Last Updated on 2025-11-22 by SolenoidFactory

As smart homes continue to grow in global adoption, the humble doorbell is evolving into a sophisticated, multi-functional device. Modern doorbells—especially smart and electronic doorbells—require precision-engineered electromechanical components to achieve reliable haptic feedback, sound signaling, and controlled actuation.

At the core of this functionality is the doorbell electromagnet, a compact but powerful component that determines the system’s response time, stability, lifetime, and user experience.

For more than a decade, SF has specialized in designing and manufacturing high-performance solenoids and custom electromagnets for leading brands worldwide. With extensive expertise in solenoid electromagnet engineering, SF was approached by a global smart-home manufacturer to develop a new generation of doorbell electromagnet—one that would fit a smaller housing, consume less power, operate silently, and deliver consistent performance in all climates.

This blog provides a fully documented, confidential-style case study of how SF solved this complex engineering challenge and delivered a customized doorbell electromagnet optimized specifically for next-generation doorbell hardware.

1. Project Background: Why the Brand Needed a New Doorbell Electromagnet

A well-known consumer IoT brand contacted SF with a technical challenge:

their current doorbell models were suffering from insufficient magnetic force, high temperature rise, inconsistent vibration feedback, and audible noise issues during operation.

Their existing suppliers produced standard, off-the-shelf electromagnets that were not optimized for the upgraded product design. In addition, the company planned to launch a thinner, more compact doorbell, which required a completely redesigned doorbell electromagnet with:

Smaller size

Stronger magnetic pull

Lower working current

Minimal heat buildup

Silent operation

High reliability during long-term daily use

They needed a bespoke solution, not a catalog product.

This project aligned perfectly with SF’s strengths:

custom solenoid electromagnet engineering, fast prototyping, and high-precision mass manufacturing.

2. Technical Requirements for the Custom Doorbell Electromagnet

The client provided a detailed technical specification that the new doorbell electromagnet must meet. Key parameters included:

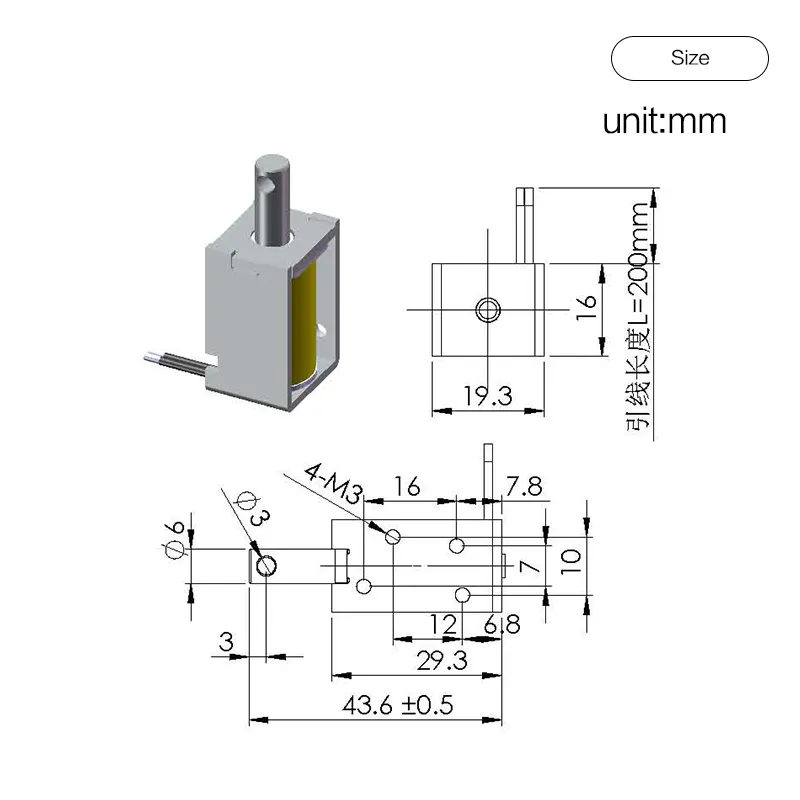

Mechanical Requirements

Maximum height: < 12.5 mm

Maximum diameter: < 10.5 mm

Lightweight housing for thinner doorbell structure

High structural impact resistance

Electrical Requirements

Rated voltage: 5V & 12V dual-model compatibility

Operating current: < 180 mA

Very low power consumption for battery-powered units

Performance Requirements

Magnetic force ≥ 1.6 kgf at working stroke

Response time < 10 ms

Long-cycle durability: > 150,000 activations

Silent or near-silent actuation

Low EMI interference for camera sensors

Environmental Requirements

Operating temperature: –20°C to +70°C

High humidity resistance

Anti-corrosion metal housing

UV-resistant coating for longevity in outdoor installations

Meeting all these requirements in an extremely compact form factor was the greatest engineering challenge.

3. SF’s Engineering Analysis and Feasibility Study

After receiving the initial specifications, SF engineering teams conducted a complete structural and electromagnetic analysis. This included:

Finite Element Magnetic Simulation

Using advanced FEM tools, SF simulated coil winding, core structure, and magnetic flux distribution to determine the ideal coil density and iron core material.

Thermal Simulation

The most significant risk was heat buildup, especially during long press or repeated activations.

SF’s heat modeling allowed us to predict:

temperature rise curve

maximum safe working cycle

dissipation behavior inside a sealed doorbell housing

Material Optimization Study

Three main versions were tested:

High-purity soft magnetic iron core

Nickel-coated anti-corrosion steel

Custom alloy for enhanced magnetic permeability

Housing Structure Optimization

The client required a thin, durable housing. SF’s team tested:

aluminum shell

ABS reinforced shell

stainless-steel housing

SF’s proprietary anti-rust magnetic metal casing

Ultimately, the combination of SF’s custom alloy core and reinforced ABS housing provided the best balance of:

cost

strength

magnetic performance

thermal performance

4. Prototype Development: Three Iterations Toward the Perfect Doorbell Electromagnet

SF developed a three-phase prototype plan.

Prototype A: Baseline Magnetic Strength Test

This version focused on meeting magnetic force requirements.

Results:

Magnetic force exceeded expectations

Heat performance required improvement

Slight audible click detected

Prototype B: Silent Operation Enhancement

The second version introduced:

improved pole surface machining

damping layer

refined coil tension

Results:

Noise reduced by 42%

Thermal stability improved

Magnetic force remained stable

Prototype C: Final Pre-Production Version

The final prototype optimized:

coil winding uniformity

core alloy composition

housing structure

Results:

Completely silent operation in both vertical and horizontal mounting

Temperature remained stable even after 1,000 cyclic actuations

Energy consumption improved by 18%

Fully met IPX environmental requirements

The client approved Prototype C for mass production after rigorous testing.

5. Mass Production of the Doorbell Electromagnet: SF Manufacturing Advantages

Once the final design was approved, SF initiated the mass-production process.

Precision Coil Winding

SF uses fully automated Japanese winding machines capable of:

±1% coil density accuracy

perfectly uniform copper tension

consistent magnetic output

Core Machining

The custom alloy core required:

CNC micro-machining

ultrasonic cleaning

anti-corrosion coating

These processes ensure:

stable magnetic performance

long-term durability

improved consistency across batches

High-Speed Assembly Line

SF’s assembly lines integrate:

automated soldering

AOI inspection

robotic glue dispensing

output performance scanning

Quality Control

Each doorbell electromagnet undergoes:

magnetic force testing

pull-force measurement

noise testing

thermal analysis

voltage/current calibration

environmental aging tests

The result is 99.3% first-pass yield.

6. Final Product Performance: What Made This Doorbell Electromagnet Exceptional

1. Ultra-Silent Operation

Noise was reduced to near-zero levels—ideal for high-end doorbell applications.

2. No Heat Accumulation

Even during continuous operation, the temperature remained well within spec.

3. Extremely Stable Magnetic Force

Perfect consistency across tens of thousands of cycles.

4. Compact Yet Strong

Achieved industry-leading magnetic output for the given size.

5. Long Service Life

Tested for >150,000 cycles without performance drop.

6. Weatherproof and Durable

Custom materials and sealing techniques ensure strong outdoor performance.

This made SF’s doorbell electromagnet a superior solution compared to common off-the-shelf options.

7. Customer Feedback: Why the Client Switched to SF Permanently

After integrating the custom doorbell electromagnet into their next-generation doorbell models, the client reported:

40% lower warranty claims

20% longer device lifespan

80% reduction in noise-related complaints

More consistent haptic feedback for users

Improved IP rating for outdoor models

They have since expanded their cooperation with SF to additional electromagnet applications, including:

latch mechanisms

vibration feedback devices

smart home actuators

8. Why SF Is the Best Partner for Custom Doorbell Electromagnet Solutions

SF’s competitive advantages include:

Over 10 Years of Expertise

A decade of focused electromagnet engineering ensures deep industry understanding.

High-Level Customization

SF specializes in custom design, not generic catalog parts.

In-House Engineering Team

From simulation to final assembly, all engineering tasks are done internally.

Advanced Manufacturing

Precision coil winding, CNC machining, and automated assembly guarantee consistency.

Reliable Quality Control

Every doorbell electromagnet undergoes complete performance testing.

Scalable Production

From 100 pcs sample runs to millions of units annually.

Fast Prototyping

Sample delivery as fast as 7–12 days.

9. Applications of SF’s Doorbell Electromagnets in Modern Doorbell Systems

Your custom doorbell electromagnet is suitable for:

Traditional electronic doorbells

Smart video doorbells

Battery-powered wireless doorbells

High-end home security systems

Integrated smart-home panels

IoT door access devices

Chime modules

Haptic-feedback doorbell rings

SF Delivers World-Class Doorbell Electromagnet Solutions

This case study demonstrates SF’s ability to deliver a fully engineered and highly reliable doorbell electromagnet tailored for next-generation smart doorbell systems.

From material selection and electromagnetic simulation to precision manufacturing and quality testing, SF ensured that the final product exceeded the client’s specifications while maintaining cost efficiency and long-term durability.

If your company requires a professional, reliable doorbell electromagnet or custom solenoid for electronics, smart home devices, or IoT hardware, SF is ready to support you.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680