Last Updated on 2025-09-04 by SolenoidFactory

Electromagnets are critical components in industries ranging from automotive manufacturing to medical devices. While they are designed for durability, their performance and lifespan depend heavily on daily maintenance. Neglecting routine checks can lead to unexpected downtime, safety hazards, and costly repairs. As a professional electromagnet manufacturer, we provide this comprehensive guide to help users implement effective maintenance practices, avoid common pitfalls, and learn from real-world case studies.

1. Daily Maintenance Checklist for Electromagnets

1.1 Visual Inspections

Objective: Identify visible wear, contamination, or misalignment.

Steps:

- Check for Debris: Dust, metal shavings, or liquids can interfere with magnetic fields.

- Inspect Coils and Wiring: Look for frayed wires, loose connections, or discoloration (signs of overheating).

- Examine Armature and Core: Ensure smooth surfaces free from rust, pitting, or scoring.

Case Study 1:

A steel mill’s conveyor system failed due to iron dust accumulation on electromagnet cores. Daily compressed air cleaning reduced downtime by 70%.

1.2 Electrical System Checks

Objective: Ensure stable power supply and prevent electrical faults.

Steps:

- Measure Voltage/Current: Use a multimeter to verify input matches specifications (e.g., 24V DC ±10%).

- Test Insulation Resistance: Use a megohmmeter to confirm coil insulation >100MΩ (prevents short circuits).

- Monitor Temperature: Infrared thermometers should show coils <85°C in continuous duty.

Case Study 2:

A hospital’s MRI machine suffered intermittent electromagnet failures. Daily voltage logging revealed fluctuations caused by an aging power supply—replaced within 48 hours.

1.3 Mechanical Integrity Tests

Objective: Detect wear in moving parts and mounting systems.

Steps:

- Tighten Fasteners: Bolts should be torqued to manufacturer specs (e.g., 20 N·m for M10 bolts).

- Lubricate Moving Parts: Apply high-temperature grease to sliders, hinges, or bearings.

- Check Air Gaps: Use feeler gauges to maintain gaps within ±0.1mm of design specs.

Case Study 3:

A robotic welding arm’s electromagnet dropped parts due to a 0.3mm air gap deviation. Daily gap calibration restored 99% grip reliability.

2. Critical Precautions for Electromagnet Maintenance

2.1 Preventing Overheating

Risks: Insulation degradation, demagnetization, fire hazards.

Precautions:

- Ensure Adequate Cooling: Clean ventilation slots and check fan operation.

- Avoid Overvoltage: Install surge protectors and voltage regulators.

- Limit Duty Cycles: For intermittent-use electromagnets, follow ON/OFF time ratios (e.g., 60 seconds ON, 120 seconds OFF).

Case Study 4:

A packaging machine’s electromagnet overheated after 8 hours of continuous use. Adding a PWM controller to reduce hold current lowered temperatures by 30°C.

2.2 Corrosion Prevention

Risks: Reduced magnetic force, mechanical jamming.

Precautions:

- Apply Protective Coatings: Use nickel-plated cores or epoxy seals in humid environments.

- Control Humidity: Store spare electromagnets in silica gel-dry cabinets.

- Use Stainless Steel Hardware: Replace carbon steel bolts with A4-80 grade in corrosive settings.

Case Study 5:

A coastal cargo crane’s electromagnets rusted within 6 months. Switching to marine-grade coatings and monthly anti-corrosion sprays extended lifespan to 5+ years.

2.3 Minimizing Mechanical Wear

Risks: Misalignment, noise, and premature failure.

Precautions:

- Install Shock Absorbers: Reduce impact forces in high-cycle applications.

- Use Wear Plates: Add hardened steel plates between moving parts.

- Avoid Side Loading: Ensure forces align with the electromagnet’s axis.

Case Study 6:

A stamping press’s electromagnet developed a 2mm side load due to misaligned guides. Realigning guides and adding linear bearings eliminated wear.

3. Specialized Maintenance for Industry-Specific Applications

3.1 Automotive Manufacturing

Challenges: High cycle rates, oil contamination.

Precautions:

- Daily Oil Wipe-Downs: Use lint-free cloths to remove grease from armatures.

- Weekly Coil Impedance Tests: Detect early winding degradation.

Case Study 7:

A car door latch assembly line reduced defects by 40% after implementing daily impedance checks on 200+ electromagnets.

3.2 Medical Devices

Challenges: Sterility requirements, EMI sensitivity.

Precautions:

- Autoclave Compatibility: Use coils with Class H insulation (withstands 180°C).

- EMI Shielding: Inspect braided shielding on cables weekly.

Case Study 8:

A surgical robot’s electromagnet interfered with ECG monitors. Adding ferrite chokes to power lines eliminated EMI.

3.3 Renewable Energy Systems

Challenges: Temperature extremes, vibration.

Precautions:

- Thermal Cycling Tests: Simulate -40°C to 85°C daily to check material stability.

- Vibration Analysis: Use accelerometers to detect resonant frequencies.

Case Study 9:

A wind turbine’s pitch control electromagnet failed in -30°C conditions. Switching to cold-rated lubricants and neodymium magnets solved the issue.

4. Tools and Equipment for Effective Maintenance

4.1 Essential Tools

- Digital Multimeter: For voltage, current, and resistance checks.

- Infrared Thermometer: Non-contact temperature monitoring.

- Torque Wrench: Ensures proper fastener tightness.

4.2 Advanced Diagnostics

- Megohmmeter: Tests insulation breakdown risks.

- Oscilloscope: Analyzes coil current waveforms for anomalies.

- Vibration Analyzer: Detects imbalance or misalignment.

Case Study 10:

A factory used an oscilloscope to diagnose a 10% current ripple in an electromagnet’s driver circuit, traced to a faulty capacitor.

5. Training and Documentation

5.1 Staff Training

- Monthly Workshops: Cover topics like “Identifying Overheating Signs” or “Emergency Shutdown Procedures.”

- Certification Programs: Partner with manufacturers for accredited training.

5.2 Maintenance Logs

- Digital Logs: Use CMMS (Computerized Maintenance Management Systems) to track:

- Daily inspection results.

- Repair histories.

- Replacement schedules.

Case Study 11:

A power plant avoided a $500K outage by analyzing logs showing gradual coil resistance increases, preemptively replacing 10 electromagnets.

6. Emergency Response and Troubleshooting

6.1 Immediate Actions for Failures

- Power Down: Isolate the electromagnet from the power source.

- Lockout/Tagout (LOTO): Prevent accidental re-energization.

- Diagnose: Use the 5 Whys method to identify root causes.

Common Issues and Fixes:

- No Activation: Check for open circuits (common culprits: broken wires, blown fuses).

- Weak Holding Force: Clean armature surfaces or recalibrate air gaps.

- Chattering: Stabilize voltage or replace worn armature pads.

Case Study 12:

A mining elevator’s electromagnet failed mid-operation. Technicians followed LOTO protocols, diagnosed a severed cable, and restored operations in 2 hours.

7. electromagnets Case Studies: Lessons from the Field

7.1 Case Study 13: Aerospace Component Testing

Problem: Electromagnets in a vibration test rig lost 30% force after 1,000 cycles.

Solution:

- Daily Maintenance: Replaced aluminum wear plates with tungsten carbide.

- Weekly Testing: Measured magnetic flux density with a Hall effect sensor.

Result: Achieved 10,000+ cycles without degradation.

7.2 Case Study 14: Food Processing Conveyors

Problem: Dairy residue caused corrosion and bacterial growth on electromagnets.

Solution:

- Daily Cleaning: Ultrasonic baths with food-grade detergents.

- Monthly Inspections: Swab tests for microbial contamination.

Result: Complied with FDA sanitation standards.

7.3 Case Study 15: Semiconductor Manufacturing

Problem: Static discharge damaged sensitive electromagnet controllers.

Solution:

- Daily Grounding Checks: Verified <1Ω resistance to ground.

- ESD-Safe Tools: Used antistatic wipes and wrist straps.

Result: Reduced controller failures by 90%.

8. electromagnets Long-Term Storage and Spare Parts Management

8.1 Storage Best Practices

- Climate Control: Store at 15–25°C and 40–60% humidity.

- De-Energize: Remove batteries or supercapacitors to prevent aging.

- Anti-Corrosion Packaging: Use VCI (Vapor Corrosion Inhibitor) bags.

8.2 Spare Parts Strategy

- Critical Spares: Keep 10% of operational units as backups (e.g., 10 spares for 100 electromagnets).

- Supplier Agreements: Ensure lead times <72 hours for urgent replacements.

Case Study 16:

An automotive OEM saved $1.2M annually by negotiating just-in-time spare deliveries with their electromagnet manufacturer.

electromagnets Proactive Maintenance for Uninterrupted Operations

Daily maintenance of electromagnets is not just a routine task—it’s a strategic investment in reliability and safety. By implementing the precautions and practices outlined here, you can extend equipment lifespan, reduce downtime, and avoid catastrophic failures.

As your trusted electromagnet partner, we offer customized maintenance plans and 24/7 technical support to keep your systems running smoothly. Remember: A well-maintained electromagnet isn’t just a component; it’s a cornerstone of your operational success.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact WhatsApp +86 18902611680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

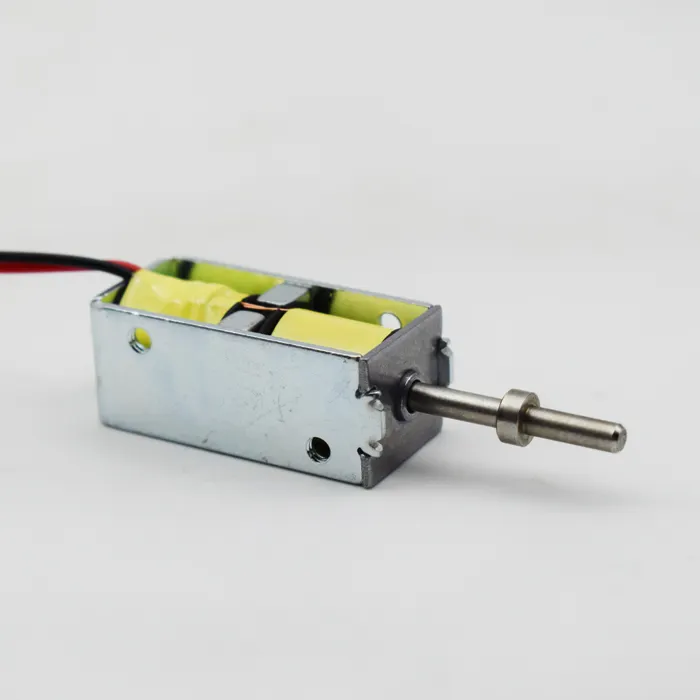

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.