Last Updated on 2026-01-23 by SolenoidFactory

Introduction to Long Stroke Solenoid Technology

A long stroke solenoid is a type of electromagnetic actuator designed to deliver extended linear motion compared to standard short-stroke solenoids. While traditional solenoids typically operate within strokes of 2–10 mm, a long stroke solenoid can achieve strokes ranging from 15 mm to over 50 mm, depending on design and force requirements.

This extended motion capability makes the long stroke solenoid an ideal solution for applications requiring significant mechanical travel, smooth actuation, and precise positional control. As industries demand smarter and more compact motion control solutions, the long stroke solenoid has become a preferred alternative to motors and pneumatic systems in many scenarios.

This article explores long stroke solenoid applications across industries, as well as design principles, advantages, and real-world case studies.

1. Long Stroke Solenoid Applications in Industrial Automation

In industrial automation, the long stroke solenoid plays a key role in systems that require linear motion with fast response and repeatability.

Typical Industrial Automation Uses

Mechanical latching and unlocking mechanisms

Conveyor sorting gates

Automated material handling stops

Packaging machinery pushers

A long stroke solenoid provides quick actuation without the complexity of a motor-driven system. Because the stroke length is extended, it can directly replace small pneumatic cylinders in compact automation systems.

Case Example

A packaging equipment manufacturer integrated a long stroke solenoid to control a carton diverter arm. The solenoid delivered a 30 mm stroke to redirect packages on a conveyor line. Compared to the previous pneumatic system, the long stroke solenoid reduced maintenance costs and eliminated air supply requirements.

2. Long Stroke Solenoid Applications in Smart Home and Security Devices

Smart home technology increasingly relies on electromagnetic actuators. A long stroke solenoid is commonly used in:

Smart lock internal bolt control

Motorized cabinet locking systems

Automated door latches

Because a long stroke solenoid can provide extended linear travel, it allows secure bolt engagement without mechanical gear assemblies.

Case Example

A smart security system manufacturer replaced a small DC motor with a long stroke solenoid in a digital lock design. The solenoid offered faster locking response, lower power consumption in pulse mode, and improved reliability over millions of cycles.

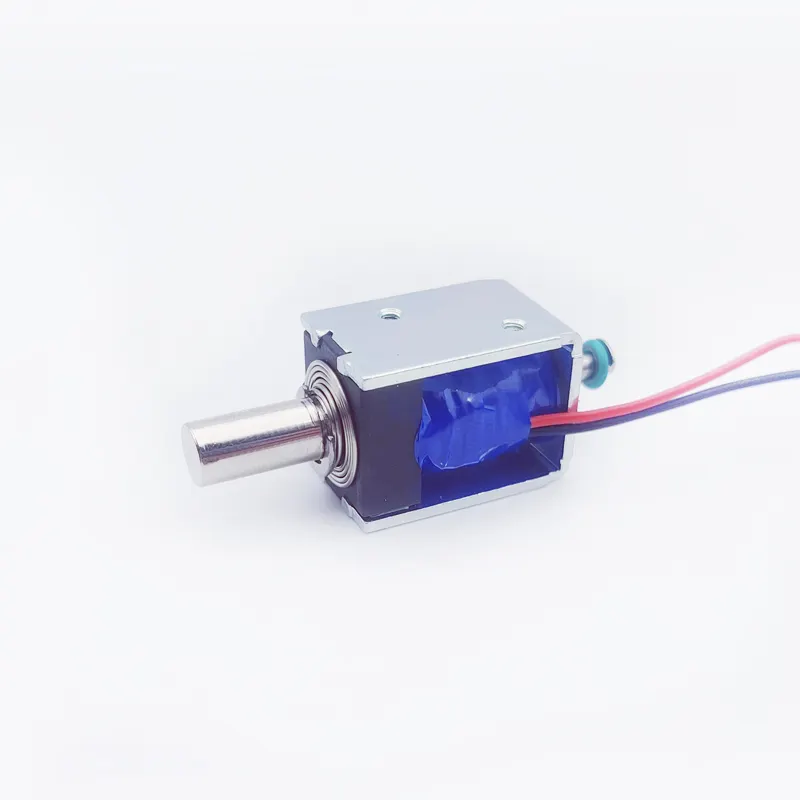

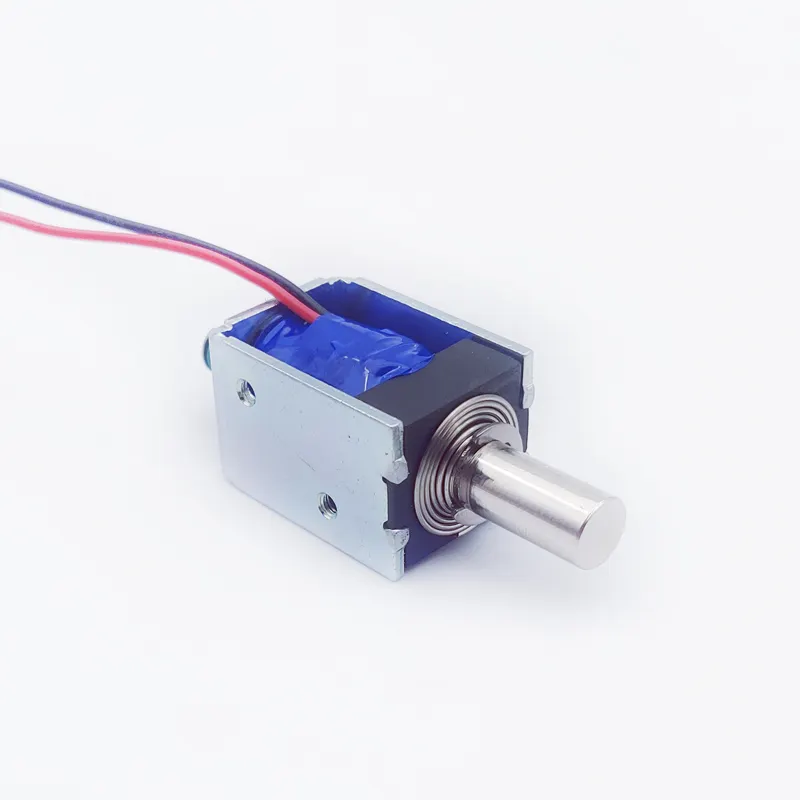

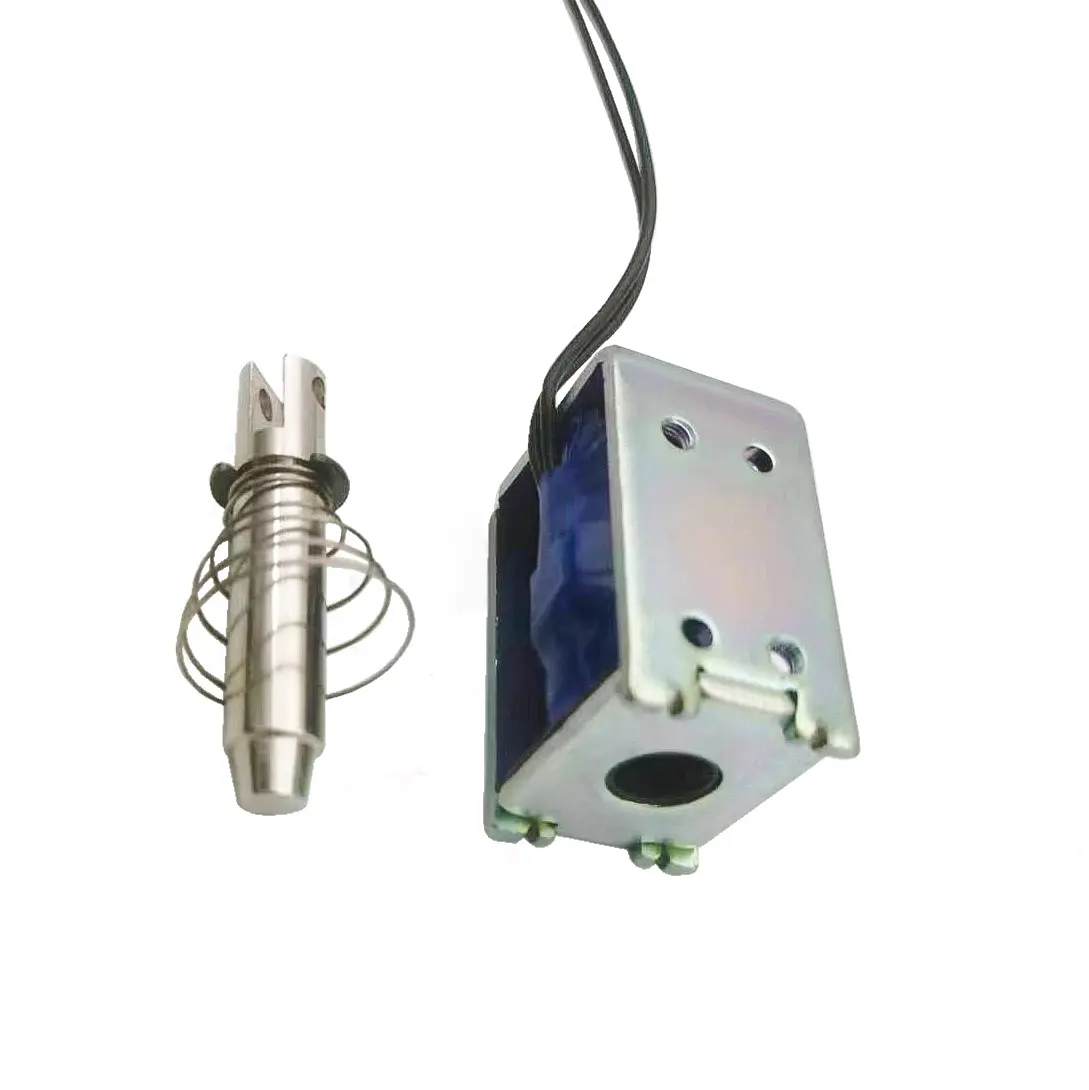

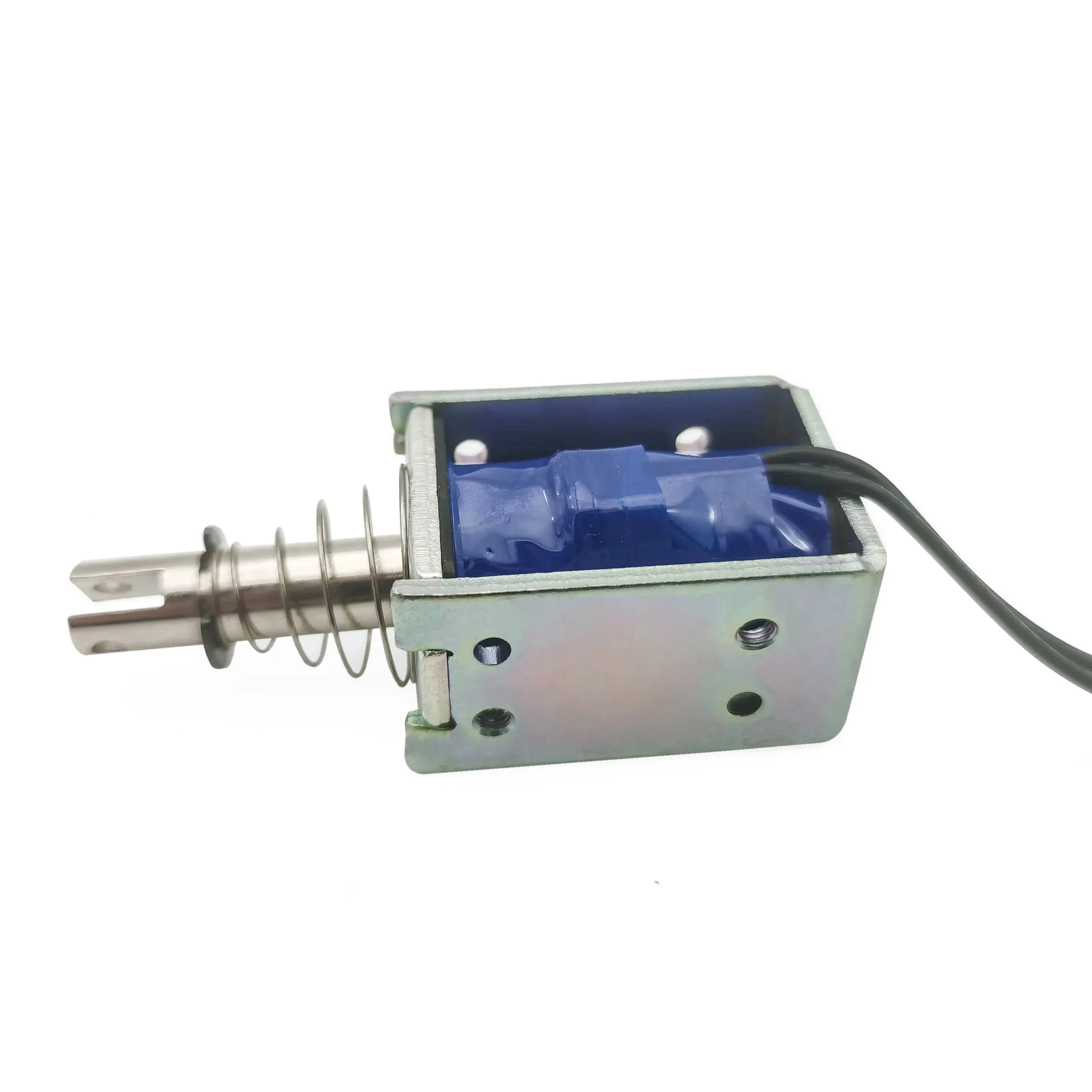

Bistable Solenoid Long Stroke 12v Dc Linear Electromagnet

Bistable Solenoid Long Stroke Custom Dc Linear Electromagnet

Bistable Solenoid 6mm Stroke 12v Dc Linear Electromagnet

Bistable Solenoid Electromagnet for 12v 24v Locker Latching

3. Long Stroke Solenoid Applications in Medical Equipment

Medical devices often require compact, reliable actuation systems. A long stroke solenoid is used in:

Drug dispensing systems

Sample collection devices

Diagnostic analyzers

The controlled motion of a long stroke solenoid ensures precise dosing and repeatability.

Case Example

A laboratory automation company used a long stroke solenoid to drive a reagent dispensing plunger. The long stroke ensured consistent fluid delivery, while the electromagnetic actuation allowed silent operation in clinical environments.

4. Long Stroke Solenoid Applications in Consumer Appliances

In home appliances, a long stroke solenoid supports mechanisms that require controlled motion in compact spaces.

Common applications include:

Coffee machine brewing units

Washing machine door locks

Refrigerator ice dispensers

Rice cooker lid locks

Case Example

A coffee machine manufacturer integrated a long stroke solenoid to control the brewing chamber lock. The extended stroke allowed the mechanism to engage securely while maintaining a compact design. The long stroke solenoid operated in a high-humidity environment without performance degradation.

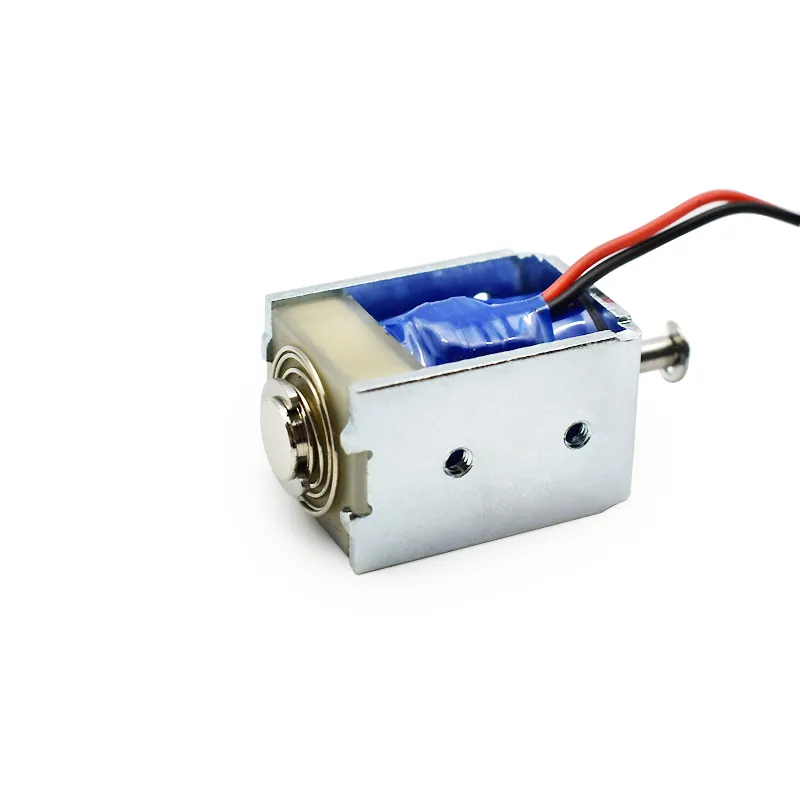

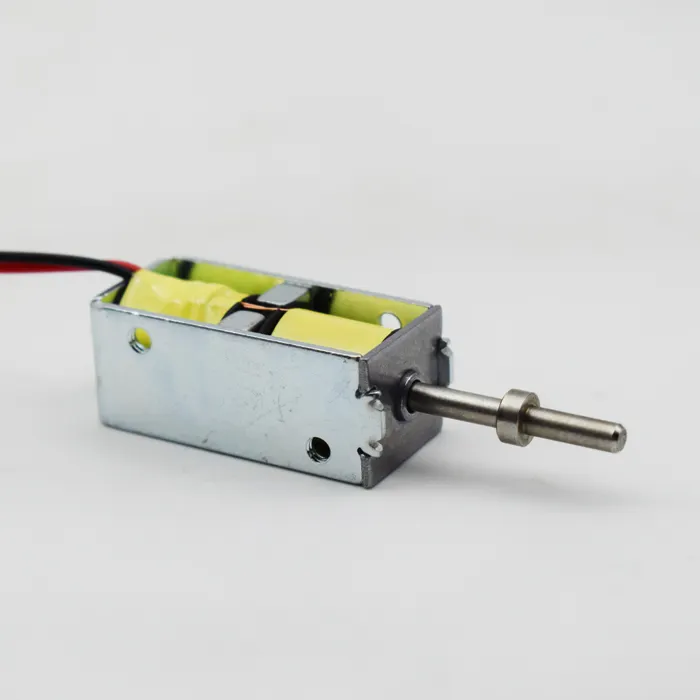

Custom Latching Solenoid 8mm Stroke DC 12v 24v Electromagnet

Custom Latching Solenoid DC 12v 24v 8mm Stroke Electromagnet

Custom 8mm Stroke Latching Solenoid 12v DC Electromagnet

Dc 12v Latching Solenoid Customized Push Pull Electromagnet

5. Long Stroke Solenoid Applications in Automotive Systems

The automotive industry benefits from the long stroke solenoid in applications that require reliable motion under harsh conditions.

Examples include:

Electronic door latch systems

Fuel system control mechanisms

Adjustable airflow vents

EV charging port locks

Case Example

An automotive OEM implemented a long stroke solenoid to control a charge port locking pin in an electric vehicle. The extended travel ensured reliable engagement even with alignment tolerances and temperature variations.

6. Long Stroke Solenoid Applications in Vending and Payment Systems

Vending machines and automated kiosks rely on compact actuators. A long stroke solenoid is used for:

Coin lock mechanisms

Product dispensing gates

Anti-theft locking devices

The fast response of a long stroke solenoid ensures reliable operation in high-cycle commercial environments.

7. Long Stroke Solenoid Applications in Industrial Safety Systems

Safety interlock systems often require actuators capable of longer travel distances. A long stroke solenoid is used in:

Machine guard locking

Emergency stop mechanical releases

Access control barriers

The reliability of a long stroke solenoid in high-cycle conditions makes it ideal for safety-critical designs.

8. Engineering Considerations for Long Stroke Solenoid Design

Designing a long stroke solenoid requires balancing stroke length, force output, and thermal performance.

Key Design Parameters

| Parameter | Importance in Long Stroke Solenoid |

|---|---|

| Stroke Length | Determines total travel distance |

| Pull Force Curve | Must remain sufficient across stroke |

| Coil Power | Affects temperature rise |

| Duty Cycle | Continuous vs intermittent use |

| Mechanical Return | Spring or gravity-assisted |

Because magnetic force decreases over distance, a long stroke solenoid often requires optimized magnetic circuits and longer coils to maintain force output.

9. Advantages of Long Stroke Solenoid Compared to Alternatives

A long stroke solenoid offers multiple advantages over motors and pneumatic cylinders:

Faster response time

Lower system complexity

No compressed air requirement

Lower maintenance

Compact structure

For many OEM designs, replacing small motors with a long stroke solenoid reduces system cost and increases reliability.

10. Custom Long Stroke Solenoid Solutions from SF

SF specializes in designing custom long stroke solenoid solutions for OEM applications. With more than 10 years of electromagnet manufacturing experience, SF provides:

Custom stroke lengths up to 50 mm+

Optimized force curves

Low-noise structural designs

High-temperature coil options

Long-life cycle performance

SF engineering teams work closely with customers to tailor each long stroke solenoid to the mechanical and electrical requirements of the application.

Sucker Solenoid DC 12-24v 10-15N Holding Force Electromagnet

12-24v Sucker Solenoid 10-15N Holding Force DC Electromagnet

DC Sucker Solenoid 10-15N Holding Force Electromagnet

Sucker Solenoid Custom Mini Round 12v 24v Dc Electromagnet

Why Long Stroke Solenoid Technology Is Expanding Across Industries

The long stroke solenoid has become an increasingly important actuator across industries due to its ability to provide extended linear motion in a compact, efficient design. From industrial automation to smart home devices and medical systems, the versatility of the long stroke solenoid continues to drive innovation.

As OEMs seek reliable, low-maintenance alternatives to motors and pneumatic systems, the long stroke solenoid stands out as a high-performance electromagnetic solution.

Manufacturers like SF, with deep expertise in custom electromagnet engineering, are helping companies integrate long stroke solenoid technology into next-generation products with improved reliability, efficiency, and design flexibility.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680