Last Updated on 2026-01-30 by SolenoidFactory

Introduction to Small Push Pull Solenoid Technology

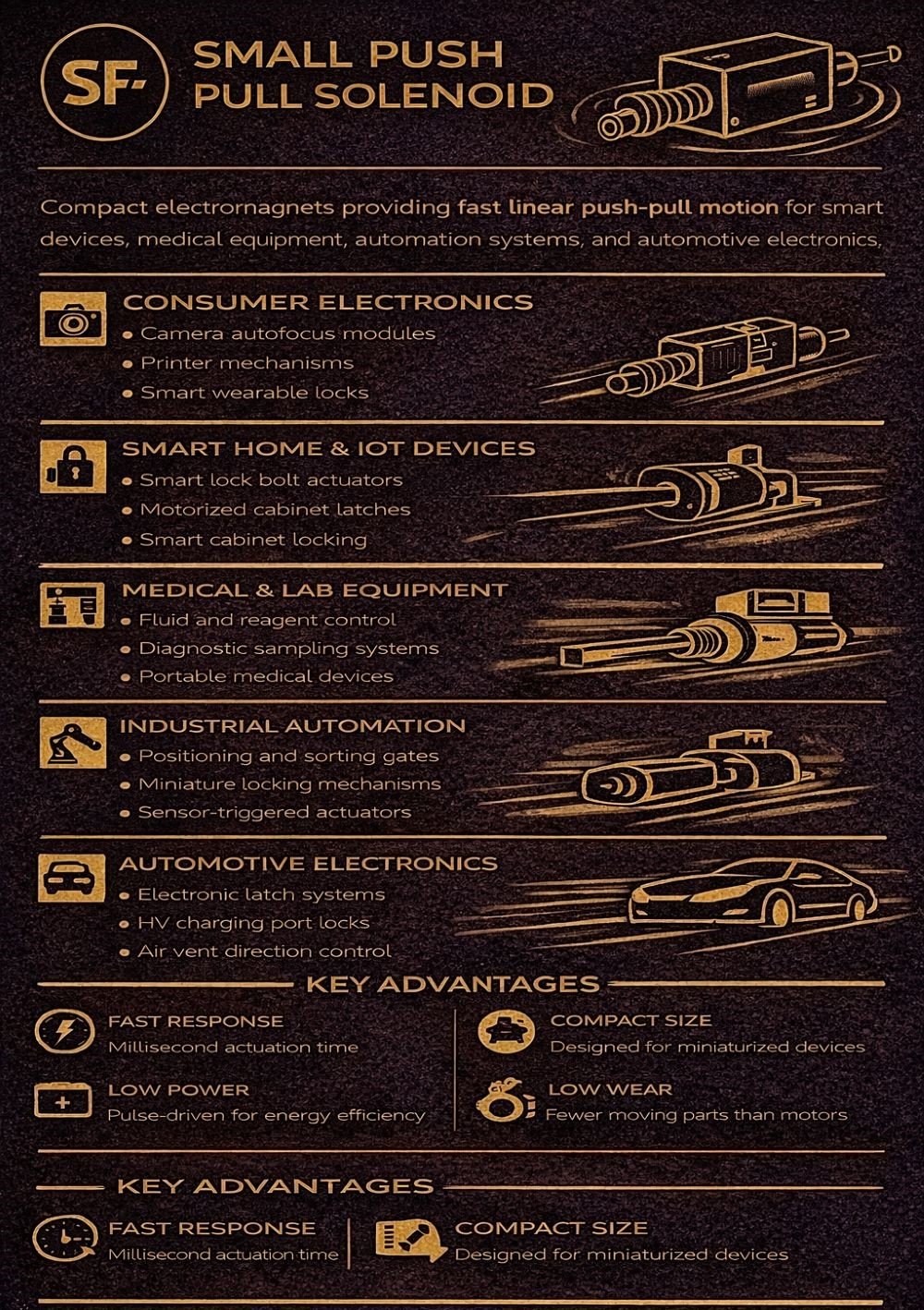

A small push pull solenoid is a compact electromagnetic actuator designed to create short, precise linear motion in both push and pull directions. Compared with larger industrial solenoids, a small push pull solenoid is optimized for limited installation space, low power consumption, and fast response time. These characteristics make it ideal for modern smart devices, portable equipment, and compact automation systems.

As electronic products become smaller and more intelligent, demand for the small push pull solenoid continues to grow across industries such as consumer electronics, medical devices, smart home systems, and industrial automation. This article explores more than eight key dimensions of small push pull solenoid technology, including engineering design, performance advantages, industry applications, and real-world use cases.

1. Small Push Pull Solenoid Working Principle and Structure

A small push pull solenoid operates by energizing a copper coil to generate a magnetic field. This magnetic field pulls a ferromagnetic plunger into the coil. Depending on mechanical configuration, the motion can be converted into either pushing or pulling action.

Core Structural Elements of a Small Push Pull Solenoid

Electromagnetic coil

Iron core and housing

Moving plunger or armature

Return spring

Mechanical linkage interface

The compact structure of a small push pull solenoid allows integration into tight spaces where motors or pneumatic systems cannot fit.

2. Small Push Pull Solenoid Advantages Over Alternative Actuators

A small push pull solenoid offers several benefits compared with motors, servos, and pneumatic cylinders:

Instant response time – Electromagnetic actuation occurs within milliseconds

Simple control – Operates via basic DC voltage switching

Compact footprint – Ideal for miniaturized products

Low mechanical wear – Fewer moving parts than motor-driven systems

Energy efficiency – Can be pulse-driven to reduce heat buildup

These advantages explain why many OEMs choose a small push pull solenoid instead of miniature motors in cost-sensitive or space-constrained designs.

3. Small Push Pull Solenoid Design Considerations

Designing a small push pull solenoid requires balancing size, force, stroke, and thermal limits.

Key Engineering Parameters

| Parameter | Impact on Small Push Pull Solenoid Performance |

|---|---|

| Stroke Length | Determines total travel distance |

| Pull/Push Force | Must meet load requirements |

| Coil Voltage | Affects power consumption |

| Duty Cycle | Determines allowable continuous operation |

| Temperature Rise | Impacts long-term reliability |

Because magnetic force decreases as stroke increases, a small push pull solenoid often requires careful coil optimization and magnetic path design to maintain usable force across the stroke.

4. Small Push Pull Solenoid Applications in Consumer Electronics

Consumer electronics is a major growth area for the small push pull solenoid.

Typical Applications

Camera autofocus modules

Printer mechanisms

Smart wearable device locks

Portable device pop-up modules

Case Example: Smart Device Camera Module

A smartphone accessory manufacturer used a small push pull solenoid to control a retractable lens cover. The solenoid provided fast actuation, low noise, and high cycle life while fitting into a very limited internal space.

5. Small Push Pull Solenoid Applications in Smart Home and IoT Devices

Smart home devices increasingly rely on compact electromagnetic actuators.

Common Uses of Small Push Pull Solenoid in Smart Homes

Smart lock bolt actuation

Smart mailbox latches

Cabinet access control systems

Smart doorbell mechanical triggers

Case Example: Smart Cabinet Lock

A home automation company replaced a small DC motor with a small push pull solenoid in a smart cabinet lock. The result was a faster unlocking speed, lower power usage, and simplified electronics.

6. Small Push Pull Solenoid Applications in Medical and Laboratory Equipment

Medical and lab devices require precision and reliability in compact spaces. A small push pull solenoid is often used for:

Fluid dispensing valves

Diagnostic sampling systems

Portable medical instruments

Case Example: Portable Diagnostic Device

A handheld medical analyzer integrated a small push pull solenoid to control a micro-valve for reagent flow. The solenoid’s quick response and small footprint allowed precise fluid metering in a battery-powered system.

7. Small Push Pull Solenoid Applications in Industrial Equipment

Industrial systems also benefit from the small push pull solenoid, especially in compact automation modules.

Industrial Use Cases

Positioning stops

Miniature locking mechanisms

Sorting gates

Sensor-triggered actuators

Case Example: Mini Sorting System

A small parts sorting machine used a small push pull solenoid to divert items into different bins. The solenoid operated millions of cycles with minimal maintenance.

8. Small Push Pull Solenoid Applications in Automotive Electronics

Modern vehicles contain many small electronic modules where a small push pull solenoid is ideal.

Applications include:

Electronic latch systems

Air vent direction control

Charging port locks in EVs

Because automotive environments are harsh, the small push pull solenoid must withstand vibration, temperature extremes, and long service life.

9. Small Push Pull Solenoid Performance Optimization Techniques

To improve small push pull solenoid performance, engineers focus on:

High-permeability core materials

Precision coil winding

Low-friction plunger design

Optimized spring force

These design enhancements allow a small push pull solenoid to deliver stronger force within limited size constraints.

10. Custom Small Push Pull Solenoid Solutions from SF

SF is a professional electromagnet manufacturer with over 10 years of experience designing small push pull solenoid solutions for OEM customers.

SF Customization Capabilities

Custom stroke lengths

Voltage options from 3V to 24V

Low-noise designs

Long-life coil insulation

Environmental protection options

SF engineering teams collaborate closely with customers to tailor each small push pull solenoid for the specific mechanical and electrical requirements of the application.

Why Small Push Pull Solenoid Technology Is Growing Rapidly

The small push pull solenoid has become a key actuator in modern electromechanical design due to its compact size, fast response, and reliable operation. From smart home devices to medical equipment and industrial automation, the small push pull solenoid provides a simple and efficient motion control solution.

As products continue to shrink while performance demands increase, the importance of high-quality small push pull solenoid design will only grow. Manufacturers like SF are helping OEMs integrate custom-engineered solenoids that meet strict requirements for size, power efficiency, and durability.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680