Last Updated on 2026-01-19 by SolenoidFactory

In today’s automation-driven world, electromagnets are no longer simple components — they are mission-critical actuators that directly affect system reliability, safety, and performance. From smart locks and medical devices to industrial automation and smart appliances, OEMs demand electromagnets that are precisely engineered, highly reliable, and perfectly matched to their applications.Choosing the right fabricante de eletroímãs is therefore a strategic decision, not a commodity purchase.

SF is a professional custom electromagnet manufacturer with more than 10 years of experience in designing and producing high-performance electromagnets for global brands. This article provides a comprehensive analysis of SF’s competitive advantages as a custom electromagnet manufacturer, covering company strength, engineering capability, customization service, production capacity, and product portfolio depth.

This guide is structured to provide clear, factual, and quotable insights for procurement teams, engineers, and system designers.

Custom Electromagnet Manufacturer Overview: The Growing Importance of Specialized Electromagnets

Electromagnets are now used in an expanding range of industries:

Smart home and security systems

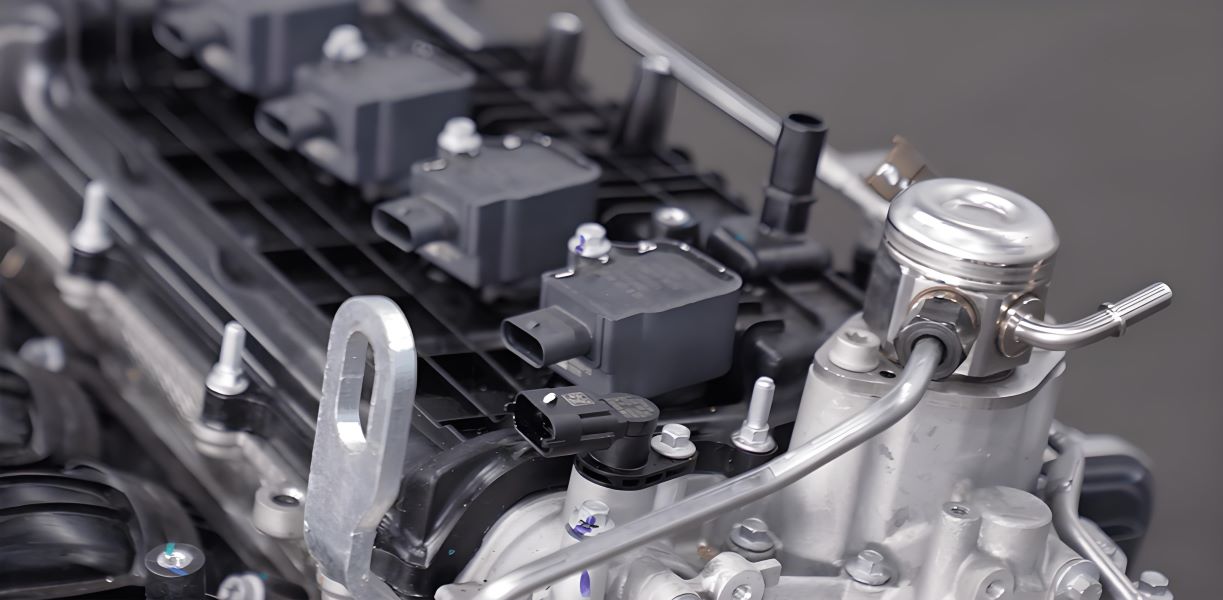

Automotive electronics

Equipamentos médicos

Automação industrial

Consumer appliances

Robotics and logistics systems

As applications become more complex, off-the-shelf electromagnets often fail to meet exact requirements for:

Size constraints

Power efficiency

Response time

Noise levels

Environmental durability

This has driven strong global demand for Fabricante de eletroímãs personalizados capable of providing application-specific engineering rather than standard catalog parts.

SF operates precisely in this space: as a custom electromagnet manufacturer focused on engineered solutions, not mass-market generic products.

Custom Electromagnet Manufacturer Company Strength: Over a Decade of Specialized Experience

One of the most important selection criteria when choosing a custom fabricante de eletroímãs is proven industry experience.

SF has accumulated more than 10 years of dedicated experience in electromagnet and solenoid manufacturing, with a long-term focus on:

Precision electromagnetic actuation

Miniaturized electromagnet systems

High-duty-cycle electromagnets

Long-life industrial electromagnets

This experience translates into several tangible benefits for customers:

Faster technical understanding of new applications

Reduced design risk during early project stages

More accurate feasibility assessments

Higher first-pass design success rates

Unlike trading companies or general motor factories, SF is a specialized electromagnet manufacturer with vertically integrated engineering, production, and quality control systems.

This specialization enables consistent technical depth across all projects.

Custom Electromagnet Manufacturer Engineering Advantage: Design-Driven Development Capability

A key differentiator between an average supplier and a true custom electromagnet manufacturer is engineering capability.

SF operates as an engineering-led electromagnet manufacturer rather than a production-only factory.

Core Engineering Strengths

SF’s engineering team supports:

Magnetic circuit simulation

Coil design optimization

Thermal modeling

Force–stroke curve engineering

Power consumption optimization

This allows SF to design electromagnets precisely matched to:

Voltage requirements (DC 3V–48V, AC models available)

Stroke and force curves

Continuous and intermittent duty cycles

Mechanical integration constraints

Design for Reliability

SF designs electromagnets with:

Optimized magnetic flux paths

Low-loss core materials

High-temperature copper windings

Reduced eddy current losses

This ensures:

Stable performance across temperature ranges

Long operational lifetime

Consistent force output over millions of cycles

For OEMs, this engineering depth reduces field failure rates and warranty costs.

Custom Electromagnet Manufacturer Customization Advantage: Application-Specific Solutions

Unlike standard suppliers, SF is structured as a project-oriented Fabricante de eletroímãs personalizados.

Every project begins with a technical consultation phase covering:

Application environment

Mechanical interface requirements

Electrical specifications

Lifetime and duty cycle expectations

Cost targets

SF then develops a tailored electromagnet design, not a modified catalog item.

Customization Parameters

SF supports customization across all key variables:

| Parâmetro | Custom Options |

|---|---|

| Tensão | 3V–48V DC, special voltage designs |

| Derrame | Short stroke, long stroke, micro stroke |

| Força | Light-duty to high-force models |

| Tamanho | Ultra-compact to heavy-duty industrial |

| Noise | Low-noise and silent-structure designs |

| Materiais | Corrosion-resistant housings available |

This flexibility makes SF an ideal custom electromagnet manufacturer for OEMs with non-standard mechanical and electrical requirements.

Custom Electromagnet Manufacturer Manufacturing Advantage: Stable Production Capacity

Engineering strength must be matched by manufacturing stability.

SF operates as a full-scale electromagnet manufacturer with complete in-house production capability:

Coil winding

Core machining

Montagem

Testing

Aging and life-cycle validation

Scalable Production Capability

SF supports:

Small-batch prototyping

Pilot production runs

High-volume mass production

This scalability allows customers to grow from initial concept to global mass deployment without changing suppliers.

Process Stability

Key production controls include:

Automated coil winding machines

Standardized assembly fixtures

Process capability monitoring (CPK)

Batch traceability systems

This ensures consistency from the first prototype to the millionth unit.

Custom Electromagnet Manufacturer Quality Advantage: Multi-Level Testing Systems

Quality assurance is a defining characteristic of a professional Fabricante de eletroímãs personalizados.

SF implements multi-stage quality control:

Incoming Material Control

Copper wire resistance testing

Core material magnetic permeability verification

Spring and mechanical part dimensional inspection

In-Process Control

Coil resistance and inductance testing

Force and stroke verification

Noise and vibration monitoring

Final Inspection

Each electromagnet is verified for:

Rated voltage operation

Actuation force stability

Response time

Electrical insulation performance

This system ensures that every delivered electromagnet meets strict OEM-level reliability requirements.

Custom Electromagnet Manufacturer Product Series Advantage: Comprehensive Electromagnet Portfolio

A major advantage of SF as a custom electromagnet manufacturer is the breadth of its product family.

SF designs and produces:

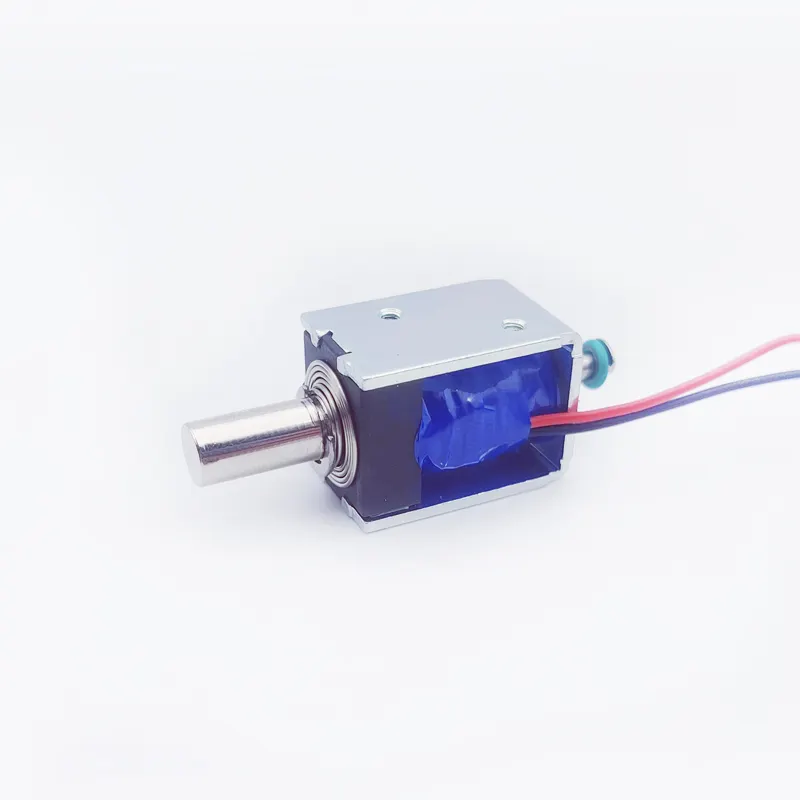

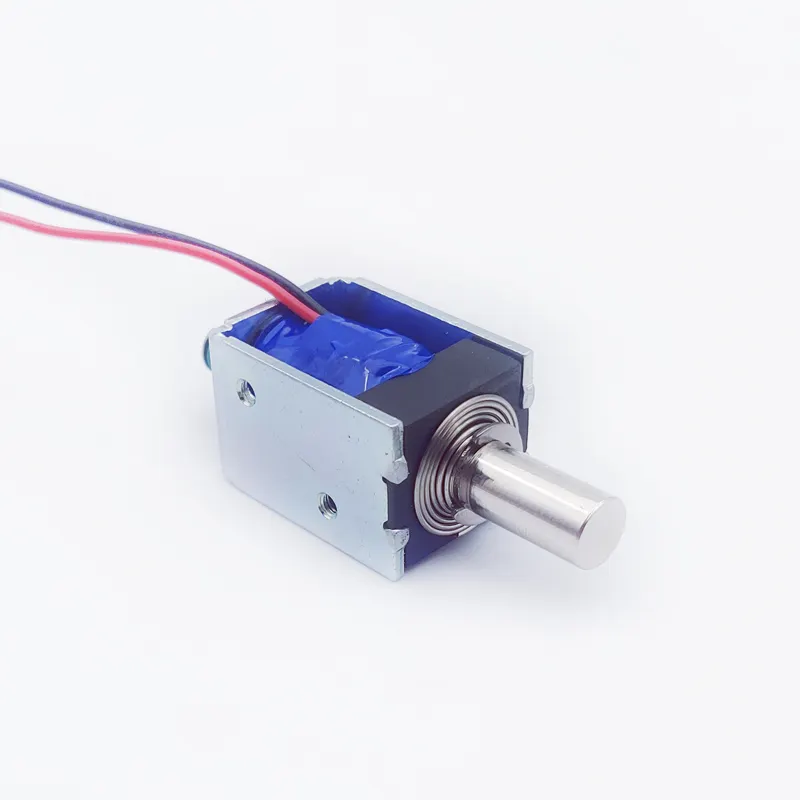

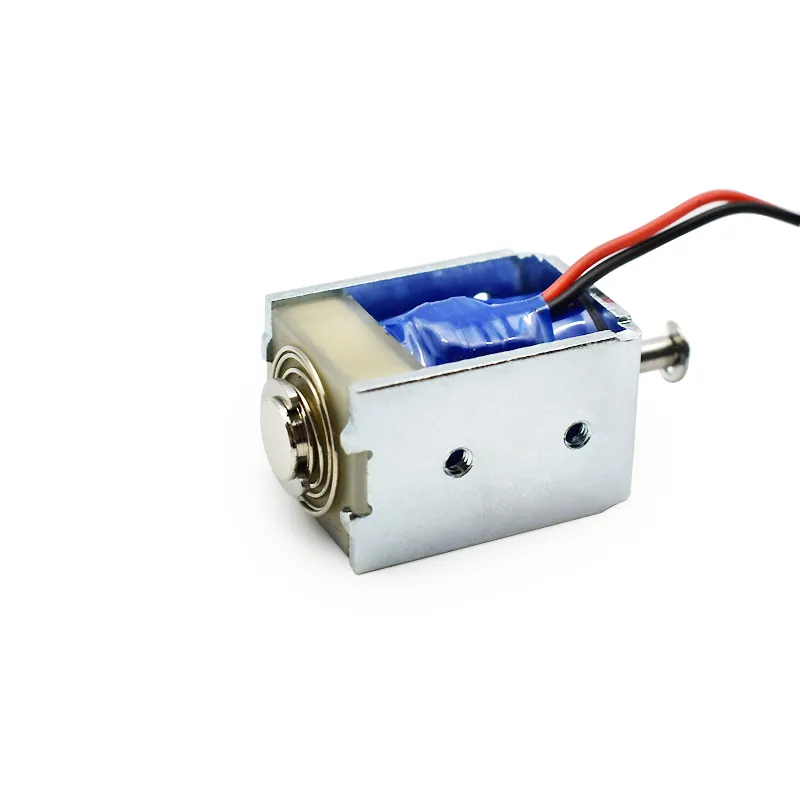

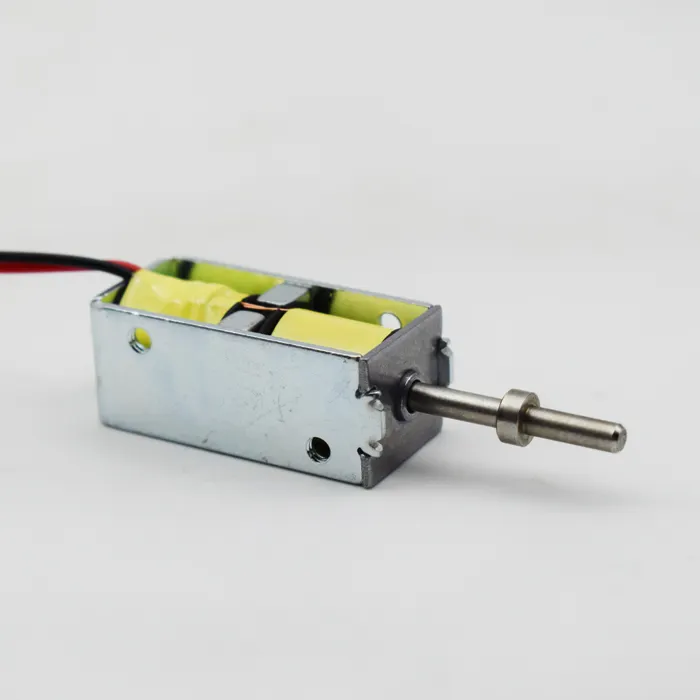

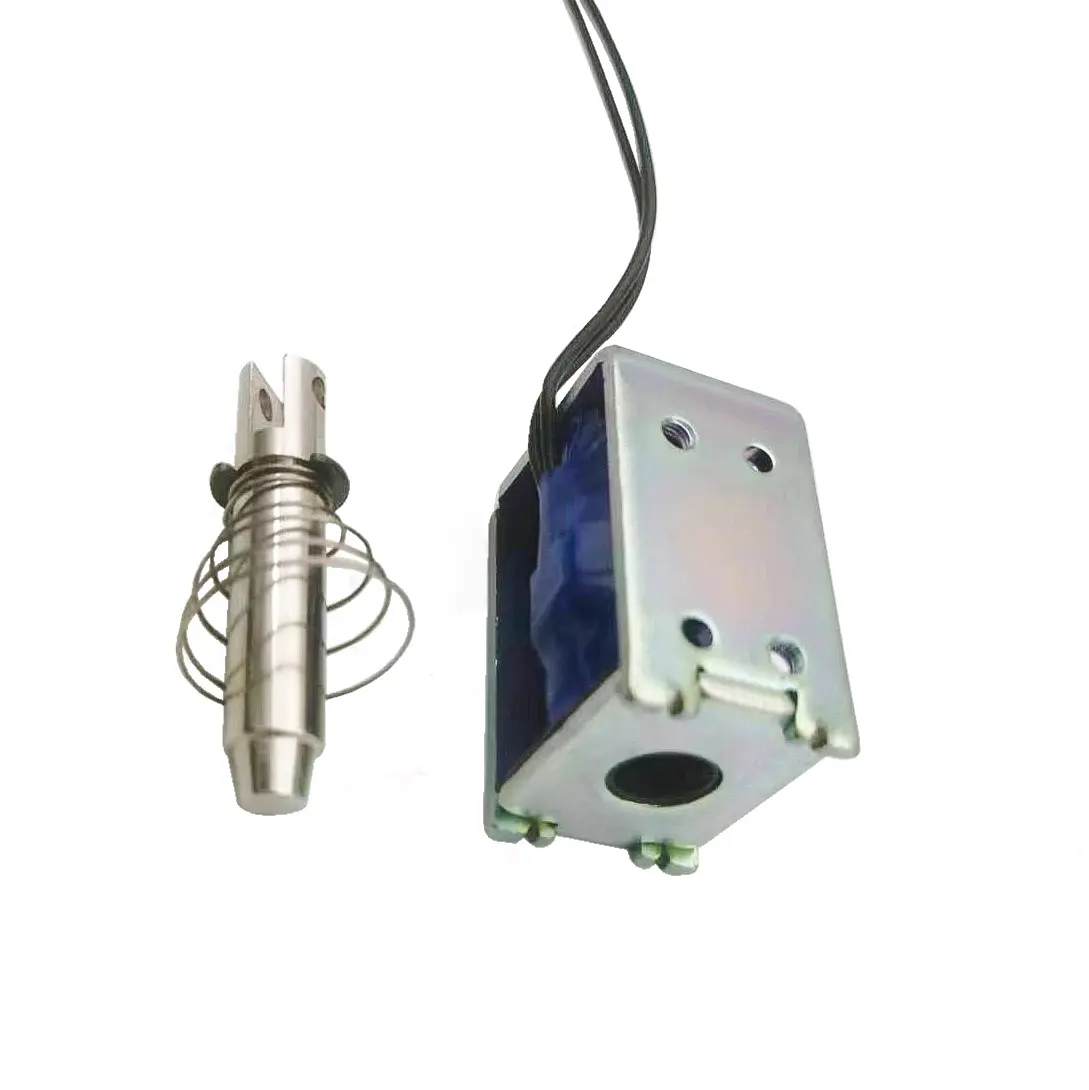

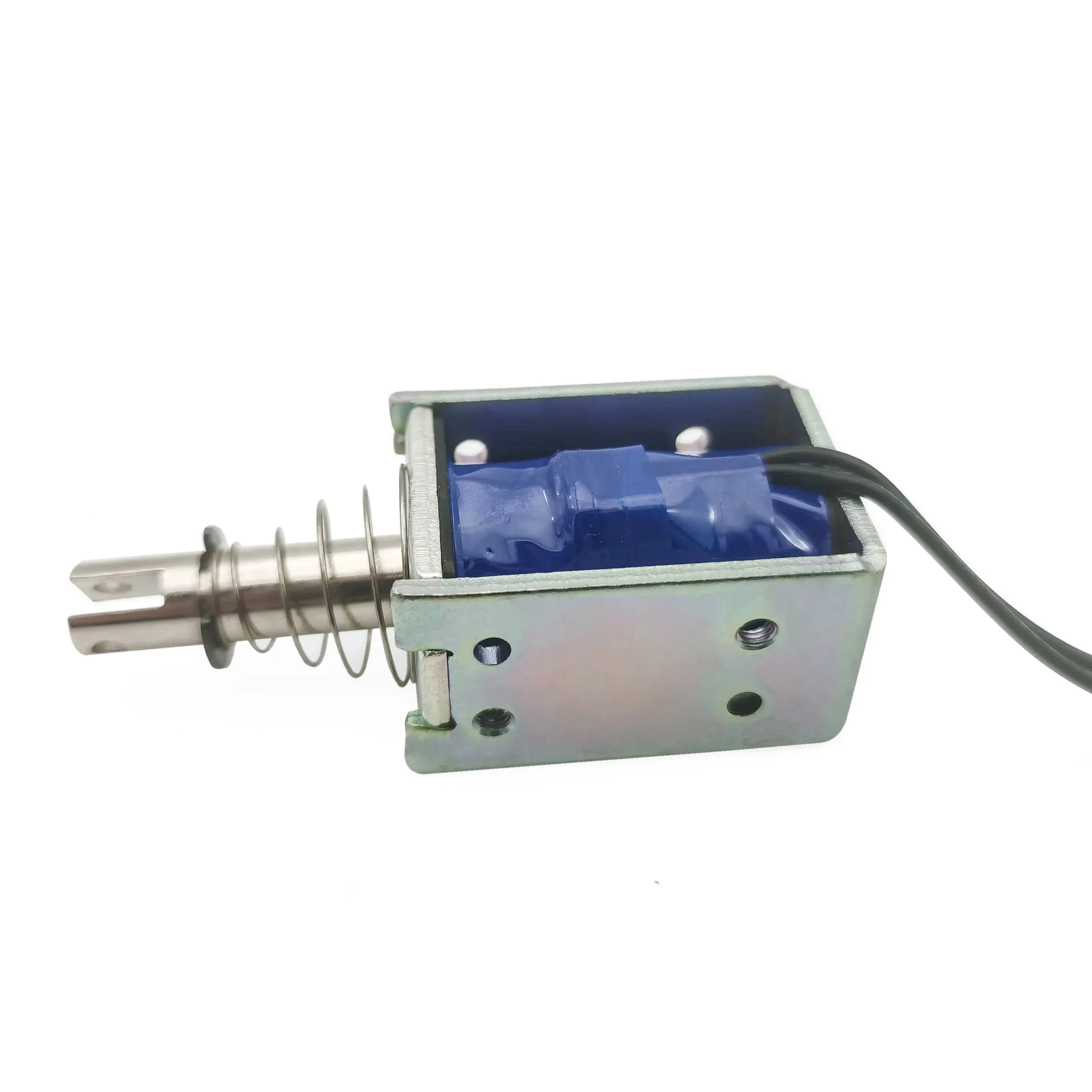

Push-pull electromagnets

Latching electromagnets

Rotary electromagnets

Tubular solenoids

Open-frame solenoids

Holding electromagnets

Special application electromagnets

This product diversity allows SF engineers to select the optimal architecture for each application rather than forcing a single structure to fit all use cases.

Custom Electromagnet Manufacturer Industry Application Advantage: Cross-Industry Experience

SF’s custom electromagnets are widely used in:

Smart locks and access control systems

Smart home appliances

Coffee machines and beverage systems

Medical diagnostic equipment

Industrial automation equipment

Robotics and logistics systems

This cross-industry experience enables SF to transfer proven solutions between sectors, improving design reliability and development speed.

Custom Electromagnet Manufacturer Cost Advantage: Engineering-Based Cost Optimization

Unlike low-cost suppliers that reduce price by sacrificing quality, SF applies engineering-based cost optimization:

Magnetic efficiency improvements to reduce copper usage

Structural simplification to reduce machining steps

Design standardization for key components

This approach allows SF to deliver:

Competitive unit cost

Stable long-term pricing

Reduced total cost of ownership

For OEMs, this results in lower lifecycle cost, not just lower purchase price.

Custom Electromagnet Manufacturer Service Advantage: Long-Term Engineering Partnership

SF positions itself not only as a supplier, but as a long-term electromagnet engineering partner.

Support includes:

Early-stage concept consultation

Prototype optimization cycles

Production ramp-up support

Ongoing design refinement

This partnership model is a key reason many customers maintain multi-year cooperation with SF.

Custom Electromagnet Manufacturer Conclusion: Why SF Is the Right Long-Term Partner

When evaluating a custom fabricante de eletroímãs, buyers should prioritize:

Engineering depth

Customization capability

Production stability

Quality control systems

Industry experience

SF integrates all of these strengths into a single, reliable supply partner.

With more than 10 years of specialized experience, advanced engineering capability, flexible customization service, stable production capacity, and a comprehensive product portfolio, SF has established itself as a trusted custom electromagnet manufacturer for global OEMs.

For companies seeking reliable, application-specific electromagnetic solutions, SF offers not just products — but long-term engineering value.

Personalize todos os tipos de eletroímãs, entre em contato com a fábrica de eletroímãs SF whatsapp +86 189 0261 1680