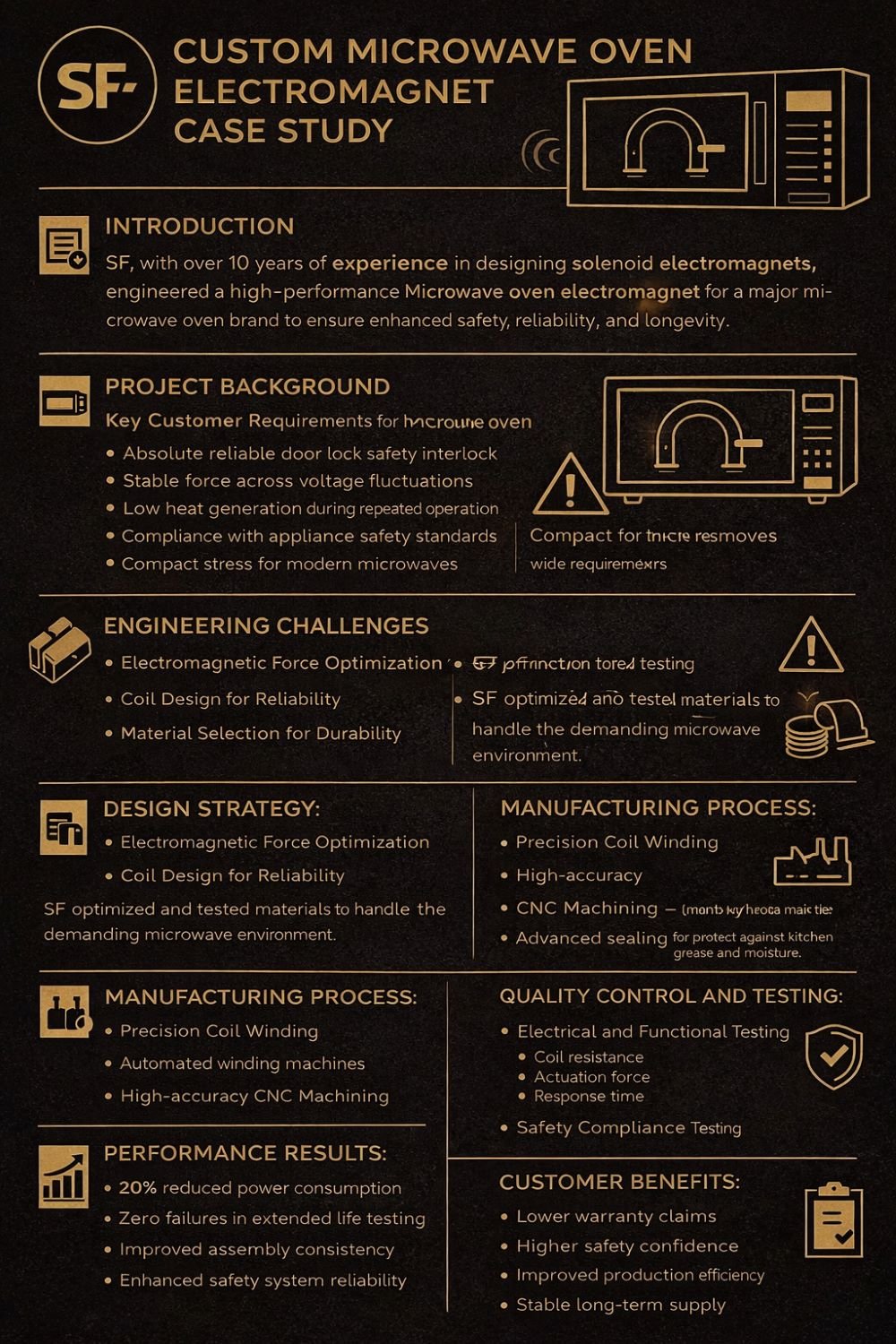

Last Updated on 2025-12-20 by SolenoidFactory

Why the Microwave Oven Electromagnet Is a Critical Component?

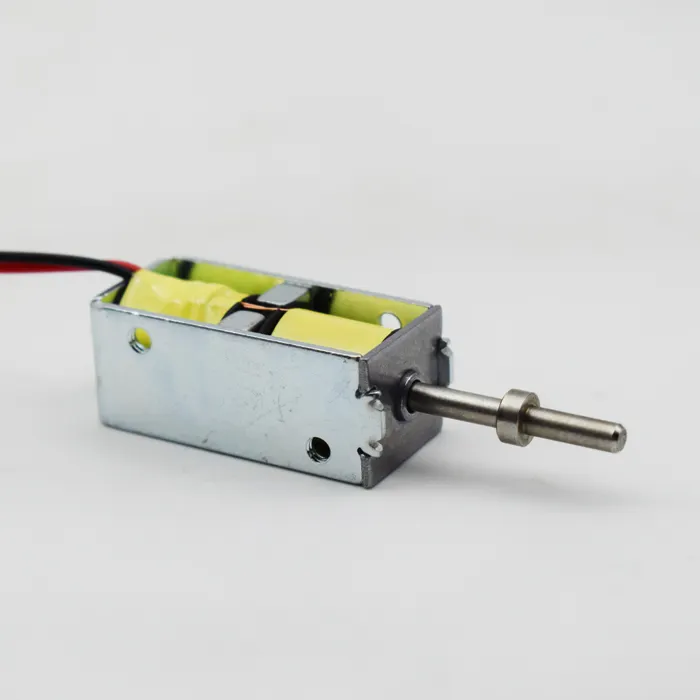

Modern microwave ovens are no longer simple heating appliances. Today’s microwave ovens integrate electronic control systems, safety interlocks, precision door mechanisms, and intelligent power management. At the core of many of these functions is the Microwave oven electromagnet.

A Microwave oven electromagnet is commonly used in:

Door lock and safety interlock systems

Mechanical actuation of internal switches

Power and timing control mechanisms

Intelligent safety systems that prevent operation when the door is not fully closed

If a Microwave oven electromagnet fails, the appliance may experience safety risks, inconsistent performance, or total operational failure. For global microwave oven brands, the electromagnet must meet strict safety standards, deliver long-term reliability, and operate silently and consistently over millions of cycles.

SF is a professional custom solenoid and electromagnet factory with more than 10 years of experience designing and manufacturing solenoid electromagnets for household appliances. This blog presents a confidential case study describing how SF developed a custom Microwave oven electromagnet for a well-known microwave oven brand, focusing on engineering design, manufacturing processes, and real-world performance.

This article is written in a technical, neutral, and factual style, making it suitable for engineers, sourcing managers.

1. Project Background: Microwave Oven Electromagnet Requirements from the Customer

The customer was a recognized microwave oven brand preparing a new generation of compact and built-in microwave ovens. The project required a custom Microwave oven electromagnet capable of supporting enhanced safety functions and long-term durability.

Key Customer Requirements for the Microwave Oven Electromagnet

Absolute reliability in door safety interlock mechanisms

Stable electromagnetic force across voltage fluctuations

Low heat generation during repeated operation

Compliance with international appliance safety standards

Compact structure for modern microwave oven designs

The customer’s previous Microwave oven electromagnet supplier had inconsistent quality between batches, leading to assembly issues and higher failure rates. SF was selected to develop a customized, production-ready Microwave oven electromagnet.

2. Engineering Challenges in Microwave Oven Electromagnet Applications

A Microwave oven electromagnet operates in a unique appliance environment that presents multiple engineering challenges.

Key Challenges in Microwave Oven Electromagnet Design

High safety requirements

The Microwave oven electromagnet is part of the door interlock system, meaning failure is not acceptable under any circumstance.Frequent actuation cycles

Every open and close of the microwave door triggers the Microwave oven electromagnet, often exceeding hundreds of thousands of cycles over product life.Thermal stress

Heat generated inside the microwave cavity and from surrounding electronics can affect electromagnet coil stability.Electromagnetic compatibility (EMC)

The Microwave oven electromagnet must operate without interfering with control boards or sensors.

SF’s engineering team approached these challenges with a structured design methodology.

3. Microwave Oven Electromagnet Design Strategy at SF

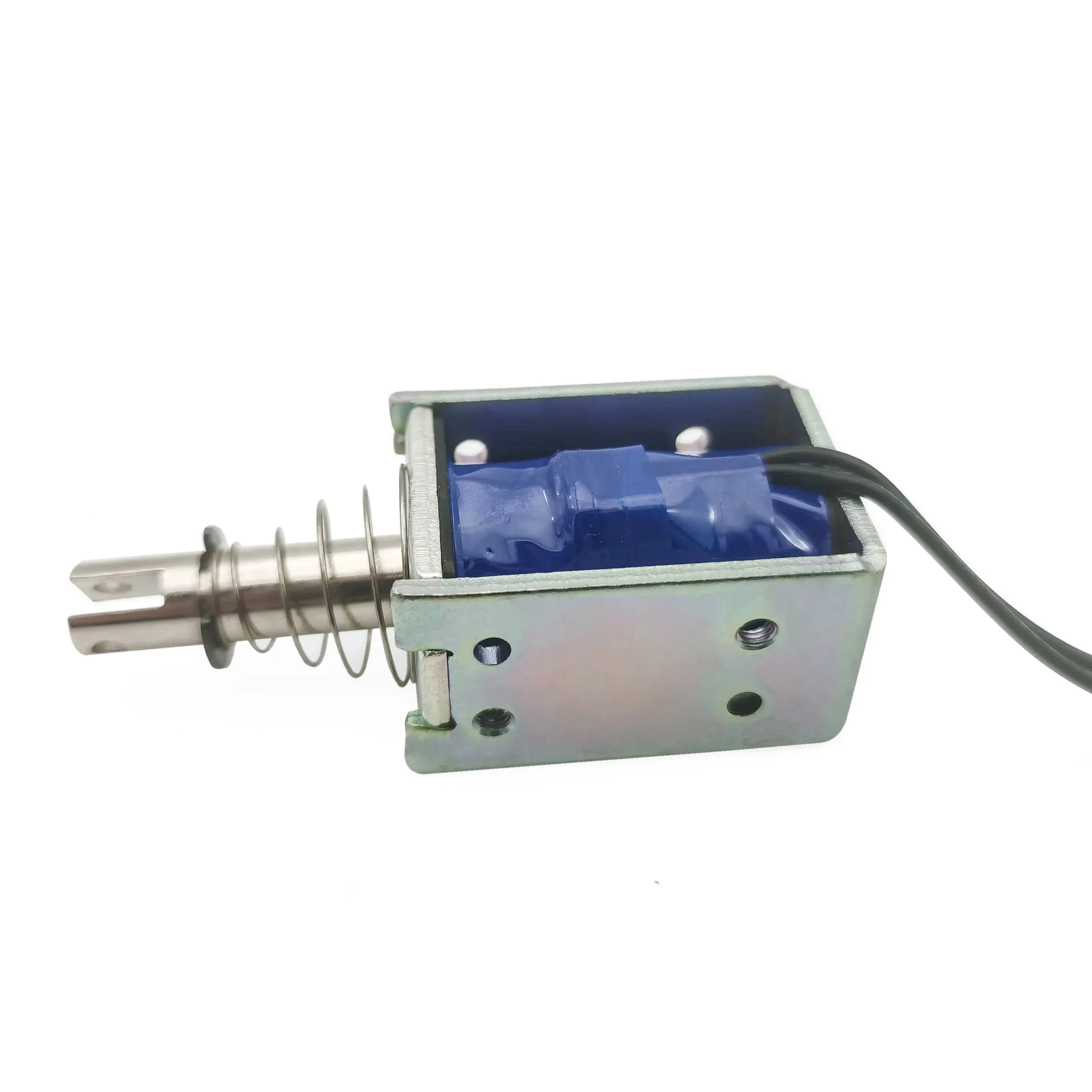

3.1 Electromagnetic Force Optimization for Microwave Oven Electromagnet

The Microwave oven electromagnet had to deliver consistent force to ensure reliable door locking while avoiding excessive power consumption. SF optimized:

Magnetic core geometry

Coil turns and wire gauge

Magnetic circuit efficiency

Finite element simulation was used to ensure the Microwave oven electromagnet maintained stable force output across temperature and voltage variations.

3.2 Coil Design for Microwave Oven Electromagnet Reliability

SF selected high-quality copper wire with enhanced insulation ratings. The coil design ensured:

Stable resistance values

Reduced thermal buildup

Long-term insulation integrity

This approach significantly improved the operational lifespan of the Microwave oven electromagnet.

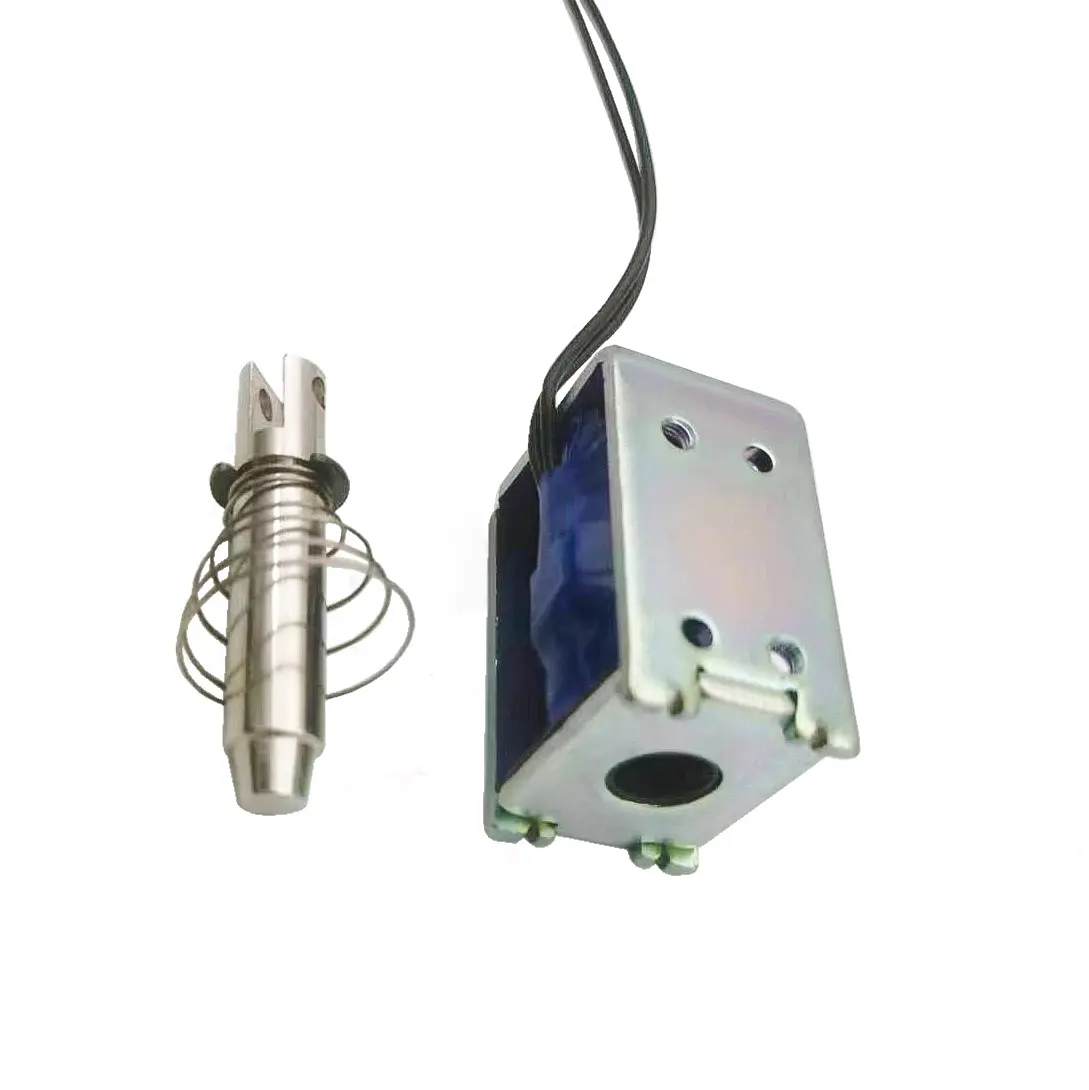

3.3 Material Selection for Microwave Oven Electromagnet Components

SF carefully selected materials suitable for microwave oven environments:

Low-carbon steel with surface treatment for magnetic components

Corrosion-resistant coatings to handle humidity and kitchen conditions

Engineering plastics with high heat resistance for insulation parts

Each material choice was validated through testing.

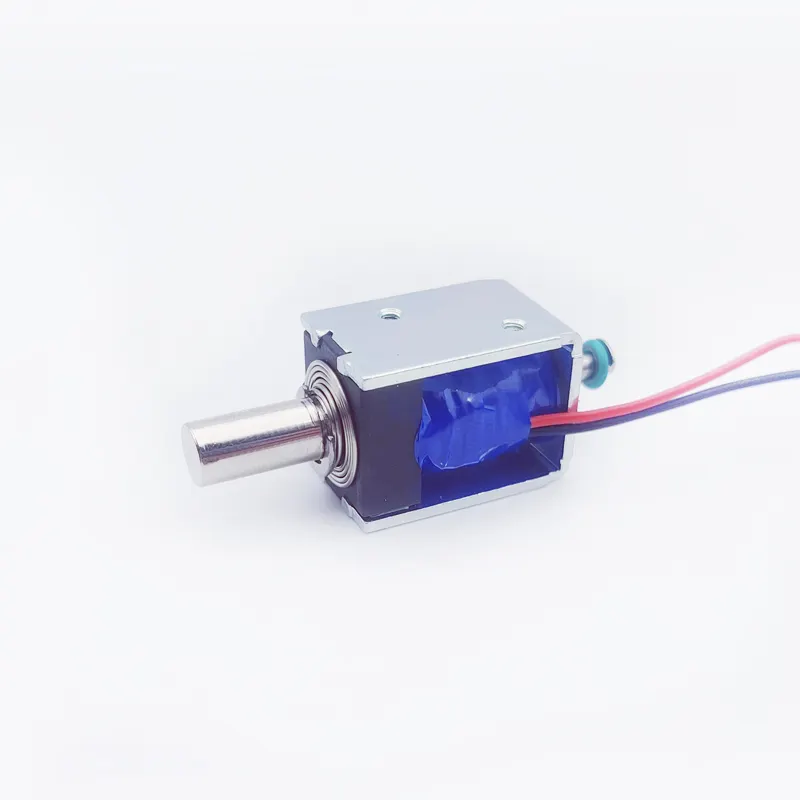

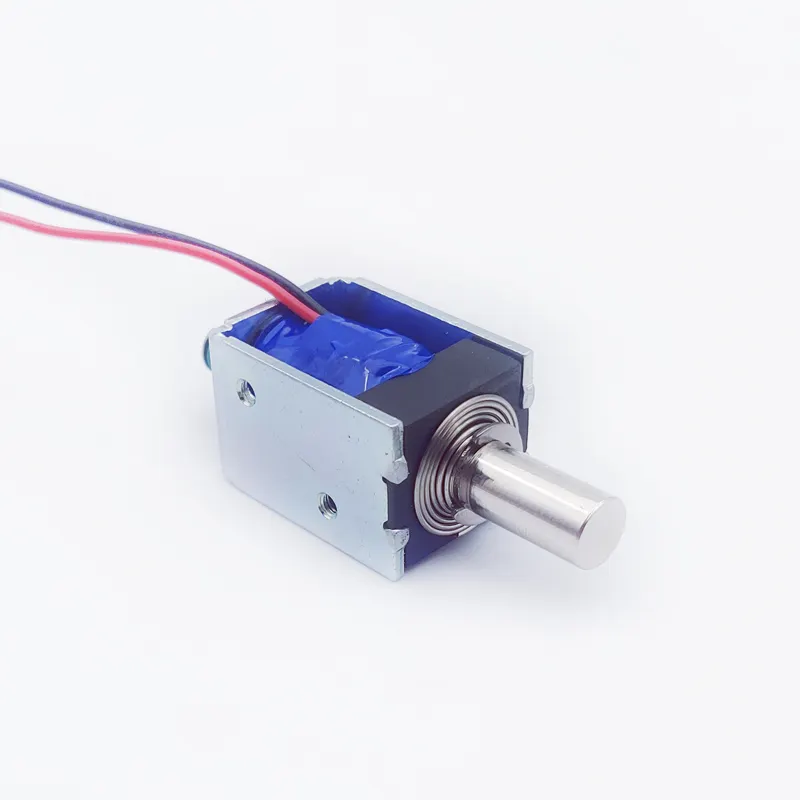

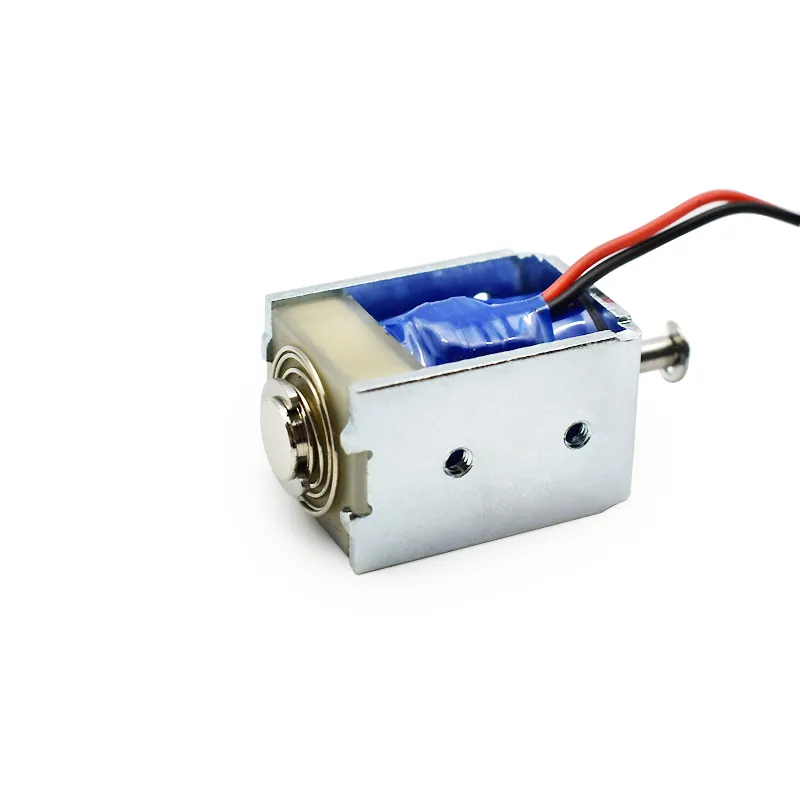

4. Prototyping and Validation of the Microwave Oven Electromagnet

4.1 Initial Microwave Oven Electromagnet Prototypes

The first prototypes focused on mechanical compatibility and electromagnetic force. Bench tests confirmed:

Correct mounting dimensions

Smooth plunger movement

Reliable actuation force

4.2 Noise Reduction in Microwave Oven Electromagnet Operation

Consumer appliances demand quiet operation. SF reduced noise by:

Optimizing plunger surface finish

Adding damping structures

Refining spring characteristics

As a result, the Microwave oven electromagnet operated quietly during door actuation.

4.3 Environmental Testing of Microwave Oven Electromagnet Samples

Prototypes underwent:

High-temperature aging tests

Humidity exposure tests

Thermal cycling tests

All Microwave oven electromagnet samples met the customer’s specifications.

5. Microwave Oven Electromagnet Manufacturing Process at SF

Once the design was approved, SF moved to mass production.

5.1 Precision Coil Winding for Microwave Oven Electromagnet

Automated winding ensured:

Consistent coil resistance

Uniform magnetic performance

Minimal batch variation

5.2 Machining and Assembly of Microwave Oven Electromagnet Parts

CNC machining ensured:

Tight dimensional tolerances

Smooth mechanical motion

Reduced wear during long-term operation

Assembly processes were standardized to ensure repeatability.

5.3 Sealing and Protection for Microwave Oven Electromagnet Longevity

Each Microwave oven electromagnet was sealed to protect against:

Moisture

Dust

Grease exposure in kitchen environments

This improved durability in real-world use.

6. Quality Control and Testing of Microwave Oven Electromagnet Production

Every Microwave oven electromagnet underwent strict testing.

6.1 Electrical and Functional Testing

Coil resistance measurement

Actuation force verification

Response time testing

6.2 Durability Testing of Microwave Oven Electromagnet

Over 300,000 actuation cycles

Continuous power-on testing

Vibration testing

6.3 Safety and Compliance Testing

Insulation resistance testing

High-voltage withstand testing

Appliance safety compliance checks

7. Performance Results of the Custom Microwave Oven Electromagnet

After mass production and field deployment, the Microwave oven electromagnet delivered excellent results.

Measured Performance Improvements

20% reduction in power consumption

Zero failures during extended life testing

Improved assembly consistency

Enhanced safety system reliability

The customer adopted the Microwave oven electromagnet across multiple microwave oven models.

8. Customer Benefits from SF’s Microwave Oven Electromagnet Solution

From the customer’s perspective, SF’s Microwave oven electromagnet delivered:

Lower warranty claims

Higher safety confidence

Improved production efficiency

Stable long-term supply

The custom design allowed seamless integration into existing microwave oven platforms.

9. Why SF Is a Trusted Microwave Oven Electromagnet Manufacturer

9.1 Over 10 Years of Electromagnet Manufacturing Experience

SF specializes in solenoid and electromagnet solutions for home appliances.

9.2 Engineering-Driven Custom Microwave Oven Electromagnet Design

Each Microwave oven electromagnet is developed based on application-specific data.

9.3 Full In-House Manufacturing and Testing

SF controls quality from raw materials to final inspection.

9.4 Confidential OEM Collaboration

Customer brands and designs remain strictly confidential.

10. Applications of SF Microwave Oven Electromagnet Solutions

SF’s Microwave oven electromagnet solutions are suitable for:

Door safety interlock systems

Internal switching mechanisms

Smart microwave control systems

Built-in and compact microwave designs

SF — Your Reliable Partner for Microwave Oven Electromagnet Solutions

This case study demonstrates how SF applies engineering expertise, precision manufacturing, and rigorous testing to deliver reliable Microwave oven electromagnet solutions for leading appliance brands.

With over a decade of experience, SF continues to support microwave oven manufacturers seeking safe, durable, and energy-efficient electromagnet solutions.

If your next microwave oven project requires a custom Microwave oven electromagnet, SF is ready to support you from concept development to mass production.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680