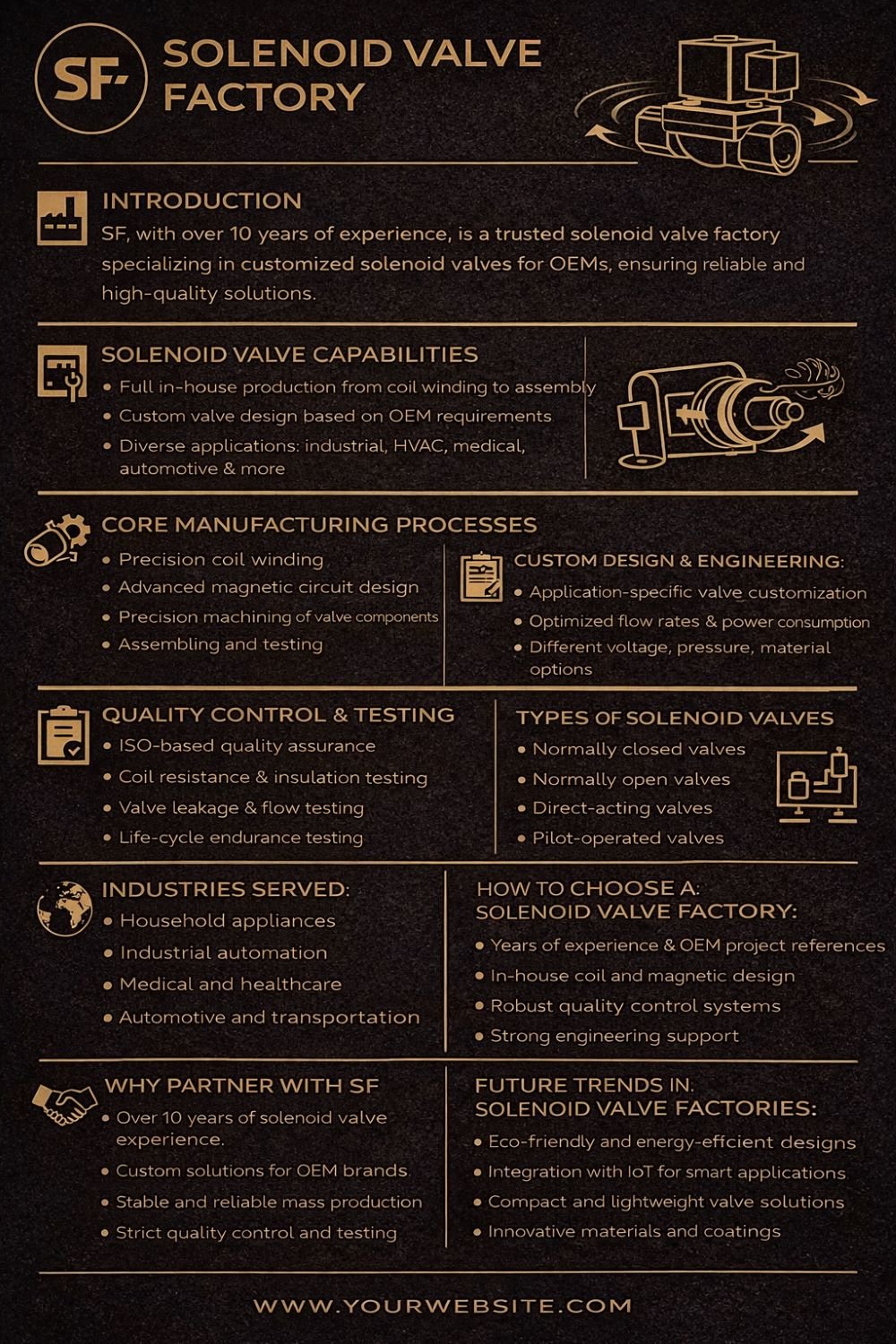

Last Updated on 2025-12-29 by SolenoidFactory

Why Choosing the Right Solenoid Valve Factory Matters

In modern industrial automation, fluid control systems, and smart appliances, the fábrica de válvulas solenoides you choose directly impacts product reliability, lifecycle cost, and overall system performance. A solenoid valve is often a small component, but its failure can cause complete system shutdowns, safety risks, or costly recalls.

As global demand increases for customized, compact, and energy-efficient solenoid valves, OEM brands are no longer looking for generic suppliers. Instead, they seek a professional solenoid valve factory with strong engineering capability, stable manufacturing processes, and long-term cooperation experience.

SF é um profissional custom solenoid valve factory with more than 10 years of experience in manufacturing solenoid electromagnets and solenoid valves for global brands. This article provides a comprehensive, technical overview of how a solenoid valve factory operates, how to evaluate suppliers, and why experienced factories like SF are increasingly preferred by OEM customers worldwide.

What Is a Solenoid Valve Factory?

A fábrica de válvulas solenoides is a specialized manufacturing facility that designs, produces, tests, and supplies solenoid valves for various applications, including:

Automação industrial

Household appliances

Medical devices

Automotive systems

Water and gas control equipment

Unlike trading companies or assemblers, a true solenoid valve factory controls core processes, such as coil winding, magnetic circuit design, precision machining, assembly, and performance testing.

A professional solenoid valve factory integrates electromagnetic engineering, fluid dynamics, e mechanical design to ensure consistent valve operation under different pressures, temperatures, and duty cycles.

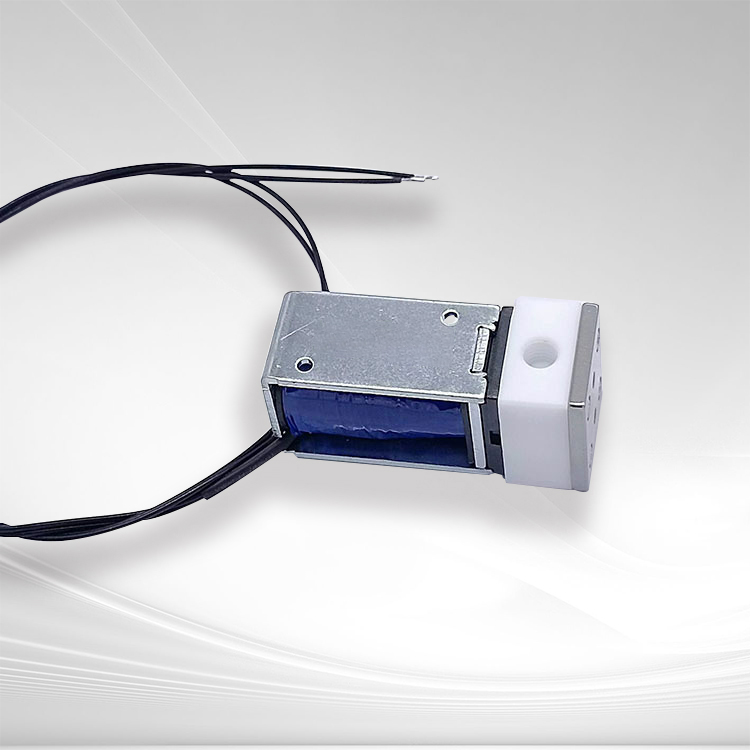

Core Components Manufactured by a Solenoid Valve Factory

To understand the capability of a fábrica de válvulas solenoides, it is important to understand the components it produces and controls internally.

Electromagnetic Coil Manufacturing in a Solenoid Valve Factory

The coil is the heart of any solenoid valve. A professional solenoid valve factory controls:

Copper wire grade and insulation class

Winding tension and turn count

Resistance tolerance

Thermal rise performance

At SF, all solenoid valve coils are produced in-house to ensure stable electromagnetic force and long service life.

Magnetic Circuit Design in a Solenoid Valve Factory

Magnetic circuit efficiency directly affects response time and power consumption. A qualified solenoid valve factory optimizes:

Core material selection

Armature geometry

Air gap tolerance

Magnetic saturation margin

These factors are critical for low-power solenoid valves used in smart appliances and IoT devices.

Valve Body and Sealing Systems

A solenoid valve factory must also master fluid control components, including:

Valve body materials (brass, stainless steel, engineering plastics)

Sealing materials (NBR, EPDM, FKM, silicone)

Seat structure and flow path design

SF’s solenoid valve factory customizes sealing solutions based on media type, pressure range, and temperature requirements.

Types of Products Offered by a Solenoid Valve Factory

A full-service fábrica de válvulas solenoides typically provides multiple valve categories:

Normally Closed and Normally Open Solenoid Valves

These are the most common products supplied by a solenoid valve factory for water, air, and gas control systems.

Direct-Acting Solenoid Valves

Used in low-pressure or zero-pressure-differential systems, direct-acting solenoid valves require precise magnetic force design.

Pilot-Operated Solenoid Valves

A professional solenoid valve factory designs pilot-operated valves for higher flow rates and industrial applications.

Custom Solenoid Valves for OEM Projects

Leading solenoid valve factories like SF focus on custom solenoid valve solutions, including:

Special voltage (12V, 24V, 110V, 220V)

Compact or low-noise designs

Long-life or high-frequency operation

Application-specific mounting structures

Why OEM Brands Prefer a Custom Solenoid Valve Factory

OEM brands increasingly avoid standard off-the-shelf valves. Instead, they partner with a personalizado fábrica de válvulas solenoides to gain competitive advantages.

Application-Specific Optimization

A custom solenoid valve factory tailors:

Flow rate

Response time

Power consumption

Acoustic noise

This level of optimization is impossible with generic products.

Supply Chain Stability

A professional solenoid valve factory provides stable mass production, long-term material sourcing, and predictable lead times—critical for appliance and industrial brands.

Engineering Collaboration

SF works directly with customer R&D teams, offering DFM (Design for Manufacturing) and DFA (Design for Assembly) support from early development stages.

Manufacturing Process Inside a Professional Solenoid Valve Factory

Understanding the internal workflow of a fábrica de válvulas solenoides helps buyers evaluate technical strength.

Step 1: Requirement Analysis

The solenoid valve factory reviews:

Media type

Pressure and temperature range

Voltage and duty cycle

Target lifecycle

Step 2: Electromagnetic and Mechanical Design

Using simulation tools, the solenoid valve factory optimizes magnetic force and mechanical movement.

Step 3: Prototype Development

Prototypes are built and tested for flow rate, response time, leakage, and thermal performance.

Step 4: Pilot Production

Small batch production validates assembly processes and quality stability.

Step 5: Mass Production and Quality Control

A professional solenoid valve factory implements 100% functional testing and statistical process control.

Quality Control Standards in a Solenoid Valve Factory

Quality control differentiates a reliable solenoid valve factory from low-cost suppliers.

At SF, the solenoid valve factory applies:

Incoming material inspection

Coil resistance and insulation testing

Valve leakage and pressure testing

Life-cycle endurance testing

Final functional testing before shipment

Compliance with ISO-based quality systems ensures consistent performance across production batches.

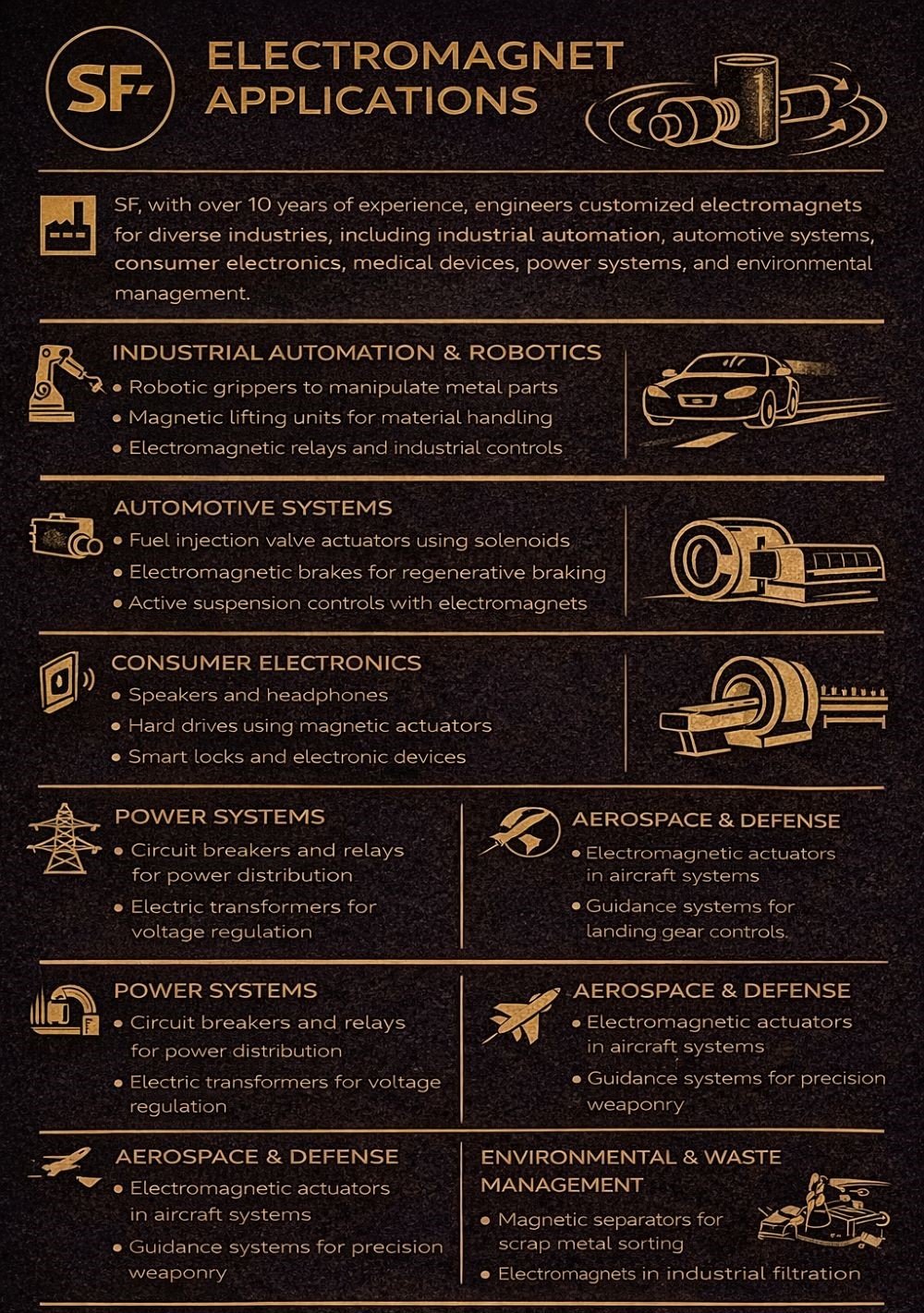

Applications Served by a Solenoid Valve Factory

Um profissional fábrica de válvulas solenoides supports a wide range of industries.

Household Appliances

Solenoid valve factory solutions are widely used in:

Washing machines

Dishwashers

Coffee machines

Refrigerators

Automação industrial

Factories rely on solenoid valve factory products for:

Pneumatic systems

Process control

Fluid automation

Medical and Healthcare Devices

Precision and reliability are critical in medical-grade solenoid valves.

Automotive and Transportation

Solenoid valve factory products support emission control, fluid management, and safety systems.

How to Evaluate a Solenoid Valve Factory

Ao selecionar um fábrica de válvulas solenoides, buyers should assess:

Years of manufacturing experience

In-house coil and magnetic design capability

Custom engineering support

Quality control and testing systems

OEM project references

SF’s solenoid valve factory meets all these criteria, making it a trusted partner for international brands.

Why SF Is a Trusted Solenoid Valve Factory

SF é um profissional fábrica de válvulas solenoides with more than 10 years of experience in solenoid electromagnet manufacturing.

Key advantages of SF include:

Full in-house production from coil to assembly

Strong custom design capability

Stable mass production for OEM customers

Strict quality control standards

Long-term cooperation with global brands

As a specialized solenoid valve factory, SF focuses on engineering-driven solutions, not just product supply.

Future Trends in the Solenoid Valve Factory Industry

The solenoid valve factory industry is evolving rapidly due to:

Energy efficiency requirements

Compact and lightweight designs

Smart and connected devices

Environmentally friendly materials

Factories that invest in R&D and customization, like SF, are better positioned for long-term growth.

Partnering with the Right Solenoid Valve Factory

Escolhendo o caminho certo fábrica de válvulas solenoides is a strategic decision that affects product quality, cost, and brand reputation. OEM brands increasingly favor experienced, engineering-focused factories that can deliver customized, reliable solutions.

With over a decade of experience, SF has established itself as a professional solenoid valve factory capable of supporting complex OEM projects across industries.

For brands seeking a long-term, technically competent solenoid valve factory partner, working with an experienced manufacturer like SF is a proven path to success.

Personalize todos os tipos de eletroímãs, entre em contato com a fábrica de eletroímãs SF whatsapp +86 189 0261 1680