Last Updated on 2025-10-29 by SolenoidFactory

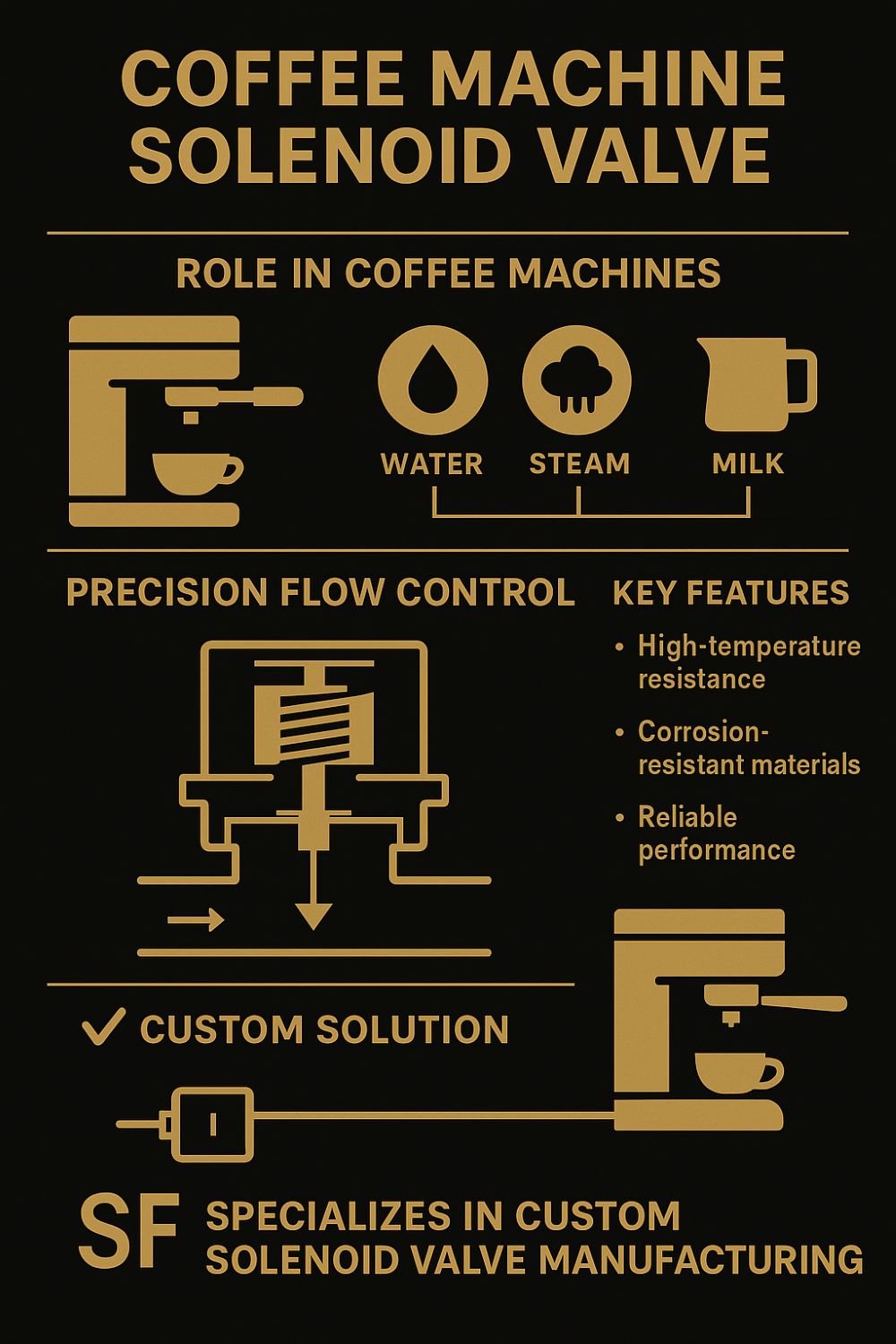

In the world of modern coffee machines, precision is everything. From water temperature to pressure and flow rate, every small detail determines the quality of the final cup. At the heart of this precise control lies a small but critical component — the coffee machine solenoid valve.

As a leading custom solenoid manufacturer with more than a decade of experience, SF specializes in engineering and producing advanced coffee machine solenoid valves for global coffee equipment brands. Our valves ensure stable flow, rapid response, long-term durability, and food-grade reliability — all essential for high-end commercial and home coffee machines.

This case study reveals how SF collaborated with a leading international coffee equipment manufacturer to design, test, and mass-produce a custom coffee machine solenoid valve that met demanding performance and quality standards.

1. Understanding the Role of Coffee Machine Solenoid Valves

Before exploring the project details, it’s essential to understand why a coffee machine solenoid valve is so important.

A coffee machine solenoid valve controls the precise flow of liquids and gases — typically water, steam, and sometimes milk — within the coffee machine’s internal system. When energized, the valve opens or closes instantly, regulating the flow path in response to electronic control signals.

Key functions include:

Water Flow Regulation: Controls the amount of hot water delivered to the coffee chamber.

Steam Control: Manages the flow of steam for milk frothing and temperature stabilization.

Safety and Pressure Management: Prevents over-pressurization and ensures safe operation.

Because the coffee machine solenoid valve must operate in high-temperature, high-moisture environments, its design demands precision materials, thermal insulation, and corrosion resistance.

2. Project Background — A Challenge from a Global Coffee Machine Brand

In 2024, a well-known international coffee equipment brand approached SF with a unique challenge. The client needed a custom coffee machine solenoid valve that could:

Operate reliably under continuous high-temperature conditions (up to 140°C)

Provide silent switching for premium consumer experience

Be compact enough to fit within a small, high-density system layout

Maintain consistent flow control across thousands of daily cycles

Meet international safety and food-grade standards

Existing market valves failed to achieve all these targets simultaneously. The client required a partner who could engineer a custom solution from the ground up — balancing thermal performance, response speed, and durability.

That’s where SF entered the picture.

3. SF’s Engineering Approach to Custom Coffee Machine Solenoid Valves

3.1 Initial Analysis and Feasibility Study

SF’s engineering team began by analyzing the machine’s hydraulic circuit, temperature profile, and voltage system. The target was a 12 V DC solenoid valve with a 0.5 mm orifice and response time under 40 milliseconds.

A simulation model was created to predict magnetic field strength, coil heating, and armature travel time. Using this data, SF identified the ideal coil geometry and plunger dimensions for energy efficiency and response accuracy.

3.2 Material Selection

Choosing the right materials was vital to ensure long-term reliability in hot, humid environments typical of coffee equipment.

Valve Body: Stainless steel (SUS 304) for corrosion resistance and food contact safety.

Sealing Material: EPDM and PTFE composite seals to withstand high temperature and steam exposure.

Plunger and Sleeve: Magnetic stainless alloy for consistent actuation force under heat.

Coil Housing: High-temperature thermoplastic capable of withstanding up to 180°C.

Each material was certified to meet RoHS, REACH, and FDA food-grade requirements.

4. Prototyping and Functional Testing

After design approval, SF’s prototype workshop produced the first batch of coffee machine solenoid valve samples using precision CNC machining and automated coil winding.

4.1 Laboratory Testing

Each prototype underwent a comprehensive testing protocol:

Response Time Test: < 40 ms actuation verified using laser displacement sensors.

Thermal Endurance Test: 10 000 on-off cycles at 140°C.

Leakage Test: 100% tightness under 10 bar pressure.

Noise Level Measurement: Operation noise below 30 dB to meet the quiet-machine requirement.

4.2 Electrical and Magnetic Testing

Coil resistance, inductance, and current draw were verified across temperature ranges. Magnetic flux simulations were validated by direct Hall-sensor measurement to confirm theoretical performance.

The results exceeded customer expectations — zero leakage, rapid response, and stable operation even after extended thermal exposure.

5. Design Optimization for Mass Production

While the prototype performed excellently, SF’s engineers refined the design for manufacturability and cost optimization without sacrificing quality.

5.1 Coil Optimization

SF’s winding automation achieved ± 1 turn precision for coil winding, ensuring identical electromagnetic force in every coffee machine solenoid valve.

5.2 Assembly Process

A custom assembly line was developed for high-volume production, integrating:

Automated plunger insertion

Laser welding of valve bodies

Leak testing on every unit

Final electrical inspection

5.3 Quality Control Integration

Every production stage used traceable barcodes for component tracking. This ensured complete transparency — from material sourcing to finished product shipment.

6. Long-Term Reliability and Lifecycle Testing

A coffee machine solenoid valve must operate flawlessly for years. SF conducted accelerated lifecycle tests equivalent to 5 years of continuous use:

| Test Type | Conditions | Duration | Result |

|---|---|---|---|

| Thermal Aging | 140 °C hot water and steam | 1000 hrs | No deformation |

| Electrical Fatigue | 12 V DC, 10 Hz switching | 1 million cycles | 100% functional |

| Corrosion Resistance | Salt spray (5%) | 96 hrs | Pass |

| Flow Stability | 0.5 MPa inlet pressure | Continuous | ± 2% variance |

Results confirmed the SF coffee machine solenoid valve could maintain its performance for the entire service life of the appliance.

7. Certification and Compliance

All SF coffee machine solenoid valves comply with:

RoHS 3 and REACH regulations

CE and UL electrical safety standards

FDA food-grade material requirements

ISO 9001:2015 quality management certification

This compliance guarantees that SF valves are safe for global coffee equipment integration — from espresso machines to automatic brewing systems.

8. Production Scaling and Supply Chain Management

Once validation was complete, SF moved to full-scale production. The production line now delivers thousands of coffee machine solenoid valves monthly, maintaining batch consistency within 1% performance tolerance.

8.1 Efficient Supply Chain

SF’s in-house machining, coil winding, and assembly eliminate external dependency — reducing lead time to 4 weeks for mass orders.

8.2 Customized Packaging and Traceability

Each valve is laser-engraved with part numbers and batch codes. Packaging is moisture-resistant, with anti-static protection for electronic components.

9. Real-World Application: Performance in Coffee Machines

In actual field operation, the coffee machine solenoid valve functions as the precision gatekeeper of fluid dynamics.

9.1 Hot Water Dispensing

The solenoid opens instantly when the brew cycle begins, delivering the exact volume of water to the coffee chamber with millisecond timing accuracy.

9.2 Steam Regulation

Another valve manages steam for milk frothing. Its thermal endurance ensures smooth control of pressure even after extended use.

9.3 Dual-Flow Control

For high-end models, SF designed a dual-valve assembly combining two coffee machine solenoid valves in a compact module, enabling both water and steam control in one integrated housing — reducing footprint while increasing precision.

These systems have demonstrated consistent pressure response and temperature stability, resulting in superior coffee quality and machine reliability.

10. Customer Results and Feedback

After implementing SF’s custom coffee machine solenoid valve, the client reported:

35% improvement in valve response consistency

20% reduction in power consumption

50% lower failure rate compared with previous supplier

Noticeably quieter operation — critical for premium coffee machines

Customer satisfaction was extremely high, leading to ongoing collaboration for other solenoid applications (e.g., dosing valves and magnetic locks).

11. Why Choose SF as Your Coffee Machine Solenoid Valve Partner

11.1 Over a Decade of Expertise

With more than 10 years of experience manufacturing solenoid and electromagnet solutions, SF offers deep technical knowledge and practical manufacturing expertise.

11.2 Custom Engineering

Every coffee machine has unique design constraints. SF’s R&D team tailors coil geometry, orifice size, and response speed to exact OEM specifications.

11.3 Advanced Manufacturing

Automated assembly, CNC precision machining, and inline testing ensure zero-defect production.

11.4 Reliable Global Supply

SF supports clients in Europe, North America, and Asia with consistent delivery schedules and full technical documentation.

12. Looking Ahead: The Future of Coffee Machine Solenoid Valves

As coffee machines evolve toward smart connectivity and energy efficiency, the coffee machine solenoid valve will continue to play a crucial role in achieving fast, accurate, and sustainable operation.

SF is already developing next-generation solenoid valves featuring:

Low-power coils for energy savings

Integrated sensors for flow and temperature feedback

Miniaturized housings for compact system designs

These innovations will further improve the performance, efficiency, and reliability of modern coffee equipment.

SF — Your Trusted Coffee Machine Solenoid Valve Manufacturer

he success of any coffee machine depends on the precision of its internal components. The coffee machine solenoid valve is one of the most vital — controlling water and steam with accuracy that defines taste, texture, and consistency.

Through advanced design, precision manufacturing, and rigorous testing, SF has proven to be a global leader in custom coffee machine solenoid valve solutions.

If your company is seeking a reliable, technically advanced, and globally trusted solenoid valve manufacturer for coffee equipment, SF is ready to support your next innovation.

📩 Contact SF Today

Website: www.solenoidfactory.com

Email: shanyxu@hotmail.com

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680