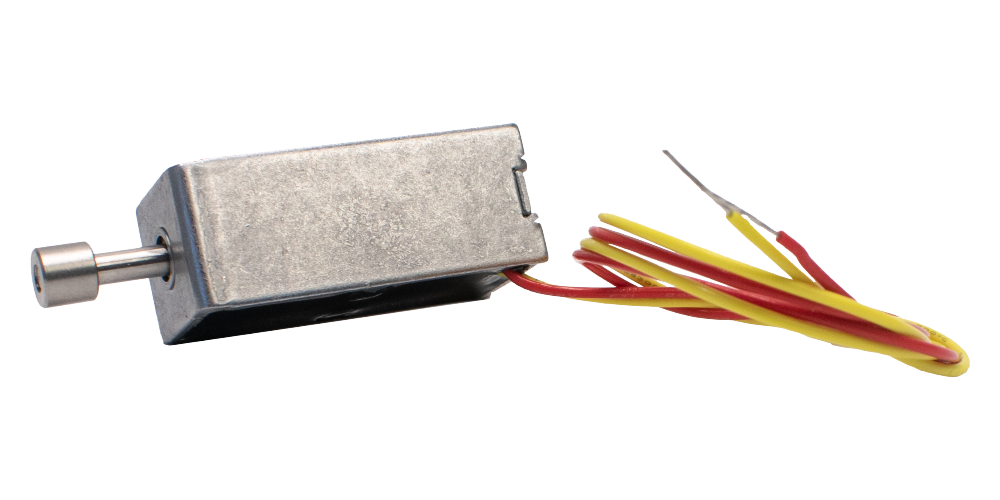

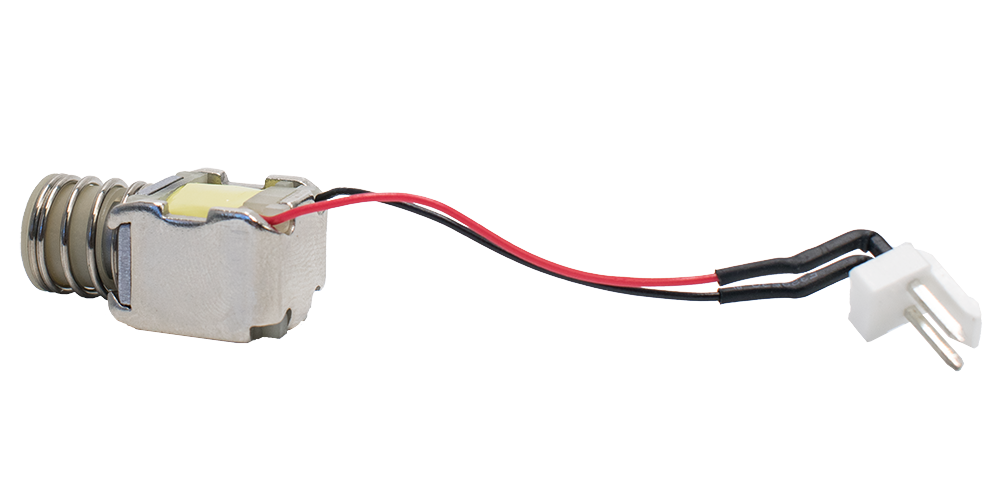

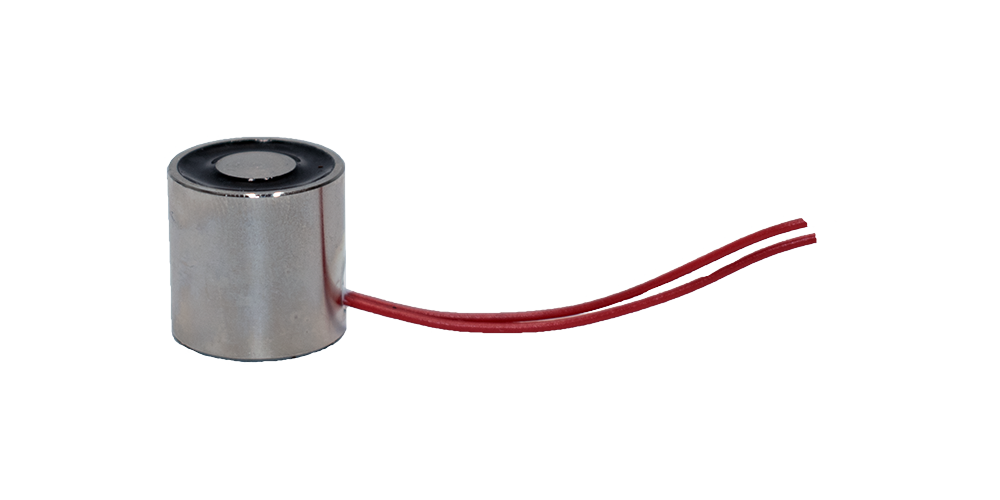

Product Category:Round Tubular Solenoid

Rated Voltage:DC 12V 24V/(Customized)

Rated Power:70w

Rated Stroke:5mm(Customized)

Temperature Rise:65℃ Max

Duty Circle:10%

Work Life:0.5 million cycle(10% )

Dimension:L39*D19mm

The working principle of the round tubular solenoid is to generate a magnetic field in the solenoid through current, which in turn drives the internal plunger to move. Specifically, when current passes through the wire of the solenoid, a uniform magnetic field is generated, which acts on the plunger inside the solenoid, causing it to move under the action of the magnetic field. When the current is disconnected, the magnetic field disappears and the plunger returns to its original position.

1.1.1-Current generates magnetic field: When current passes through the wire of the solenoid, the magnetic field around the wire becomes stronger. The direction and strength of this magnetic field depend on the direction and magnitude of the current.

1.1.2-Magnetic field drives the plunger: The plunger inside the solenoid is made of magnetic material, and when a magnetic field is generated, it moves under the action of magnetic force. This movement can be achieved through mechanical connection to achieve various functions, such as opening or closing a valve.

1.1.3-Current is disconnected, magnetic field disappears: When the current is disconnected, the magnetic field disappears, and the plunger returns to its original position under the action of a spring or other restoring force.

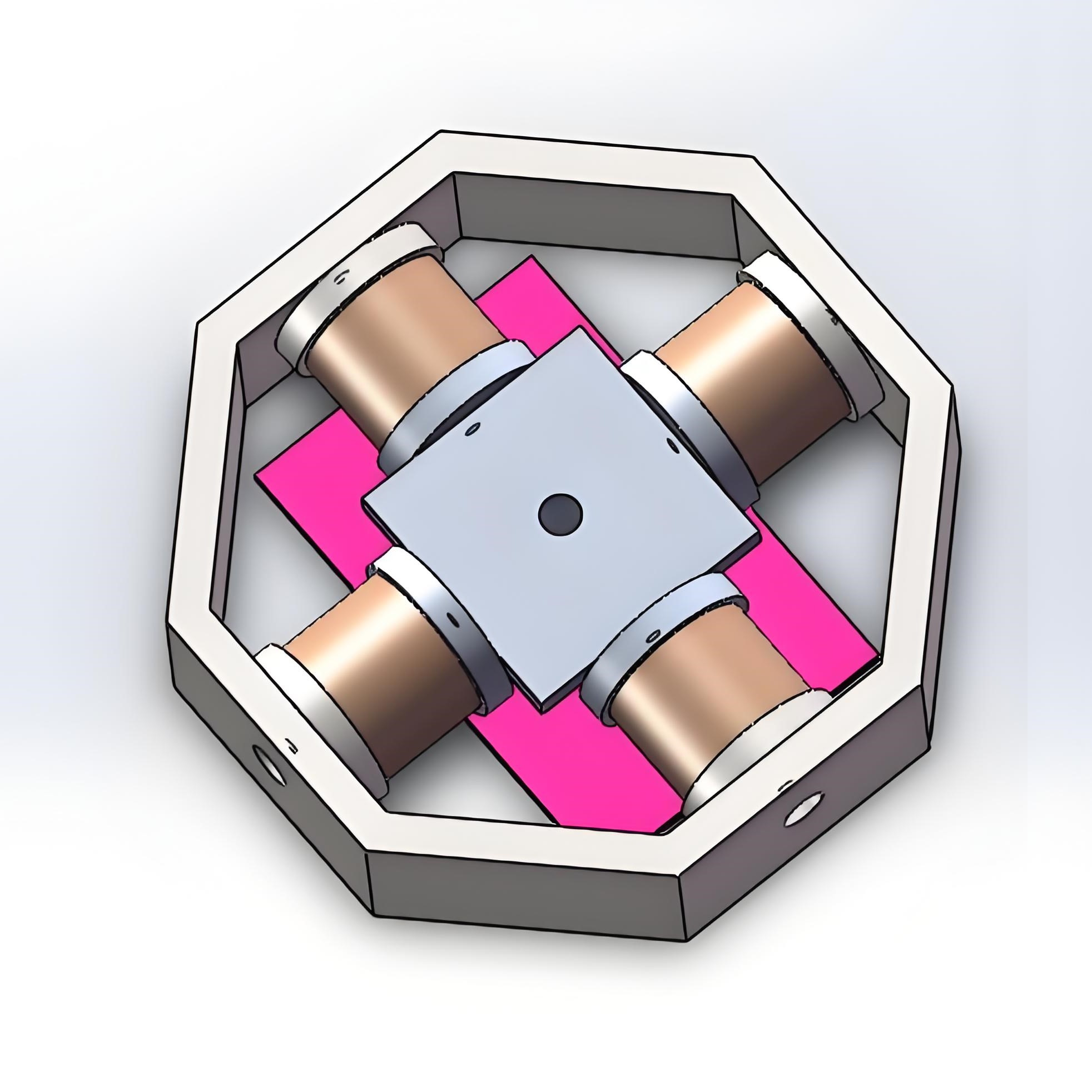

The structure of round tubular solenoid mainly includes the following parts:

1.2.1-Coil: The coil of Tubular Solenoid is usually wound with Class “F” 23 to 40 AWG wire, and the insulation level is Class “A”;

1.2.2-Ends: The ends of the coil are adjacent to each other and are made of magnetic materials. These ends are used to enhance the effect of the magnetic field;

1.2.3-Yoke: The magnetic yoke surrounding the coil and the ends is used to concentrate and enhance the magnetic field;

1.2.4-Plunger: The plunger is set in the hollow part of the yoke to slide freely. It is usually made of a magnetic material and covered with non-magnetic material on the outer layer to reduce friction.

These components work together to enable Tubular Solenoid to generate a magnetic field when powered on and drive the plunger to move. It is often used in various automation equipment and mechanical systems.

The advantages of round tubular solenoid mainly include the following aspects:

1.3.1-Large thrust and long stroke: Tubular Solenoid has the characteristics of large thrust and long stroke, can provide strong pulling and pushing force, and is suitable for application scenarios that require greater force; High efficiency: Tubular Solenoid can respond quickly in a short time, suitable for applications that require fast action, such as car locking mechanisms, etc.

1.3.2-Stability and durability: The design focuses on stability, can maintain stable performance in high temperature environments, and ensure long-term reliability;

1.3.3-Multiple specifications: Tubular Solenoid is available in various specifications on the market, and users can choose appropriate voltage, force, stroke and other parameters according to specific needs;

1.3.4-Wide application: Tubular Solenoid is widely used in various automation equipment and industrial control systems, such as automated production lines, robots, automotive industry, etc.

Products Specifications | |||

Brand | Customized | Product Series | Round Tubular solenoid |

Model | SFLS-003 | Voltage | 12v/24v dc |

Power | 70w | Force | 5N |

Stroke | 5mm | Duty Cycle | 10% |

Cable Length | 200mm or customization | Materials | steel & enamelled wire |

Action Form | Push pull type | Weight (N.W.) | 0.12kg |

Install style | Screw | Thread size & Deepth(mm) | L39*D19mm |

Hi-Pot Test | AC 600V 50/60Hz 2s | Insulation Class | B |

Strong spring toughness is high, repeated use is still elastic, to ensure that each expansion can be fast in and out

Using the national standard copper coil, wound core components, faster heat dissipation, low power consumption, low temperature, long time use, improve the efficiency of the electromagnet and extend the life

Easy and convenient installation,the screw thread is fixed, the installation is stable, the disassembly is convenient, saving time and labor

Good heat dissipation performance:The use of high quality raw materials, durable, good heat dissipation, not afraid of large temperature difference changes, no remanent magnetic power

The round tubular solenoid electromagnet is a non-standard customized electronic component. Except for the coil frame which is molded, other accessories and parameters can be customized as required.

Customization process:

4.1. Contact us: Please send an email or WhatsApp to contact us(+86 18902611680)

4.2. Provide requirements: Provide parameters such as voltage, force, stroke, on-off ratio and size.

4.3. Specification confirmation: We select and issue specifications according to requirements. Except for the outer frame size, other shaft sizes and lengths can be customized. If it is made according to a specific outer frame size, a mold needs to be opened.

4.4. Proofing: We make samples according to the specifications, and the production cycle is about 7 days.

4.5. Sample testing: If the sample test is qualified, a batch order will be placed. If it is unqualified, the sample will be remade.

4.6. Mass production: Sign a bulk purchase and sale contract.

Our headquarters is located in Guangdong, China. Since 2015, we have developed and produced electromagnets and sold them to North America (35.00%), South Asia (25.00%), Western Europe (20.00%), South America (15.00%), Northern Europe (5.00%).

We are a Chinese top manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid bistable solenoids latching solenoids open frame solenoids tubular solenoids self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

Use our professional design experience to customize your brand electromagnet!