Last Updated on 2025-09-03 by SolenoidFactory

In the realm of electromagnetic technology, bistable solenoids are a unique breed that offer distinct advantages for various applications. Unlike traditional solenoids, which require continuous power to maintain their position, bistable solenoids utilize a pulsed current to switch between two stable states, significantly reducing energy consumption. Whether you’re developing an automated system, creating a locking mechanism, or integrating a valve control, choosing the right bistable solenoid is crucial for ensuring optimal performance and reliability.

This blog serves as a comprehensive guide to help you navigate the world of bistable solenoids, with a focus on key selection criteria, application considerations, and tips for evaluating potential suppliers. By the end, you’ll be equipped with the knowledge necessary to make an informed decision that aligns with your project’s requirements.

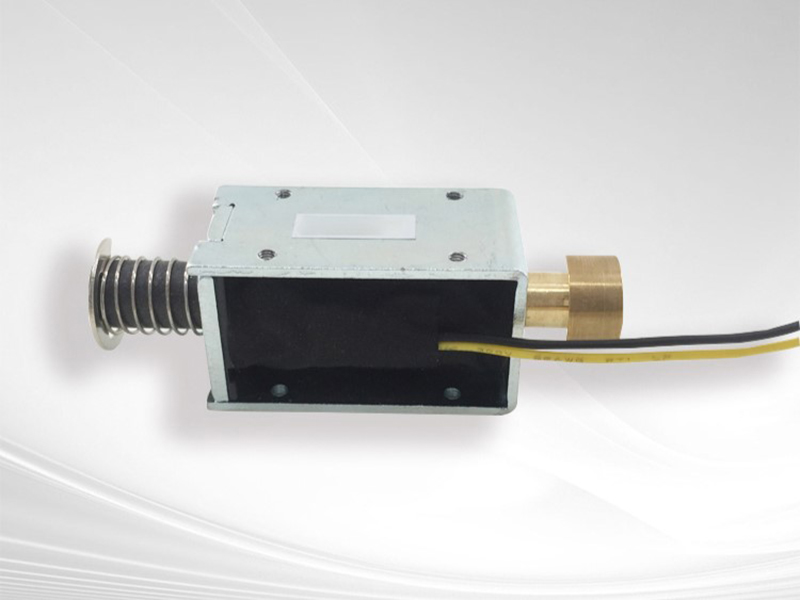

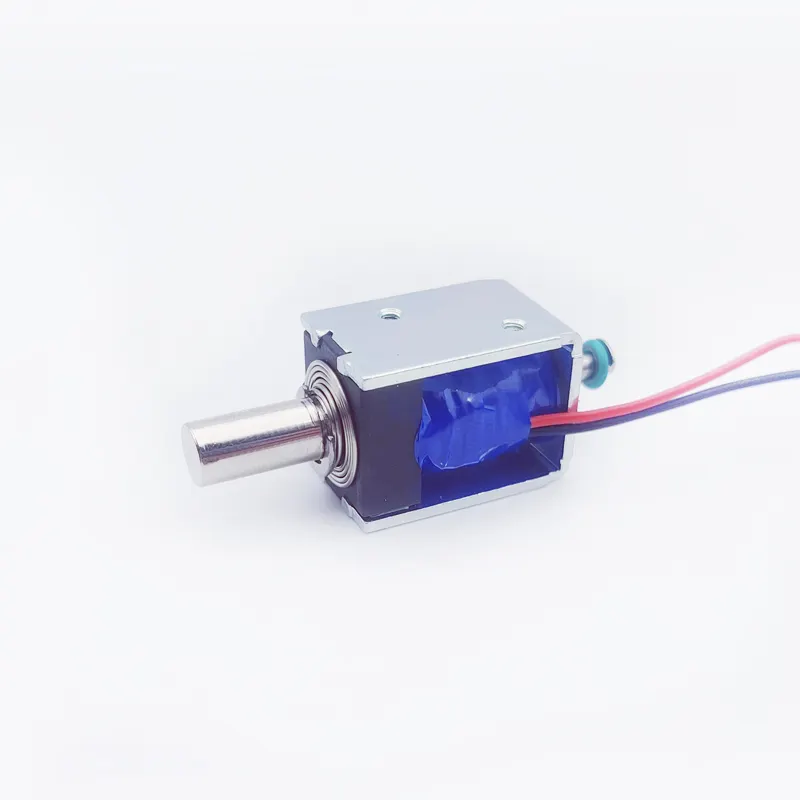

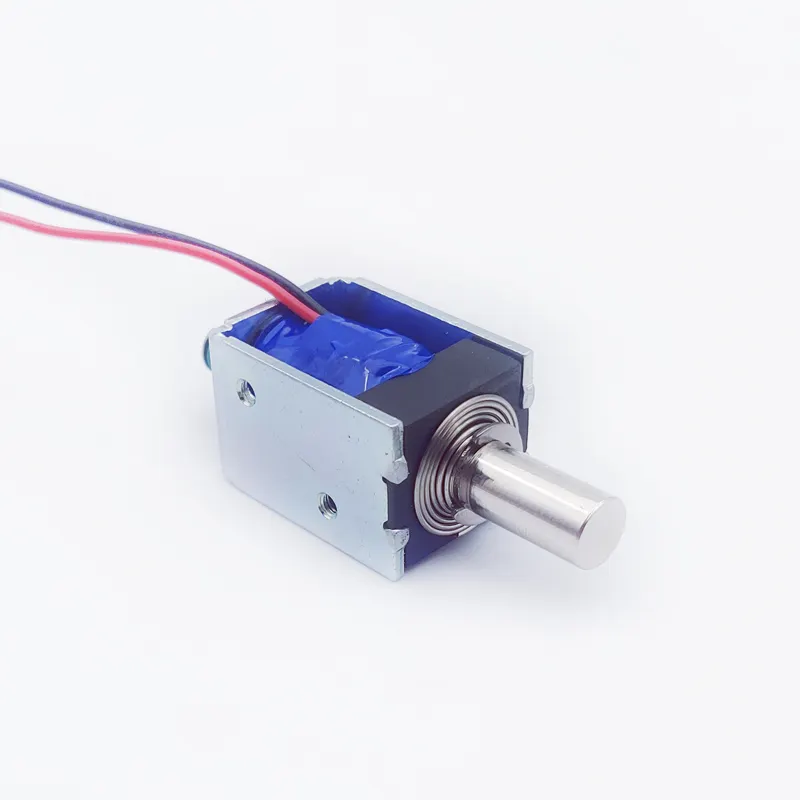

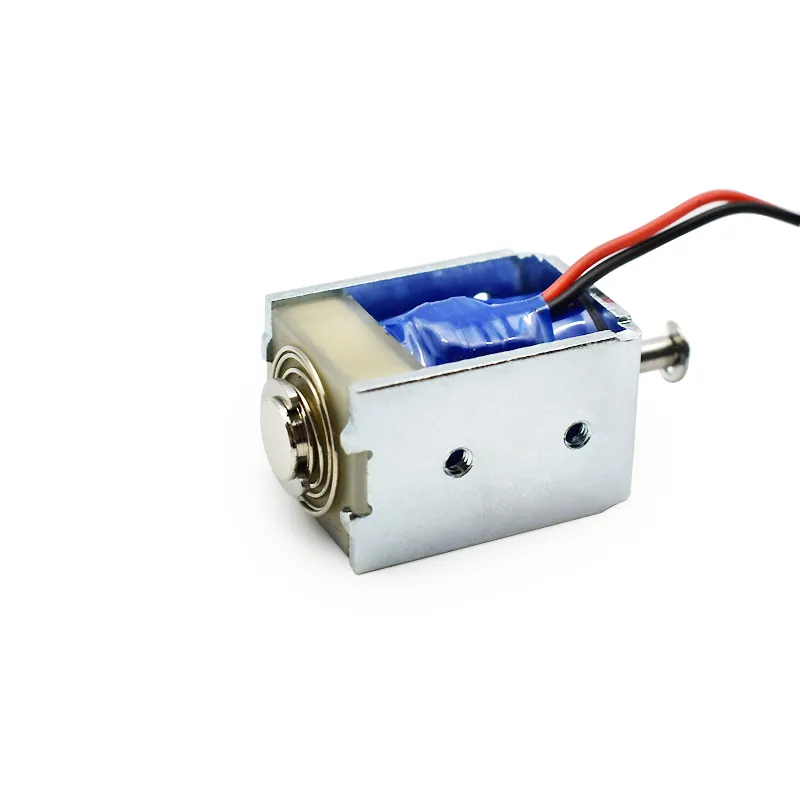

what are Bistable Solenoids

Before diving into the selection process, it’s essential to grasp the basics of bistable solenoids. A bistable solenoid operates on the principle of magnetic latching. When energized with a brief pulse, the armature (moving part) is attracted to either of two stable positions, held there by residual magnetism until the next pulse reverses its direction. This dual-state stability eliminates the need for continuous power, making bistable solenoids ideal for applications requiring low power consumption and long-term reliability.

Key Characteristics:

- Two Stable States: The armature latches in one of two positions after being pulsed.

- Energy Efficiency: No continuous power is required to maintain position.

- Compact Design: Often suitable for space-constrained applications.

- Long Lifespan: High durability due to reduced wear and tear.

Choosing the Right Bistable Solenoid: Key Criteria

Choosing the right bistable solenoid involves several critical steps, each requiring careful consideration to ensure compatibility with your application’s specific needs. Here are the primary criteria to evaluate:

1. Force and Stroke Requirements

Why It Matters:

The force required to actuate the armature and the stroke (distance it travels) are fundamental parameters. They dictate the solenoid’s ability to perform the intended function, whether it’s moving a lever, locking a mechanism, or controlling a valve.

Evaluation Tips:

- Calculate the Required Force: Determine the maximum force needed to overcome friction, inertia, or other loads in your application.

- Consider Stroke Length: Measure the distance the armature must travel to engage or disengage the target component.

Example:

In a security locking system, a bistable solenoid with a high holding force ensures the lock remains secure, while an adequate stroke allows the latch to engage and disengage smoothly.

2. Power Consumption and Voltage Range

Why It Matters:

Energy efficiency is a significant advantage of bistable solenoids. However, understanding the power consumption during pulsing and the operating voltage range is crucial for compatibility with your system’s power supply.

Evaluation Tips:

- Assess Power Budget: Determine the maximum pulsed power your system can provide without overloading.

- Voltage Compatibility: Ensure the solenoid’s voltage range aligns with your power supply specifications.

Example:

For battery-powered devices, selecting a low-power bistable solenoid extends operational life by minimizing energy consumption.

3. Size and Weight

Why It Matters:

Space constraints and weight limitations often dictate the physical dimensions of components in many applications. A solenoid’s size and weight can affect installation, system balance, and overall performance.

Evaluation Tips:

- Measure Available Space: Ensure the solenoid fits within the designated area without interfering with other components.

- Consider Weight: Lightweight solenoids reduce stress on mounting structures and can be easier to integrate.

Example:

In aerospace applications, where every gram counts, choosing a compact, lightweight bistable solenoid optimizes payload and fuel efficiency.

4. Environmental Conditions

Why It Matters:

Operational environment can significantly impact a solenoid’s performance and lifespan. Factors such as temperature, humidity, and exposure to contaminants can degrade materials and affect magnetic properties.

Evaluation Tips:

- Identify Environmental Factors: Determine the temperature range, humidity levels, and potential contaminants in your application.

- Select Appropriate Materials: Choose solenoids with materials that can withstand the identified environmental conditions.

Example:

In outdoor applications exposed to extreme temperatures and moisture, a bistable solenoid with rust-resistant coatings and temperature-stable materials ensures long-term reliability.

5. Duty Cycle and Lifespan

Why It Matters:

The duty cycle (ratio of on-time to total cycle time) and lifespan (number of cycles before failure) are critical for applications requiring frequent actuation or long-term operation.

Evaluation Tips:

- Calculate Duty Cycle: Estimate the solenoid’s operating time relative to the rest period.

- Review Lifespan Specifications: Ensure the solenoid’s lifespan meets or exceeds your application’s expected operational duration.

Example:

In industrial automation, where solenoids may cycle thousands of times a day, selecting a high-durability bistable solenoid minimizes downtime and maintenance costs.

6. Control and Monitoring Requirements

Why It Matters:

Controlling and monitoring the solenoid’s state is essential for ensuring system reliability and diagnosing issues. Compatibility with existing control systems and the need for additional sensors can influence your choice.

Evaluation Tips:

- Assess Control System Compatibility: Ensure the solenoid’s control interface (e.g., voltage pulse, digital signal) matches your system’s requirements.

- Consider Monitoring Needs: Determine if additional sensors (e.g., position sensors, temperature sensors) are necessary for real-time monitoring.

Example:

In a medical device, integrating a bistable solenoid with compatible control electronics and sensors ensures precise, reliable operation and enhances system diagnostics.

7. Certifications and Compliance

Why It Matters:

Certifications and compliance with industry standards ensure that the solenoid meets safety, environmental, and performance benchmarks. They can be critical for gaining market acceptance and satisfying regulatory requirements.

Evaluation Tips:

- Identify Relevant Standards: Determine the certifications and standards required for your application (e.g., UL, CE, RoHS).

- Verify Compliance: Ensure the supplier provides documentation proving compliance with the identified standards.

Example:

In automotive applications, selecting a bistable solenoid with ISO/TS 16949 certification ensures it meets rigorous quality management standards.

Evaluating Bistable Solenoid Suppliers

Choosing the right supplier is as crucial as selecting the right solenoid. A reputable supplier can provide valuable insights, technical support, and quality assurance to ensure your project’s success. Here are some tips for evaluating potential suppliers:

1. Technical Expertise and Experience

Why It Matters:

Suppliers with deep technical expertise and experience in bistable solenoids can offer tailored solutions, address complex challenges, and provide valuable recommendations.

Evaluation Tips:

- Review Technical Literature: Assess the supplier’s knowledge base, white papers, and technical guides.

- Consult with Engineers: Engage with their engineering team to discuss your specific requirements and challenges.

Example:

A supplier with a proven track record in custom bistable solenoids can design a solution tailored to your unique application.

2. Manufacturing Capabilities and Quality Control

Why It Matters:

In-house manufacturing capabilities and robust quality control protocols ensure consistent performance and reliability.

Evaluation Tips:

- Tour the Facility: If possible, visit the supplier’s manufacturing facility to observe processes and quality checks.

- Request Quality Certifications: Ensure the supplier holds relevant ISO certifications for quality management.

Example:

A supplier with ISO 9001 certification demonstrates a commitment to high-quality manufacturing processes.

3. Customization and Prototype Support

Why It Matters:

Customization capabilities and support for prototype development can加速 the design process and ensure the solenoid meets your exact specifications.

Evaluation Tips:

- Discuss Customization Options: Inquire about the supplier’s ability to modify materials, dimensions, and control interfaces.

- Request Prototype Development: Seek a supplier willing to collaborate on prototype development and testing.

Example:

A supplier that offers rapid prototyping services can accelerate your product development timeline.

4. Customer Support and After-Sales Service

Why It Matters:

Responsive customer support and comprehensive after-sales service are essential for addressing issues, optimizing performance, and ensuring long-term reliability.

Evaluation Tips:

- Request Customer References: Speak with existing customers to gauge the supplier’s responsiveness and support quality.

- Review Service Agreements: Ensure the supplier offers comprehensive warranty and maintenance services.

Example:

A supplier with a dedicated customer support team and a robust warranty program ensures peace of mind and reduces long-term costs.

5. Sustainability Practices

Why It Matters:

Environmental sustainability is increasingly important. Choosing a supplier committed to sustainable practices supports your efforts to reduce environmental impact.

6. Price and Cost-Effectiveness

Why It Matters:

While price is a critical factor, it should not be the sole determinant. Evaluating the overall cost-effectiveness, which includes performance, reliability, and long-term maintenance costs, is essential.

Evaluation Tips:

- Request Detailed Quotes: Ensure quotes include all necessary components, shipping, and any potential setup fees.

- Assess Lifecycle Costs: Consider the solenoid’s expected lifespan and maintenance requirements when evaluating cost-effectiveness.

Example:

A slightly higher-priced solenoid with superior durability and lower maintenance costs may be more cost-effective in the long run.

Making the Final Decision of bistable solenoids

Choosing the right bistable solenoids involves a thorough evaluation of your application’s requirements and a careful assessment of potential suppliers. By focusing on key criteria such as force and stroke requirements, power consumption, size and weight, environmental conditions, duty cycle and lifespan, control and monitoring needs, and certifications and compliance, you can narrow down your options to those that best meet your needs.

Furthermore, evaluating suppliers based on their technical expertise, manufacturing capabilities, customization support, customer service, sustainability practices, and cost-effectiveness ensures you partner with a reliable, responsive organization committed to your project’s success.

Remember, the best bistable solenoid is not necessarily the cheapest or the most advanced; it’s the one that aligns perfectly with your application’s specific requirements and supports your long-term goals.

Additional Resources and Next Steps

As you continue your search for the ideal bistable solenoids, consider these additional resources and next steps:

- Supplier Websites: Visit the websites of potential suppliers to learn more about their products, services, and technical capabilities.

- Industry Publications: Read industry publications and trade journals to stay informed about the latest trends, advancements, and best practices in bistable solenoid technology.

- Trade Shows and Conferences: Attend industry trade shows and conferences to network with suppliers, learn about new products, and gather insights from peers and experts.

- Pilot Testing: Consider pilot testing a few selected solenoids in your application environment to validate performance and reliability before making a final decision.

By leveraging these resources and following the guidance outlined in this blog, you’ll be well-equipped to choose the right bistable solenoid for your application, ensuring optimal performance, reliability, and cost-effectiveness.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.