Last Updated on 2026-01-05 by SolenoidFactory

Why the Role of a Solenoid Factory Is More Important Than Ever

In today’s global manufacturing environment, electromechanical components are becoming smaller, smarter, and more application-specific. Among these components, solenoids play a critical role in motion control, locking systems, fluid control, and automation equipment. As a result, choosing the right solenoid factory has become a strategic decision for OEM brands and system integrators.

A professional solenoid factory does far more than produce standard parts. It provides engineering support, custom design capability, stable mass production, and long-term quality assurance. For industries such as home appliances, industrial automation, automotive systems, medical devices, and smart hardware, the performance of a solenoid directly affects product reliability and brand reputation.

SF is a professional custom solenoid factory with more than 10 years of experience in manufacturing various solenoids and solenoid electromagnets for global customers. This article explains what defines a reliable solenoid factory, how solenoids are designed and manufactured, and why experienced factories like SF are increasingly preferred by OEM brands worldwide.

What Is a Solenoid Factory?

A solenoid factory is a specialized manufacturing facility dedicated to the design, production, testing, and customization of solenoids and solenoid-based electromagnetic components.

Unlike trading companies or simple assembly workshops, a true solenoid factory controls key technical processes, including:

Electromagnetic coil design and winding

Magnetic circuit optimization

Mechanical structure design

Precision assembly

Electrical and functional testing

A professional solenoid factory combines electromagnetics, mechanics, materials science, and manufacturing engineering to deliver consistent and reliable products.

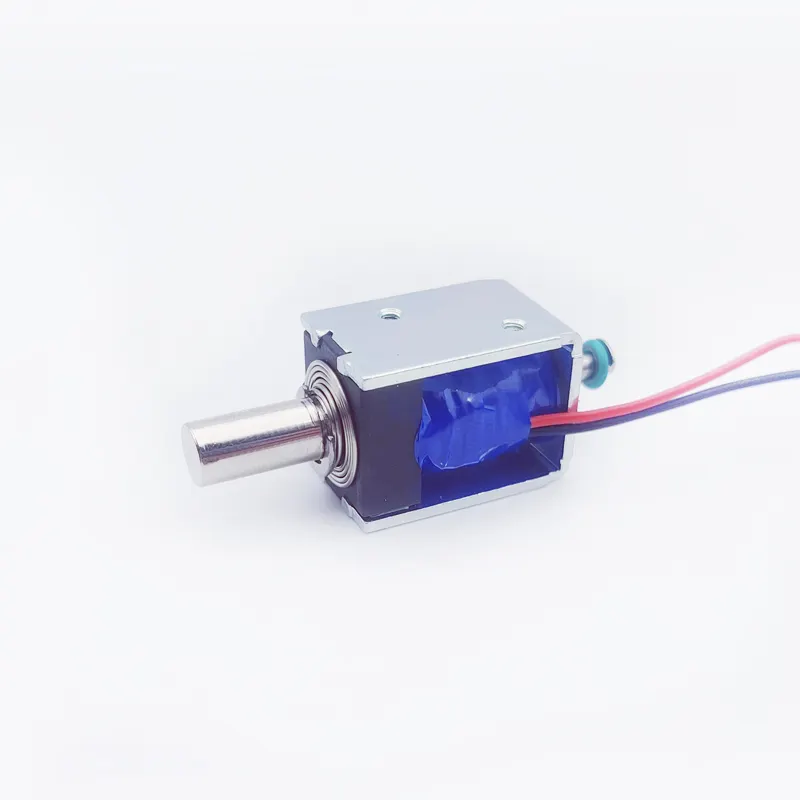

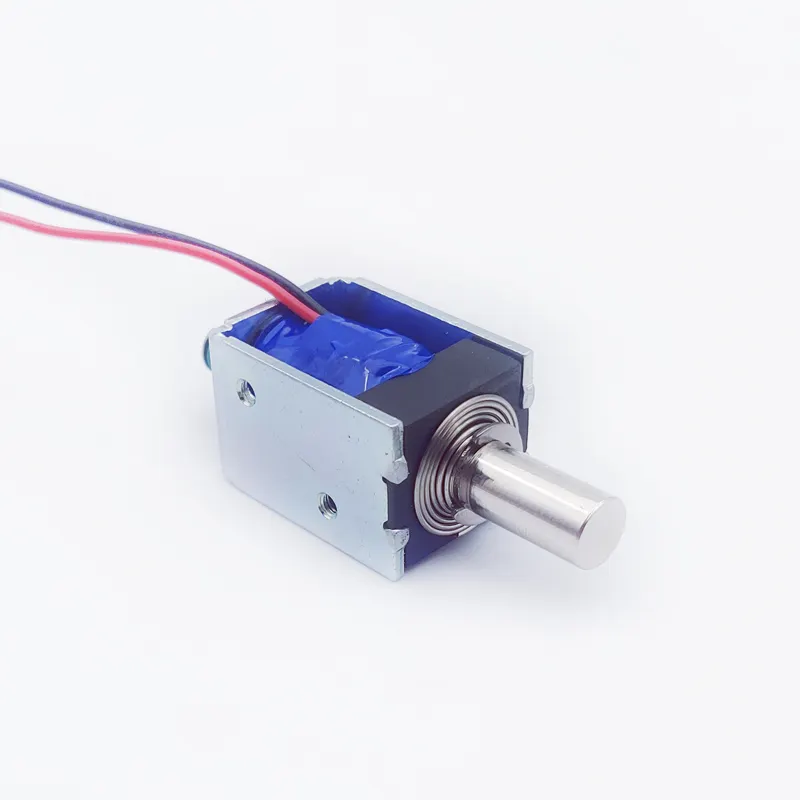

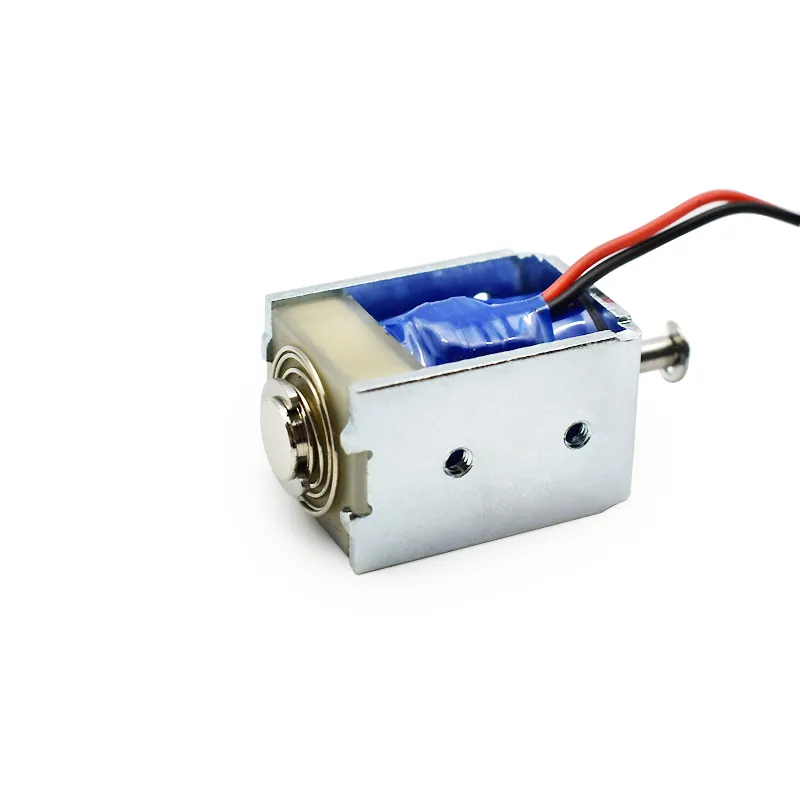

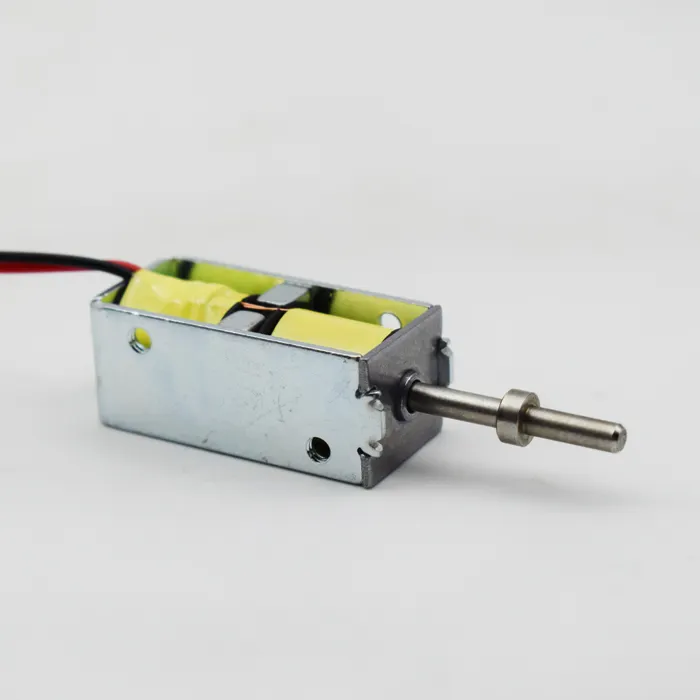

Core Products Manufactured by a Solenoid Factory

A full-capability solenoid factory typically produces a wide range of solenoid types to meet different application requirements.

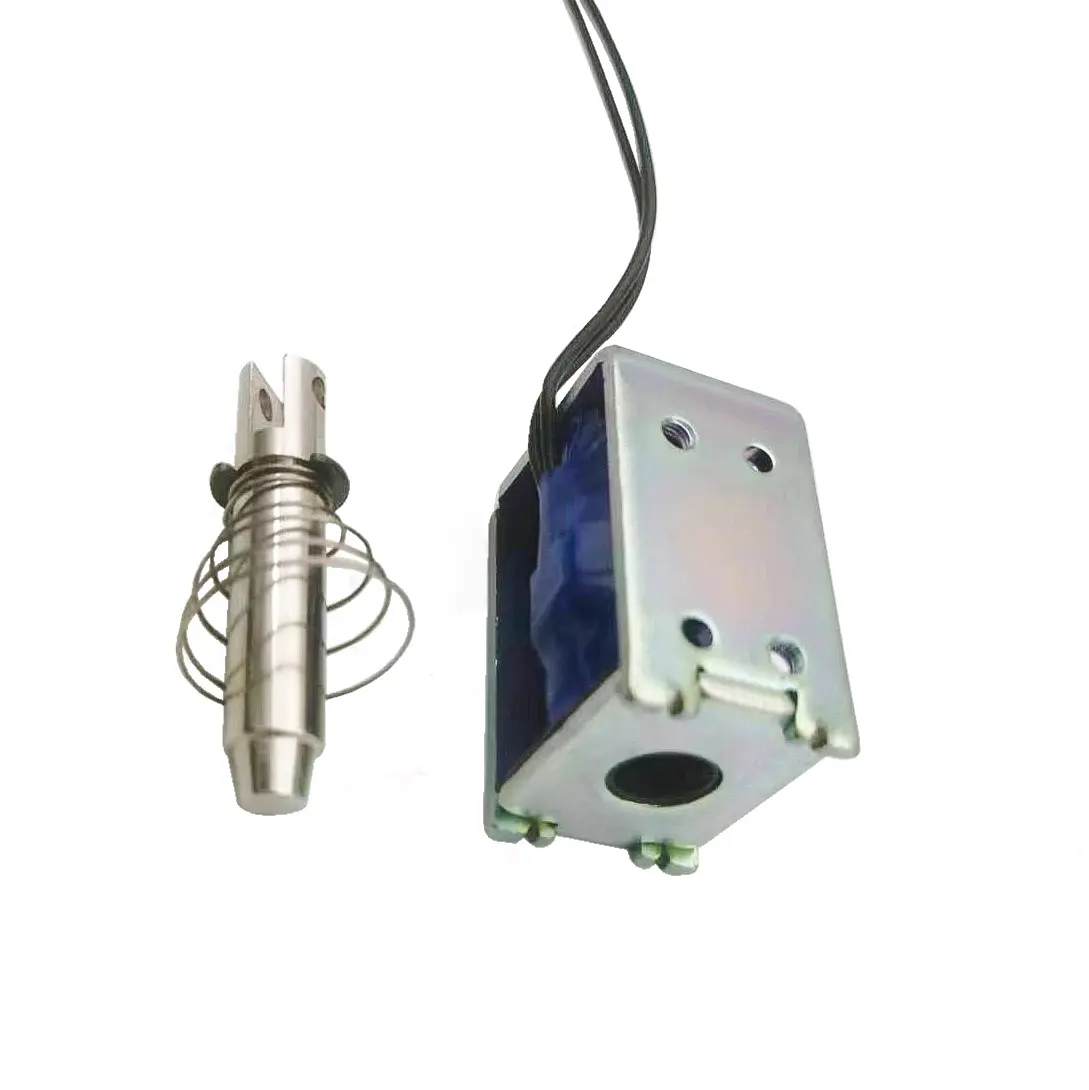

Linear Solenoids Produced by a Solenoid Factory

Linear solenoids generate straight-line motion and are widely used in:

Locking mechanisms

Actuators

Sorting systems

Consumer electronics

A solenoid factory customizes stroke length, force, voltage, and duty cycle based on application needs.

Rotary Solenoids Manufactured by a Solenoid Factory

Rotary solenoids convert electrical energy into angular motion. A professional solenoid factory designs rotary solenoids for:

Automotive systems

Industrial automation

Smart devices

Torque output, rotation angle, and response time are carefully engineered.

Latching and Bistable Solenoids from a Solenoid Factory

Latching solenoids retain position without continuous power. A solenoid factory produces bistable designs for:

Energy-saving applications

Smart meters

Battery-powered devices

Custom Solenoid Electromagnets

A professional solenoid factory like SF specializes in custom solenoid electromagnets, including open-frame, tubular, sucker, and special-shape designs.

How a Solenoid Factory Designs a Solenoid

Design capability is one of the most important differentiators between solenoid factories.

Requirement Analysis in a Solenoid Factory

Every project begins with detailed analysis, including:

Required force or torque

Stroke or rotation angle

Operating voltage and current

Duty cycle and ambient temperature

Installation constraints

A professional solenoid factory works closely with customer engineering teams at this stage.

Electromagnetic Design in a Solenoid Factory

Using simulation tools, a solenoid factory optimizes:

Coil turns and wire diameter

Core and armature materials

Magnetic flux path

Air gap tolerance

This ensures stable performance and efficient power consumption.

Mechanical Design and Material Selection

A solenoid factory selects materials based on:

Mechanical strength

Wear resistance

Corrosion resistance

Thermal stability

Housing, springs, bearings, and insulation materials are all engineered for long service life.

Manufacturing Process Inside a Professional Solenoid Factory

Understanding the internal manufacturing process helps buyers evaluate the technical strength of a solenoid factory.

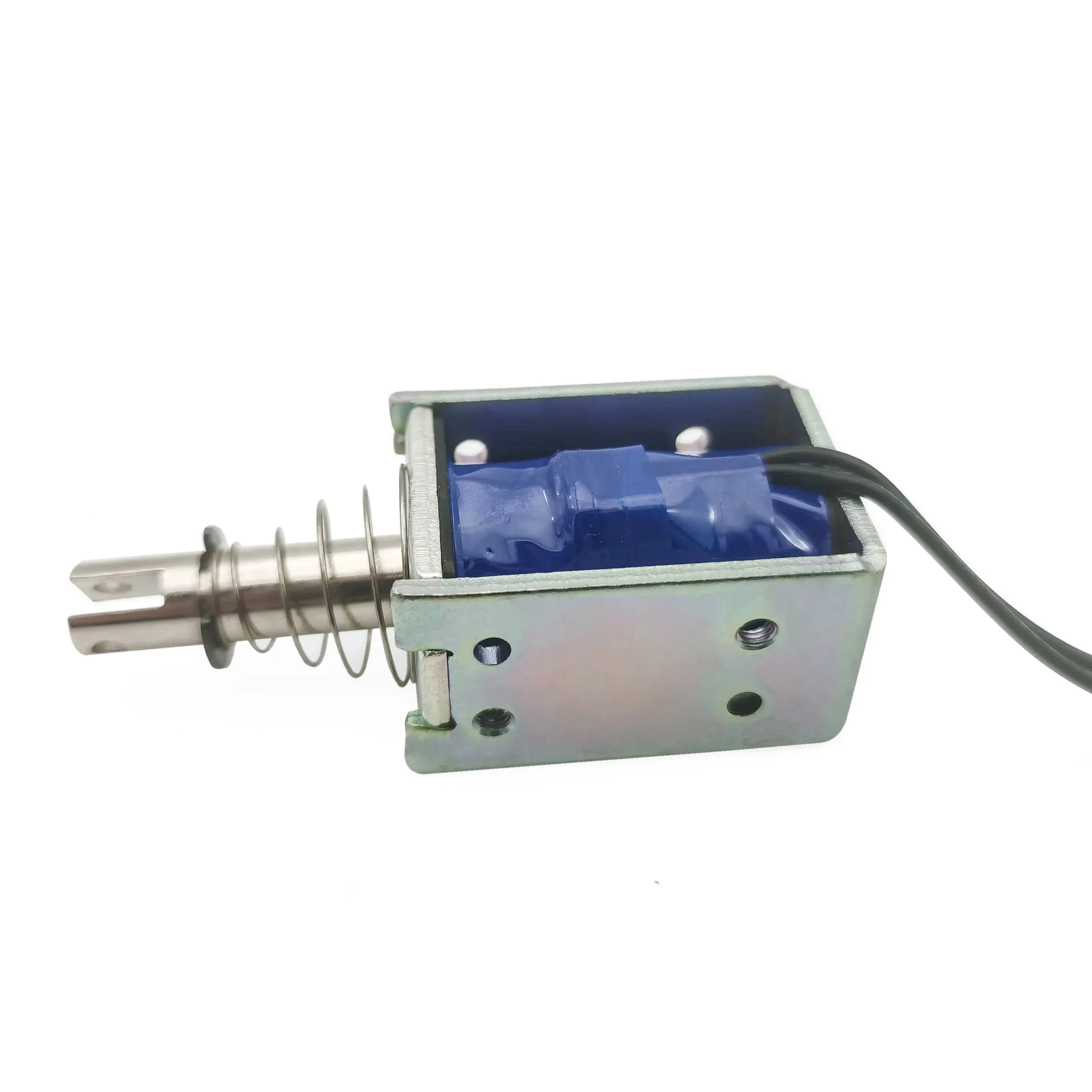

Coil Winding in a Solenoid Factory

High-precision coil winding is essential. A professional solenoid factory controls:

Winding tension

Turn accuracy

Resistance tolerance

Insulation quality

SF performs coil winding in-house to ensure consistency.

Magnetic Component Processing

The solenoid factory machines and treats magnetic cores and armatures to achieve optimal permeability and minimal hysteresis loss.

Assembly and Calibration

During assembly, a solenoid factory ensures:

Precise alignment

Smooth movement

Stable return force

Calibration ensures that every solenoid meets design specifications.

Testing and Quality Control in a Solenoid Factory

Each solenoid undergoes multiple tests, such as:

Electrical resistance testing

Force or torque measurement

Stroke or angle verification

Thermal rise testing

Life cycle endurance testing

A reliable solenoid factory implements strict quality standards.

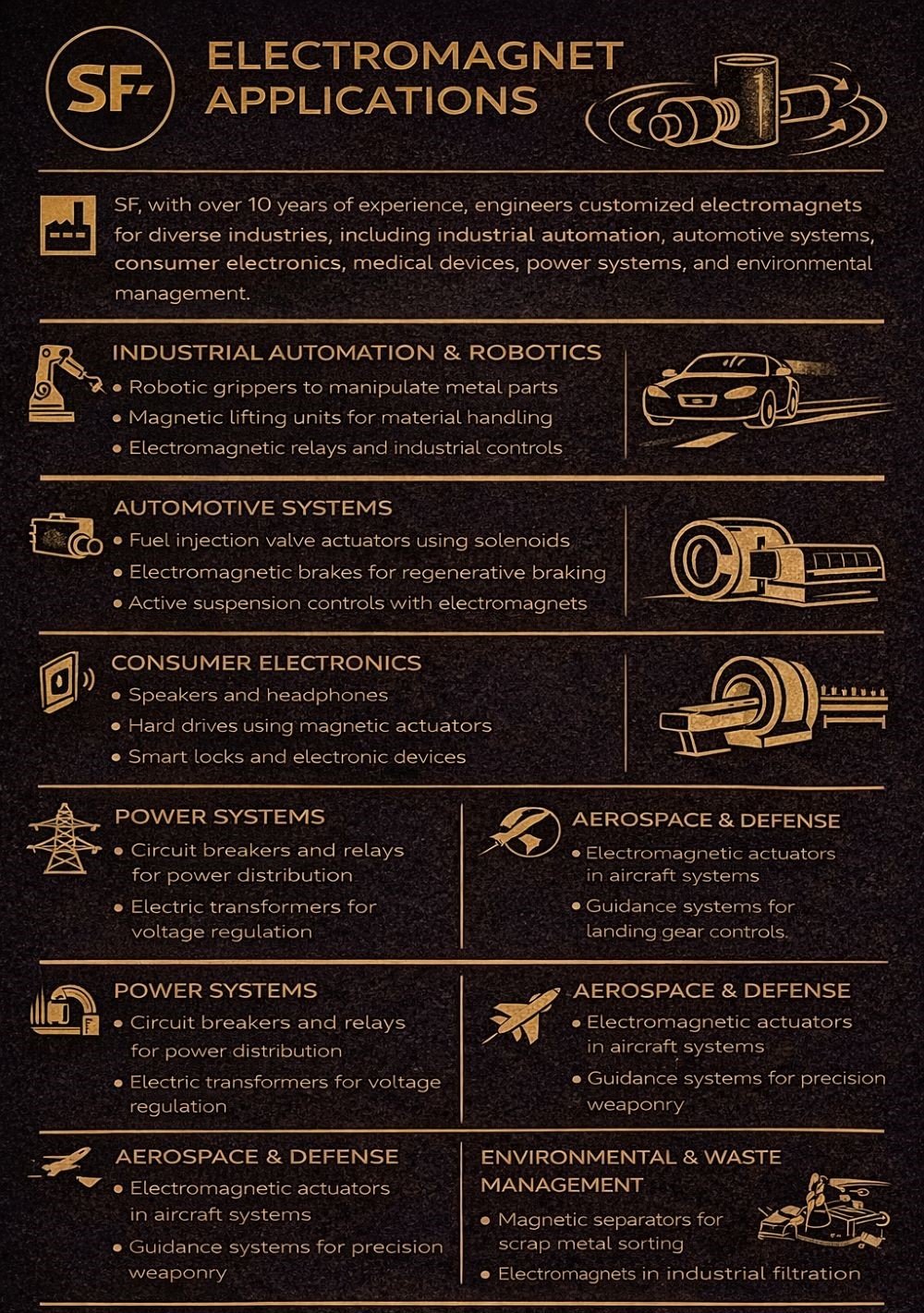

Applications Served by a Solenoid Factory

A professional solenoid factory supports a wide range of industries.

Home Appliances and Consumer Products

Solenoids manufactured by a solenoid factory are widely used in:

Washing machines

Coffee machines

Rice cookers

Refrigerators

Reliability and low noise are critical requirements.

Industrial Automation Systems

Factories rely on solenoid factory products for:

Pneumatic control

Automation equipment

Mechanical actuators

Industrial applications require high durability and repeatability.

Automotive and Transportation Systems

A solenoid factory supplies solenoids for:

Locking systems

Fluid control

Safety mechanisms

Automotive standards demand strict quality control.

Medical and Healthcare Devices

Medical equipment requires solenoids with:

High precision

Long life

Stable performance

A professional solenoid factory ensures compliance with these requirements.

Why OEM Brands Prefer a Custom Solenoid Factory

OEM brands increasingly choose a custom solenoid factory rather than standard product suppliers.

Application-Specific Optimization

A custom solenoid factory tailors:

Force curves

Power consumption

Noise levels

Mechanical interfaces

This results in better system performance.

Engineering Collaboration

SF provides engineering support from concept to mass production, helping customers reduce development risk.

Supply Chain Stability

A reliable solenoid factory offers consistent quality, stable lead times, and long-term production support.

How to Evaluate a Solenoid Factory

When selecting a solenoid factory, buyers should consider:

Years of manufacturing experience

In-house design and coil winding capability

Customization experience

Quality control systems

Industry application references

A professional solenoid factory will be transparent about these capabilities.

Why SF Is a Trusted Solenoid Factory

SF is a professional custom solenoid factory with over 10 years of experience in solenoid manufacturing.

Key strengths of SF include:

Full in-house manufacturing

Strong custom design capability

Strict quality control processes

Stable mass production for OEM customers

Long-term cooperation with global brands

SF focuses on engineering-driven solutions rather than generic products.

Future Trends in the Solenoid Factory Industry

The solenoid factory industry is evolving due to:

Increasing demand for compact designs

Energy efficiency requirements

Smart and connected devices

Higher reliability expectations

Solenoid factories that invest in R&D and customization, like SF, are well positioned for the future.

Choosing the Right Solenoid Factory for Long-Term Success

Selecting the right solenoid factory is not only a purchasing decision but also a strategic partnership choice. A professional solenoid factory provides technical expertise, customization capability, and production stability that directly impact product success.

With more than a decade of experience, SF has established itself as a reliable solenoid factory capable of supporting complex OEM projects across multiple industries.

For brands seeking a long-term, technically competent solenoid factory partner, working with an experienced manufacturer like SF offers clear advantages in quality, performance, and reliability.

Customize all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680