Last Updated on 2025-09-03 by SolenoidFactory

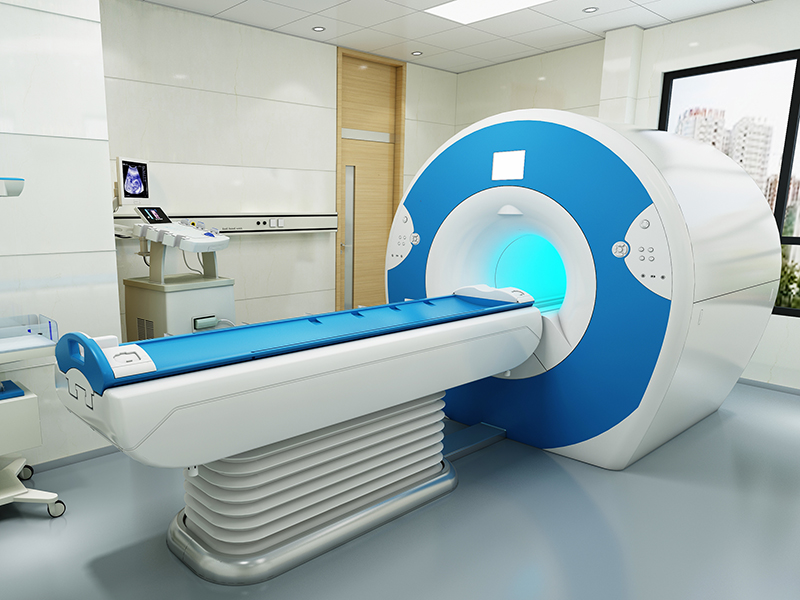

In the realm of medical imaging, Magnetic Resonance Imaging (MRI) stands as a pillar of modern healthcare, providing detailed and accurate insights into the human body. Behind this sophisticated technology lies a crucial component: the electromagnet. This blog delves into the significance, workings, and advancements of electromagnets in MRI machines, highlighting their pivotal role in revolutionizing medical diagnostics.

The Heart of MRI: Electromagnet Basics

MRI machines leverage the principles of nuclear magnetic resonance and electromagnetism to create detailed images of internal body structures. At the core of this technology is a powerful electromagnet, typically a superconducting magnet, which generates a strong, static magnetic field. This field aligns the magnetic moments of hydrogen atoms, predominantly found in water molecules within the body, creating the foundation for the imaging process.

The strength of the magnetic field, often measured in teslas (T), is crucial. Standard MRI machines operate with field strengths ranging from 0.5T to 3.0T, while cutting-edge systems, like the recently developed 5.0T MRI, push the boundaries even further. The stronger the magnetic field, the more pronounced the alignment of hydrogen atoms and the higher the resolution of the resulting images.

How Electromagnet Work in MRI

When a patient enters the MRI scanner, they are surrounded by the powerful magnetic field generated by the electromagnet. This field aligns the hydrogen atoms in the body’s water molecules. Next, the MRI machine uses radiofrequency (RF) pulses to temporarily flip the alignment of these atoms. As the atoms return to their original alignment, they release energy in the form of RF signals, which are detected by the MRI machine’s receiver coils.

These signals are then processed by a computer, which converts them into detailed, cross-sectional images of the body. The process is repeated multiple times, with slight variations in the RF pulses and magnetic field gradients, to build a comprehensive picture of the internal structures.

Advancements and Challenges

The development of superconducting electromagnets has been a significant breakthrough in MRI technology. Superconducting magnets operate at extremely low temperatures, usually achieved through liquid helium cooling, allowing them to generate very strong and stable magnetic fields with minimal energy consumption.

However, these electromagnets come with their own set of challenges. The need for constant cooling and the complexity of maintaining superconducting conditions necessitate specialized infrastructure and regular maintenance. Furthermore, the presence of a strong magnetic field necessitates stringent safety protocols, particularly for patients with metallic implants or other ferromagnetic objects.

Innovations in MRI Electromagnet

Recent innovations in MRI electromagnet technology have focused on enhancing field strength, improving image resolution, and reducing the overall footprint and maintenance requirements of the machines. The advent of 5.0T MRI systems represents a significant leap forward, offering unparalleled image quality and faster scan times.

Moreover, researchers are exploring new materials and designs to develop more efficient and cost-effective electromagnets. For instance, the use of high-temperature superconductors could potentially eliminate the need for liquid helium cooling, simplifying maintenance and reducing operational costs.

Safety and Regulatory Considerations

The use of electromagnets in MRI machines necessitates strict adherence to safety and regulatory guidelines. Electromagnetic compatibility (EMC) is a crucial aspect, ensuring that the MRI machine operates without causing unacceptable interference to other medical devices and vice versa. Manufacturers must comply with international standards such as IEC 60601 and conduct comprehensive EMC testing during the design and development process.

Furthermore, patient safety is paramount. Before an MRI scan, patients must undergo a thorough screening to ensure they do not have any metallic implants or objects that could be affected by the magnetic field. The use of non-ferromagnetic materials in medical implants and devices is an ongoing area of research to enhance MRI safety and accessibility.

The electromagnet at the heart of an MRI machine is a testament to the interplay of physics and medicine

The electromagnet at the heart of an MRI machine is a testament to the interplay of physics and medicine, pushing the boundaries of what we can see and understand about the human body. As technology advances, we can expect to see further refinements in electromagnet design, leading to even more powerful and efficient MRI systems. These innovations will undoubtedly continue to shape the future of medical imaging and diagnostics, ultimately contributing to better patient outcomes and advancing healthcare worldwide.

More about electromagnet in medical equipment,pls read the article: <<What is medical equipment micro electromagnets>>

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.