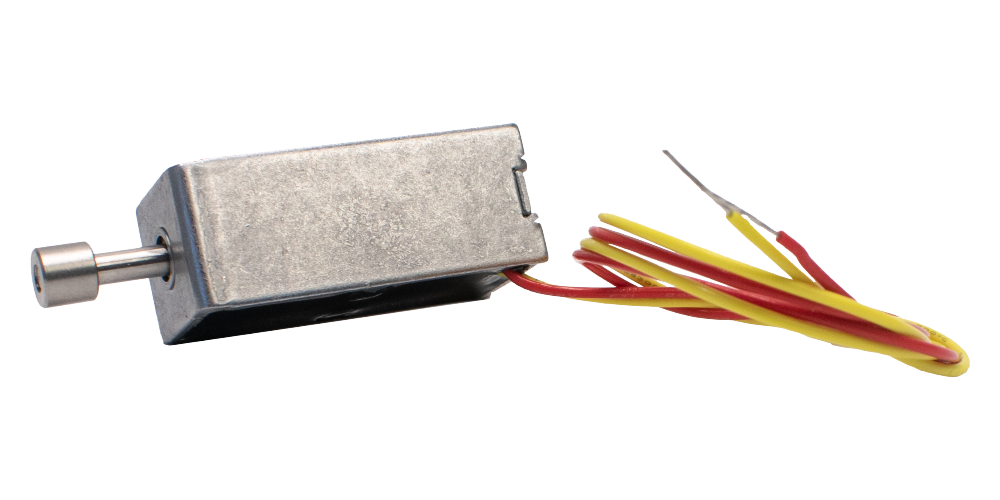

Product Category: Rectangular Sucker Solenoid

Rated Voltage: DC 6v 12v 24v/(Customized)

Rated Power: 48-90w

Force: 2200-2500N

Temperature Rise:65℃ Max

Duty Circle:50-100%

Work Life:0.5 million cycle(10% )

Dimension: 300*60*30 mm

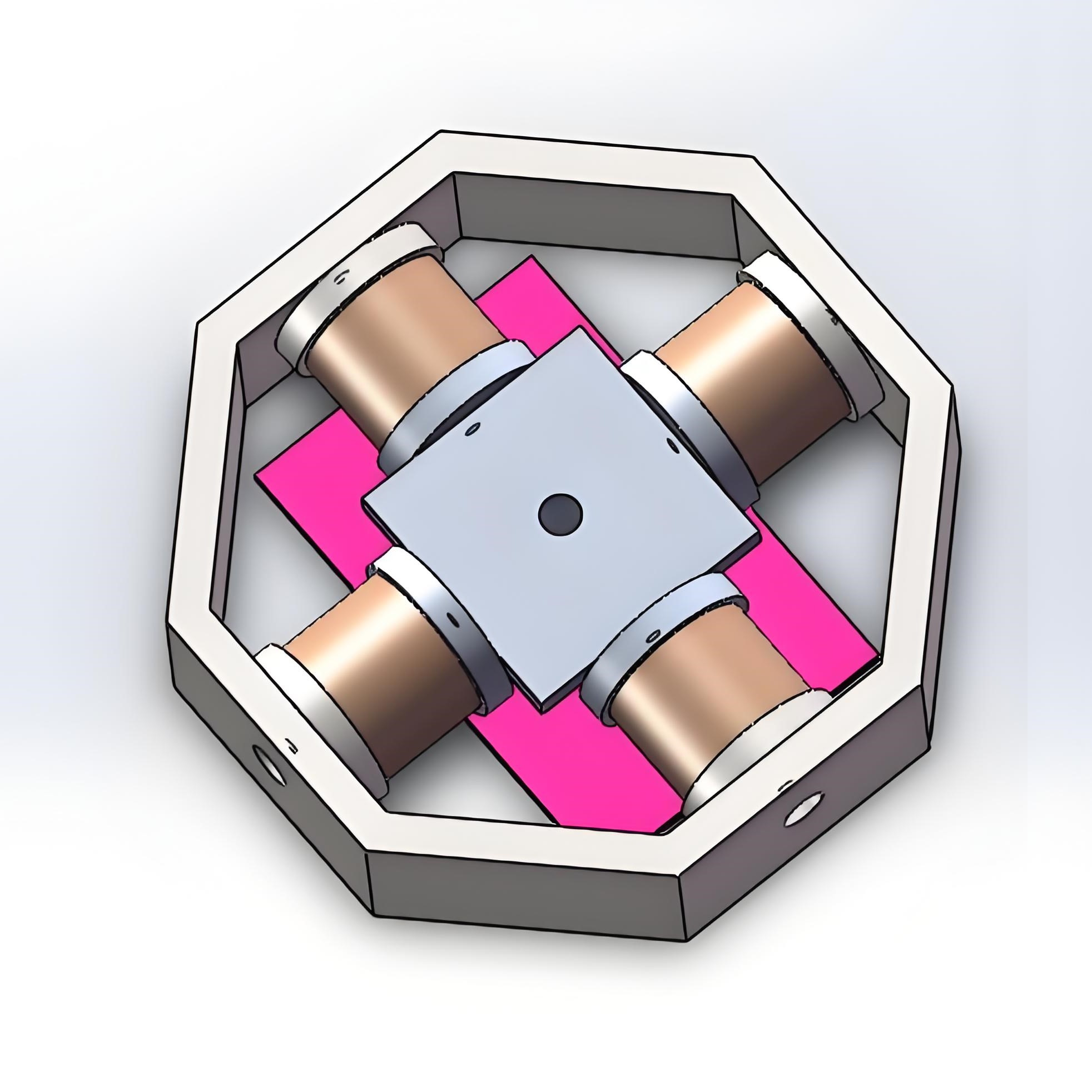

The working principle of the sucker solenoid electromagnet is to generate a magnetic field by energizing the internal coil, so that the iron core is magnetized and generates a strong suction force, thereby adsorbing the magnetic conductive parts. Specifically, when the coil is energized, a magnetic field is generated, and this magnetic field will be added to the iron core, so that the iron core is magnetized and generates a strong suction force, which can adsorb the magnetic conductive parts. The iron core is usually made of soft iron or silicon steel, the adsorption surface is integrally connected to the yoke iron part, and the hollow part is sealed with epoxy resin glue. The specific process is as follows:

1.1.1. Power on to generate a magnetic field

When current passes through the coil, a magnetic field is generated around the coil. The direction of the magnetic field is determined by the direction of the current (following the right-hand rule).

The presence of the iron core can significantly enhance the strength of the magnetic field because the iron core has a high magnetic permeability and can concentrate the magnetic lines of force.

1.1.2. The attraction of the magnetic field to ferromagnetic materials

When the adsorption surface of the suction cup electromagnet is close to the ferromagnetic material (such as steel, iron, etc.), the magnetic field will penetrate the target object.

The target object is magnetized, generating a magnetic pole opposite to the magnetic field of the electromagnet, thereby forming a strong attraction between the two.

1.1.3. Maintaining the adsorption force

As long as the coil is powered, the magnetic field will continue to exist and the adsorption force will continue to be maintained.

When the current is disconnected, the magnetic field disappears, the adsorption force disappears, and the target object is released.

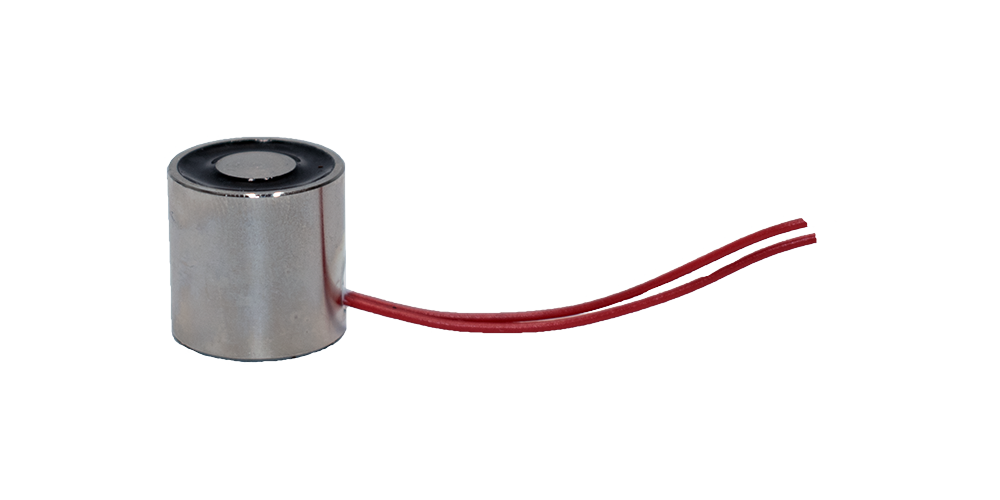

Sucker solenoid electromagnet is a device that uses electromagnetic force to generate adsorption force. It is widely used in industrial grasping, fixing and handling. Its core principle is to generate a strong magnetic field by powering on, and use the attraction of the magnetic field to ferromagnetic materials to achieve adsorption. Sucker solenoid electromagnets usually consist of the following parts:

1.2.1. Coil: Generates a magnetic field after powering on.

1.2.2. Core: Usually made of soft magnetic material (such as silicon steel) to enhance the magnetic field.

1.2.3. Housing: Protects the coil and core, and provides mechanical support.

1.2.4. Working Surface: The part that contacts the target object, usually designed as a plane or arc to increase the contact area.

The advantages of sucker solenoid electromagnets mainly include the following aspects:

1.3.1-Strong suction: Suction cup electromagnets can generate strong adsorption force when powered on, which is suitable for various lifting and fixing operations. For example, the suction force of a strong suction cup electromagnet can reach 330kgf, which is suitable for stopping and moving materials or products in automation equipment.

1.3.2-Wide range of applications: Suction cup electromagnets are suitable for a variety of industrial application scenarios, including automated distribution production lines, sorting machines, manipulators, experimental equipment, medical treatment, grinding, cutting and cutting. It is small in size, easy to install, can save labor and electricity, is safe and reliable, and supports remote operation.

1.3.3-High precision and stability: The strong electromagnetic suction cup can maintain low temperature and will not heat up during long-term use, ensuring processing accuracy. Its high-precision design makes the disk highly stable within the range of 2um/100mm, providing solid precision guarantee for the processed parts.

1.3.4-Safety performance: Suction cup electromagnets usually have a higher safety factor, for example, the rated lifting force has a safety factor of 3.5 times, ensuring safety during use.

1.3.5-Environmental protection and energy saving: Suction cup electromagnets produce almost no residual magnetism after power failure, avoiding environmental pollution and energy waste. Its design makes the power loss small, meeting the requirements of energy saving and environmental protection.

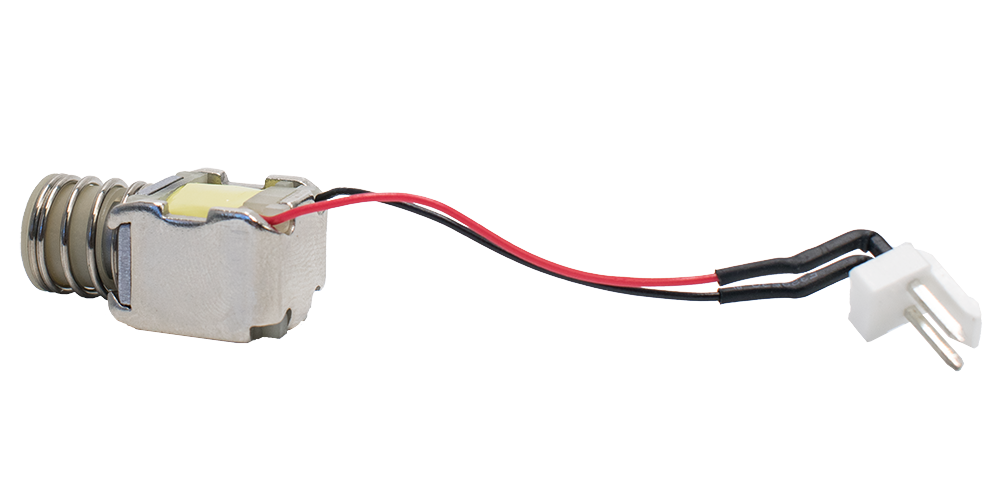

1.3.6-Diverse designs and functions: Suction cup electromagnets have a variety of design types, such as energized adsorption type, self-holding type, double-sided suction cup, etc., to meet the needs of different application scenarios.

| Specifications | |||

| Brand | Customized | Product Name | square electromagnet |

| Model | SFSS-004 | Rated Voltage | DC 12v 24v |

| Power | 48-90w | Force | 2200-2500N |

| Waterproof Class | IP65 | Duty Cycle | 50-100% |

| Cable Length | 200mm | Material | Metal, Electronic Parts |

| Action Form | Holding type | Weight(N.W.) | 3.5kg |

| Install Style | Screw | Thread Size & Deepth(mm) | 4-M8,16 |

| Hi-Pot Test | AC 600V 50/60Hz 2s | Insulation Class | B |

Strong spring toughness is high, repeated use is still elastic, to ensure that each expansion can be fast in and out

Using the national standard copper coil, wound core components, faster heat dissipation, low power consumption, low temperature, long time use, improve the efficiency of the electromagnet and extend the life

Easy and convenient installation,the screw thread is fixed, the installation is stable, the disassembly is convenient, saving time and labor

Good heat dissipation performance:The use of high quality raw materials, durable, good heat dissipation, not afraid of large temperature difference changes, no remanent magnetic power

The Sucker Solenoid electromagnet is a non-standard customized electronic component. Except for the coil frame which is molded, other accessories and parameters can be customized as required.

Customization process:

4.1. Contact us: Please send an email or WhatsApp to contact us(+86 18902611680)

4.2. Provide requirements: Provide parameters such as voltage, force, stroke, on-off ratio and size.

4.3. Specification confirmation: We select and issue specifications according to requirements. Except for the outer frame size, other shaft sizes and lengths can be customized. If it is made according to a specific outer frame size, a mold needs to be opened.

4.4. Proofing: We make samples according to the specifications, and the production cycle is about 7 days.

4.5. Sample testing: If the sample test is qualified, a batch order will be placed. If it is unqualified, the sample will be remade.

4.6. Mass production: Sign a bulk purchase and sale contract.

Sucker solenoid electromagnets are widely used in the following fields:

5.1-Industrial handling: used to carry heavy materials such as steel plates and iron blocks.

5.2-Machining: used to fix workpieces and improve processing accuracy.

5.3-Automated production lines: used to grab and move parts to achieve automated operations.

5.4-Construction industry: used to hoist and fix steel structures.

5.5-Logistics warehousing: used to sort and stack metal products.

Our headquarters is located in Guangdong, China. Since 2015, we have developed and produced electromagnets and sold them to North America (35.00%), South Asia (25.00%), Western Europe (20.00%), South America (15.00%), Northern Europe (5.00%).

We are a Chinese top manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid bistable solenoids latching solenoids open frame solenoids tubular solenoids self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

Use our professional design experience to customize your brand electromagnet!