Última atualização em 2025-09-04 por SolenoidFactory

No âmbito dos dispositivos eletromagnéticos, push pull solenoids have emerged as versatile and reliable components for a wide range of industrial and automation applications. Unlike traditional solenoids that offer either pull or push action, push pull solenoids provide bidirectional motion, making them ideal for applications requiring both extension and retraction movements.

This comprehensive guide will delve into the intricacies of selecting the perfect push pull solenoid for your specific application. We’ll explore key selection criteria, discuss the importance of understanding your application’s requirements, and offer practical tips for evaluating potential suppliers. By the end, you’ll be equipped with the knowledge necessary to make an informed decision that aligns with your project’s needs.

Understanding Push Pull Solenoids

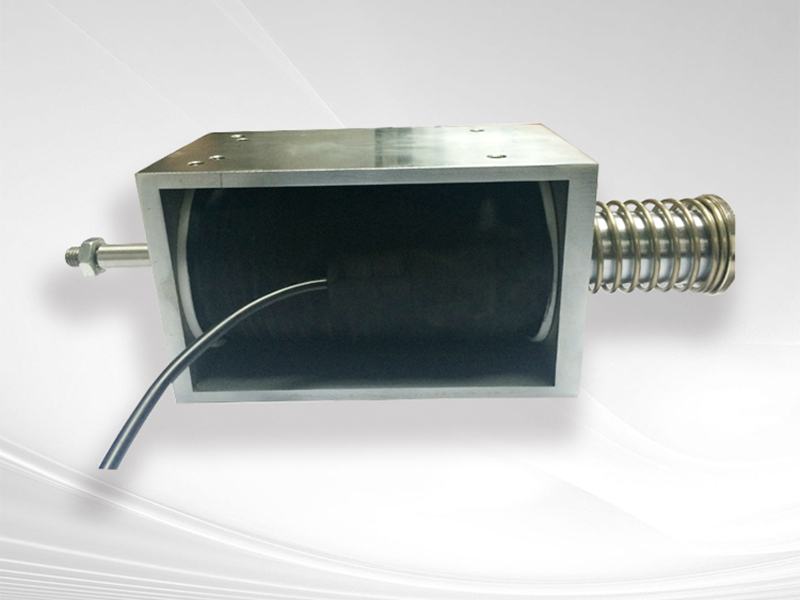

Antes de mergulhar no processo de seleção, é fundamental entender os conceitos básicos de push pull solenoids. These devices consist of a coil, a movable armature, and a spring. When the coil is energized, it creates a magnetic field that attracts or repels the armature, causing it to move in either direction. This bidirectional motion allows push pull solenoids to perform both push and pull actions, making them highly versatile for various applications.

Principais características:

- Bidirectional Motion: Capable of both extension and retraction movements.

- Design compacto: Often smaller and more compact compared to traditional solenoids.

- High Force Output: Capable of generating significant forces for precise control and actuation.

- Confiabilidade: Known for their durability and long operational lifespan.

Key Criteria for Choosing Push Pull Solenoids

Ao selecionar um solenoide push pull, Para garantir a compatibilidade com as necessidades específicas de seu aplicativo, vários critérios devem ser considerados. Aqui estão os principais fatores a serem avaliados:

1. Requisitos de força e curso

Por que é importante:

The force required to move the armature and the stroke (the distance it travels) are fundamental parameters that determine the solenoid’s ability to perform the intended function. Whether it’s actuating a valve, positioning a lever, or locking a mechanism, these specifications are critical.

Dicas de avaliação:

- Calcular a força necessária: Determine the maximum force needed to overcome friction, inertia, or other loads in your application. This can often be found in the application’s technical specifications or through testing. Ensure the selected solenoid can provide sufficient force within your desired operating conditions.

- Considere o comprimento do curso: Measure the distance the armature must travel to fully engage or disengage the target component. Ensure that the selected solenoid’s stroke matches or exceeds this requirement. Consider any additional travel needed for clearance or positioning.

Exemplo:

In an automated assembly line, a push pull solenoid with a high force output and precise stroke control ensures reliable actuation of assembly tools and components.

2. Operating Voltage and Current

Por que é importante:

The operating voltage and current of the solenoid determine its compatibility with your system’s power supply. This is especially important in applications where energy efficiency or power limitations are key concerns.

Dicas de avaliação:

- Assess Power Supply Capabilities: Determine the maximum voltage and current your system can provide without overloading. Ensure the selected solenoid’s operating voltage and current fall within these limits.

- Consider Power Consumption: Evaluate the solenoid’s power consumption to ensure it aligns with your application’s energy efficiency goals. Look for solenoids with low power consumption or energy-saving features, such as pulsed operation or standby modes.

Exemplo:

In battery-powered devices, such as portable medical equipment, choosing a push pull solenoid with low power consumption and a compatible operating voltage extends operational life by minimizing energy usage.

3. Duty Cycle and Lifespan

Por que é importante:

O ciclo de trabalho (a proporção entre o tempo de funcionamento e o tempo total do ciclo) e a vida útil (o número de ciclos antes da falha) são essenciais para aplicações que exigem acionamento frequente ou operação de longo prazo.

Dicas de avaliação:

- Calcular o ciclo de trabalho: Estimate the solenoid’s operating time relative to the rest period. Ensure the selected solenoid’s duty cycle matches or exceeds your application’s requirements. Consider any potential duty cycle variations due to operating conditions or load changes.

- Revisão das especificações de vida útil: Ensure the solenoid’s lifespan meets or exceeds your application’s expected operational duration. This may require consulting with the manufacturer or supplier for detailed lifespan testing data. Look for solenoids with proven durability and reliability in similar applications.

Exemplo:

In industrial automation, where solenoids may cycle thousands of times a day, selecting a push pull solenoid with a high-durability design and long lifespan minimizes downtime and maintenance costs.

4. Size and Weight

Por que é importante:

As restrições de espaço e as limitações de peso geralmente ditam as dimensões físicas dos componentes em muitas aplicações. O tamanho e o peso de um solenoide podem afetar a instalação, o equilíbrio do sistema e o desempenho geral.

Dicas de avaliação:

- Medir o espaço disponível: Determine the maximum dimensions that the solenoid can occupy without interfering with other components or compromising functionality. Ensure the selected solenoid fits within these constraints while providing the necessary force and stroke.

- Considerar o peso: Lightweight solenoids reduce stress on mounting structures and can be easier to integrate into existing systems. Evaluate the solenoid’s weight to ensure it aligns with your application’s requirements and limitations.

Exemplo:

In aerospace applications, where every gram counts, choosing a compact, lightweight push pull solenoid optimizes payload and fuel efficiency.

5. Environmental Conditions

Por que é importante:

O ambiente operacional pode afetar significativamente o desempenho e a vida útil de um solenoide. Fatores como temperatura, umidade e exposição a contaminantes podem degradar os materiais e afetar as propriedades magnéticas.

Dicas de avaliação:

- Identifique os fatores ambientais: Determine the temperature range, humidity levels, and potential contaminants in your application. Ensure the selected solenoid is rated for these conditions. Look for materials and coatings that provide resistance to corrosion, wear, and environmental degradation.

- Consider Sealing and Protection: Ensure the solenoid has adequate sealing and protection to prevent ingress of moisture, dust, or other contaminants. This may include O-rings, gaskets, or conformal coatings that protect internal components.

Exemplo:

In outdoor applications exposed to extreme temperatures and moisture, a push pull solenoid with rust-resistant coatings, conformal coatings, and temperature-stable materials ensures long-term reliability.

6. Requisitos de controle e monitoramento

Por que é importante:

O controle e o monitoramento do estado do solenoide são essenciais para garantir a confiabilidade do sistema e diagnosticar problemas. A compatibilidade com os sistemas de controle existentes e a necessidade de sensores adicionais podem influenciar a sua escolha.

Dicas de avaliação:

- Avalie a compatibilidade do sistema de controle: Ensure the solenoid’s control interface (e.g., voltage pulse, digital signal) matches your system’s requirements. This may involve consulting with your system’s designer or manufacturer to ensure compatibility. Look for solenoids with built-in drivers or controllers that simplify integration.

- Considere as necessidades de monitoramento: Determine if additional sensors (e.g., position sensors, temperature sensors) are necessary for real-time monitoring. Ensure the selected solenoid has appropriate sensor interfaces or options for integrating additional sensors. Look for solenoids with diagnostic features, such as LED indicators or fault codes, that provide insights into operational status and potential issues.

Exemplo:

In a medical device, integrating a push pull solenoid with compatible control electronics and sensors ensures precise, reliable operation and enhances system diagnostics. Look for solenoids with certifications for medical applications, such as ISO 13485, to ensure compliance with industry standards.

7. Certificações e conformidade

Por que é importante:

As certificações e a conformidade com os padrões do setor garantem que o solenoide atenda aos padrões de segurança, ambientais e de desempenho. Elas podem ser essenciais para obter aceitação do mercado e atender aos requisitos regulatórios.

Dicas de avaliação:

- Identificar padrões relevantes: Determine the certifications and standards required for your application (e.g., UL, CE, RoHS). Ensure the selected solenoid complies with these standards. This may involve consulting with industry associations or regulatory bodies to ensure compliance.

- Verificar a conformidade: Ensure the supplier provides documentation proving compliance with the identified standards. This may include certificates of conformity, test reports, or other documentation that verifies the solenoid’s compliance. Look for suppliers with a commitment to continuous improvement and compliance with relevant standards.

Exemplo:

In automotive applications, selecting a push pull solenoid with ISO/TS 16949 certification ensures it meets rigorous quality management standards, enhancing reliability and performance.

-

Avaliação 0 de 5

-

Avaliação 0 de 5

-

Avaliação 0 de 5

-

Avaliação 0 de 5

Evaluating Push Pull Solenoids Suppliers

A escolha do fornecedor certo é tão crucial quanto a escolha do solenoide certo. Um fornecedor de boa reputação pode fornecer informações valiosas, suporte técnico e garantia de qualidade para assegurar o sucesso de seu projeto. Aqui estão algumas dicas para avaliar possíveis fornecedores:

1. Conhecimento técnico e experiência

Por que é importante:

Fornecedores com profundo conhecimento técnico e experiência em push pull solenoids pode oferecer soluções personalizadas, abordar desafios complexos e fornecer recomendações valiosas.

Dicas de avaliação:

- Revisão da literatura técnica: Assess the supplier’s knowledge base, white papers, and technical guides. Look for detailed information on push pull solenoids, including design principles, application notes, and troubleshooting tips. This will help you gauge their understanding of the technology and their ability to provide technical support.

- Consultar os engenheiros: Engage with their engineering teamto discuss your specific application challenges and requirements. A knowledgeable and experienced team can provide insights into material selection, coil design, and other critical factors that can significantly impact performance.

Exemplo:

A supplier with extensive experience in designing push pull solenoids for aerospace applications can provide specialized solutions tailored to the unique challenges of high-altitude and low-temperature environments.

2. Manufacturing Capabilities and Quality Assurance

Por que é importante:

Manufacturing capabilities determine a supplier’s ability to produce solenoids to your specifications, while quality assurance ensures they meet stringent performance and reliability standards.

Dicas de avaliação:

- Visite as instalações: Visit the supplier’s manufacturing facility to observe their processes, equipment, and quality control measures. Look for advanced manufacturing technologies, such as CNC machining and automated assembly lines, that enhance precision and efficiency. Ensure they have rigorous inspection and testing protocols in place to verify solenoid performance and reliability.

- Request Quality Certificates: Ensure the supplier provides quality certificates, such as ISO 9001, that attest to their commitment to quality management and continuous improvement. This will give you assurance that their manufacturing processes and quality control measures meet industry standards.

Exemplo:

A supplier with ISO 9001 certification and advanced manufacturing capabilities can produce high-quality push pull solenoids with precise dimensions, consistent performance, and long-term reliability.

3. Suporte à personalização e ao design

Por que é importante:

The ability to customize solenoids to meet specific requirements is crucial for ensuring optimal performance in diverse applications.

Dicas de avaliação:

- Discutir opções de personalização: Inquire about the supplier’s ability to customize solenoids in terms of force, stroke, voltage, materials, and other critical parameters. Ensure they have the design flexibility to meet your unique needs, whether it’s modifying existing models or developing entirely new solutions.

- Solicitar consulta de design: Engage with their design team to discuss your application’s requirements and challenges. They can provide insights into material selection, coil design, and other critical factors that can significantly impact performance. Look for suppliers with a history of successful collaborations and customized solutions in similar applications.

Exemplo:

A supplier with extensive customization and design support can develop a push pull solenoid with unique force-stroke characteristics and materials tailored to your specific application, ensuring optimal performance and reliability. They can also provide guidance on integrating the solenoid into your existing system, minimizing installation and integration challenges.

4. Recursos de prototipagem e teste

Por que é importante:

A criação de protótipos e os testes são essenciais para validar o desempenho de um solenoide antes da produção em escala total.

Dicas de avaliação:

- Solicitar amostras de protótipos: Ask the supplier to provide prototype samples of the customized solenoid for testing in your application. This will give you hands-on experience with the solution and allow you to validate its performance under real-world conditions. Ensure they have the capability to produce prototypes quickly and efficiently, minimizing development timelines.

- Discutir protocolos de teste: Ensure the supplier has rigorous testing protocols in place to validate solenoid performance across various conditions. This includes testing for force, stroke, durability, environmental compatibility, and electromagnetic interference (EMI). Look for suppliers with in-house testing facilities and advanced test equipment that can simulate your application’s specific operating conditions.

Exemplo:

A supplier with in-house prototyping and testing capabilities can provide you with customized push pull solenoids that have been thoroughly tested and validated for your specific application. They can also offer ongoing support for troubleshooting and performance optimization, ensuring long-term reliability and performance.

5. Atendimento ao cliente e suporte técnico

Por que é importante:

O atendimento ao cliente e o suporte técnico responsivos são essenciais para resolver problemas, fornecer orientação e garantir um processo de integração tranquilo.

Dicas de avaliação:

- Teste o atendimento ao cliente: Contact the supplier’s customer service team with pre-sales questions to gauge their responsiveness and helpfulness. This will give you insight into their ability to support you throughout the selection, integration, and maintenance processes. Look for suppliers with dedicated customer service teams and multiple communication channels (e.g., phone, email, chat) for easy access.

- Avaliar as ofertas de suporte técnico: Evaluate the supplier’s technical support resources, including phone support, email assistance, and online resources (e.g., FAQs, troubleshooting guides, application notes). Ensure they have a team of experienced engineers who can provide ongoing support after the sale, minimizing downtime and enhancing system reliability. Look for suppliers with 24/7 support options for critical applications that require around-the-clock assistance.

Exemplo:

A supplier with comprehensive customer service and technical support offerings, including dedicated account managers and 24/7 assistance, ensures you can get help when you need it, minimizing downtime and enhancing system reliability. They can also provide training and guidance for your team, ensuring smooth integration and optimal performance.

6. Práticas de sustentabilidade e conformidade ambiental

Por que é importante:

No mundo atual, que se preocupa com o meio ambiente, as práticas de sustentabilidade dos fornecedores e a conformidade com as normas ambientais são cada vez mais importantes.

Dicas de avaliação:

- Informe-se sobre as políticas ambientais: Ask about the supplier’s environmental policies, including waste reduction, energy efficiency, and use of sustainable materials. Ensure they have a commitment to minimizing their environmental footprint throughout the manufacturing process.

- Solicitar documentação de conformidade: Ensure the supplier provides documentation proving compliance with relevant environmental regulations (e.g., RoHS, REACH). This will give you assurance that their push pull solenoids meet environmental standards and are safe for use in your application. Look for suppliers with certifications for environmental management, such as ISO 14001, that demonstrate their commitment to sustainable practices.

Exemplo:

A supplier committed to sustainable practices, such as recycling materials, minimizing energy consumption during manufacturing, and using environmentally friendly coatings, can help you reduce your application’s environmental impact while ensuring reliable performance. They can also provide guidance on selecting solenoids with lower energy consumption and longer lifespans, contributing to overall sustainability.

Choosing the right push pull solenoids for your application

Escolhendo o caminho certo push pull solenoids for your application involves a thorough evaluation of your specific requirements and a careful assessment of potential suppliers. By focusing on key criteria such as force and stroke requirements, operating voltage and current, duty cycle and lifespan, size and weight, environmental conditions, control and monitoring needs, certifications and compliance, you can narrow down your options to those that best meet your needs.

Além disso, a avaliação dos fornecedores com base em seu conhecimento técnico, recursos de fabricação, suporte à personalização, recursos de prototipagem e teste, atendimento ao cliente, suporte técnico e práticas de sustentabilidade garante a parceria com uma organização confiável, ágil e comprometida com o sucesso do seu projeto.

Remember, the best push pull solenoid is not necessarily the cheapest or the most advanced; it’s the one that aligns perfectly with your application’s specific requirements and supports your long-term goals. By leveraging the guidance outlined in this blog, you’ll be well-equipped to make an informed decision that ensures optimal performance, reliability, and cost-effectiveness.

More Tips

À medida que você continua sua busca pelo produto ideal solenoide push pull, Considere estes recursos adicionais e as próximas etapas:

- Sites de fornecedores: Visit the websites of potential suppliers to learn more about their products, services, and technical capabilities. Look for detailed specifications, application notes, and technical guides that provide insights into their push pull solenoids. Use search terms like “push pull solenoid selection guide” or “high-force push pull solenoids” to find relevant information.

- Publicações do setor: Read industry publications and trade journals to stay informed about the latest trends, advancements, and best practices in push pull solenoid technology. This can help you identify new suppliers, technologies, and innovations that may benefit your application. Look for articles discussing new materials, design principles, and performance enhancements.

- Feiras e conferências: Attend industry trade shows and conferences to network with suppliers, learn about new products, and gather insights from peers and experts. These events provide an excellent opportunity to see push pull solenoids in action, discuss potential applications with suppliers, and gather feedback from industry professionals. Look for events focused on automation, industrial controls, or specific industries where push pull solenoids are commonly used.

- Teste piloto: Consider pilot testing a few selected push pull solenoids in your application environment to validate performance and reliability before making a final decision. This can help you identify any potential issues or limitations and ensure that the selected solenoid meets your application’s specific needs. Look for suppliers who are willing to collaborate on pilot testing and provide support throughout the process.

By leveraging these resources and following the guidance outlined in this blog, you’ll be well-equipped to choose the right push pull solenoid for your application, ensuring optimal performance, reliability, and cost-effectiveness. With a focus on technical expertise, customization, prototyping, and sustainability, you’ll be able to make an informed decision that aligns with your project’s goals and requirements.

Sobre a fábrica de eletroímãs SF

A Shengfeng Electromagnet Co., Ltd. foi fundada em 2015 e está localizada no Parque Industrial de Xiansha, com belas paisagens e transporte conveniente. A empresa ocupa uma área de 16.000 metros quadrados e tem instalações de produção modernas, equipamentos de produção avançados e uma equipe técnica de alta qualidade. Desde sua fundação, sempre aderimos à filosofia corporativa de “inovação, qualidade e serviço”, com foco em pesquisa, desenvolvimento e produção de eletroímãs, A empresa está constantemente promovendo atualizações de produtos e progresso tecnológico, além de fornecer aos clientes produtos e serviços da melhor qualidade.

Por que escolher o eletroímã SF

QUALIDADE DE PONTA:Como o melhor fabricante de eletroímãs solenoides da China, nossa equipe de controle de qualidade garantirá que todos os produtos que você receber sejam da melhor qualidade. Temos uma máquina de teste de qualidade profissional.

DESIGN DO PRODUTO:Nosso departamento de amostragem tem um processo completo de transformar desenhos em realidade. Também aprimoramos o design do seu produto com base em nossos anos de experiência de trabalho.

TEMPO DE ENTREGA ESTÁVEL:Como o melhor fabricante e fornecedor de eletroímãs, temos capacidade de fabricação suficiente, grandes pedidos não nos vencem e ainda podemos entregar o pedido a tempo.

MELHOR PREÇO:Somos uma fábrica de fontes de eletroímãs e o melhor fabricante de solenóides da China, por isso podemos fornecer bolsas de alta qualidade com o melhor preço.

GERENCIAMENTO PRECISO:Nada pode ser alcançado se não implementarmos um gerenciamento preciso. Somos uma empresa com um sistema de gerenciamento completo.

7-24 SERVIÇO:Como o melhor fabricante de solenóides, resposta imediata 24 horas por dia, 7 dias por semana: Receberemos seu feedback para nos tornar um fornecedor melhor.

Perguntas frequentes sobre o eletroímã

Somos uma empresa chinesa de ponta eletroímã e nossa fábrica está localizada em Dongguan. Bem-vindo a visitar nossa fábrica!

Somos especializados no design e na produção de produtos de alta qualidade eletroímã,válvula solenoide,como solenoide rotativo, solenoides biestáveis, solenoides de travamento, solenoides de estrutura aberta, solenoides tubulares, solenoide de retenção automática

-É claro que, normalmente, fornecemos amostras grátis, e você só precisa arcar com o frete. Para amostras personalizadas de eletroímãs, envie-nos seus requisitos para verificarmos o custo da amostra.

- A produção de amostras leva cerca de 7 dias.

Sim, fornecemos serviços gratuitos de design, design estrutural e design gráfico simples.

Claro, podemos fazer qualquer eletroímã com seu projeto. Agora, abrimos um solenoide ODM que é para pequenas quantidades de 100 a 500 unidades, mas você ainda pode ter seu próprio logotipo.

Dependendo da quantidade do pedido e dos detalhes da produção, o prazo é de 15 a 20 dias.

Sempre uma amostra de pré-produção antes da produção em massa; sempre a inspeção final antes do envio

- Potência, uso, tamanho, material, quantidade, destino da remessa, etc.

- Você também pode simplesmente nos informar suas necessidades e nós recomendaremos produtos para você.

- Por via marítima, aérea ou expressa.

- Se você tiver seu próprio despachante na China, esse é o preço à saída da fábrica ou FOB.

-CFR ou CIF, etc., se precisar que façamos o envio em seu nome.

- DDP e DDU também podem ser usados.

- Mais opções, consideraremos suas opções.

- O preço é determinado pela quantidade, material, método de processamento, tamanho e outros fatores. Além disso, devido à nossa contínua

inovação tecnológica, os preços de alguns de nossos produtos são extremamente competitivos; entre em contato conosco para fazer uma cotação.