Last Updated on 2025-09-04 by SolenoidFactory

In the vast landscape of industrial automation and fluid control systems, solenoid valves play a crucial role. These versatile devices are used to control the flow of liquids and gases in a wide range of applications, from simple on/off operations to complex, precision-controlled processes. By understanding the key factors involved in choosing the right solenoid valve, you can ensure that your fluid control system operates efficiently, reliably, and cost-effectively. This blog serves as a comprehensive guide, walking you through the process of selecting the optimal solenoid valve for your specific needs.

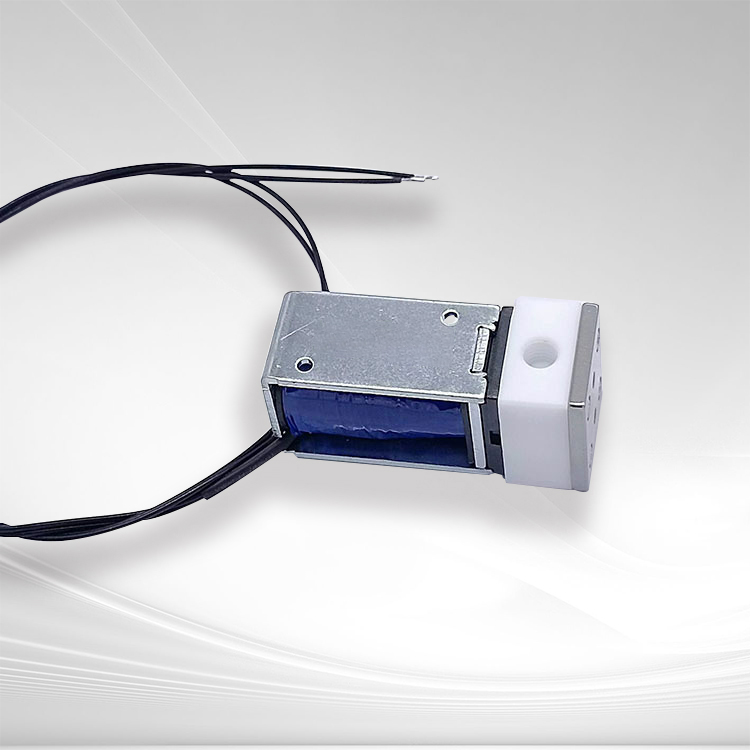

1: Fundamentals of Solenoid Valves

1.1 What is a Solenoid Valve?

A solenoid valve is an electromechanical device that uses an electromagnetic coil (the solenoid) to control the movement of a valve element, such as a plunger or diaphragm, thereby regulating the flow of fluid. When the coil is energized, it generates a magnetic field that attracts the valve element, causing it to move and either open or close the valve. De-energizing the coil reverses the process, allowing the valve to return to its original position.

1.2 Types of Solenoid Valves

Solenoid valves come in a variety of designs and configurations, tailored to meet the diverse needs of fluid control applications. Some common types include:

- Direct-Acting Solenoid Valves: These valves use the force generated by the solenoid coil directly to move the valve element. They are typically used in low-pressure applications and are characterized by fast response times.

- Pilot-Operated Solenoid Valves: These valves use a smaller solenoid coil to control a pilot valve, which in turn operates the main valve element. They are suitable for high-pressure and high-flow applications and offer greater control over fluid flow.

- Normally Closed (NC) and Normally Open (NO) Valves: Normally closed valves are designed to close when the solenoid coil is de-energized, while normally open valves are designed to open when the coil is de-energized. The choice between NC and NO valves depends on the specific requirements of the application.

- Two-Way, Three-Way, and Four-Way Valves: These refer to the number of ports or passages through which fluid can flow. Two-way valves control the flow between two ports, three-way valves allow fluid to flow in two directions but can block one path, and four-way valves can direct fluid flow between four ports, enabling more complex control strategies.

1.3 Key Performance Parameters

When selecting a solenoid valve, several key performance parameters must be considered:

- Operating Pressure and Temperature Range: The maximum pressure and temperature the valve can handle without failing or losing performance.

- Flow Rate: The rate of fluid flow that the valve can handle without causing excessive pressure drop or flow restriction.

- Response Time: The time it takes for the valve to fully open or close after energizing or de-energizing the solenoid coil.

- Power Consumption: The amount of electrical energy the solenoid coil consumes during operation.

- Material Compatibility: The compatibility of the valve’s internal components with the fluid being controlled, to prevent corrosion, contamination, or other adverse effects.

2: Evaluating Your Application's Requirements

2.1 Understanding Fluid Characteristics

The first step in selecting a solenoid valve is to understand the characteristics of the fluid you need to control. Consider the following:

- Fluid Type: Is the fluid a liquid or a gas? This will affect the valve’s design and material selection.

- Viscosity and Density: Higher viscosity and density fluids require valves with larger orifices and stronger solenoid coils to ensure adequate flow and response times.

- Corrosivity and Chemical Compatibility: Choose valve materials that are compatible with the fluid to prevent leaks, contamination, and premature failure.

- Particle Content: Fluids containing particles or impurities may require valves with special filtering or sealing features to prevent clogging or wear.

2.2 Determining Control Requirements

Next, assess the control requirements of your application. Consider the following:

- On/Off or Modulating Control: Decide whether you need a simple on/off valve or a modulating valve that can control fluid flow continuously over a range.

- Precision and Accuracy: Determine the level of precision and accuracy required for fluid flow control. High-precision applications may require valves with more sophisticated control mechanisms.

- Failure Mode: Consider the desired failure mode of the valve in case of power failure or other malfunctions. Normally closed valves will prevent fluid flow when de-energized, while normally open valves will allow flow to continue.

2.3 Environmental Conditions

The environmental conditions in which the solenoid valve will operate can also affect its selection. Consider the following:

- Ambient Temperature: Choose a valve with an operating temperature range that encompasses the ambient temperatures in your application.

- Humidity and Moisture: In high-humidity or moist environments, select valves with moisture-resistant or waterproof enclosures to prevent corrosion and electrical shorts.

- Vibration and Shock: In applications subject to vibration or shock, choose valves with robust construction and shock-absorbing features to ensure reliability.

3: Choosing the Right Solenoid Valves

3.1 Researching Supplier Options

With a clear understanding of your application’s requirements, it’s time to research potential suppliers of solenoid valves. Consider the following criteria:

- Product Range and Variety: Look for suppliers that offer a wide range of solenoid valves to accommodate various operating pressures, flow rates, and control requirements. This provides flexibility in selecting the best match for your application.

- Technical Expertise and Support: Choose suppliers with deep technical expertise in solenoid valves. They should be able to provide insights into material selection, coil design, and other critical factors that can significantly impact performance.

- Customization Capabilities: Assess the supplier’s ability to customize solenoid valves to meet specific requirements. This includes modifications to flow rates, pressure ratings, and control strategies to ensure optimal performance in diverse applications.

3.2 Product Evaluation

Once you’ve narrowed down your supplier options, evaluate the specific solenoid valves they offer based on your application’s requirements:

- Operating Pressure and Temperature Matching: Compare the operating pressure and temperature ranges of the solenoid valves to the conditions in your application. Ensure the selected valve can meet or exceed these requirements.

- Flow Rate and Response Time: Verify that the solenoid valve’s flow rate and response time are sufficient for your application’s control requirements. Consider any variations in fluid viscosity or density that may affect these parameters.

- Material Compatibility: Ensure the valve’s internal components are compatible with the fluid being controlled. Look for materials that resist corrosion, wear, and contamination.

- Power Consumption and Efficiency: Evaluate the power consumption of the solenoid coil and its impact on your electrical system. Look for valves with energy-efficient designs that minimize power consumption and heat generation.

3.3 Testing and Validation

Before making a final decision, consider testing and validating the selected solenoid valve in your application environment:

- Prototype Testing: Request a prototype of the selected solenoid valve for testing in your specific application. This allows you to validate its performance under real-world conditions and identify any potential issues or limitations.

- Performance Metrics: Establish performance metrics and benchmarks for the solenoid valve based on your application’s requirements. Monitor these metrics during testing to ensure the valve meets or exceeds expectations.

- Feedback and Adjustments: Provide feedback to the supplier based on your testing results. They may offer adjustments or modifications to improve performance and alignment with your application’s needs.

4: Ensuring Long-Term Reliability and Performance

4.1 Maintenance and Servicing

Maintaining the reliability and performance of your solenoid valve over time is crucial. Consider the following best practices:

- Regular Inspections: Schedule regular inspections of the solenoid valve to check for signs of wear, contamination, or damage. This helps identify potential issues before they become critical and ensures the valve operates safely and effectively.

- Cleaning and Lubrication: Clean the solenoid valve regularly to remove dirt, debris, and other contaminants. Apply suitable lubricants to moving parts, such as shafts and seals, to reduce friction and wear.

- Spare Parts Inventory: Maintain an inventory of spare parts, such as solenoid coils, diaphragms, and seals, to minimize downtime in case of failures. Ensure these parts are compatible with your installed solenoid valves.

4.2 Supplier Support and Warranty

Partnering with a supplier that offers comprehensive support and warranty services can enhance the lifespan and reliability of your solenoid valves. Consider the following:

- Technical Support: Ensure the supplier provides ongoing technical support for troubleshooting, maintenance, and performance optimization. Look for suppliers with dedicated support teams and quick response times.

- Warranty Coverage: Verify the warranty coverage provided by the supplier. Look for comprehensive warranties that cover defects in materials and workmanship, as well as any additional services or replacements required.

- Training and Documentation: Ensure the supplier provides adequate training and documentation for installing,operating, and maintaining the solenoid valve. This should include user manuals, technical specifications, and training sessions to ensure your team is equipped to handle the valve effectively.

5: Trends and Innovations in Solenoid Valves

5.1 Smart Solenoid Valves and IoT Integration

The integration of smart technology and Internet of Things (IoT) connectivity is transforming solenoid valves. Smart solenoid valves incorporate sensors and communication modules that enable real-time monitoring, diagnostics, and control. This allows for predictive maintenance, optimized performance, and remote monitoring, enhancing reliability and reducing downtime.

IoT-enabled solenoid valves can transmit data on operating conditions, flow rates, and energy consumption to a central control system. Operators can then analyze this data to identify trends, predict failures, and adjust control strategies for optimal performance. Additionally, remote access capabilities enable troubleshooting and adjustments to be made without the need for physical intervention, reducing maintenance costs and improving safety.

5.2 Energy-Efficient Designs

Energy efficiency is a growing concern in industrial automation and fluid control systems. Manufacturers are responding by developing solenoid valves with energy-efficient designs that minimize power consumption and heat generation. These valves use advanced materials, optimized coil designs, and energy-recovery mechanisms to reduce energy waste.

Energy-efficient solenoid valves can significantly lower operational costs and reduce the environmental impact of industrial processes. Look for valves with low power consumption ratings and energy-saving features, such as adjustable control signals and sleep modes, to minimize energy use when not in active use.

5.3 Compact and Lightweight Designs

The trend towards compact and lightweight designs is driving innovation in solenoid valves. Manufacturers are leveraging advanced manufacturing techniques, such as precision machining and additive manufacturing, to create valves with reduced footprints and lighter weights. This makes solenoid valves more suitable for applications with limited space or weight constraints, such as aerospace, robotics, and medical devices.

Compact and lightweight solenoid valves also offer benefits in terms of installation and maintenance. They are easier to integrate into existing systems, require less space, and can be serviced more quickly and efficiently. Look for valves with optimized designs that maximize performance while minimizing size and weight.

5.4 Enhanced Material Compatibility and Corrosion Resistance

Manufacturers are continually developing new materials and coatings to enhance the compatibility and corrosion resistance of solenoid valves. These advanced materials offer improved resistance to chemicals, high temperatures, and abrasive fluids, extending the lifespan of the valve and reducing the risk of leaks or failures.

Consider solenoid valves with materials tailored to your specific application’s requirements. For example, valves designed for use with aggressive chemicals may benefit from corrosion-resistant alloys or special coatings that protect against chemical attack. Similarly, valves operating in high-temperature environments may require materials with higher thermal stability and resistance to thermal cycling.

6: solenoid valves Case Studies and Application Examples

6.1 Automated Manufacturing Lines

In automated manufacturing lines, solenoid valves play a critical role in controlling the flow of various fluids, such as coolants, lubricants, and cleaning agents. They ensure precise and reliable fluid delivery, enabling efficient and high-quality production processes.

For example, in a metalworking application, solenoid valves may be used to control the flow of cutting fluids to machine tools. By precisely regulating the fluid’s pressure, temperature, and flow rate, manufacturers can optimize cutting performance, reduce tool wear, and improve surface finish.

6.2 Water Treatment Plants

Solenoid valves are essential components in water treatment plants, where they control the flow of water and treatment chemicals. They are used in various stages of the treatment process, from raw water intake and filtration to chemical dosing and disinfection.

In one example, solenoid valves may be used to regulate the flow of chlorine or other disinfectants into the water supply. By precisely controlling the dosage and distribution of these chemicals, water treatment plants can ensure the safety and quality of the water they provide to consumers.

6.3 Pneumatic Systems

Solenoid valves are widely used in pneumatic systems to control the flow of compressed air or other gases. They are essential components in automation and robotics applications, enabling precise and reliable control of pneumatic actuators, cylinders, and other devices.

In a robotic assembly line, for instance, solenoid valves may be used to control the movement of robotic arms and tools. By precisely regulating the flow of compressed air to these devices, manufacturers can achieve high levels of accuracy and repeatability in their assembly processes.

Choosing the right solenoid valves

Choosing the right solenoid valve involves a thorough understanding of your application’s requirements, careful evaluation of potential suppliers and products, and ongoing maintenance and support to ensure long-term reliability and performance. By following the guidelines outlined in this blog, you can navigate the complex world of solenoid valves and make an informed decision that meets your needs today and adapts to your future demands.

Remember, the key to successful solenoid valve selection is balance. Balance the operating pressure, flow rate, and response time against the environmental conditions, material compatibility, and control requirements of your application. Balance the need for customization and flexibility with the supplier’s technical expertise, product range, and support services. And finally, balance the initial cost with the long-term benefits of reliability, performance, and energy efficiency.

In conclusion, solenoid valves are indispensable components in numerous industrial applications, and selecting the right one requires careful consideration and planning. By staying informed about the latest trends and innovations, you can ensure you are always leveraging the best technology for your applications. Happy solenoid valve selecting!

This comprehensive guide has covered the essentials of choosing a solenoid valve. By following the outlined steps and considerations, you can make an informed decision that ensures your application benefits from the optimal performance and reliability of a well-chosen solenoid valve.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.