved a 20% reduction in stopping distance by using electromagnetic brake-by-wire technology, which eliminates hydraulic lag.

3.3 Regenerative Braking in Electric Vehicles (EVs)

In EVs, electromagnets are integral to regenerative braking systems. When the driver decelerates, the electric motor acts as a generator, converting kinetic energy into electrical energy. Electromagnetic controls manage the transition between regenerative and friction braking, maximizing energy recovery without compromising safety.

3.4 Fail-Safe Braking Systems

Electromagnetic systems include redundancy features, such as backup power supplies and self-diagnostic algorithms, to ensure braking functionality even during electrical failures.

4. Technical Challenges and Solutions of electromagnets

4.1 High-Temperature Environments

Challenge: Prolonged exposure to engine heat degrades coil insulation and magnetic performance.

Solution: High-temperature-resistant materials (e.g., Class H insulation, ceramic coatings) and active cooling systems.

4.2 Vibration and Mechanical Stress

Challenge: Automotive vibrations can loosen components or cause coil fatigue.

Solution: Ruggedized designs with shock-absorbing mounts and reinforced solder joints.

4.3 Electromagnetic Interference (EMI)

Challenge: EMI from motors or high-voltage systems disrupts solenoid operation.

Solution: Shielded cables, ferrite cores, and optimized grounding schemes.

4.4 Energy Efficiency

Challenge: Continuous power draw in solenoids increases battery load.

Solution: Latching electromagnets that maintain position without power and energy-recovery circuits.

5. Innovations Driving electromagnets

5.1 Integrated Electromechanical Systems

Next-generation vehicles are moving toward fully electrified powertrains, where electromagnetic actuators control transmissions, brakes, and steering. This integration reduces weight, simplifies wiring, and enhances responsiveness.

5.2 AI-Optimized Control Algorithms

Machine learning algorithms analyze driving patterns, road conditions, and vehicle diagnostics to optimize electromagnetic responses. For example, AI can predict gear shifts in automatic transmissions or pre-load braking pressure in anticipation of a stop.

5.3 Smart Materials and Miniaturization

- Shape-Memory Alloys (SMAs): Combined with electromagnets, SMAs enable self-adjusting components that adapt to wear or temperature changes.

- Micro-Electromechanical Systems (MEMS): Miniaturized electromagnetic actuators for compact, high-precision braking modules.

5.4 Sustainability in Manufacturing

Recyclable materials and energy-efficient production processes reduce the environmental footprint of electromagnetic components. For instance, copper coils are being replaced with aluminum in some applications to lower costs and weight.

6. Selecting the Right Electromagnetic Solutions

6.1 Key Considerations for Automotive Applications

- Durability: Resistance to heat, vibration, and corrosion.

- Response Time: Critical for ABS and transmission shift solenoids.

- Power Efficiency: Minimize energy draw to preserve battery life in EVs.

- Certifications: Compliance with automotive standards like ISO/TS 16949 and AEC-Q200.

6.2 Customization for OEM Needs

As a manufacturer, we offer tailored electromagnetic solutions, including:

- High-Speed Solenoids: For dual-clutch transmissions and performance vehicles.

- Waterproof Actuators: For off-road and electric parking brake systems.

- Low-EMI Designs: For hybrid and electric vehicles with sensitive electronics.

Electromagnets—The Driving Force of Automotive Innovation

Electromagnets have become the backbone of modern automatic transmissions and braking systems, enabling unprecedented levels of precision, safety, and efficiency. From the millisecond gear shifts in high-performance cars to the life-saving responsiveness of ABS, electromagnetic technology is at the heart of automotive advancement.

As the industry transitions toward electrification and autonomous driving, the role of electromagnets will only expand. Innovations in AI, materials science, and energy efficiency will further enhance their capabilities, making vehicles smarter, greener, and safer.

For automotive manufacturers and suppliers, partnering with an experienced electromagnet manufacturer is essential to staying ahead in this competitive landscape. By leveraging cutting-edge electromagnetic solutions, the automotive industry can continue to push the boundaries of what’s possible—one precise, reliable actuation at a time.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact Shany +86 18902611680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.