Last Updated on 2025-09-03 by SolenoidFactory

In the intricate world of electromagnetics, the operating temperature range and protection level of an electromagnet are pivotal parameters that significantly impact its performance, reliability, and lifespan. Understanding these aspects is essential for ensuring that electromagnet-based systems function optimally across diverse applications, from industrial automation to automotive systems and beyond. This blog aims to provide a comprehensive analysis of electromagnet operating temperature range and protection level, exploring their definitions, significance, influencing factors, and implications for various use cases.

Defining Operating Temperature Range of electromagnet

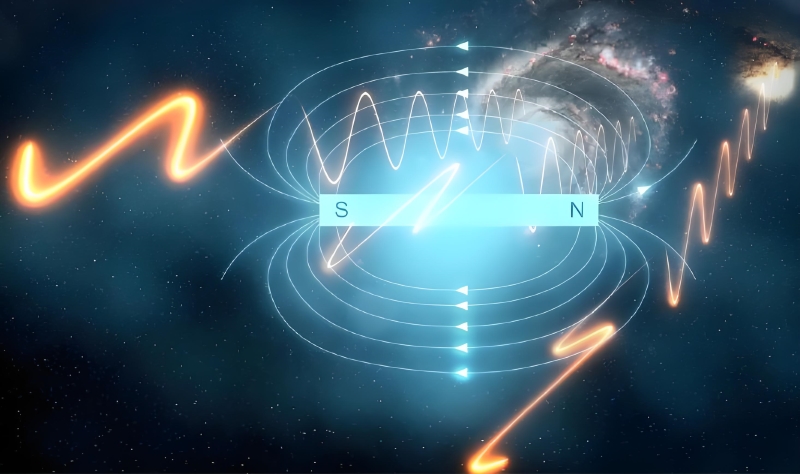

The operating temperature range specifies the minimum and maximum temperatures at which an electromagnet can function reliably without experiencing performance degradation or damage. This range is crucial because electromagnets are composed of materials with temperature-sensitive properties, such as ferromagnetic cores and insulating materials. Exceeding these temperature limits can lead to reduced magnetic performance, increased power consumption, and premature failure.

Understanding Protection Level

The protection level of an electromagnet refers to its ability to withstand environmental conditions and potential hazards that could impair its operation or cause damage. This includes protection against moisture, dust, mechanical impacts, and electrical faults. The protection level is often specified using Ingress Protection (IP) ratings, which provide a standardized measure of an electromagnet’s resistance to ingress of solid objects and liquids.

Significance of Operating Temperature Range and Protection Level

The operating temperature range and protection level are significant for several reasons:

Performance Stability: Maintaining the electromagnet within its operating temperature range ensures consistent and reliable performance, preventing magnetic field weakening or power consumption spikes.

Safety and Reliability: Adequate protection levels safeguard the electromagnet against environmental contaminants and mechanical stress, enhancing its durability and reducing the risk of failure.

Application Versatility: Understanding these parameters allows engineers to select electromagnets that are suitable for diverse applications, ensuring optimal performance across a wide range of conditions.

Factors Influencing electromagnet Operating Temperature Range

Several factors contribute to defining the operating temperature range of an electromagnet:

Material Properties: The Curie temperature of the ferromagnetic core material sets an upper limit beyond which the material loses its magnetic properties. Similarly, the glass transition temperature of insulating materials affects the electromagnet’s lower temperature limit.

Thermal Management: The electromagnet’s cooling system, if any, and its ability to dissipate heat determine its operational temperature limits. Poor thermal management can lead to overheating and premature failure.

Environmental Conditions: External factors such as ambient temperature, humidity, and contaminants can affect the electromagnet’s temperature range and overall performance.

Factors Influencing electromagnet Protection Level

The protection level of an electromagnet is influenced by:

Enclosure Design: The physical design of the electromagnet’s enclosure, including sealing and gasketing, determines its resistance to ingress of dust and water.

Material Selection: Choosing materials with high resistance to corrosion, chemicals, and mechanical stress enhances the electromagnet’s protection level.

Mounting and Orientation: The way the electromagnet is mounted and oriented within a system can affect its exposure to environmental hazards and, thus, its protection requirements.

Application-Specific Considerations

When selecting an electromagnet for a specific application, engineers must consider:

Operating Environment: The temperature extremes, humidity levels, and contaminants present in the operating environment determine the required operating temperature range and protection level.

System Integration: The electromagnet’s integration into the larger system, including its location, orientation, and proximity to other components, affects its exposure to potential hazards and, thus, its protection needs.

Safety Regulations: Adherence to industry standards and safety regulations often mandates specific protection levels for electromagnets used in critical applications, such as automotive systems or industrial automation.

The operating temperature range and protection level of an electromagnet are critical parameters

The operating temperature range and protection level of an electromagnet are critical parameters that determine its performance, reliability, and suitability for diverse applications. Understanding these aspects and the factors that influence them is essential for designing and selecting electromagnets that meet specific requirements. By carefully considering operating environment, system integration, safety regulations, and material properties, engineers can ensure that electromagnet-based systems deliver optimal performance, reliability, and safety. As technology advances, ongoing research and innovation will likely lead to more efficient, versatile, and robust electromagnet designs, further expanding their potential applications and contributions to modern technology.

About SF electromagnet factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.