Última atualização em 2025-09-03 por SolenoidFactory

In the vast world of electromagnetic technology, Solenoides tubulares redondos (round tubular electromagnets) have become a shining star in electromagnet technology with their unique structural design and wide application fields. As a factory specializing in the production of electromagnets, we are well aware of the outstanding capabilities of Round Tubular Solenoids in improving equipment performance, simplifying system design, and enhancing system reliability. This article will conduct a comprehensive and in-depth analysis of Solenoides tubulares redondos from multiple dimensions such as working principle, structural composition, advantage analysis, customization process, application scope, and application cases.

1. What is the Working principle of Round Tubular Solenoids ?

O princípio de funcionamento do Solenoides tubulares redondos baseia-se na lei da indução eletromagnética. Quando a corrente passa por uma bobina enrolada em um núcleo tubular redondo, um campo magnético é gerado ao redor do núcleo. Esse campo magnético interage com o material magnético no núcleo para gerar uma força de atração ou repulsão. Essa força pode atuar na armadura ou em outros componentes magnéticos fora do núcleo para mover ou manter uma determinada posição. Ao controlar a magnitude e a direção da corrente na bobina, é possível obter um controle preciso da armadura ou de outros componentes magnéticos, realizando assim várias funções de controle automatizado.

2. What is the Structural composition of Round Tubular Solenoids ?

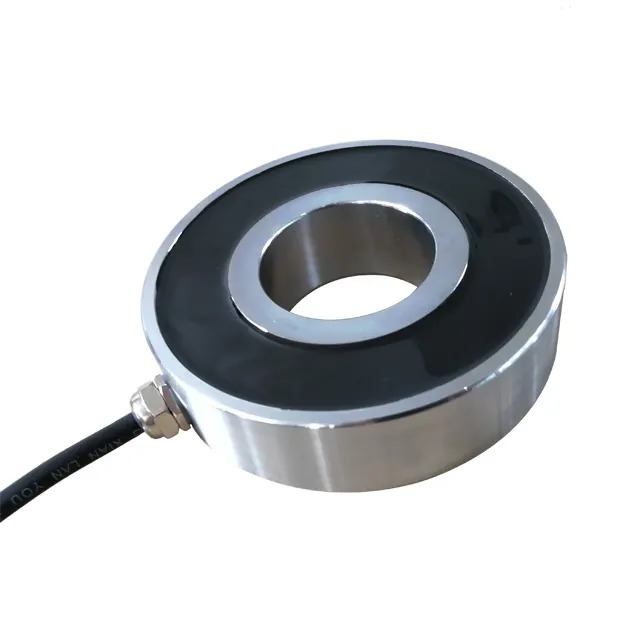

O projeto estrutural de Solenoides tubulares redondos is exquisite and compact, and is usually composed of the following key parts:

Core: The core is the core component of Round Tubular Solenoids, usually made of soft magnetic materials with high magnetic permeability, such as silicon steel sheets or ferrites. The shape of the core is a circular tube, and its internal space is used to accommodate components such as coils and armatures.

Bobina: The coil is a wire wound around the outside of the core, usually made of copper wire or aluminum wire. The number of turns and wire diameter of the coil determine the strength of the magnetic field and the magnitude of the electromagnetic force. In Round Tubular Solenoids, the coil is tightly wound on the core to ensure uniform distribution and high efficiency of the magnetic field.

Armature: The armature is a movable part in Round Tubular Solenoids, usually made of magnetic materials. When the coil is energized, the armature moves due to the attraction or repulsion of the magnetic field. The shape and size of the armature can be customized according to specific application requirements.

Mecanismo de guia: The guide mechanism is used to ensure the smoothness and accuracy of the armature during movement. It usually includes components such as guide sleeves and springs to limit the movement trajectory of the armature and reduce friction and wear.

Concha: The shell is used to protect the internal structure of the Round Tubular Solenoids from interference and damage from the external environment. The shell is usually made of metal or plastic and has a certain strength and sealing.

Connectors: Connectors are used to connect Round Tubular Solenoids to other components or systems. It usually includes components such as wiring terminals and fixing screws to achieve electrical connection and mechanical fixation.

-

Avaliação 0 de 5

-

Avaliação 0 de 5

-

Avaliação 0 de 5

-

Avaliação 0 de 5

3. What are Advantages of Round Tubular Solenoids ?

Solenoides tubulares redondos have many advantages over other types of electromagnets, which make them stand out in many application fields:

Compact structure: Round Tubular Solenoids adopts a round tubular structure, which makes it smaller and lighter, and easy to install and use in a limited space.

Alta eficiência: Due to the close fit of the core and the coil and the uniform distribution of the magnetic field, Round Tubular Solenoids requires less current to generate the same electromagnetic force, thereby reducing energy consumption and heat generation.

Precise control: By accurately controlling the current size and direction in the coil, precise control of the armature or other magnetic components can be achieved, thereby meeting various complex application requirements.

High reliability: Round Tubular Solenoids adopts high-quality materials and advanced manufacturing processes, with high reliability and stability. At the same time, its compact structure and no moving parts (except the armature) reduce failure points and maintenance costs.

Forte adaptabilidade: Round Tubular Solenoids can be customized according to specific application requirements, such as changing the length, diameter, number of turns and wire diameter of the core to adapt to different working environments and control requirements.

4. How to customize Round Tubular Solenoids

In order to meet the needs of different customers, we provide customized services for Round Tubular Solenoids. The following are several key steps in the customization process:

Comunicação de demanda: Primeiro, nos comunicamos com os clientes em detalhes para entender seus cenários de aplicação específicos, requisitos de desempenho, ambiente de instalação e outras informações. Isso nos ajudará a oferecer aos clientes as soluções personalizadas mais adequadas.

Solution design: According to customer needs, our engineers will design the solution. This includes selecting the appropriate core material, determining the number of turns and wire diameter of the coil, and designing the shape and size of the armature. At the same time, we will also consider factors such as the heat dissipation performance and electromagnetic compatibility of Round Tubular Solenoids to ensure the reliability and stability of the product. After the solution design is completed, we will confirm with the customer and adjust and optimize according to the feedback.

Fabricação: After the solution is confirmed, we will enter the manufacturing stage. We will use advanced production equipment and processes to ensure that the quality and performance of the products meet the design requirements. At the same time, we will conduct strict quality inspection and control to ensure that each Round Tubular Solenoids can meet customer expectations.

Teste e depuração: After the production is completed, we will test and debug the Round Tubular Solenoids. This includes performance testing, functional testing, reliability testing, etc. Through testing and debugging, we can ensure that the product can operate stably and reliably in actual applications.

Entrega e pós-venda: After the testing and debugging are completed, we will package and deliver according to the customer’s requirements. At the same time, we provide perfect after-sales service and technical support to ensure that customers can get timely and effective help and support during use.

5. Application scope of Round Tubular Solenoids

Solenoides tubulares redondos tem sido amplamente utilizado em muitos campos devido ao seu desempenho e vantagens exclusivos:

Automação industrial: In automated production lines, Round Tubular Solenoids are often used to control the switching and movement of valves, cylinders, clamping devices and other components. Its compact structure and precise control enable automated production lines to operate more efficiently and stably.

Eletrônicos automotivos: In the field of automotive electronics, Round Tubular Solenoids are widely used in seat adjustment, window lifting, sunroof switch and other components. Its high efficiency and high reliability make automotive electronic systems more intelligent and humanized.

Equipamentos médicos: In medical equipment, Round Tubular Solenoids are often used to control surgical instruments, bed lifting and other components. Its precise control and strong adaptability ensure the safety and reliability of medical equipment.

Aeroespacial: In the field of aerospace, Round Tubular Solenoids are used to control the opening and moving of various aircraft components such as control surfaces and doors. Its small size, light weight and high reliability make aerospace equipment more flexible and efficient.

Eletrônicos de consumo: In the field of consumer electronics, Round Tubular Solenoids are used in the functions of automatic camera flipping and automatic screen flipping of mobile phones, tablets and other devices. Its compact structure and precise control make consumer electronic devices more intelligent and convenient.

6. Application Cases of Round Tubular Solenoids

A seguir, alguns exemplos de Solenoides tubulares redondos em aplicações específicas:

Controle de válvulas na automação industrial: In automated production lines, Round Tubular Solenoids are used to control the opening and closing of pneumatic valves. When the valve needs to be opened or closed, the control system sends a signal to the Round Tubular Solenoids, which generates electromagnetic force and pushes the valve to perform the corresponding action. This application not only improves the automation level of the production line, but also reduces energy consumption and maintenance costs.

Ajuste do assento em eletrônica automotiva: In modern cars, Round Tubular Solenoids are widely used in electric seat adjustment systems. When the driver or passenger needs to adjust the seat position, just press the corresponding button to trigger the Round Tubular Solenoids to act, thereby driving the seat motor to adjust forward and backward, up and down, or tilt. This application not only improves driving and riding comfort, but also makes seat adjustment more intelligent and convenient.

Surgical instrument control in medical equipment: In medical equipment, Round Tubular Solenoids are used to control the opening and moving of surgical instruments. For example, in minimally invasive surgery, doctors can control Round Tubular Solenoids to achieve precise movement and cutting of surgical instruments. This application not only improves the success rate and safety of surgery, but also reduces the operating burden of doctors.

Inversão automática de câmera em produtos eletrônicos de consumo: Round Tubular Solenoids are used to achieve the automatic flipping function of the camera in devices such as smartphones and tablets. When the user needs to switch the front and rear cameras, the device triggers the Round Tubular Solenoids to move, thereby driving the camera module to flip. This application not only improves the convenience of taking photos and videos, but also makes consumer electronic devices more intelligent and humane.

7. Perspectivas futuras

Com o avanço da ciência e da tecnologia e as mudanças contínuas nas necessidades dos aplicativos, Solenoides tubulares redondos será aplicado e desenvolvido em mais campos. No futuro, podemos esperar progresso nos seguintes aspectos:

Technological innovation: With the continuous emergence of new materials, new processes and new technologies, the performance of Round Tubular Solenoids will be further improved. For example, the use of high-performance permanent magnetic materials can improve the magnetic field strength and electromagnetic force; the use of advanced winding technology can reduce resistance and heat generation; the use of intelligent control technology can achieve more precise control and monitoring, etc.

Application expansion: With the rapid development of industrial automation, automotive electronics, medical equipment and other fields, the application scope of Round Tubular Solenoids will be further expanded. For example, in the field of industrial automation, Round Tubular Solenoids can be used for more complex control systems and harsher working environments; in the field of automotive electronics, Round Tubular Solenoids can be used for more advanced driving assistance systems and automatic driving systems; in the field of medical equipment, Round Tubular Solenoids can be used for more sophisticated surgical robots and rehabilitation equipment, etc.

Environmental protection and energy saving: With the increasing global attention to environmental protection and energy saving, Round Tubular Solenoids will play a greater role in energy saving and consumption reduction. For example, by optimizing the design and adopting new energy technologies, the energy consumption and emissions of Round Tubular Solenoids can be reduced; by recycling and reusing the components and materials of waste Round Tubular Solenoids, resource waste and environmental pollution can be reduced.

As a factory focusing on the production of electromagnets, we will continue to be committed to the research and development and innovation of Round Tubular Solenoids technology to provide customers with better products and services. We believe that in the near future, Round Tubular Solenoids will show its unique charm and huge potential in more fields and make greater contributions to promoting scientific and technological progress and social development.

Sobre a fábrica de eletroímãs SF

A Shengfeng Electromagnet Co., Ltd. foi fundada em 2015 e está localizada no Parque Industrial de Xiansha, com belas paisagens e transporte conveniente. A empresa ocupa uma área de 16.000 metros quadrados e tem instalações de produção modernas, equipamentos de produção avançados e uma equipe técnica de alta qualidade. Desde sua fundação, sempre aderimos à filosofia corporativa de “inovação, qualidade e serviço”, com foco em pesquisa, desenvolvimento e produção de eletroímãs, A empresa está constantemente promovendo atualizações de produtos e progresso tecnológico, além de fornecer aos clientes produtos e serviços da melhor qualidade.

Por que escolher a eletromagne SF

QUALIDADE DE PONTA:Como o melhor fabricante de eletroímãs solenoides da China, nossa equipe de controle de qualidade garantirá que todos os produtos que você receber sejam da melhor qualidade. Temos uma máquina de teste de qualidade profissional.

DESIGN DO PRODUTO:Nosso departamento de amostragem tem um processo completo de transformar desenhos em realidade. Também aprimoramos o design do seu produto com base em nossos anos de experiência de trabalho.

TEMPO DE ENTREGA ESTÁVEL:Como o melhor fabricante e fornecedor de eletroímãs, temos capacidade de fabricação suficiente, grandes pedidos não nos vencem e ainda podemos entregar o pedido a tempo.

MELHOR PREÇO:Somos uma fábrica de fontes de eletroímãs e o melhor fabricante de solenóides da China, por isso podemos fornecer bolsas de alta qualidade com o melhor preço.

GERENCIAMENTO PRECISO:Nada pode ser alcançado se não implementarmos um gerenciamento preciso. Somos uma empresa com um sistema de gerenciamento completo.

7-24 SERVIÇO:Como o melhor fabricante de solenóides, resposta imediata 24 horas por dia, 7 dias por semana: Receberemos seu feedback para nos tornar um fornecedor melhor.

Perguntas frequentes sobre o eletroímã

Somos uma empresa chinesa de ponta eletroímã e nossa fábrica está localizada em Dongguan. Bem-vindo a visitar nossa fábrica!

Somos especializados no design e na produção de produtos de alta qualidade eletroímã,válvula solenoide,como solenoide rotativo, solenoides biestáveis, solenoides de travamento, solenoides de estrutura aberta, solenoides tubulares, solenoide de retenção automática

-É claro que, normalmente, fornecemos amostras grátis, e você só precisa arcar com o frete. Para amostras personalizadas de eletroímãs, envie-nos seus requisitos para verificarmos o custo da amostra.

- A produção de amostras leva cerca de 7 dias.

Sim, fornecemos serviços gratuitos de design, design estrutural e design gráfico simples.

Claro, podemos fazer qualquer eletroímã com seu projeto. Agora, abrimos um solenoide ODM que é para pequenas quantidades de 100 a 500 unidades, mas você ainda pode ter seu próprio logotipo.

Dependendo da quantidade do pedido e dos detalhes da produção, o prazo é de 15 a 20 dias.

Sempre uma amostra de pré-produção antes da produção em massa; sempre a inspeção final antes do envio

- Potência, uso, tamanho, material, quantidade, destino da remessa, etc.

- Você também pode simplesmente nos informar suas necessidades e nós recomendaremos produtos para você.

- Por via marítima, aérea ou expressa.

- Se você tiver seu próprio despachante na China, esse é o preço à saída da fábrica ou FOB.

-CFR ou CIF, etc., se precisar que façamos o envio em seu nome.

- DDP e DDU também podem ser usados.

- Mais opções, consideraremos suas opções.

- O preço é determinado pela quantidade, material, método de processamento, tamanho e outros fatores. Além disso, devido à nossa contínua

inovação tecnológica, os preços de alguns de nossos produtos são extremamente competitivos; entre em contato conosco para fazer uma cotação.