Última atualização em 2025-09-03 por SolenoidFactory

In the ever-evolving landscape of industrial automation, one technology stands out for its versatility, precision, and reliability: sugadores eletromagnéticos. These innovative devices have become indispensable in automated production lines across various industries, from automotive manufacturing to electronics assembly. This comprehensive blog post delves into the world of electromagnetic suckers, exploring their function, benefits, technological advancements, applications, and future trends. By the end, you’ll have a comprehensive understanding of why electromagnetic suckers are essential tools in modern automated production lines.

Understanding Electromagnetic Suckers

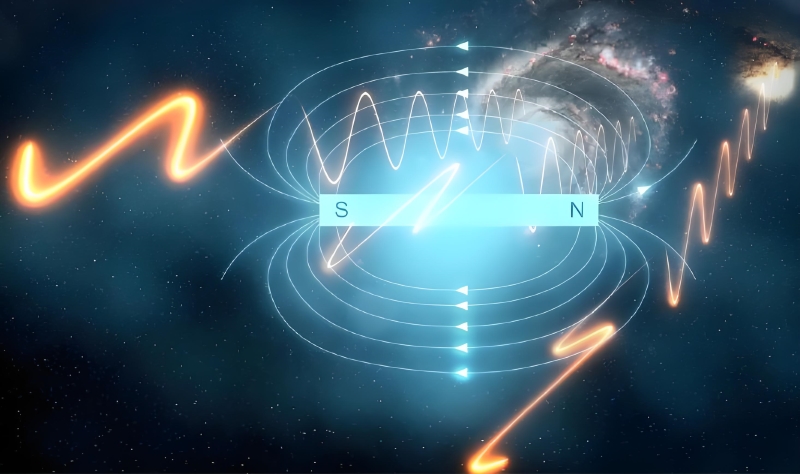

Electromagnetic suckers, also known as electromagnetic lifters or electromagnetic clamping devices, utilize electromagnetic force to hold and manipulate objects. When an electric current passes through a coil wound around a ferromagnetic core, it generates a magnetic field. This magnetic field can attract ferromagnetic materials, such as iron, nickel, and cobalt, creating a strong suction force. By controlling the flow of electric current, electromagnetic suckers can be activated and deactivated with remarkable precision and speed.

In automated production lines, electromagnetic suckers are often mounted on robotic arms or conveyor belts, enabling them to pick up, move, and place objects with high accuracy and repeatability. They are particularly useful for handling flat or curved surfaces, as well as for lifting and transporting heavy loads.

Function and Operation of Electromagnetic Suckers

Electromagnetic suckers function based on the principle of electromagnetic induction. When an electric current flows through a coil of wire, it creates a magnetic field. This magnetic field can attract ferromagnetic objects, creating a suction force that holds the object in place. To release the object, the current is discontinued, causing the magnetic field to collapse and the suction force to diminish.

In automated production lines, electromagnetic suckers are typically controlled by programmable logic controllers (PLCs) or industrial computers. These controllers send signals to activate or deactivate the electromagnetic suckers, coordinating their movement with other components of the automated system. Sensors and cameras may also be used to monitor the position and orientation of the objects being handled, ensuring precise and reliable operation.

Benefits of Using Electromagnetic Suckers in Automated Production Lines

O uso de sugadores eletromagnéticos in automated production lines offers several significant benefits, driving efficiency, precision, and cost savings:

Versatilidade: Electromagnetic suckers can handle a wide range of materials, including sheet metal, glass, and plastics. This versatility makes them ideal for use in diverse industries and applications.

Precision and Accuracy: Electromagnetic suckers provide exceptional precision and accuracy in handling objects. They can be activated and deactivated with millisecond timing, enabling rapid and reliable movement of objects in automated production lines.

Non-Contact Handling: Unlike mechanical grippers or clamps, electromagnetic suckers do not require physical contact with the object being handled. This reduces wear and tear on both the sucker and the object, extending their useful life and reducing maintenance costs.

Load Capacity: Electromagnetic suckers can handle heavy loads, making them suitable for applications that require lifting and transporting significant weights.

Eficiência energética: Advances in electromagnet design and materials science have led to more energy-efficient electromagnetic suckers. These devices consume less power, reducing energy costs and minimizing environmental impact.

Scalability and Flexibility: Electromagnetic suckers can be scaled to suit various sizes and weights of objects. They can also be integrated with other automation components, such as conveyors, robots, and sensors, to create highly flexible and adaptable automated production lines.

Technological Advancements in Electromagnetic Suckers

O campo de sugadores eletromagnéticos is constantly evolving, driven by technological advancements and increasing demand for automation in industrial settings. Here are some of the most significant developments in this area:

Smart Sensors and Controls: Modern electromagnetic suckers incorporate smart sensors and controls that monitor their operation in real-time. These sensors provide feedback on the position, orientation, and load of the object being handled, enabling precise control and error detection.

Enhanced Materials and Coatings: Advances in materials science have led to the development of stronger, more durable cores and coils for electromagnetic suckers. Coatings that resist wear, corrosion, and heat are also becoming more prevalent, extending the useful life of these devices.

Coleta de energia: Energy harvesting technologies, which capture and convert ambient energy into electrical power, have the potential to revolutionize electromagnetic suckers. By incorporating energy harvesting components, these devices can become even more energy-efficient and self-sustaining.

Modular and Scalable Designs: Manufacturers are increasingly offering modular and scalable designs for electromagnetic suckers. This enables customers to configure devices to suit their specific needs, facilitating easy integration and adaptation in diverse automated production lines.

Applications of Electromagnetic Suckers in Automated Production Lines

Electromagnetic suckers have a wide range of applications in automated production lines, spanning various industries and processes. Here are some examples:

Automotive Manufacturing: Electromagnetic suckers are commonly used in automotive manufacturing for handling sheet metal parts, such as body panels and chassis components. They enable rapid and reliable assembly of vehicles, improving production efficiency and quality.

Electronics Assembly: In the electronics industry, electromagnetic suckers are used for picking up and placing components, such as integrated circuits and printed circuit boards. Their precision and accuracy make them ideal for delicate assembly tasks, reducing the risk of damage to sensitive components.

Glass and Window Manufacturing: Electromagnetic suckers are essential in the glass and window manufacturing industry for lifting and transporting large, heavy sheets of glass. They provide a safe and efficient means of handling these materials, minimizing the risk of breakage and injury.

Packaging and Labeling: In packaging and labeling applications, electromagnetic suckers are used to pick up and apply labels, tags, and other adhesive materials. Their ability to handle flat surfaces with precision makes them ideal for these tasks, ensuring accurate and consistent labeling.

Material Handling and Logistics: Electromagnetic suckers play a critical role in material handling and logistics operations, such as warehousing and distribution centers. They enable the rapid and reliable movement of goods, improving efficiency and reducing labor costs.

Case Studies: Real-World Applications of Electromagnetic Suckers

To better understand the role of sugadores eletromagnéticos in automated production lines, let’s examine a few real-world applications:

Automated Sheet Metal Handling: A leading automotive manufacturer implemented electromagnetic suckers in its automated sheet metal handling system. These devices enabled the rapid and reliable pick-up and placement of sheet metal parts, improving production efficiency by 30% and reducing labor costs.

Automated Electronics Assembly: An electronics manufacturer incorporated electromagnetic suckers into its automated assembly line for handling integrated circuits. The precision and accuracy of these devices enabled the manufacturer to achieve defect rates below 0.1%, significantly improving product quality and customer satisfaction.

Automated Glass Handling: A glass manufacturing company utilized electromagnetic suckers to automate the handling of large sheets of glass. This reduced the risk of breakage and injury, improving workplace safety and productivity.

Future Trends and Innovations in Electromagnetic Suckers

As industrial automation continues to evolve, we can expect to see further innovations in sugadores eletromagnéticos. Here are some of the most exciting trends on the horizon:

Integration with Advanced Robotics: Electromagnetic suckers will increasingly be integrated with advanced robotics systems, enabling more complex and sophisticated handling tasks. This will drive further efficiency and precision in automated production lines.

Enhanced Sensors and Controls: Future electromagnetic suckers will incorporate even more advanced sensors and controls, providing real-time monitoring and feedback on their operation. This will enable predictive maintenance, reducing downtime and extending the useful life of these devices.

Material Handling Automation: Electromagnetic suckers will play a critical role in the ongoing automation of material handling operations, such as warehousing and distribution centers. They will enable the rapid and reliable movement of goods, improving efficiency and reducing labor costs.

Sustainability and Eco-friendliness: Manufacturers will continue to focus on developing electromagnetic suckers that are sustainable and eco-friendly. This may involve using more energy-efficient components, incorporating recyclable materials, and reducing the overall carbon footprint of these devices.

Customizable and Configurable Designs: Future electromagnetic suckers will likely feature customizable and configurable designs, enabling customers to tailor devices to suit their specific needs. This will facilitate easy integration and adaptation in diverse automated production lines, driving further efficiency and cost savings.

Electromagnetic suckers are revolutionizing industrial automation

Electromagnetic suckers are revolutionizing industrial automation, driving efficiency, precision, and cost savings in automated production lines across various industries. By utilizing electromagnetic force to handle objects with high accuracy and repeatability, these devices enable rapid and reliable assembly, packaging, and material handling tasks. As technological advancements continue to drive innovation in this field, we can expect to see even more exciting developments in electromagnetic suckers in the coming years.

In conclusion, electromagnetic suckers are essential tools in modern automated production lines, driving the future of industrial automation. By staying informed and proactive about the latest advancements and applications of these devices, you can stay ahead of the curve, ensuring your production processes remain competitive and efficient. With their versatility, precision, and reliability, electromagnetic suckers will continue to play a critical role in shaping the future of industrial automation.

Sobre a fábrica de eletroímãs SF

A Shengfeng Electromagnet Co., Ltd. foi fundada em 2015 e está localizada no Parque Industrial de Xiansha, com belas paisagens e transporte conveniente. A empresa ocupa uma área de 16.000 metros quadrados e tem instalações de produção modernas, equipamentos de produção avançados e uma equipe técnica de alta qualidade. Desde sua fundação, sempre aderimos à filosofia corporativa de “inovação, qualidade e serviço”, com foco em pesquisa, desenvolvimento e produção de eletroímãs, A empresa está constantemente promovendo atualizações de produtos e progresso tecnológico, além de fornecer aos clientes produtos e serviços da melhor qualidade.

Por que escolher o eletroímã SF

QUALIDADE DE PONTA:Como o melhor fabricante de eletroímãs solenoides da China, nossa equipe de controle de qualidade garantirá que todos os produtos que você receber sejam da melhor qualidade. Temos uma máquina de teste de qualidade profissional.

DESIGN DO PRODUTO:Nosso departamento de amostragem tem um processo completo de transformar desenhos em realidade. Também aprimoramos o design do seu produto com base em nossos anos de experiência de trabalho.

TEMPO DE ENTREGA ESTÁVEL:Como o melhor fabricante e fornecedor de eletroímãs, temos capacidade de fabricação suficiente, grandes pedidos não nos vencem e ainda podemos entregar o pedido a tempo.

MELHOR PREÇO:Somos uma fábrica de fontes de eletroímãs e o melhor fabricante de solenóides da China, por isso podemos fornecer bolsas de alta qualidade com o melhor preço.

GERENCIAMENTO PRECISO:Nada pode ser alcançado se não implementarmos um gerenciamento preciso. Somos uma empresa com um sistema de gerenciamento completo.

7-24 SERVIÇO:Como o melhor fabricante de solenóides, resposta imediata 24 horas por dia, 7 dias por semana: Receberemos seu feedback para nos tornar um fornecedor melhor. Entre em contato conosco WhatsApp +86 18902611680

Perguntas frequentes sobre o eletroímã

Somos uma empresa chinesa de ponta eletroímã e nossa fábrica está localizada em Dongguan. Bem-vindo a visitar nossa fábrica!

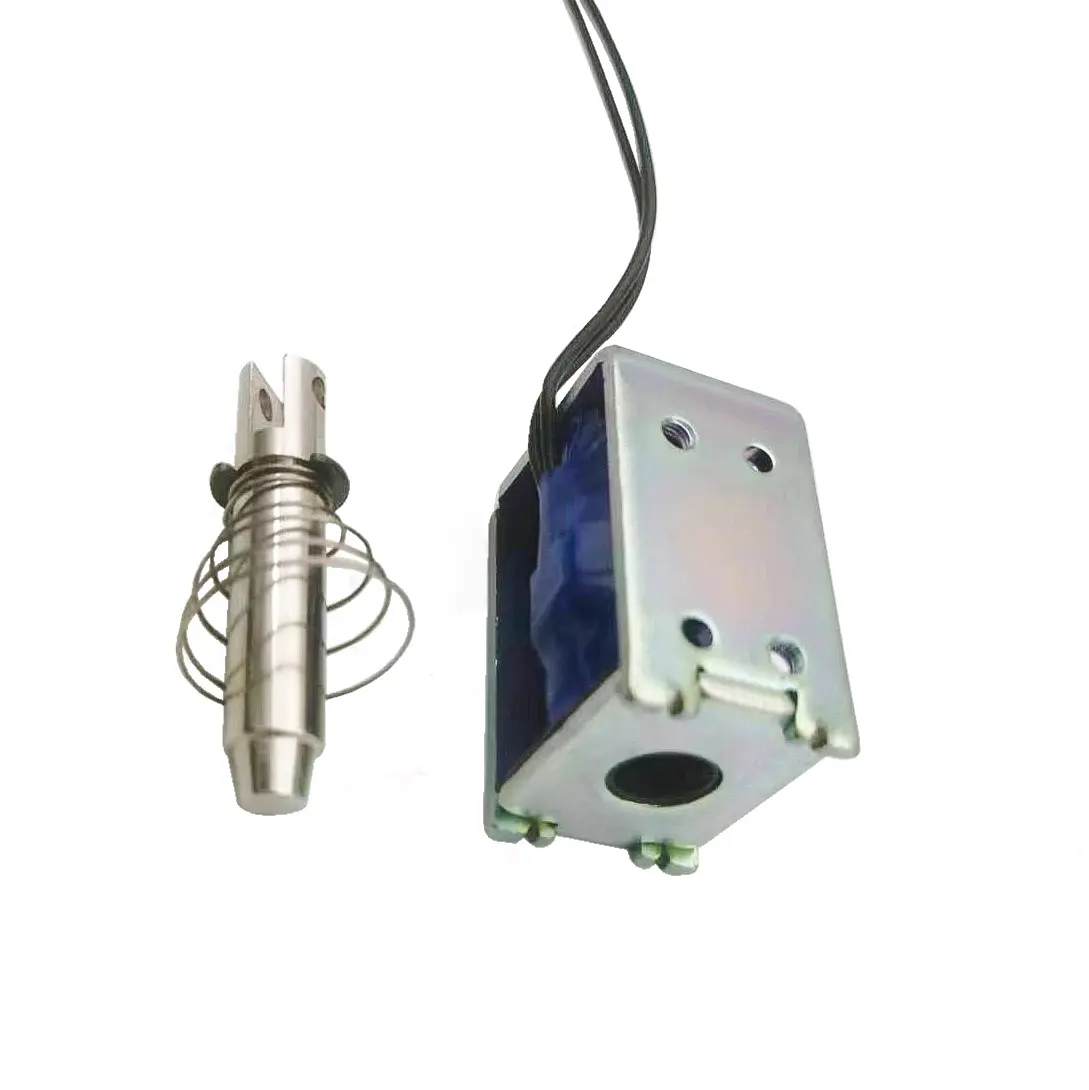

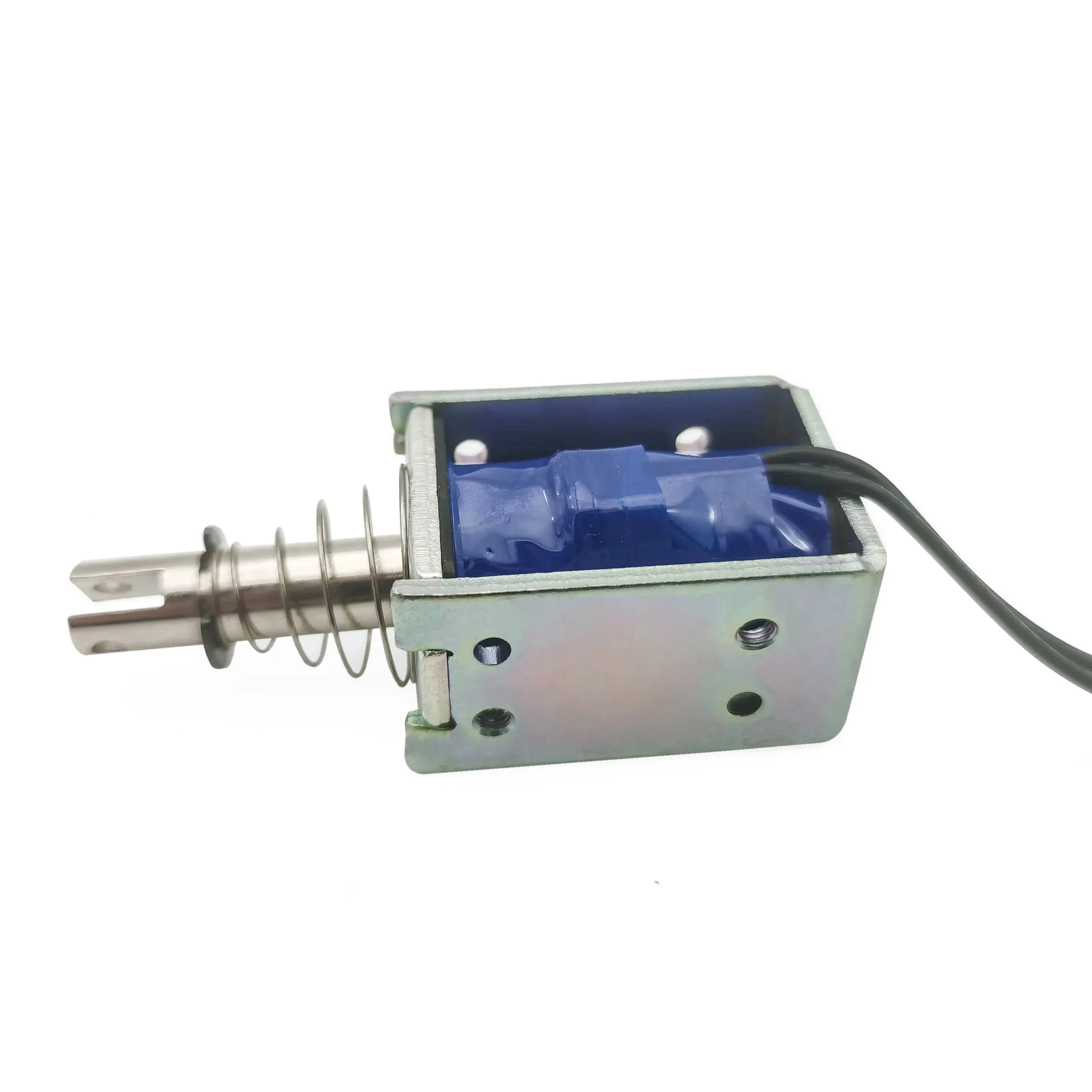

Somos especializados no design e na produção de produtos de alta qualidade eletroímã,válvula solenoide,como solenoide rotativo, solenoides biestáveis, solenoides de travamento, solenoides de estrutura aberta, solenoides tubulares, solenoide de retenção automática

-É claro que, normalmente, fornecemos amostras grátis, e você só precisa arcar com o frete. Para amostras personalizadas de eletroímãs, envie-nos seus requisitos para verificarmos o custo da amostra.

- A produção de amostras leva cerca de 7 dias.

Sim, fornecemos serviços gratuitos de design, design estrutural e design gráfico simples.

Claro, podemos fazer qualquer eletroímã com seu projeto. Agora, abrimos um solenoide ODM que é para pequenas quantidades de 100 a 500 unidades, mas você ainda pode ter seu próprio logotipo.

Dependendo da quantidade do pedido e dos detalhes da produção, o prazo é de 15 a 20 dias.

Sempre uma amostra de pré-produção antes da produção em massa; sempre a inspeção final antes do envio

- Potência, uso, tamanho, material, quantidade, destino da remessa, etc.

- Você também pode simplesmente nos informar suas necessidades e nós recomendaremos produtos para você.

- Por via marítima, aérea ou expressa.

- Se você tiver seu próprio despachante na China, esse é o preço à saída da fábrica ou FOB.

-CFR ou CIF, etc., se precisar que façamos o envio em seu nome.

- DDP e DDU também podem ser usados.

- Mais opções, consideraremos suas opções.

- O preço é determinado pela quantidade, material, método de processamento, tamanho e outros fatores. Além disso, devido à nossa contínua

inovação tecnológica, os preços de alguns de nossos produtos são extremamente competitivos; entre em contato conosco para fazer uma cotação.