Last Updated on 2025-11-14 by SolenoidFactory

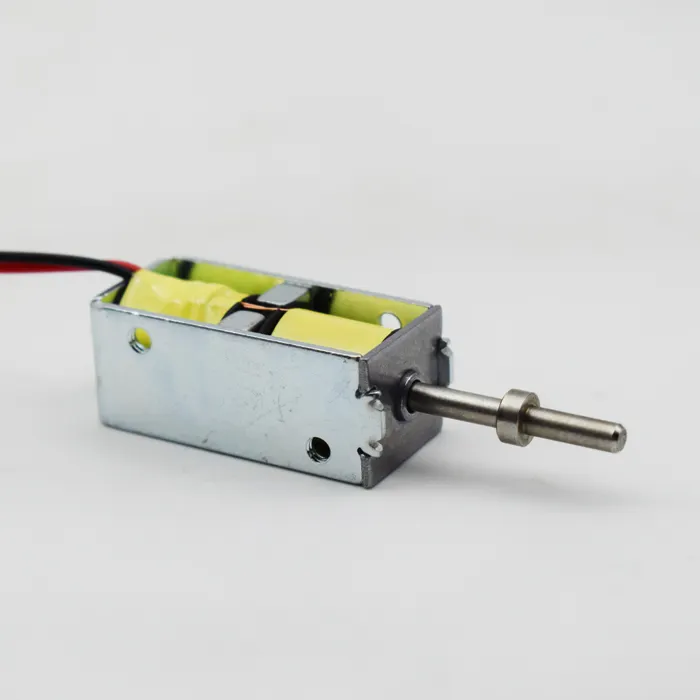

As smart home technology evolves, the smart lock electromagnet has become one of the most essential components in ensuring secure, reliable, and energy-efficient locking performance. Modern smart locks depend on precisely engineered electromagnets to control latch movement, holding force, actuation timing, and long-term durability.

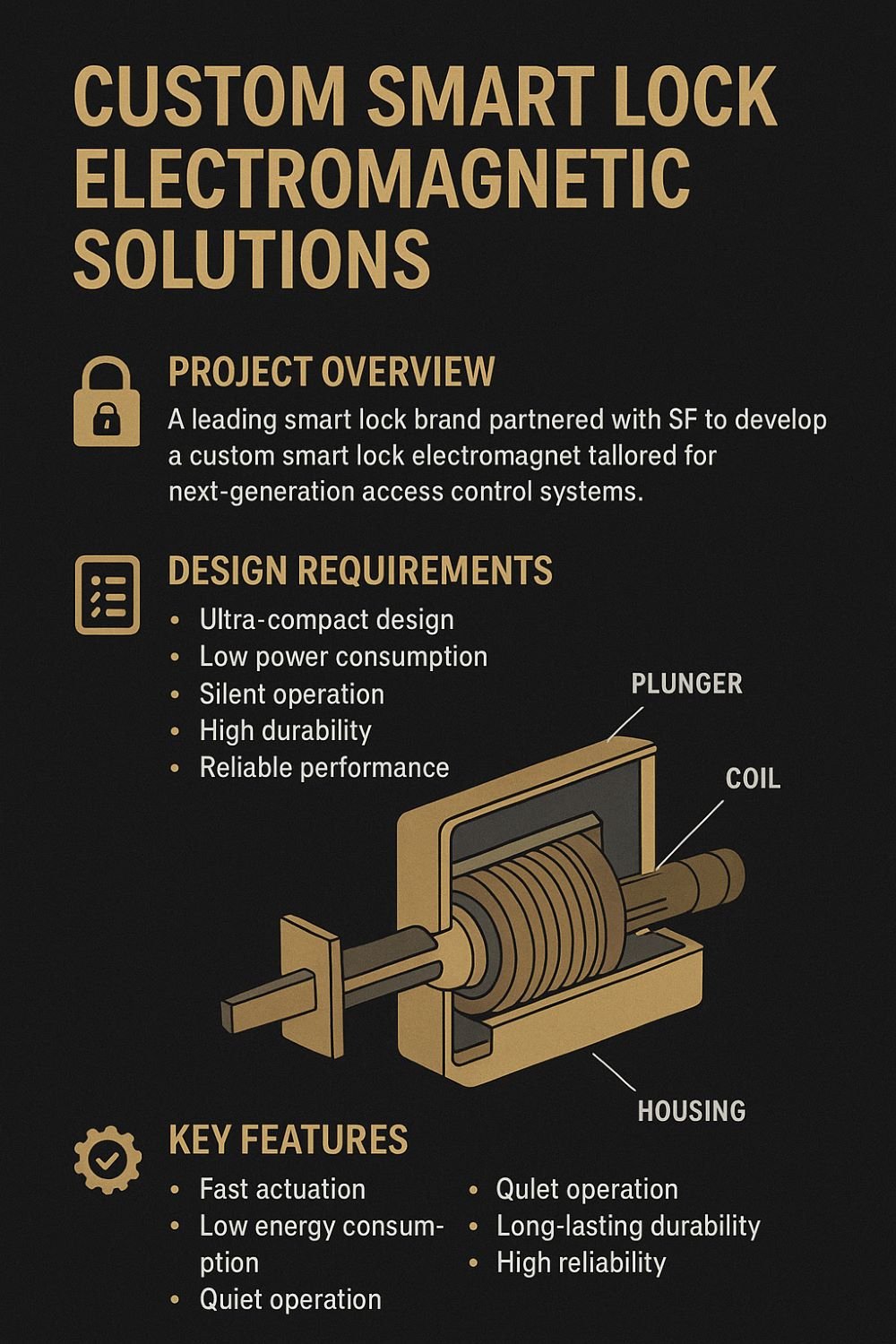

For more than 10 years, SF has specialized in the custom design and manufacturing of solenoids and electromagnets, serving global brands across security, IoT, commercial access systems, industrial automation, and consumer electronics. One of our most successful engineering collaborations has been with a leading (confidential) smart lock manufacturer who required a high-performance custom smart lock electromagnet designed for long service life, quiet operation, strict energy limits, and compact structural constraints.

This article provides a detailed technical case study of how SF engineered a custom smart lock electromagnet solution, from initial requirements to prototyping, performance validation, and final mass production.

1. Understanding the Functional Requirements of a Smart Lock Electromagnet

Before developing a next-generation smart lock electromagnet, it is necessary to understand the unique operational demands of digital locking systems. Unlike traditional solenoids, a smart lock electromagnet must satisfy a combination of mechanical, electrical, thermal, and environmental constraints that collectively determine safety and user experience.

1.1 Miniaturization and Compact Space Usage

Smart locks have extremely limited internal space due to:

Motor or drive components

Wireless communication modules

Battery compartments

Mechanical latching systems

Structural housings

This means a smart lock electromagnet must deliver a high holding force within a very compact coil and plunger structure.

1.2 Low-Power Operation for Battery Efficiency

Most smart locks are battery-powered. The electromagnet must therefore:

Operate efficiently under 3–6V DC

Minimize energy draw during each actuation

Sustain performance even under battery voltage decay

A poorly designed smart lock electromagnet can shorten battery life dramatically, leading to poor user reviews and increased maintenance.

1.3 Quiet and Smooth Actuation

Users expect:

Silent or near-silent unlocking

Smooth movement with no metal clicking

Zero mechanical vibration

Achieving this requires:

Precision fit tolerances

Optimized plunger mass

Correct spring selection

Coil winding optimization

1.4 High Reliability and Long Cycle Life

A smart lock may be opened 10,000–50,000+ times yearly, so its electromagnet must handle:

High cycle load

Consistent force output

Non-stop daily use

Indoor/outdoor temperature changes

1.5 Safety Requirements

A smart lock electromagnet is part of a security system. Therefore it must:

Deliver predictable holding force

Avoid overheating

Maintain stable magnetic performance over time

Continue functioning when partially degraded

This is why SF uses premium core materials, high-temperature coils, and advanced process controls.

2. Project Brief: The Customer’s Requirements for a Custom Smart Lock Electromagnet

A globally recognized smart lock brand approached SF with a clear but challenging requirement:

Customer Requirements Summary

Ultra-compact electromagnet suitable for a thin smart lock housing

Fast actuation under 20–40 milliseconds

Silent operation, less than 30 dB

Low power consumption, optimized for long battery life

High temperature resistance for outdoor summer installations

Ability to sustain 100,000+ life cycles

Stable force output throughout battery discharge curve

Corrosion-resistant materials for long-term durability

Tight tolerances for plunger movement

High safety margin for continuous lock reliability

Meeting the customer’s expectations required a full engineering collaboration, advanced simulation, and multiple rounds of prototyping.

3. SF’s Technical Development Process for the Smart Lock Electromagnet

SF follows a structured engineering methodology for designing every smart lock electromagnet, ensuring consistent quality, repeatability, and performance.

3.1 Magnetic Field Simulation & Force Modeling

Our R&D engineers first performed electromagnetic simulation using:

Finite element analysis (FEA)

Magnetic flux density modeling

Plunger force curve prediction

Energy efficiency optimization

The goal was to create a smart lock electromagnet that delivers maximum force at minimum current.

Simulation allowed us to:

Reduce unnecessary copper windings

Optimize core geometry

Improve magnetic saturation behavior

Minimize heat buildup

3.2 Coil Design for Low-Power Performance

We engineered a custom coil that balanced:

Wire gauge

Number of turns

Resistance

Current efficiency

Heat rise limits

This produced a smart lock electromagnet coil with:

Faster response time

Lower energy consumption

Better temperature stability

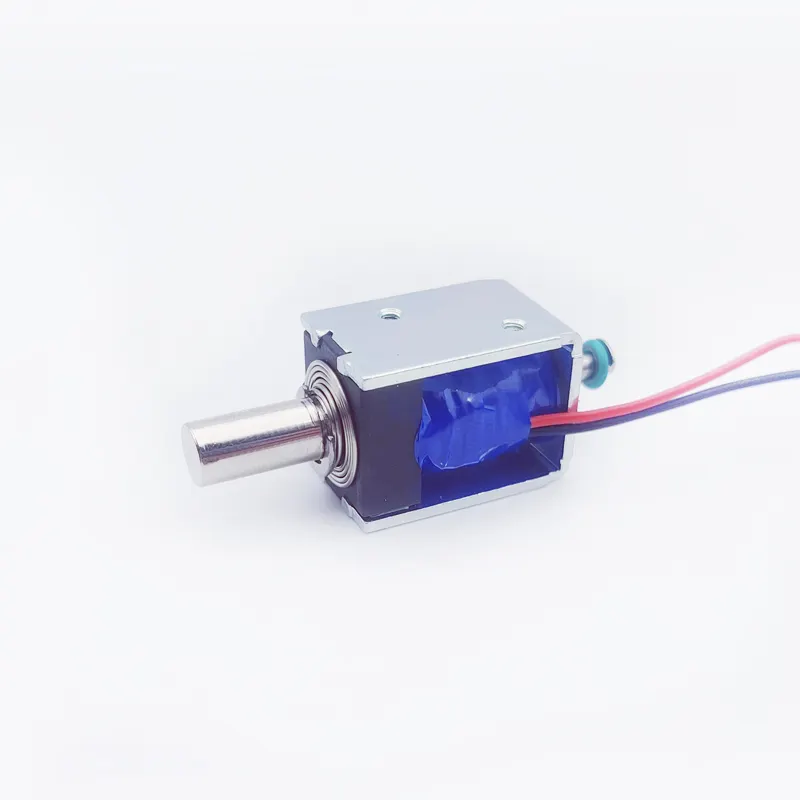

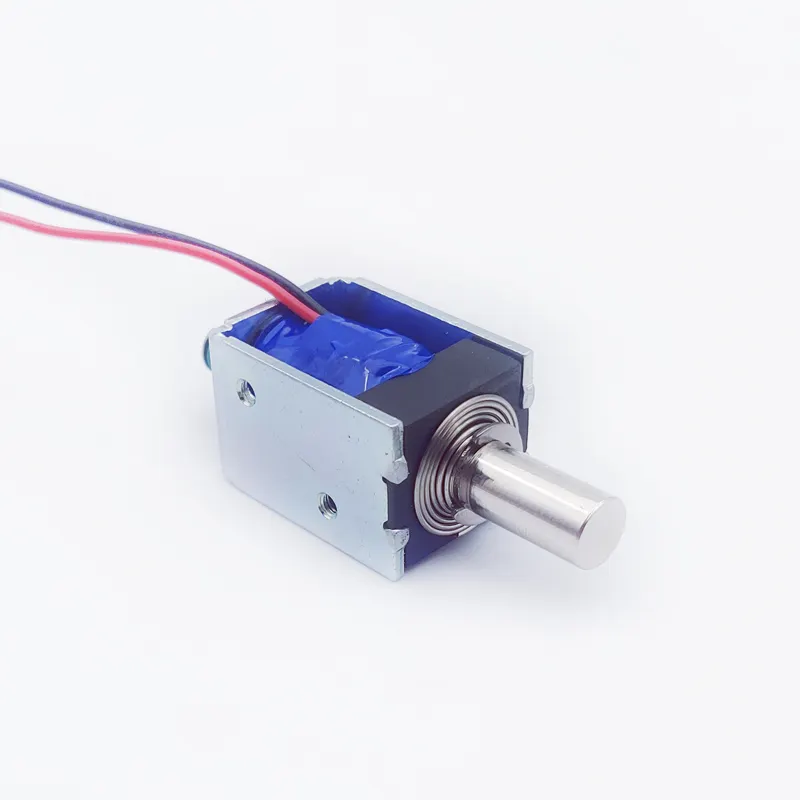

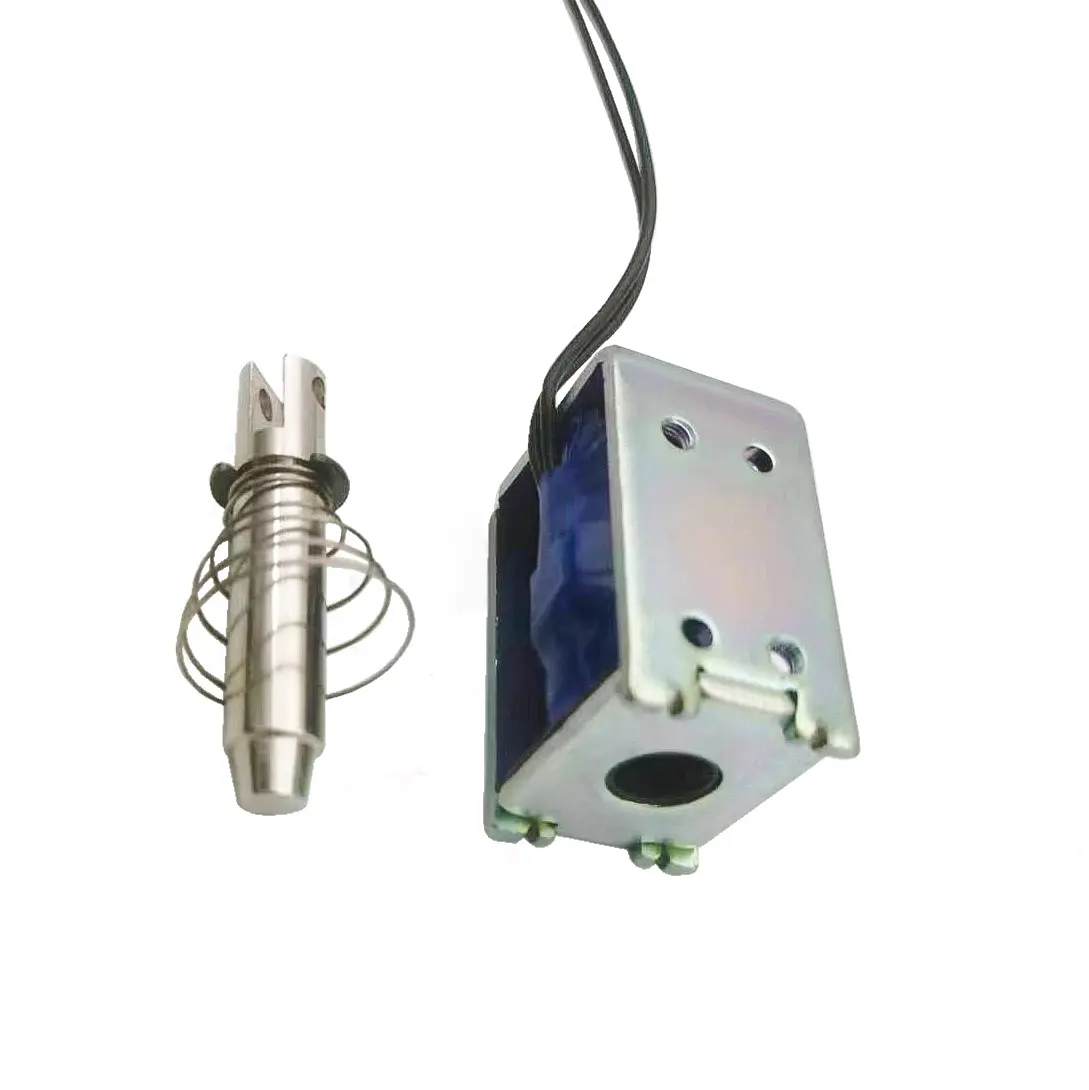

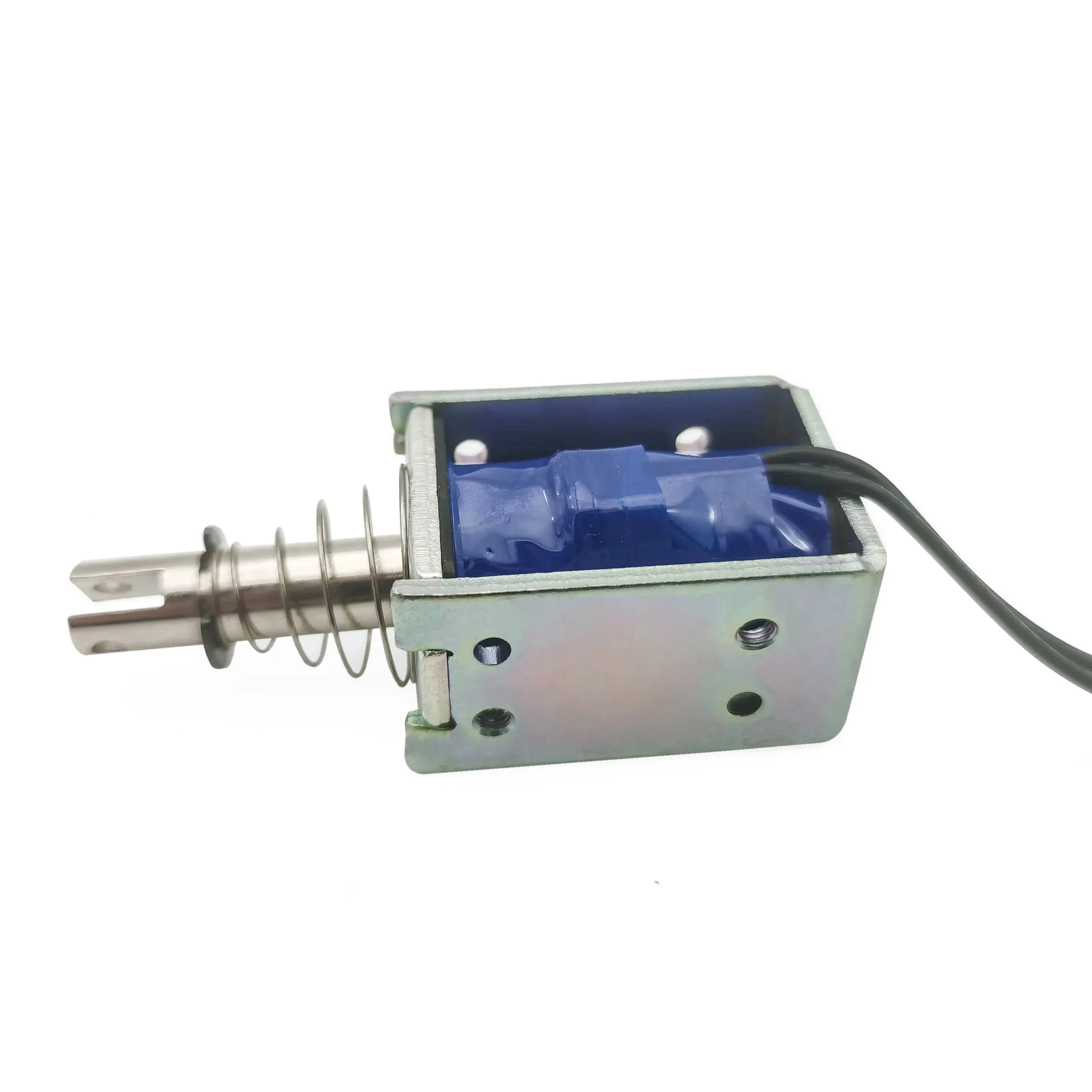

3.3 Precision Plunger and Housing Engineering

The plunger system is the mechanical heart of any smart lock electromagnet.

SF utilized:

High-precision CNC machining

Surface finishing to reduce friction

Tolerance control within ±0.02mm

Stainless steel alloy resistant to wear

The result was smooth, silent, repeatable linear motion.

3.4 Noise Reduction Techniques

To meet the <30 dB requirement, SF applied:

Sound-dampening coatings

Low-impact spring design

Anti-vibration housing

Soft-close plunger head geometry

This produced a smart lock electromagnet that operates almost silently in residential environments.

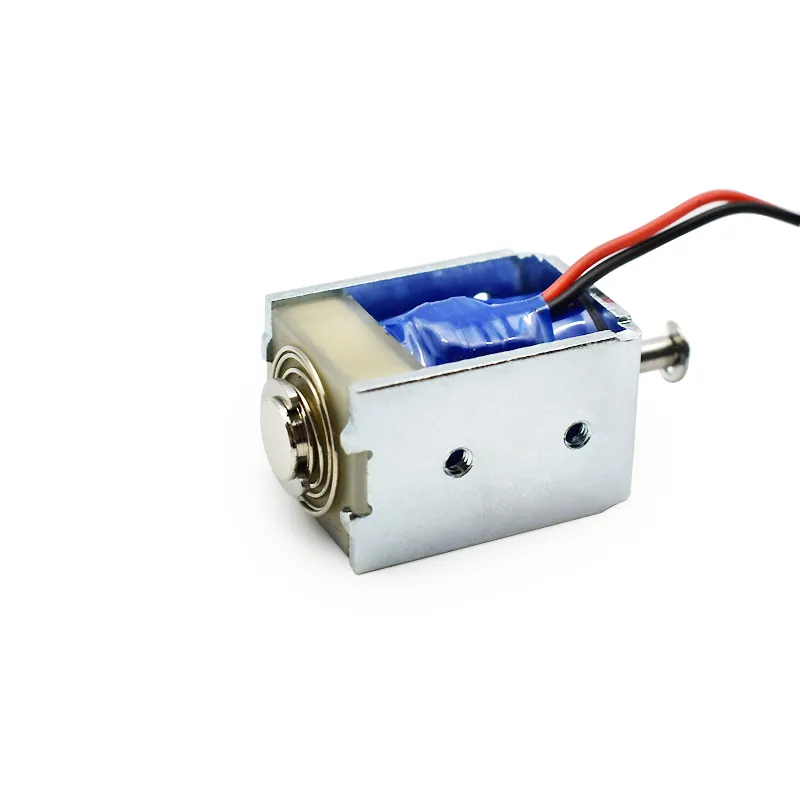

3.5 Thermal Management & High-Temperature Materials

Smart locks installed outdoors face:

Summer heat

Direct sunlight

Enclosed space thermal buildup

To handle this, we used:

High-temperature enameled wire

Heat-resistant bobbin materials

Magnetic steel with stable permeability

Our final design maintained performance even at 80°C ambient temperature.

3.6 Lifecycle Testing and Durability Optimization

The customer required 100,000+ cycles, but SF engineered for 200,000 cycles to ensure extra safety margin.

Testing included:

Continuous cycle fatigue testing

Voltage drop simulation

Elevated temperature aging

Corrosion resistance testing

Mechanical shock and vibration tests

The final smart lock electromagnet exceeded all durability targets.

4. Prototype Development and Validation

After simulation and design approval, SF produced multiple prototype batches for validation.

4.1 Batch A — Baseline Functionality

The first batch confirmed:

General force output

Fit into housing

Basic performance

4.2 Batch B — Silent Operation Testing

This batch focused on noise reduction and plunger smoothness.

4.3 Batch C — Power Optimization

Here we adjusted:

Coil resistance

Winding strategy

Energy consumption efficiency

4.4 Batch D — Final Engineering Refinement

This was the final production-ready version, optimized for:

Force stability

Minimal heat rise

Maximum cycle life

Strong magnetic retention

5. Final Smart Lock Electromagnet Specification

(Representative specifications; confidential customer details excluded.)

Electrical Specifications

Voltage: 3–6V DC

Current: 0.3–0.6A

Coil Resistance: Customized per model

Actuation Time: <40ms

Mechanical Specifications

Stroke: 1–4mm depending on model

Holding Force: 3–15N

Materials: Stainless steel, soft magnetic alloy

Environmental

Working Temperature: -10°C to 80°C

Humidity: up to 95%

Corrosion Resistance: IP-grade housing optional

Lifecycle

Tested to 200,000+ cycles

6. How the Smart Lock Electromagnet Performs in Real Applications

Once integrated into the customer’s smart lock product, the electromagnet delivered exceptional results.

6.1 Faster and Smoother Unlocking

The improved plunger geometry and reduced friction delivered:

Instantaneous latch disengagement

Smoother user experience

6.2 Lower Power Consumption

The optimized coil reduced energy use, extending battery life by 18–25%.

6.3 Silent Operation

Users reported significantly quieter unlocking — a major competitive advantage.

6.4 Higher Reliability and Safety

Long-term stability improved due to:

Wear-resistant materials

Stronger magnetic circuit design

Premium coil insulation

The final smart lock electromagnet improved overall product reliability.

7. Manufacturing Process Control at SF

To ensure consistent quality, every final batch of the smart lock electromagnet passed:

Incoming Material Inspection

Core metal composition check

Copper wire inspection

Coil insulation verification

Housing tolerance measurement

In-Process QC

Coil resistance testing

Plunger smoothness measurement

Magnetic force verification

Final QC

Noise test

Vibration test

Functional test

High/low temperature performance

8. Why Smart Lock Brands Choose SF

Smart lock manufacturers trust SF because:

✔ Over 10 years of electromagnet engineering

✔ Advanced simulation and R&D capabilities

✔ Customization for unique space and force requirements

✔ Strict QC and reliability testing

✔ Competitive pricing with superior performance

✔ Scalable production capacity

SF provides a complete smart lock electromagnet solution, not just a component.

SF Leads the Future of Smart Lock Electromagnet Innovation

As smart homes become more widespread, the demand for high-performance smart lock electromagnet technology continues to grow. SF’s ability to engineer advanced, compact, low-power, silent, and durable electromagnets gives smart lock manufacturers a powerful competitive advantage.

This case study demonstrates SF’s full engineering capability:

Technical simulation

Custom design

Prototype optimization

Performance validation

Mass production quality stability

If your brand is developing next-generation smart locking products, SF is ready to provide custom smart lock electromagnet solutions that meet the highest standards of reliability and performance.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680