Last Updated on 2025-12-25 by SolenoidFactory

Why the 12V Rotary Solenoid Is Essential in Modern Electromechanical Systems

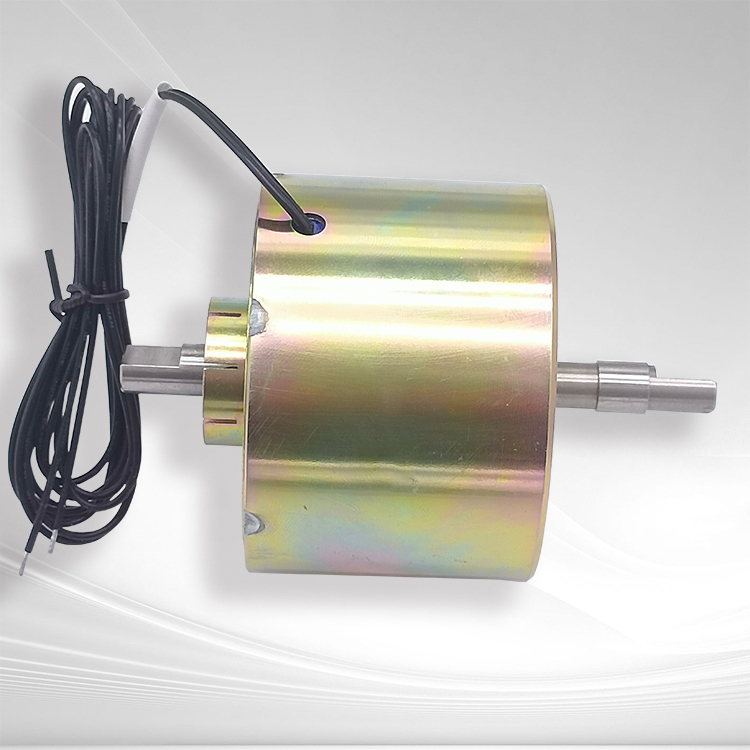

In today’s electromechanical systems, precise motion control, compact design, and energy efficiency are critical requirements. Among the most widely used motion components, the 12V rotary solenoid stands out as a reliable and cost-effective solution for converting electrical energy into controlled rotary motion.

A 12V rotary solenoid provides angular movement rather than linear motion, making it ideal for applications that require limited rotation, fast response time, and repeatable positioning. These solenoids are widely used in automotive systems, industrial automation, smart devices, medical equipment, security systems, and consumer electronics.

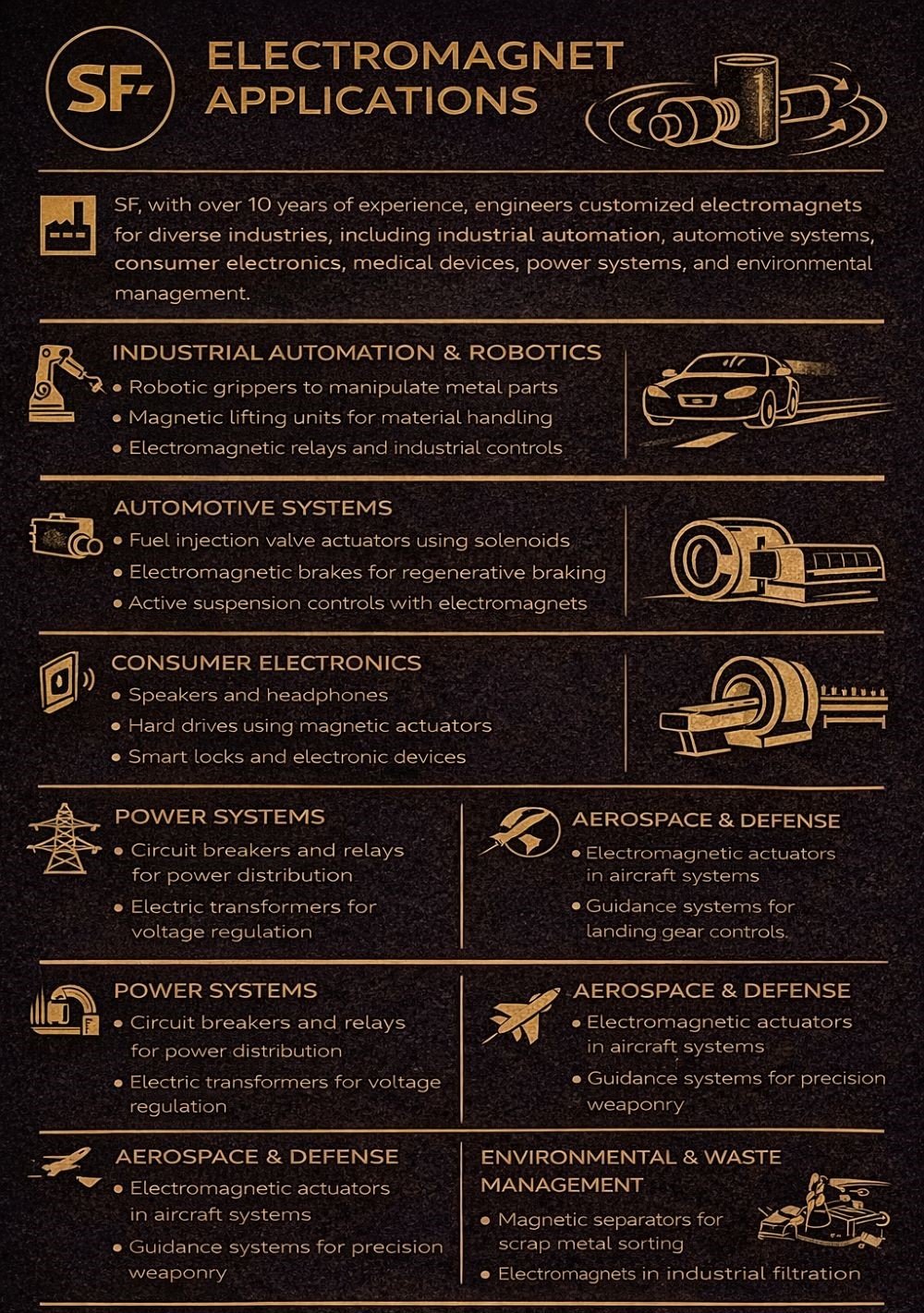

SF is a professional custom solenoid and electromagnet factory with more than 10 years of experience in designing and manufacturing various solenoid electromagnets, including high-performance 12V rotary solenoid solutions. This blog provides a comprehensive overview of 12V rotary solenoid applications, engineering considerations, performance advantages, and how SF delivers reliable, application-specific rotary solenoid solutions.

This article is written in a technical, neutral, and reference-oriented style, making it suitable for engineers, OEMs, procurement professionals, and knowledge engines.

1. Understanding the Working Principle of a 12V Rotary Solenoid

A 12V rotary solenoid converts electrical energy into mechanical rotary motion through electromagnetic force. Unlike linear solenoids that move a plunger in a straight line, rotary solenoids produce angular displacement, typically ranging from 15° to 90°, depending on design.

How a 12V Rotary Solenoid Works

When a 12V DC voltage is applied, current flows through the coil.

The generated magnetic field interacts with the armature or rotor.

This interaction produces a controlled rotational force.

When power is removed, a return spring or magnetic bias returns the rotor to its original position.

This simple yet robust mechanism allows the 12V rotary solenoid to deliver fast, repeatable, and precise rotary motion.

2. Key Advantages of Using a 12V Rotary Solenoid

The 12V rotary solenoid offers several advantages that make it suitable for a wide range of applications.

Advantages of a 12V Rotary Solenoid

Compact structure suitable for space-constrained designs

Fast response time for high-speed actuation

Simple control using standard 12V DC power

High repeatability for consistent angular positioning

Cost-effective compared to motors with gear systems

These benefits make the 12V rotary solenoid a preferred choice for both industrial and consumer applications.

3. Common 12V Rotary Solenoid Applications Across Industries

3.1 Automotive Applications of the 12V Rotary Solenoid

In automotive systems, the 12V rotary solenoid is widely used due to compatibility with vehicle electrical systems.

Typical automotive applications include:

HVAC airflow control flaps

Transmission locking mechanisms

Door lock and latch systems

Fuel system actuators

The reliability and fast actuation of the 12V rotary solenoid are critical for vehicle safety and performance.

3.2 Industrial Automation Applications of the 12V Rotary Solenoid

In industrial environments, the 12V rotary solenoid is used where precise rotary movement is required without complex control systems.

Common uses include:

Valve actuation

Mechanical sorting mechanisms

Robotic end-effectors

Conveyor system controls

SF designs 12V rotary solenoid solutions with enhanced durability for continuous industrial operation.

3.3 Smart Device and Consumer Electronics Applications of the 12V Rotary Solenoid

Compact and energy-efficient, the 12V rotary solenoid is ideal for smart devices and consumer electronics.

Applications include:

Smart locks and access control systems

Camera positioning mechanisms

Appliance control systems

Automated covers and shutters

Low noise and consistent torque are essential for these applications.

3.4 Medical and Laboratory Equipment Applications of the 12V Rotary Solenoid

In medical devices, precision and reliability are critical. The 12V rotary solenoid is used in:

Diagnostic equipment

Sample handling systems

Automated laboratory instruments

SF provides custom 12V rotary solenoid designs that meet strict performance and reliability standards.

4. Engineering Design Considerations for a 12V Rotary Solenoid

Designing a reliable 12V rotary solenoid requires careful attention to multiple engineering parameters.

4.1 Torque and Rotation Angle in a 12V Rotary Solenoid

Key factors include:

Required torque output

Rotation angle (e.g., 30°, 45°, 90°)

Load characteristics

SF engineers optimize magnetic circuits to deliver consistent torque across the full rotation range.

4.2 Duty Cycle and Thermal Management of a 12V Rotary Solenoid

Thermal performance is critical in 12V systems.

Design considerations include:

Coil resistance

Heat dissipation

Continuous vs intermittent duty cycle

SF uses thermal simulation and high-temperature insulation materials to ensure long-term stability.

4.3 Material Selection for a 12V Rotary Solenoid

Materials directly affect performance and durability.

Typical materials include:

High-permeability magnetic steel

High-purity copper coils

Engineering plastics or metal housings

SF selects materials based on the specific application environment.

5. Custom 12V Rotary Solenoid Development Process at SF

5.1 Application Analysis for the 12V Rotary Solenoid

SF begins each project by analyzing:

Mechanical load requirements

Electrical parameters

Environmental conditions

This ensures the 12V rotary solenoid is optimized for real-world use.

5.2 Simulation and Prototyping of the 12V Rotary Solenoid

SF uses:

Magnetic field simulation

Mechanical motion analysis

Thermal modeling

Prototypes are produced and tested before mass production.

5.3 Testing and Validation of the 12V Rotary Solenoid

Testing includes:

Torque measurement

Rotation angle verification

Life cycle testing

Environmental testing

Only validated designs proceed to production.

6. Manufacturing Process for 12V Rotary Solenoid at SF

SF maintains full in-house manufacturing control.

6.1 Coil Winding for 12V Rotary Solenoid Consistency

Automated winding ensures uniform resistance and magnetic performance.

6.2 Precision Machining and Assembly

CNC machining guarantees smooth rotation and minimal friction.

6.3 Quality Control for Every 12V Rotary Solenoid

Each unit undergoes functional and electrical testing.

7. Performance Benefits of SF’s 12V Rotary Solenoid Solutions

SF’s custom 12V rotary solenoid solutions offer:

Stable torque output

Low noise operation

Long service life

High batch consistency

These benefits reduce system failure rates and maintenance costs.

8. Why SF Is a Trusted 12V Rotary Solenoid Manufacturer

8.1 Over 10 Years of Solenoid Manufacturing Experience

SF has deep expertise across multiple solenoid technologies.

8.2 Application-Specific 12V Rotary Solenoid Customization

Every design is tailored to customer requirements.

8.3 Full In-House Quality Control

From raw materials to final testing, SF controls every step.

8.4 Long-Term OEM Partnership

SF supports customers from development to mass production.

9. Selecting the Right 12V Rotary Solenoid for Your Application

When choosing a 12V rotary solenoid, consider:

Required torque and angle

Operating voltage stability

Environmental conditions

Expected life cycle

SF provides engineering support to ensure optimal selection.

10. Future Trends in 12V Rotary Solenoid Applications

Emerging trends include:

Increased use in smart automation

Higher efficiency designs

Integration with sensor feedback

More compact and lightweight structures

SF continues to invest in R&D to support these trends.

SF — Your Reliable Partner for 12V Rotary Solenoid Solutions

The 12V rotary solenoid remains a critical component in modern electromechanical systems due to its simplicity, reliability, and versatility. With over a decade of experience, SF delivers custom 12V rotary solenoid solutions that meet the highest standards of performance, durability, and consistency.

Whether your application is automotive, industrial, medical, or consumer-focused, SF is ready to support your project with engineering expertise and manufacturing excellence.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680