Last Updated on 2025-09-04 by SolenoidFactory

In the realm of industrial automation and material handling, sucker electromagnets play a pivotal role. These devices utilize electromagnetic forces to lift, hold, and release ferromagnetic materials, such as steel and iron. The term “sucker electromagnet” typically refers to a type of electromagnet that uses a flat or concave surface to create a strong vacuum-like grip, hence the name “sucker.” This capability makes sucker electromagnets ideal for a wide range of applications, from automated manufacturing lines to recycling operations.

Choosing the right sucker electromagnet for your specific needs can be a complex task, given the variety of models, specifications, and performance characteristics available. This blog serves as a comprehensive guide, walking you through the key considerations and steps involved in selecting the optimal sucker electromagnet for your application.

1: Fundamentals of Sucker Electromagnets

1.1 What is a Sucker Electromagnet?

A sucker electromagnet is a device that generates an electromagnetic field to attract and hold ferromagnetic materials. Unlike permanent magnets, sucker electromagnets rely on an external power supply to create the magnetic field. When energized, the electromagnetic coil within the sucker electromagnet produces a magnetic flux that attracts metallic objects to its surface. Once de-energized, the magnetic field collapses, allowing the held objects to be released.

1.2 Types of Sucker Electromagnets

Sucker electromagnets come in various designs and configurations, tailored to meet the diverse needs of industrial applications. Some common types include:

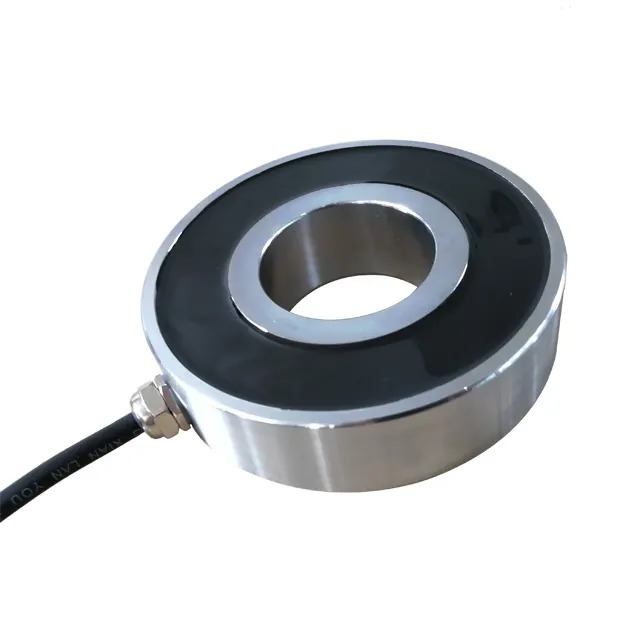

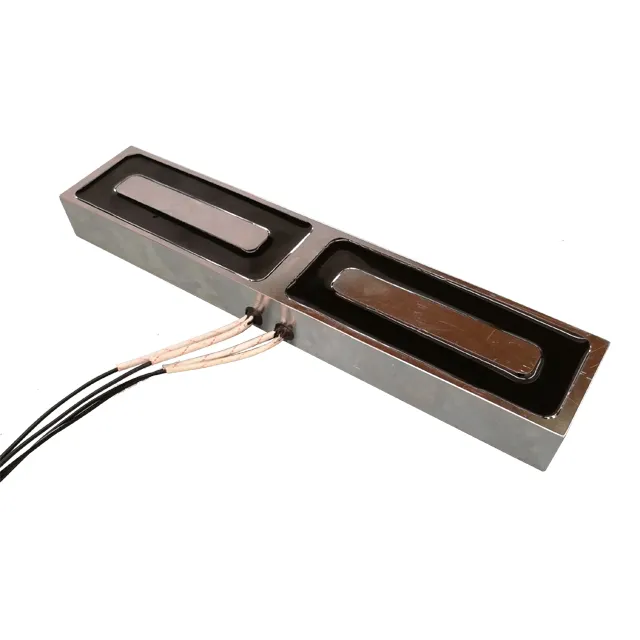

- Flat Sucker Electromagnets: These feature a flat, disc-shaped surface that provides a broad and even gripping area. They are ideal for lifting and holding flat objects.

- Concave Sucker Electromagnets: Designed with a concave surface, these electromagnets offer a more focused gripping point, suitable for holding curved or irregularly shaped objects.

- Adjustable Sucker Electromagnets: These models feature adjustable gripping surfaces or force outputs, allowing them to accommodate a range of object sizes and weights.

- Combination Sucker Electromagnets: Some sucker electromagnets combine features from different types, offering a versatile solution for multifaceted applications.

1.3 Key Performance Parameters

When selecting a sucker electromagnet, several key performance parameters must be considered:

- Holding Force: The maximum force the sucker electromagnet can exert to hold an object, measured in newtons (N) or kilograms (kgf).

- Operating Voltage and Current: The electrical power required to energize the sucker electromagnet, specified in volts (V) and amperes (A).

- Duty Cycle: The percentage of time the sucker electromagnet is energized during a complete cycle of operation.

- Coil Resistance and Inductance: Important electrical characteristics that affect the electromagnet’s power consumption and response time.

- Operating Temperature Range: The range of temperatures within which the sucker electromagnet can operate reliably.

2: Evaluating Your Application's Requirements

2.1 Determining Load Characteristics

The first step in selecting a sucker electromagnet is to understand the load characteristics of your application. Consider the following:

- Weight and Shape: Determine the weight and shape of the objects you need to lift and hold. This will help you select a sucker electromagnet with sufficient holding force and the appropriate gripping surface.

- Surface Condition: Evaluate the surface condition of the objects. Rough, rusted, or painted surfaces may require a sucker electromagnet with stronger magnetic properties or a specialized gripping surface to ensure reliable holding.

- Environmental Factors: Consider any environmental factors that could affect the sucker electromagnet’s performance, such as temperature, humidity, and the presence of debris or contaminants.

2.2 Mounting and Integration Considerations

The physical constraints of your application, such as space limitations and mounting requirements, will also play a role in your sucker electromagnet selection. Consider the following:

- Mounting Options: Determine the most suitable mounting method for your application, such as threaded holes, flange mounting, or bracket mounting. Ensure the sucker electromagnet you select offers the necessary mounting features.

- Accessories and Connectivity: Assess any additional accessories or connectivity requirements, such as power cables, control circuits, or sensors. Ensure the sucker electromagnet is compatible with your existing systems and can be easily integrated into your automation process.

- Space Constraints: Measure the available space for the sucker electromagnet and ensure the selected model fits within your application’s physical constraints. Consider the sucker electromagnet’s dimensions, including its overall size and the required clearance for its operation.

2.3 Safety and Compliance Considerations

Safety and compliance are critical factors in industrial applications. Ensure the sucker electromagnet you select meets the relevant safety standards and regulations for your industry. Consider the following:

- Certifications and Standards: Look for sucker electromagnets that are certified to meet industry standards, such as CE, UL, or ISO. This ensures the device has undergone rigorous testing and complies with safety requirements.

- Emergency Release Mechanisms: Evaluate whether the sucker electromagnet features an emergency release mechanism, such as a manual override or a fail-safe design. This can help prevent accidents and minimize downtime in case of power failures or other emergencies.

- Maintenance and Inspection Requirements: Familiarize yourself with the maintenance and inspection requirements for the sucker electromagnet. Regular inspections and proper maintenance are essential for ensuring long-term reliability and safety.

3: Choosing the Right Sucker Electromagnets

3.1 Researching Supplier Options

With a clear understanding of your application’s requirements, it’s time to research potential suppliers of sucker electromagnets. Consider the following criteria:

- Technical Expertise: Look for suppliers with deep technical expertise in sucker electromagnets. They should be able to provide insights into material selection, coil design, and other critical factors that can significantly impact performance.

- Product Range: Ensure the supplier offers a wide range of sucker electromagnets to accommodate various holding forces, mounting options, and size requirements. This provides flexibility in selecting the best match for your application.

- Customization Capabilities: Assess the supplier’s ability to customize sucker electromagnets to meet specific requirements. This includes modifications to holding force, gripping surface, and other parameters to ensure optimal performance in diverse applications.

3.2 Product Evaluation

Once you’ve narrowed down your supplier options, evaluate the specific sucker electromagnets they offer based on your application’s requirements:

- Holding Force Matching: Compare the holding force specifications of the sucker electromagnets to the weight and shape of the objects you need to lift and hold. Ensure the selected sucker electromagnet can meet or exceed the required holding force.

- Voltage and Current Compatibility: Verify that the sucker electromagnet’s operating voltage and current are compatible with your electrical system. Consider any power supply limitations or surge protection requirements.

- Duty Cycle and Life Expectancy: Evaluate the duty cycle and life expectancy of the sucker electromagnet to ensure it can withstand the operational demands of your application. Look for sucker electromagnets with higher duty cycles and longer life expectancies for continuous or high-cycle applications.

3.3 Testing and Validation

Before making a final decision, consider testing and validating the selected sucker electromagnet in your application environment:

- Prototype Testing: Request a prototype of the selected sucker electromagnet for testing in your specific application. This allows you to validate its performance under real-world conditions and identify any potential issues or limitations.

- Performance Metrics: Establish performance metrics and benchmarks for the sucker electromagnet based on your application’s requirements. Monitor these metrics during testing to ensure the sucker electromagnet meets or exceeds expectations.

- Feedback and Adjustments: Provide feedback to the supplier based on your testing results. They may offer adjustments or modifications to improve performance and alignment with your application’s needs.

4: Ensuring Long-Term Reliability and Performance

4.1 Maintenance and Servicing

Maintaining the reliability and performance of your sucker electromagnet over time is crucial. Consider the following best practices:

- Regular Inspections: Schedule regular inspections of the sucker electromagnet to check for signs of wear, contamination, or damage. This helps identify potential issues before they become critical and ensures the sucker electromagnet operates safely and effectively.

- Cleaning and Lubrication: Clean the sucker electromagnet regularly to remove dirt, debris, and other contaminants. Apply suitable lubricants to moving parts, such as bearings and guides, to reduce friction and wear.

- Spare Parts Inventory: Maintain an inventory of spare parts, such as coils, bearings, and gripping surfaces, to minimize downtime in case of failures. Ensure these parts are compatible with your installed sucker electromagnets.

4.2 Supplier Support and Warranty

Partnering with a supplier that offers comprehensive support and warranty services can enhance the lifespan and reliability of your sucker electromagnets. Consider the following:

- Technical Support: Ensure the supplier provides ongoing technical support for troubleshooting, maintenance, and performance optimization. Look for suppliers with dedicated support teams and quick response times.

- Warranty Coverage: Verify the warranty coverage provided by the supplier. Look for comprehensive warranties that cover defects in materials and workmanship, as well as any additional services or replacements required.

5: Innovations and Trends in Sucker Electromagnets

5.1 Advancements in Materials and Coatings

The development of new materials and coatings is driving significant advancements in sucker electromagnets. Manufacturers are leveraging advanced materials such as neodymium-iron-boron (NdFeB) magnets, which offer higher magnetic strength and energy density compared to traditional ferrite magnets. These materials enable sucker electromagnets to achieve stronger holding forces and more compact designs.

In addition, coatings such as nickel, zinc, and epoxy are becoming increasingly popular for sucker electromagnets. These coatings provide enhanced corrosion resistance, wear resistance, and temperature stability, extending the lifespan of sucker electromagnets in harsh environments. They also help maintain the electromagnetic properties of the device, ensuring consistent performance over time.

5.2 Integration of Sensors and Controls

The integration of sensors and controls within sucker electromagnets is a growing trend. By incorporating sensors such as Hall-effect sensors or inductive proximity sensors, manufacturers can provide real-time feedback on the sucker electromagnet’s status, such as whether it is energized or holding an object. This enables more precise control and monitoring of the sucker electromagnet, enhancing safety and efficiency in automated applications.

Furthermore, the integration of advanced controls, such as proportional-integral-derivative (PID) controllers or programmable logic controllers (PLCs), allows for more sophisticated control strategies. These controllers can adjust the sucker electromagnet’s power supply to optimize performance based on real-time data, such as load weight or environmental conditions.

5.3 Energy Efficiency and Sustainability

Energy efficiency and sustainability are becoming increasingly important considerations in the selection of sucker electromagnets. Manufacturers are developing sucker electromagnets with lower power consumption and higher efficiency ratings to meet these demands. Innovations such as energy-recovery systems, optimized coil designs, and advanced materials contribute to reducing energy waste and environmental impact.

In addition, manufacturers are increasingly adopting eco-friendly manufacturing processes, such as additive manufacturing (3D printing) and lean manufacturing techniques, to minimize waste and reduce the carbon footprint of sucker electromagnets. These efforts help ensure that sucker electromagnets meet the environmental standards and regulations of various industries and regions.

5.4 Compact Design and Miniaturization

The trend towards compact design and miniaturization is driving the development of smaller, lighter sucker electromagnets. These devices are ideal for applications with limited space or weight constraints, such as aerospace, robotics, and medical devices. Manufacturers are using advanced manufacturing techniques, such as precision machining and additive manufacturing, to create sucker electromagnets with intricate designs and reduced footprints.

Miniaturization not only reduces the physical size of sucker electromagnets but also enables higher force outputs and faster response times in smaller packages. This makes sucker electromagnets an attractive option for a wide range of applications, from precision machinery to automotive systems.

6: Sucker electromagnets Case Studies and Application Examples

6.1 Automated Assembly Lines

In automated assembly lines, sucker electromagnets are commonly used for handling and positioning components. For example, in automotive manufacturing, sucker electromagnets can lift and move engine parts, transmissions, and other heavy components with precision and reliability. The ability to control the sucker electromagnet’s power supply and incorporate sensors for real-time monitoring enhances safety and efficiency in these applications.

6.2 Scrap Handling and Recycling

Sucker electromagnets play a crucial role in scrap handling and recycling operations. They can efficiently lift and transport metal scraps, such as steel and aluminum, from one location to another. The strong holding force and adjustable gripping surfaces of sucker electromagnets make them ideal for handling a wide range of scrap sizes and shapes.

Furthermore, the integration of sensors and controls allows for more intelligent scrap handling systems. For example, sensors can detect the presence of metal scraps and adjust the sucker electromagnet’s power supply accordingly, optimizing energy use and reducing wear and tear on the device.

6.3 Material Handling in Warehouses

In warehouse environments, sucker electromagnets are used for lifting and moving pallets, boxes, and other ferromagnetic loads. The ability to quickly and reliably engage and disengage the sucker electromagnet’s holding force makes it an efficient solution for automated material handling systems.

Advanced controls, such as PLCs or robotics, can further enhance the performance of sucker electromagnets in warehouse applications. These controls can coordinate the movement of multiple sucker electromagnets, optimize loading and unloading sequences, and provide real-time monitoring and diagnostics to ensure smooth and efficient operations.

Choosing the right sucker electromagnets

Choosing the right sucker electromagnet for your application involves a thorough understanding of the fundamentals, careful evaluation of your application’s requirements, and diligent selection of the right supplier and product. By following the guidelines outlined in this blog, you can navigate the complex world of sucker electromagnets and make an informed decision that ensures optimal performance, reliability, and cost-effectiveness.

Remember, the key to successful sucker electromagnet selection is balance. Balance the holding force, operating voltage, and current requirements against the environmental conditions, space constraints, and mounting options. Balance the need for customization and flexibility with the supplier’s technical expertise and product range. And finally, balance the initial cost with the long-term benefits of reliability, performance, and support.

In conclusion, sucker electromagnets are indispensable components in numerous industrial applications, and selecting the right one requires careful consideration and planning. By understanding the fundamentals, evaluating your application’s requirements, and assessing potential suppliers, you can choose a sucker electromagnet that meets your needs today and adapts to your future demands.

With the advancements in materials, controls, energy efficiency, and compact design, the future of sucker electromagnets is bright. Stay informed about the latest trends and innovations to ensure you are always leveraging the best technology for your applications. Happy sucker electromagnet selecting!

This comprehensive guide has covered the essentials of choosing a sucker electromagnet.By following the outlined steps and considerations, you can make an informed decision that ensures your application benefits from the optimal performance and reliability of a well-chosen sucker electromagnet.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.