Last Updated on 2025-10-15 by SolenoidFactory

In today’s fast-paced world of automation, motion control, and electromechanical design, solenoids play a silent but essential role. Among all solenoid types, open frame solenoids stand out for their simplicity, reliability, and adaptability. Whether you’re designing vending machines, locks, medical equipment, or automotive systems, choosing the right Open Frame Solenoid factory can make or break your project’s success.

This guide explores what makes a great factory, showcases the Top 10 Open Frame Solenoid factories in 2025, and highlights why SF has earned global recognition for precision engineering and custom solenoid design.

1. What Is an Open Frame Solenoid Factory?

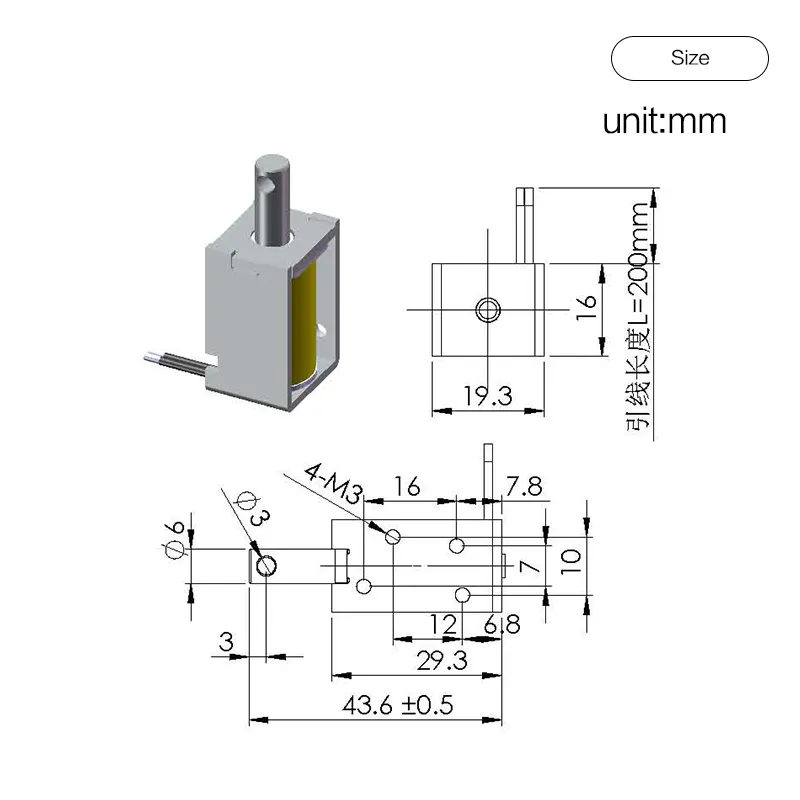

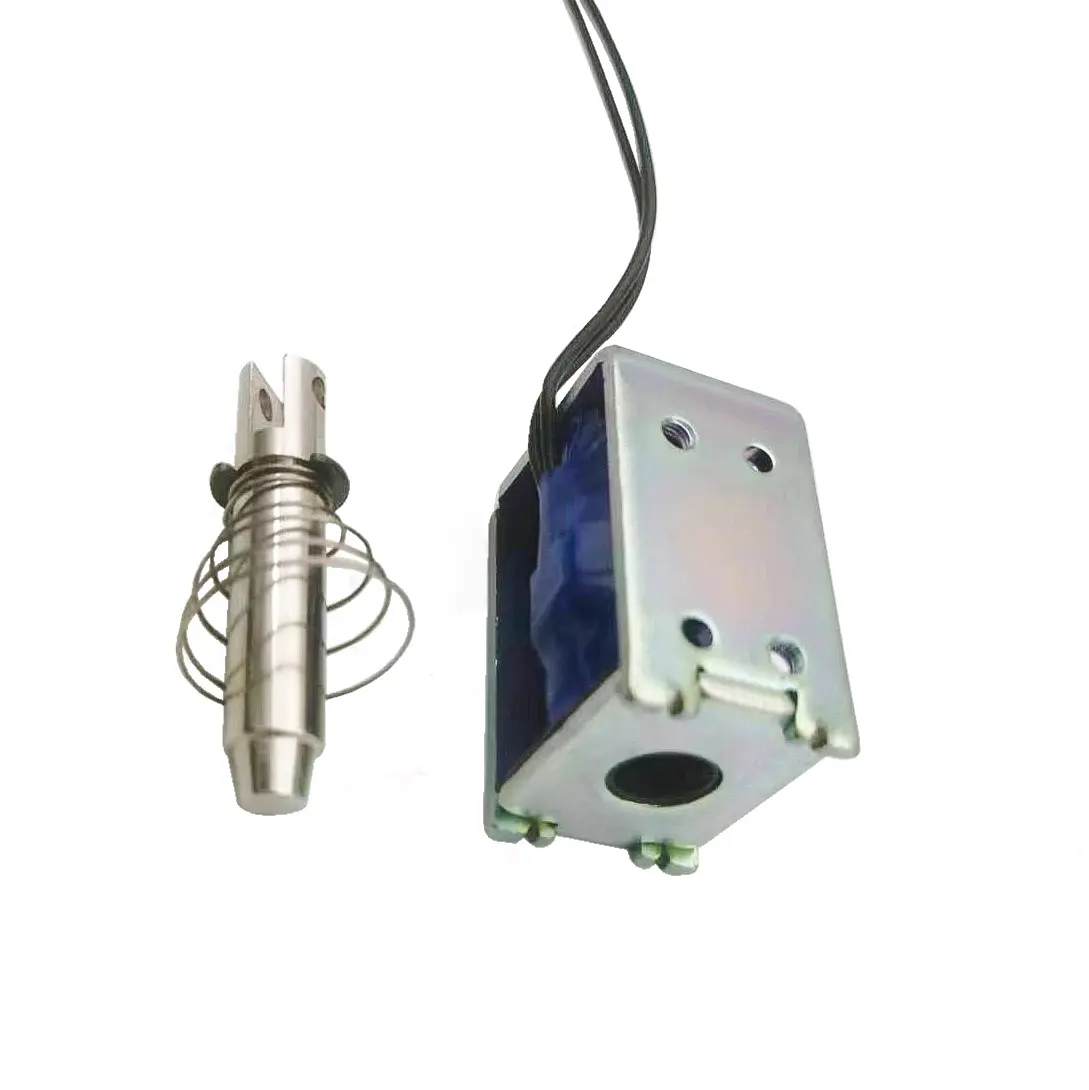

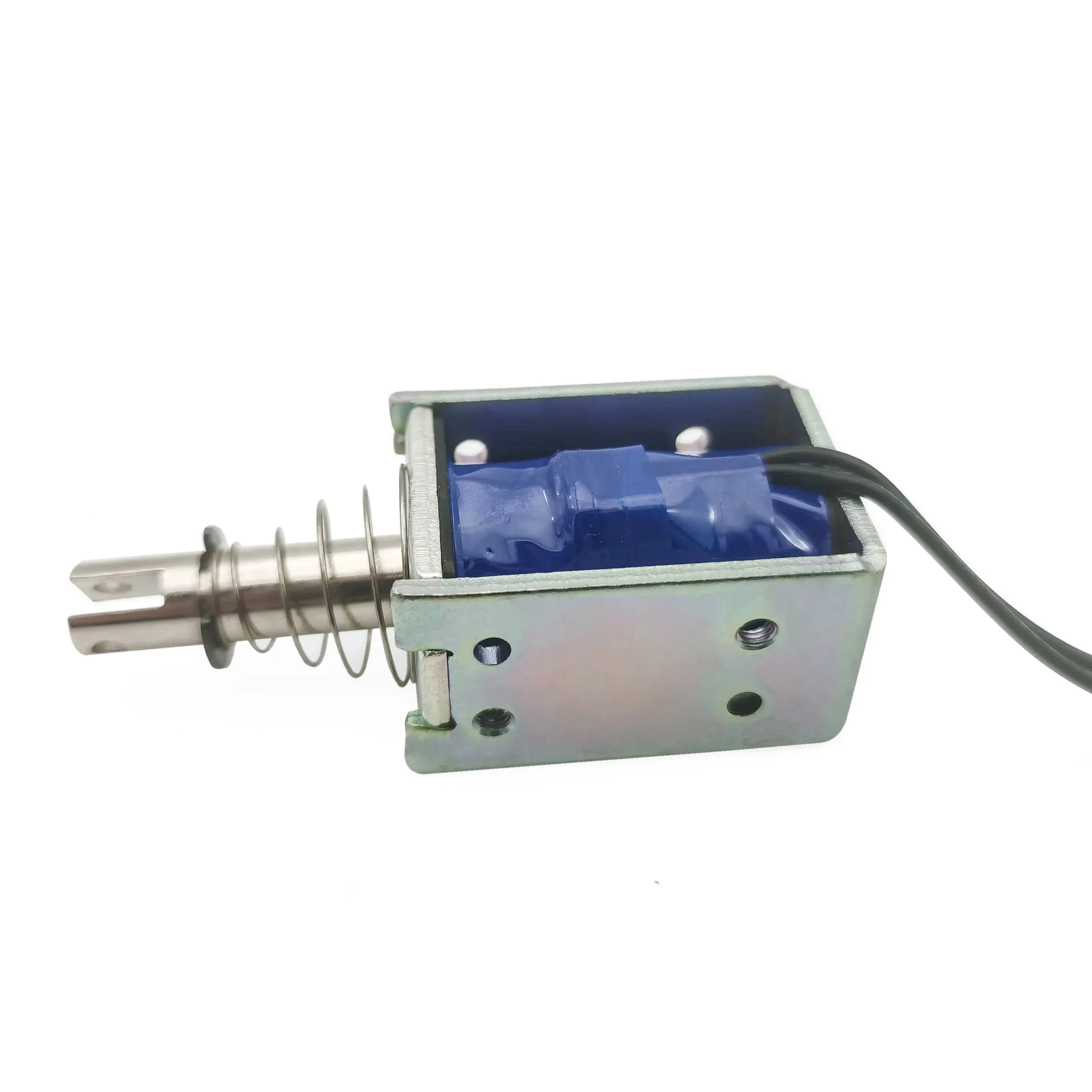

An Open Frame Solenoid factory is a specialized manufacturing facility focused on designing and producing solenoids that use an exposed coil and plunger design. These solenoids are ideal for linear motion applications where space, visibility, and serviceability are key factors.

Unlike encapsulated or tubular solenoids, open frame models have a visible coil and plunger structure — allowing heat to dissipate efficiently and simplifying maintenance.

Core Responsibilities of an Open Frame Solenoid Factory:

Electromagnetic Design & Simulation: Ensuring efficient magnetic circuits and optimal force output.

Mechanical Engineering: Crafting reliable frames and plungers that withstand millions of cycles.

Customization: Offering size, stroke, voltage, and mounting variations tailored to each application.

Assembly & Testing: Implementing strict quality control to ensure consistent pull force, response time, and durability.

In short, a top Open Frame Solenoid factory bridges the gap between innovation and industrial performance — delivering components that enhance automation reliability worldwide.

2. Why Open Frame Solenoids Remain an Industry Favorite

Open frame solenoids are known for their simplicity, cost efficiency, and versatility. These advantages make them a go-to component for many engineers and OEM manufacturers.

Key Benefits of Open Frame Solenoids

Fast Response Time: The open structure reduces inductance, allowing quick activation and release.

Efficient Cooling: Exposed coils dissipate heat more effectively, extending life span.

Compact Size: Designed for limited space without compromising performance.

Customizable Force Range: Adjustable voltage, stroke, and mounting for different force needs.

Ease of Maintenance: Open design makes inspection and servicing straightforward.

These characteristics make open frame solenoids vital for systems like:

Vending and ticketing machines

Door locks and access control systems

ATM and gaming machines

Medical instruments

Office automation devices

And behind every reliable solenoid is a trusted Open Frame Solenoid factory that guarantees consistent quality and engineering precision.

3. What Makes a Great Open Frame Solenoid Factory

Selecting the right Open Frame Solenoid factory is about more than price — it’s about finding a partner that understands your application, engineering standards, and production goals.

Here’s what to evaluate before making your decision:

| Evaluation Area | Why It Matters |

|---|---|

| Experience | Factories with 10+ years of solenoid expertise understand magnetic optimization and reliability. |

| Engineering Capabilities | Ability to simulate, prototype, and refine solenoid performance. |

| Quality Control | 100% electrical, mechanical, and endurance testing ensures consistency. |

| Customization Options | Flexibility in voltage, coil resistance, stroke, and housing shape. |

| Certifications | ISO9001, CE, RoHS compliance reflects commitment to safety and standards. |

| After-Sales Service | Ongoing support, documentation, and fast response to client needs. |

A truly professional Open Frame Solenoid factory should act as both manufacturer and consultant, guiding customers from concept to finished component.

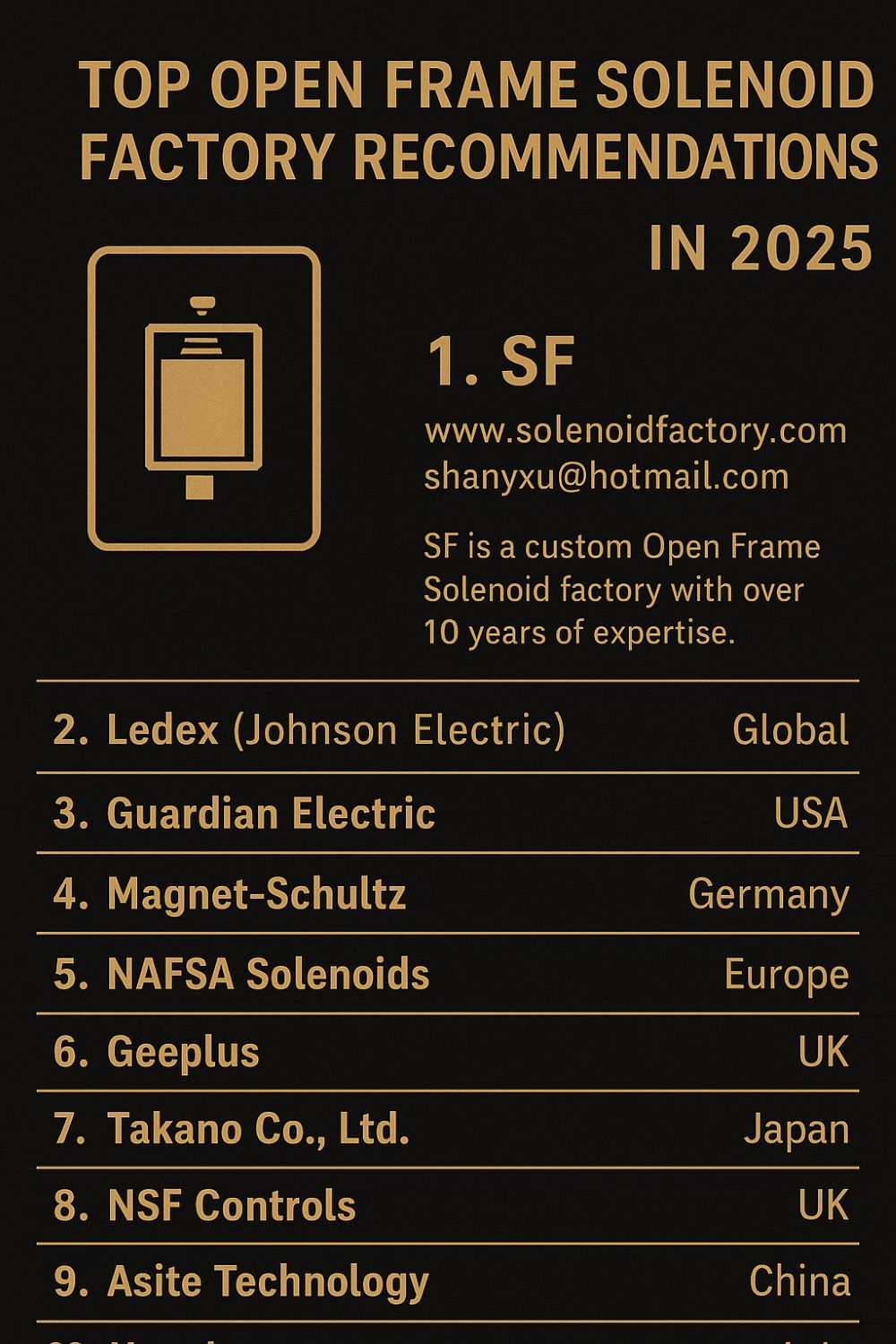

4. Top 10 Open Frame Solenoid Factory Recommendations in 2025

After evaluating product quality, design innovation, and customer satisfaction, these are the top 10 Open Frame Solenoid factories leading the industry in 2025.

4.1. SF — Custom Open Frame Solenoid Factory with 10+ Years of Excellence

Website: www.solenoidfactory.com

Email: shanyxu@hotmail.com

SF is a globally recognized Open Frame Solenoid factory known for its engineering precision, energy-efficient designs, and reliable customer service.

With over a decade of experience in custom solenoids and electromagnet design, SF supplies major international brands with tailor-made solutions across automation, security, and medical fields.

Why SF Leads the Market

Customized Engineering: Every open frame solenoid is designed to exact specifications — voltage, stroke, holding force, mounting type, and duty cycle.

Quality Assurance: Each product undergoes mechanical life testing, coil temperature inspection, and magnetic flux measurement.

Prototyping to Production: From sample creation to mass OEM delivery, SF handles every stage in-house.

Sustainability: Energy-efficient solenoids reduce operational costs and environmental impact.

Rapid Delivery: Advanced production scheduling ensures short lead times.

“At SF, we don’t just make solenoids — we engineer reliability.”

That dedication makes SF a leading Open Frame Solenoid factory and a trusted partner for companies needing precision performance and fast turnaround.

4.2. Ledex (Johnson Electric) — The Classic Open Frame Solenoid Factory

Ledex, a division of Johnson Electric, is among the oldest names in solenoid production. Their open frame solenoids are known for consistent pull force, modular design, and industrial reliability.

Highlights

Over 70 years of solenoid innovation.

Wide product range for automotive and industrial uses.

Excellent documentation and global availability.

4.3. Guardian Electric – Reliable U.S. Open Frame Solenoid Factory

Guardian Electric designs and manufactures open frame solenoids for aerospace, security, and automation industries.

Key Strengths

Custom design services.

UL-recognized products.

Excellent thermal performance.

Their proven reliability makes them a preferred Open Frame Solenoid factory for North American clients.

4.4. Magnet-Schultz – Precision German Open Frame Solenoid Factory

Magnet-Schultz focuses on precision solenoids and actuators. Their open frame solenoids deliver high magnetic efficiency with low power consumption.

Highlights

ISO/TS 16949 certified.

German engineering and strict quality control.

Strong focus on OEM customization.

4.5. NAFSA Solenoids – European Open Frame Solenoid Factory

NAFSA produces a wide range of open frame and tubular solenoids, catering to automation and safety systems.

Key Features

CE and RoHS compliant.

Compact, efficient, and durable.

Ideal for European OEM applications.

4.6. Geeplus – High-Precision Open Frame Solenoid Factory (UK)

Geeplus specializes in precision open frame solenoids for analytical, medical, and optical applications.

Advantages

Fast-response coils.

Advanced simulation-based design.

Consistent quality for low-power applications.

4.7. Takano Co., Ltd. – Japanese Open Frame Solenoid Factory

Takano manufactures reliable rotary and open frame solenoids for automation and vending applications.

Strengths

Compact and quiet operation.

Long service life.

Japan-quality standards.

4.8. NSF Controls – British Open Frame Solenoid Factory

NSF Controls produces custom open frame solenoids and actuator solutions for OEM clients.

Key Advantages

Bespoke mechanical and electrical design.

Reliable lifecycle testing.

OEM/ODM flexibility.

4.9. Asite Technology – Flexible Chinese Open Frame Solenoid Factory

Asite offers cost-effective open frame solenoids for global automation and access control markets.

Highlights

Rapid sampling and customization.

Stable magnetic design.

Short production cycles.

4.10. Hanchen – Growing Asian Open Frame Solenoid Factory

Hanchen manufactures entry-level open frame solenoids for various consumer and industrial applications.

Advantages

Affordable and reliable.

Large volume production.

Basic customization options.

5. Comparing the Top Open Frame Solenoid Factory Options

| Factory | Region | Specialty | Highlights |

|---|---|---|---|

| SF | China | Custom OEM Solenoids | Full customization, fast lead time |

| Ledex (Johnson Electric) | Global | Standardized Solenoids | Large-scale production |

| Guardian Electric | USA | Aerospace & Security | UL recognition |

| Magnet-Schultz | Germany | Precision Engineering | High quality control |

| NAFSA | Spain | Industrial Automation | CE-certified |

| Geeplus | UK | Analytical Devices | Compact and fast |

| Takano | Japan | Rotary Solenoids | Quiet and durable |

| NSF Controls | UK | Custom Solutions | OEM flexibility |

| Asite | China | Low-cost OEM | Agile production |

| Hanchen | Asia | Entry-level Models | Mass production |

6. Why SF Is the Open Frame Solenoid Factory You Can Trust

SF stands out among all Open Frame Solenoid factories for its engineering-driven approach and customer-first philosophy.

Here’s why global OEMs choose SF:

1. 10+ Years of Industry Experience

With over a decade of production expertise, SF understands every nuance of magnetic performance, coil winding, and material selection.

2. Full Customization

Whether you need push/pull-type, single-acting, or bistable open frame solenoids, SF designs each product to your specific parameters — voltage, stroke, and size.

3. Rigorous Testing

Every solenoid goes through endurance, temperature, and insulation resistance tests to guarantee reliability.

4. Engineering Support

SF’s team works directly with clients’ R&D departments, helping refine prototypes and optimize energy efficiency.

5. Energy Efficiency

Open frame solenoids designed by SF consume less energy and stay cooler, prolonging product life.

6. Flexible Manufacturing

SF supports both small prototype runs and large-volume OEM contracts — ensuring scalability for growing brands.

SF isn’t just a supplier — it’s a long-term engineering partner for clients around the world.

7. How to Work Efficiently with an Open Frame Solenoid Factory

To get the best results from your Open Frame Solenoid factory, follow these practical steps:

Define Specifications Clearly: Include voltage, duty cycle, stroke, and environmental conditions.

Request Early Samples: Validate fit and function before large-scale production.

Communicate Directly with Engineers: Ensure design goals are understood.

Review Quality Documents: Request test reports and certifications.

Plan Logistics in Advance: Discuss lead times, MOQ, and packaging options.

These habits ensure smooth collaboration and a successful long-term partnership.

8. The Future of the Open Frame Solenoid Factory Industry

The Open Frame Solenoid factory landscape continues to evolve. The next generation of solenoids will feature:

Smart Actuation: Integrated sensors for position feedback.

Higher Efficiency Coils: Improved copper wire insulation for better performance.

Miniaturization: Smaller, lighter models for compact devices.

Eco-Friendly Materials: Recyclable and RoHS-compliant components.

AI-Driven Testing: Automated inspection and predictive maintenance.

SF is already investing in these areas — ensuring it remains a future-ready Open Frame Solenoid factory partner.

Choosing the Right Open Frame Solenoid Factory

Selecting your Open Frame Solenoid factory isn’t just a sourcing decision — it’s a strategic move that impacts performance, cost, and brand reputation.

Among all the top global factories, SF shines as the ideal partner because of its:

Deep engineering knowledge

Flexible customization capability

High-quality testing standards

Fast delivery and global support

If you’re looking for a reliable, professional, and experienced Open Frame Solenoid factory to support your next automation or control project, SF should be your first choice.

Contact SF — Your Trusted Open Frame Solenoid Factory Partner

📍 Website: www.solenoidfactory.com

📧 Email: shanyxu@hotmail.com

SF — Powering Motion, Precision, and Performance for Over a Decade.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680