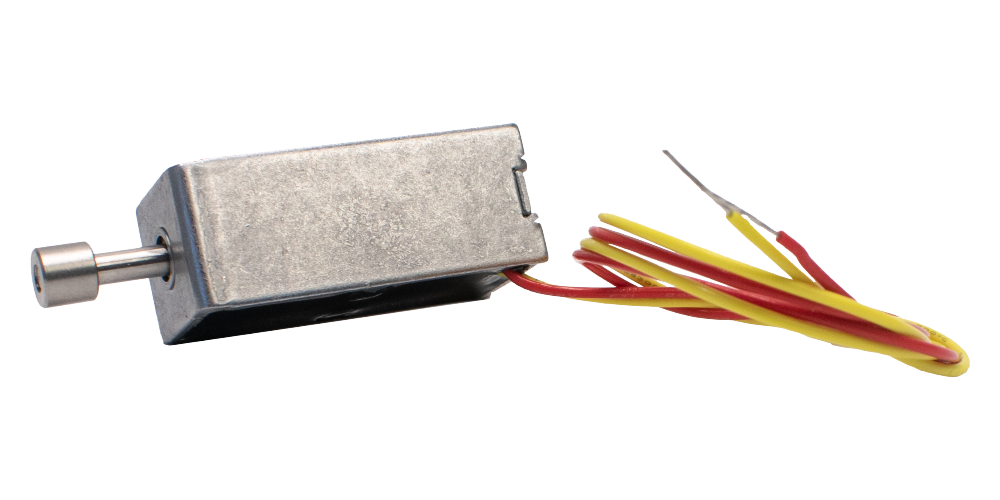

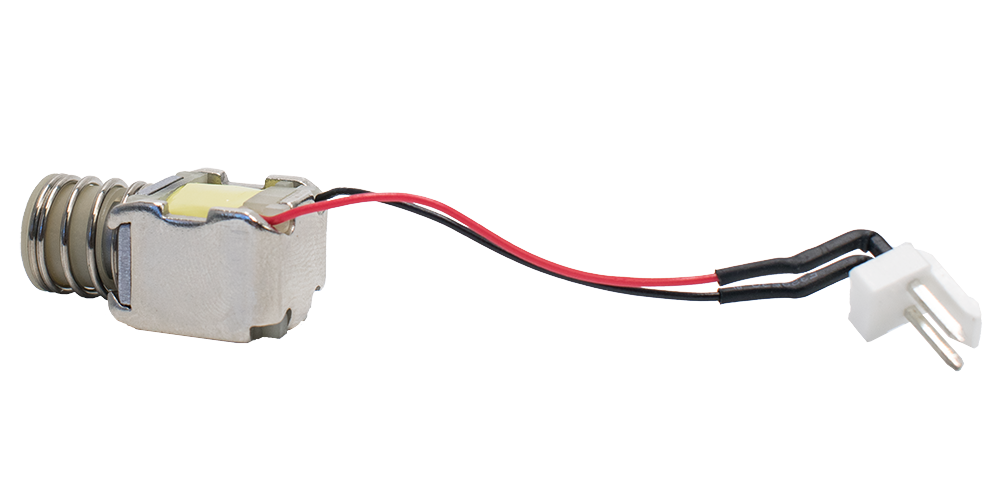

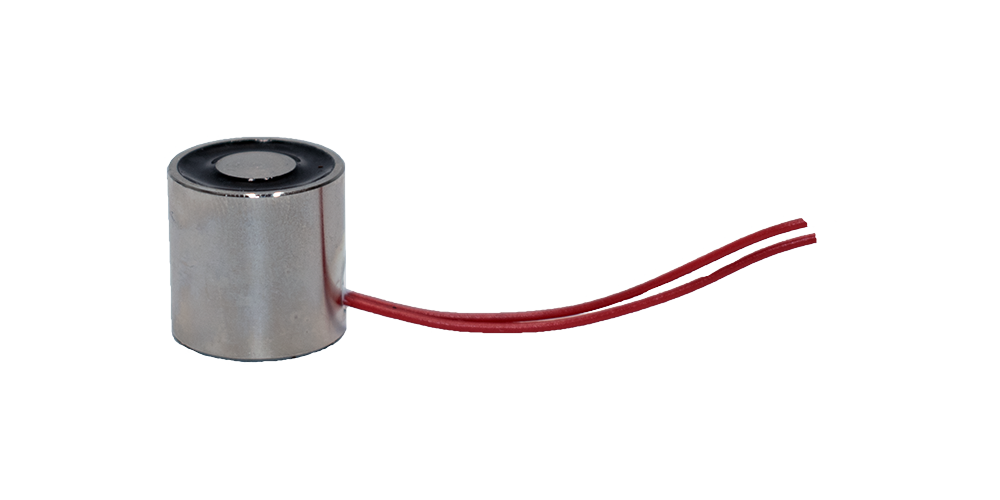

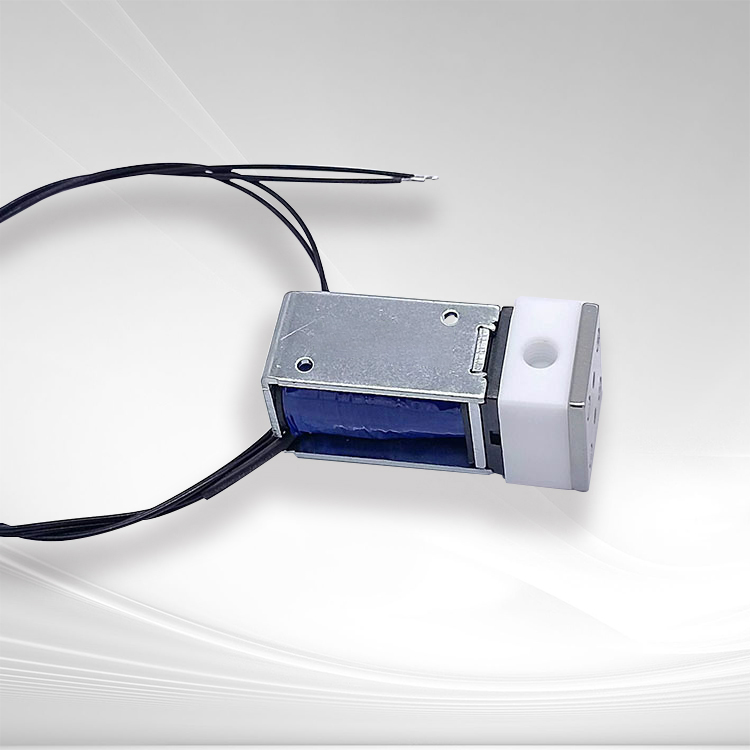

Product Category: Solenoid Valve

Rated Voltage: DC 24v/(Customized)

Rated Power: 5.76w

Current: 0.24A

Temperature Rang: -10℃-85℃

Duty Circle: 25%

Vida útil: 0,5 milhão de ciclos (10%)

Dimension: 75*35*25 mm

O princípio de funcionamento do Válvula solenoide é controlar a abertura e o fechamento do núcleo da válvula por meio do campo magnético gerado pela bobina eletromagnética, controlando assim o fluxo do fluido. Especificamente, quando a válvula solenoide é energizada, a bobina eletromagnética gera uma força eletromagnética, que atua no núcleo da válvula para mover e abrir a válvula; quando a energia é desligada, a força eletromagnética desaparece, e o núcleo da válvula é reiniciado sob a ação da mola para fechar a válvula.

1.1.1-Electrification and de-energization of the coil: When the coil of the solenoid valve is energized, a magnetic field is generated, which interacts with the ferromagnetic material in the valve core to generate a torque, causing the valve core to move. When the coil is de-energized, the magnetic field disappears, and the valve core returns to its initial position under the action of the reset spring.

1.1.2-Fluid control: The valve body of the solenoid valve is usually provided with two inlet and outlet interfaces, as well as one or more control ports. When the coil is energized, the valve core is displaced, so that the channel between the inlet and outlet is opened or closed, and at the same time connected or disconnected with the control port, thereby realizing the on-off control of the fluid.

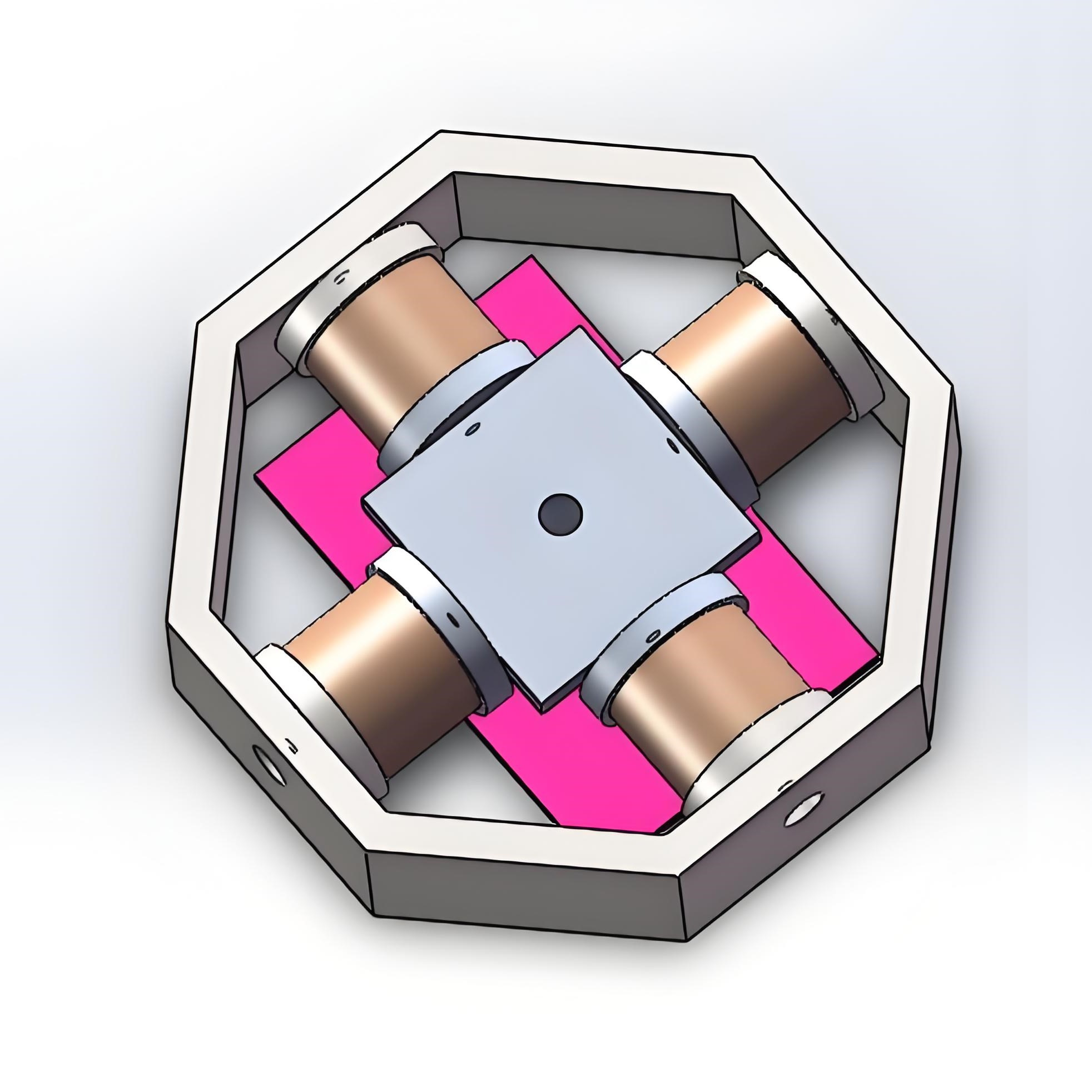

Solenoid Valve is a device driven by an electromechanical solenoid, and its structural components mainly include the following parts:

1.2.1-Coil: A coil frame made of non-magnetic material, which is wound to form a coil. The coil is one of the core components of the solenoid valve, and generates a magnetic field through current to drive other components.

1.2.2-Ends: Adjacent to both ends of the coil, it is made of a magnetic material. These ends will generate magnetic force when energized, thereby driving the valve to open or close.

1.2.3-Yoke: A magnetic material surrounding the coil and the ends. The function of the yoke is to concentrate the magnetic field and enhance the magnetic effect.

1.2.4-Plunger: Slides freely in the hollow part formed radially inward of the coil frame and the end. The plunger realizes the opening and closing function of the valve through magnetic force.

1.2.5-Sealing components: Including sealing surfaces, packings and valve stems, etc., to ensure the sealing performance of the valve when it is opened or closed and prevent medium leakage.

As vantagens de Válvula solenoide incluem principalmente os seguintes aspectos:

1.3.1-Wide application field: Solenoid valves are widely used in various industrial control systems for fine adjustment of the direction, flow rate, speed, etc. of the medium. They are not limited to hydraulic or pneumatic systems, but also widely used in washing equipment, biopharmaceuticals, refrigeration, HVAC, water plants, and environmental water treatment industries.

1.3.2-Efficient working performance: Solenoid valves can maintain normal operation under vacuum, negative pressure and zero pressure environments, and are particularly suitable for gas fluid control, such as air, tap water, gas, coal gas, diesel, low-pressure steam and hot water pipelines.

1.3.3-Simple structure and high reliability: Solenoid valves usually have the characteristics of simple structure and high reliability. For example, imported direct-acting solenoid valves are small in size, exquisite in appearance, strong in resistance to action fatigue, special coils are not easy to burn, piston rings are scientifically designed, made of special materials, and will not be stuck by the medium.

1.3.4-Easy to install and maintain: Many solenoid valves are designed to be repaired online and do not need to be removed from the pipeline, which greatly simplifies maintenance work.

1.3.5-Various types and specifications: There are many types of solenoid valves, including direct-acting, distributed direct-acting and pilot-operated, each of which has its specific application scenarios and advantages. For example, direct-acting solenoid valves can maintain normal operation in vacuum, negative pressure and zero pressure environments, but their diameter is usually not more than 25 mm.

1.3.6-Energy saving and environmental protection: Solenoid valves usually have lower power consumption, which helps to reduce energy consumption and operating costs. In addition, their good sealing performance and long life further reduce maintenance costs and environmental impact.

Válvula solenoide is a device that uses electromagnetic force to control the flow of liquid or gas, and is widely used in automatic control systems. According to different classification standards, solenoid valves can be divided into the following categories:

1.4.1-Classification by control method:

Direct-acting solenoid valve: Directly convert electrical signals into magnetic force, and control the on-off state of medium flow through the valve core or valve plate. Suitable for low-pressure and small flow occasions.

Indirect solenoid valve: By first converting electrical signals into mechanical movement, and then controlling the flow state of the medium through mechanical movement. Suitable for high-pressure and large flow occasions.

1.4.2-Classification by valve structure:

Straight-through solenoid valve: The medium flows directly through the valve from the inlet and is directly discharged.

Angle solenoid valve: The direction of the medium flowing through the valve needs to change.

Balanced solenoid valve: The flow of the medium is adjusted by balancing the position of the valve core.

1.4.3-Classification by the number of valve channels:

Two-way solenoid valve: There are only two states of on and off, which are used to control the on and off of unidirectional media.

Three-way solenoid valve: has two passages and one cut-off passage, used to control the mixing or diversion of two media.

Four-way solenoid valve: has two inlets and two outlets, can control the intersection and mixing of two media

1.4.4-Classification by function:

Ordinary solenoid valve: can only control the on and off of the medium, used for simple switch control.

Proportional solenoid valve: can accurately control the flow size of the medium, used in systems that require precise control

| Especificações | |||

| Marca | Personalizado | Nome do produto | Válvula solenoide |

| Modelo | SFSV-003 | Tensão nominal | DC 12v 24v |

| Potência | 5.76w | Current | 0.24A |

| Suitable medium | Air/Hydraulic | Ciclo de trabalho | 50-100% |

| Comprimento do cabo | Personalizado | Material | Metal, peças eletrônicas |

| Temperature Rang | -10℃-85℃ | Peso (N.W.) | 0.06kg |

| Estilo de instalação | Parafuso | Size | 75*35*25mm |

| Teste Hi-Pot | AC 600V 50/60Hz 2s | Resistance | 100Ω |

A forte resistência da mola é alta, o uso repetido ainda é elástico, para garantir que cada expansão possa entrar e sair rapidamente

O uso de bobina de cobre de padrão nacional, componentes de núcleo enrolado, dissipação de calor mais rápida, baixo consumo de energia, baixa temperatura, uso prolongado, melhora a eficiência do eletroímã e prolonga a vida útil

Instalação fácil e conveniente, a rosca do parafuso é fixa, a instalação é estável, a desmontagem é conveniente, economizando tempo e trabalho

Bom desempenho de dissipação de calor: O uso de matérias-primas de alta qualidade, duráveis, boa dissipação de calor, sem medo de grandes mudanças de diferença de temperatura, sem potência magnética remanescente

O Solenoid Valve electromagnet é um componente eletrônico personalizado não padronizado. Com exceção da estrutura da bobina, que é moldada, outros acessórios e parâmetros podem ser personalizados conforme necessário.

Processo de personalização:

4.1. Entre em contato conosco: Envie um e-mail ou WhatsApp para entrar em contato conosco(+86 18902611680)

4.2. Fornecer requisitos: Forneça parâmetros como tensão, força, curso, relação liga-desliga e tamanho.

4.3. Confirmação da especificação: Selecionamos e emitimos especificações de acordo com os requisitos. Com exceção do tamanho da estrutura externa, outros tamanhos e comprimentos de eixo podem ser personalizados. Se for feito de acordo com um tamanho específico de estrutura externa, será necessário abrir um molde.

4.4. Prova: Fazemos amostras de acordo com as especificações, e o ciclo de produção é de aproximadamente 7 dias.

4.5. Teste de amostras: Se o teste da amostra for qualificado, será feito um pedido de lote. Se não for qualificado, a amostra será refeita.

4.6. Produção em massa: Assinar um contrato de compra e venda em massa.

Solenoid Valve has a wide range of applications, covering multiple industrial fields and life application scenarios.

5.1-Application in the industrial field

5.1.1-Water treatment system: Solenoid valves are used in water treatment systems to automatically control the switching and flow regulation of fluids to ensure the stable operation of the system.

5.1.2-Refrigeration and air-conditioning system: In refrigeration and air-conditioning systems, solenoid valves are used to control the flow of refrigerants to achieve temperature regulation and system protection.

5.1.3-Compressed air system: Used to control the flow of compressed air to achieve automatic control.

5.1.4-Industrial manufacturing: In industrial manufacturing fields such as machine tools, metallurgical equipment, and pharmaceutical equipment, solenoid valves are used to control the flow of industrial fluids to improve production efficiency and product quality.

5.1.5-Automotive industry: In automotive components such as engine control systems, braking systems, and transmissions, solenoid valves are used to control the flow of various liquids and gases to ensure the normal operation and performance of automotive systems.

5.2- Application scenarios in daily life

5.2.1- Household appliances: In household appliances such as washing machines, dishwashers, and water dispensers, solenoid valves are used to realize automatic switching and flow control of water flow, improving the intelligence and convenience of products.

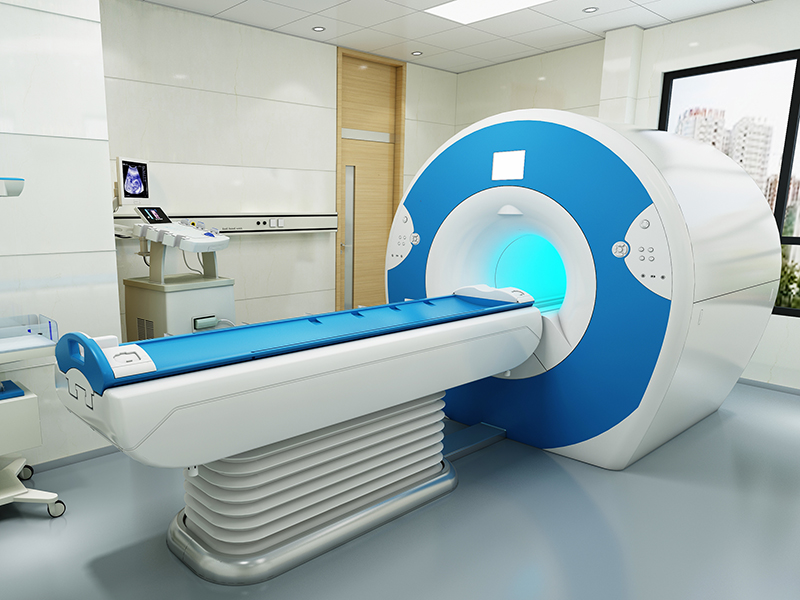

5.2.2- Medical equipment: In medical equipment such as ventilators and infusion pumps, solenoid valves are used to achieve precise control and regulation of fluids to provide support for medical treatment.

5.3- Specific types and application scenarios

5.3.1- Ball valve: Controls flow by rotating a sphere with holes, suitable for water treatment, petrochemical, natural gas pipelines and other fields.

5.3.2- Gate valve: Controls the switch of fluid by lifting the gate, suitable for large-diameter, high-pressure pipelines.

5.3.3- Butterfly valve: Compact structure, small size, light weight, suitable for large-diameter, low-pressure pipeline systems.

5.3.4- Stop valve: Controls fluid by rotating the handwheel to move the valve disc up and down, suitable for working conditions where flow adjustment is required.

5.3.5-Check valve: prevents medium from flowing back, widely used in pipes such as pump outlets and drainage systems that need to prevent backflow.

5.3.6-Safety valve: automatically opens to release pressure when system pressure exceeds the set value, protecting equipment and systems from overpressure damage.

Nossa sede está localizada em Guangdong, China. Desde 2015, desenvolvemos e produzimos eletroímãs e os vendemos para a América do Norte (35.00%), Sul da Ásia (25.00%), Europa Ocidental (20.00%), América do Sul (15.00%), Norte da Europa (5.00%).

Somos um dos principais fabricantes chineses e nossa fábrica está localizada em Dongguan. Bem-vindo a visitar nossa fábrica!

Somos especializados no projeto e na produção de eletroímãs e válvulas solenoides de alta qualidade, como solenoides rotativos, solenoides biestáveis, solenoides de travamento, solenoides de estrutura aberta, solenoides tubulares, solenoides de retenção automática.

-É claro que, normalmente, fornecemos amostras grátis, e você só precisa arcar com o frete. Para amostras personalizadas de eletroímãs, envie-nos seus requisitos para verificarmos o custo da amostra.

- A produção de amostras leva cerca de 7 dias.

Sim, fornecemos serviços gratuitos de design, design estrutural e design gráfico simples.

Claro, podemos fazer qualquer eletroímã com seu projeto. Agora, abrimos um solenoide ODM que é para pequenas quantidades de 100 a 500 unidades, mas você ainda pode ter seu próprio logotipo.

Dependendo da quantidade do pedido e dos detalhes da produção, o prazo é de 15 a 20 dias.

Sempre uma amostra de pré-produção antes da produção em massa; sempre a inspeção final antes do envio

- Potência, uso, tamanho, material, quantidade, destino da remessa, etc.

- Você também pode simplesmente nos informar suas necessidades e nós recomendaremos produtos para você.

- Por via marítima, aérea ou expressa.

- Se você tiver seu próprio despachante na China, esse é o preço à saída da fábrica ou FOB.

-CFR ou CIF, etc., se precisar que façamos o envio em seu nome.

- DDP e DDU também podem ser usados.

- Mais opções, consideraremos suas opções.

Use nossa experiência profissional em design para personalizar o eletroímã de sua marca!