Last Updated on 2025-04-11 by SolenoidFactory

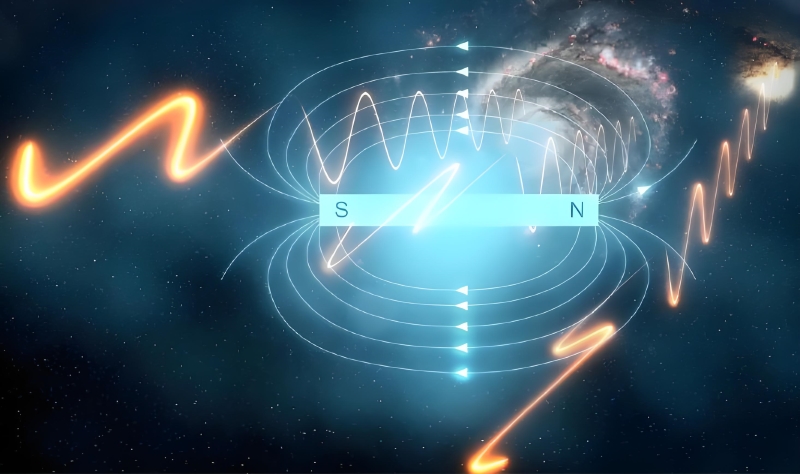

In the ever-evolving landscape of technology, electromagnetic interference (EMI) and electromagnetic compatibility (EMC) have become critical considerations in the design and operation of electrical and electronic devices. Among these devices, electromagnets play a pivotal role, often requiring robust electromagnet anti-interference abilities to function reliably in noisy environments. Similarly, electromagnetic shielding techniques are employed to protect sensitive components from the adverse effects of external electromagnetic fields. This blog delves into the intricacies of electromagnet anti-interference ability and electromagnetic shielding, providing a comprehensive guide that demystifies these concepts and explores their practical applications. By understanding these principles, engineers, designers, and hobbyists can enhance the performance and reliability of their electromagnetic devices, ensuring they operate seamlessly in a wide range of environments.

What is Electromagnet Anti-Interference Ability ?

Electromagnetic interference (EMI) occurs when an electromagnetic field emitted by one device or component affects the performance of another. This interference can manifest as noise, signal distortion, or even complete failure of electronic systems. Electromagnets, due to their inherent ability to generate strong magnetic fields, are particularly susceptible to both causing and being affected by EMI. Therefore, designing electromagnets with strong electromagnet anti-interference abilities is crucial for ensuring their reliable operation in noisy environments.

Sources of EMI:

- Internal Sources: These include the electromagnet’s own coil windings, which can radiate electromagnetic energy when excited by a current.

- External Sources: External sources of EMI can be other electrical devices, power lines, radio signals, or even natural phenomena like lightning.

Mechanisms of Interference:

- Conductive Coupling: EMI can be transferred through conductive paths, such as wires or metallic structures.

- Radiative Coupling: Electromagnetic fields can radiate through space and induce currents or voltages in nearby conductors, causing interference.

- Inductive Coupling: Changes in magnetic fields can induce voltages in nearby circuits, leading to interference.

Anti-Interference Strategies:

- Shielding: Using conductive materials to surround the electromagnet can effectively block or reduce the coupling of external electromagnetic fields.

- Filtering: Incorporating filters in the electromagnet’s circuitry can attenuate unwanted frequencies, preventing them from causing interference.

- Aterramento: Proper grounding techniques can ensure that interference currents are safely directed to earth, minimizing their impact on sensitive circuits.

- Design Optimization: Designing the electromagnet with consideration for EMC can involve techniques such as minimizing loop areas, using twisted pairs for wiring, and ensuring adequate spacing between components.

what is Electromagnetic Shielding: Practical Applications

Electromagnetic shielding is a fundamental technique used to protect sensitive components and circuits from the adverse effects of external electromagnetic fields. By creating a barrier between the source of the field and the protected component, shielding can significantly reduce or eliminate interference, ensuring reliable operation of electronic systems.

Types of Shielding:

- Conductive Shielding: Conductive materials, such as metals, are used to create a Faraday cage effect, blocking electromagnetic fields from penetrating the shielded area.

- Absorptive Shielding: Materials that absorb electromagnetic energy, such as ferrites, can be used to reduce the intensity of fields within a specific frequency range.

- Reflective Shielding: High-reflectivity materials can be used to reflect electromagnetic fields away from sensitive components, minimizing their impact.

Applications of Electromagnetic Shielding:

- Electronics and Communications: In communications systems, shielding is used to protect sensitive receiver circuits from interference caused by transmitters or other sources of EMI.

- Dispositivos médicos: Medical electronic devices, such as MRI machines and pacemakers, require rigorous shielding to prevent interference and ensure patient safety.

- Aerospace and Military: In aerospace and military applications, shielding is essential to protect electronic systems from electromagnetic pulses (EMPs) and other high-intensity electromagnetic threats.

- Power Systems: Power distribution systems often employ shielding to reduce interference between adjacent cables and to protect sensitive control circuits from noise generated by power transformers and other equipment.

- Eletrônicos de consumo: Consumer devices, such as smartphones, tablets, and laptops, incorporate shielding to protect internal circuits from interference caused by external signals and to ensure compliance with EMC standards.

Design Considerations for Electromagnetic Shielding:

- Seleção de materiais: The choice of shielding material depends on the frequency range of the electromagnetic fields to be shielded and the specific application requirements. Conductive materials like copper, aluminum, and steel are commonly used.

- Shielding Effectiveness: The effectiveness of a shielding material is determined by its conductivity, permeability, and thickness. At higher frequencies, materials with high conductivity are more effective, while at lower frequencies, permeability becomes more important.

- Shielding Geometry: The geometry of the shielding can significantly impact its effectiveness. For instance, a closed shielding structure, such as a Faraday cage, provides better protection than an open structure.

- Grounding and Bonding: Proper grounding and bonding of shielding materials are crucial for ensuring that interference currents are directed safely to earth, preventing them from circulating within the shielded area and causing interference.

-

Avaliação 0 de 5

Case Studies: Practical Applications of Electromagnet Anti-Interference and Shielding

To illustrate the practical application of electromagnet anti-interference abilities and electromagnetic shielding, let’s explore a few case studies:

MRI Machines: MRI machines generate powerful magnetic fields to image the human body. To protect patients and staff from the adverse effects of these fields, MRI rooms are equipped with thick, conductive shielding materials that create a Faraday cage effect, blocking external electromagnetic interference and preventing the MRI’s field from escaping the room.

Aerospace Communication Systems: In aerospace applications, communication systems must operate reliably in the presence of high-intensity electromagnetic interference from other systems and the external environment. Shielding techniques, such as the use of conductive gaskets and absorptive materials, are employed to protect sensitive receiver circuits from interference, ensuring clear communication.

Smartphones and Tablets: Consumer electronic devices, such as smartphones and tablets, incorporate shielding to protect internal circuits from interference caused by external signals, such as radio waves and Wi-Fi signals. This shielding is often integrated into the device’s casing and is designed to comply with international EMC standards.

Electric Vehicles: Electric vehicles (EVs) rely on complex electronic systems for control and communication. To protect these systems from interference caused by the vehicle’s own electric drive components, shielding techniques are employed, such as using shielded cables and incorporating grounding planes within the vehicle’s electrical system.

Electromagnet anti-interference ability and electromagnetic shielding are essential considerations

Electromagnet anti-interference ability and electromagnetic shielding are essential considerations in the design and operation of electrical and electronic devices. By understanding the principles of EMI and EMC, engineers and designers can develop strategies to mitigate interference and ensure reliable operation of their devices. Electromagnetic shielding techniques, such as conductive shielding, absorptive shielding, and reflective shielding, offer practical solutions for protecting sensitive components from external electromagnetic fields. Through case studies and practical applications, we can see how these principles are applied in real-world scenarios, ensuring the performance and reliability of a wide range of electronic systems. As technology continues to evolve, these concepts will remain critical in driving innovation and advancements in electromagnet design and manufacture, contributing to safer, more efficient, and more reliable electronic systems across diverse industries.

Sobre a fábrica de eletroímãs SF

A Shengfeng Electromagnet Co., Ltd. foi fundada em 2015 e está localizada no Parque Industrial de Xiansha, com belas paisagens e transporte conveniente. A empresa ocupa uma área de 16.000 metros quadrados e tem instalações de produção modernas, equipamentos de produção avançados e uma equipe técnica de alta qualidade. Desde sua fundação, sempre aderimos à filosofia corporativa de “inovação, qualidade e serviço”, com foco em pesquisa, desenvolvimento e produção de eletroímãs, A empresa está constantemente promovendo atualizações de produtos e progresso tecnológico, além de fornecer aos clientes produtos e serviços da melhor qualidade.

Por que escolher o eletroímã SF

QUALIDADE DE PONTA:Como o melhor fabricante de eletroímãs solenoides da China, nossa equipe de controle de qualidade garantirá que todos os produtos que você receber sejam da melhor qualidade. Temos uma máquina de teste de qualidade profissional.

DESIGN DO PRODUTO:Nosso departamento de amostragem tem um processo completo de transformar desenhos em realidade. Também aprimoramos o design do seu produto com base em nossos anos de experiência de trabalho.

TEMPO DE ENTREGA ESTÁVEL:Como o melhor fabricante e fornecedor de eletroímãs, temos capacidade de fabricação suficiente, grandes pedidos não nos vencem e ainda podemos entregar o pedido a tempo.

MELHOR PREÇO:Somos uma fábrica de fontes de eletroímãs e o melhor fabricante de solenóides da China, por isso podemos fornecer bolsas de alta qualidade com o melhor preço.

GERENCIAMENTO PRECISO:Nada pode ser alcançado se não implementarmos um gerenciamento preciso. Somos uma empresa com um sistema de gerenciamento completo.

7-24 SERVIÇO:Como o melhor fabricante de solenóides, resposta imediata 24 horas por dia, 7 dias por semana: Receberemos seu feedback para nos tornar um fornecedor melhor.

Perguntas frequentes sobre o eletroímã

Somos uma empresa chinesa de ponta eletroímã e nossa fábrica está localizada em Dongguan. Bem-vindo a visitar nossa fábrica!

Somos especializados no design e na produção de produtos de alta qualidade eletroímã,válvula solenoide,como solenoide rotativo, solenoides biestáveis, solenoides de travamento, solenoides de estrutura aberta, solenoides tubulares, solenoide de retenção automática

-É claro que, normalmente, fornecemos amostras grátis, e você só precisa arcar com o frete. Para amostras personalizadas de eletroímãs, envie-nos seus requisitos para verificarmos o custo da amostra.

- A produção de amostras leva cerca de 7 dias.

Sim, fornecemos serviços gratuitos de design, design estrutural e design gráfico simples.

Claro, podemos fazer qualquer eletroímã com seu projeto. Agora, abrimos um solenoide ODM que é para pequenas quantidades de 100 a 500 unidades, mas você ainda pode ter seu próprio logotipo.

Dependendo da quantidade do pedido e dos detalhes da produção, o prazo é de 15 a 20 dias.

Sempre uma amostra de pré-produção antes da produção em massa; sempre a inspeção final antes do envio

- Potência, uso, tamanho, material, quantidade, destino da remessa, etc.

- Você também pode simplesmente nos informar suas necessidades e nós recomendaremos produtos para você.

- Por via marítima, aérea ou expressa.

- Se você tiver seu próprio despachante na China, esse é o preço à saída da fábrica ou FOB.

-CFR ou CIF, etc., se precisar que façamos o envio em seu nome.

- DDP e DDU também podem ser usados.

- Mais opções, consideraremos suas opções.

- O preço é determinado pela quantidade, material, método de processamento, tamanho e outros fatores. Além disso, devido à nossa contínua

inovação tecnológica, os preços de alguns de nossos produtos são extremamente competitivos; entre em contato conosco para fazer uma cotação.