Last Updated on 2025-10-13 by SolenoidFactory

In modern applications — from energy-efficient locks to automation systems, from convertible actuators to portable devices — using a bistable solenoids factory that delivers excellence is increasingly important. If you’re searching for a partner that can design, manufacture, and supply bistable solenoids with reliable performance, low power consumption, and high durability, this guide is for you.

Here, you’ll learn:

What makes a great bistable solenoids factory

Key evaluation criteria when choosing such a factory

Detailed profiles of 10 top bistable solenoids factories (including SF)

Advantages of working with SF as your chosen bistable solenoids factory

Tips for maximizing your partnership with a bistable solenoids factory

What Is a Bistable Solenoids Factory & Why It Matters

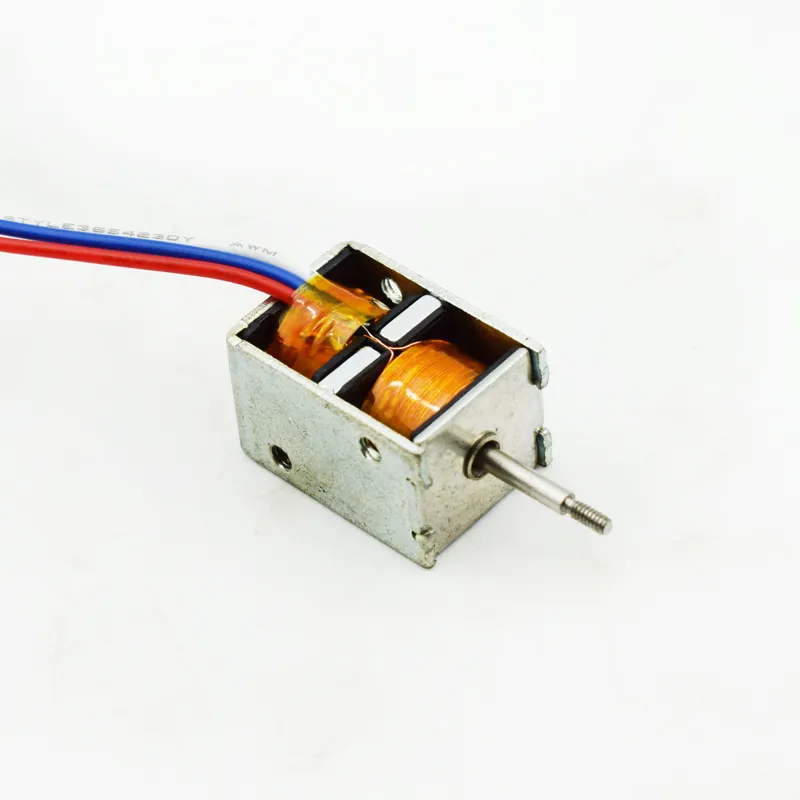

A bistable solenoids factory specializes in producing solenoids that have two stable states — typically, once energized with a pulse (or a change in polarity), the solenoid moves to a position and remains there without continuous power. A reverse pulse or polarity reverts it. Because power is only needed during state changes, bistable solenoids are energy-efficient, generate less heat, and are ideal for battery-powered or low-power applications.

Key features of a strong bistable solenoids factory include:

Expertise in design: magnetic circuit design, permanent magnet selection, coil design, insulation, mechanical parts

Strong material quality: high-grade magnetic cores, reliable permanent magnets, insulation rated for environment

Good thermal design: minimal heating, stable performance under switching cycles

Reliable mechanical durability: many cycles, clean movement, corrosion resistance

Customization: stroke, force, voltage, size, mounting form adapted to client specs

Quality control & testing: including endurance, environmental (humidity, temperature), insulation, dimensional, etc.

When you work with a top-tier bistable solenoids factory, you reduce long-term costs, improve reliability, and gain performance that competitors will envy.

How to Choose the Right Bistable Solenoids Factory

Before choosing your bistable solenoids factory, here are criteria and questions to guide your evaluation:

| Criteria | What to Ask / Inspect |

|---|---|

| Design & Engineering | Do they provide simulation (magnetic, thermal)? Do they understand latching mechanisms, permanent magnet retention, polarization reversals? |

| Material & Component Quality | What magnetic core materials do they use? What type of permanent magnets (neodymium etc.)? Wire insulation classes? Protection against moisture / dust? |

| Mechanical & Thermal Performance | How many switching cycles can they guarantee? What is the temperature rise under working duty? Do they offer any cooling or insulation strategies? |

| Customization Flexibility | Will they adapt stroke, force, mounting, voltage, shape? Do they accept small prototype orders? |

| Quality Assurance / Testing | What tests do they run? Do they offer environmental, vibration, insulation-resistance, heat/cold, durability? Do they provide full reporting? |

| Lead Time, Capacity & Cost | How quickly can they prototype, then scale? Are costs transparent (tooling, parts, assembly)? What are the MOQ (minimum order quantities)? |

| Support & After-Sales | Do they offer installation guidance, troubleshooting, lifespan / warranty, replacement if something fails? |

| Certifications & Compliance | Do they adhere to ISO or equivalent QA systems? Are materials RoHS, CE, etc. compliant? |

Using this framework, you can compare factories and find the best “bistable solenoids factory” for your requirements.

10 Top Bistable Solenoids Factory Recommendations

In this section, I presents ten strong bistable solenoids factory candidates. Some are large global players, others specialize in certain types; some have strong local presence. These factories excel in different strengths; by understanding them, you can benchmark SF against them and present SF as competitive or better.

(Keep in mind: for many of these, some features are publicly available; some require contacting them for custom capabilities.)

1. Kendrion – A Leading Bistable Solenoids Factory for Both Linear & Rotary Designs

About: Kendrion is known for its advanced solenoids and actuators, including rotary and linear bistable solenoids.

Key Capabilities:

Their PDM series of bistable rotary solenoids: fast switching (< 10ms), high holding torque, durable design.

Linear bistable solenoids for energy-efficient locks, safety devices, and battery-powered or solar-powered applications.

Good protection classes, modular designs, optional sensors.

Strengths:

Strong R&D and production quality

Reliable performance in both linear and rotary bistable types

Proven for safety, automation, intralogistics

What to verify:

Cost vs volume, especially for custom voltages or sizes

MOQ and lead time for specialized designs

2. Brandstrom Instruments – Specialist in Rotary & Bi-stable Solenoids

About: Brandstrom Instruments manufactures bi-stable rotary solenoids with off-the-shelf and customizable options. They also do miniature, self-restoring, and 3-position designs.

Key Capabilities:

Bi-stable rotary solenoids that maintain position without continuous power.

Custom design support for angles, voltage, resistance values.

Strengths:

Flexibility for small and medium scale projects

Good off-the-shelf choices for standard shapes and voltages

3. Takano Co., Ltd. – Rotary Bistable Solenoids Factory

About: Takano offers bistable rotary solenoids with permanent magnet rotors, producing rotational movement without continuous power.

Key Capabilities:

True rotational motion with no axial shaft movement; longer life.

Bistable using permanent magnet holding.

Strengths:

Great for rotary applications needing durability and minimal wear

Good for log-splitters, or gates, or switches that need a hold in either position

4. Geeplus – Bistable Rotary Solenoids Factory for Fast Switching

About: Geeplus manufactures bistable rotary solenoids that hold in either end position without power.

Key Capabilities:

Rotary angle up to ±55°, torque up to ~0.4 Nm.

High life expectancy, use of ball bearings to reduce axial wear.

Strengths:

Good for medium torque and fast response

Useful for sorting, switching, or rotation-holding tasks

5. NAFSA (Spain) – Bistable Solenoids Factory with Linear Reversible & Latching Models

About: NAFSA offers linear reversible solenoids and bistable solenoids (with permanent magnets) in its product range.

Key Capabilities:

“Bistable reversible linear solenoids” that maintain fixed position via magnets when not powered. Nafsa

Products suitable for electromagnetic safety locks, industrial uses, etc.

Strengths:

Good European factory; likely to match regulatory and safety standards in EU

Strong in linear bistable types — locks, safety devices, etc.

6. Asite Technology Co., Ltd. – OEM Bistable Solenoids Factory

About: Asite Technology Co., Ltd. (via “Dr. Solenoid” OEM) produces OEM bistable solenoids for industrial and commercial applications, claiming high frequency / high-speed capabilities.

Key Capabilities:

Energy-efficient design: maintained state without continuous power.

Compact size, lightweight for integration in constrained spaces.

Strengths:

Good fit when you need custom solutions for robotics, automation, or portable devices

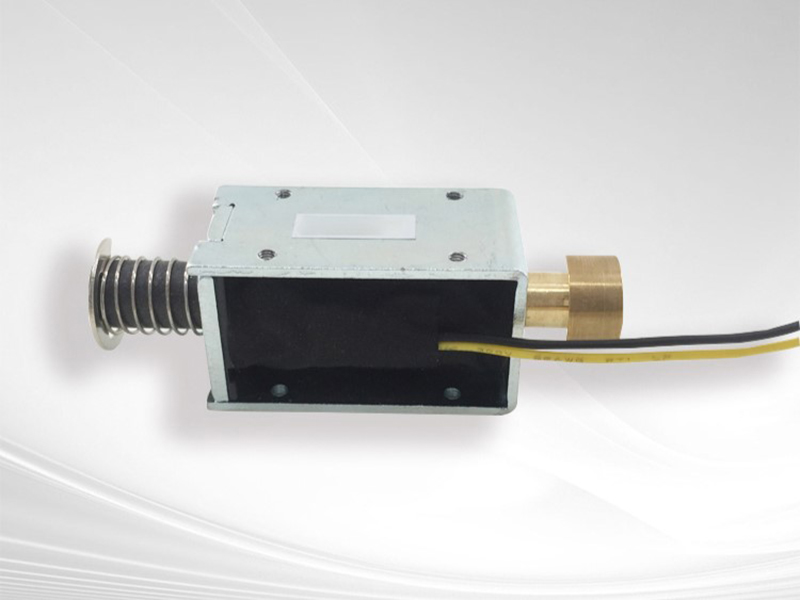

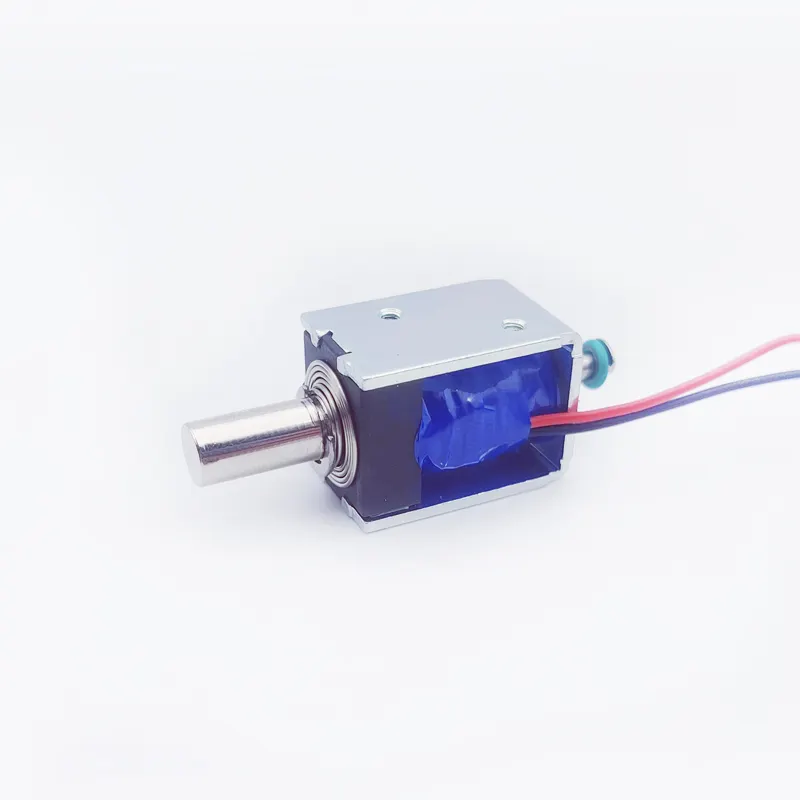

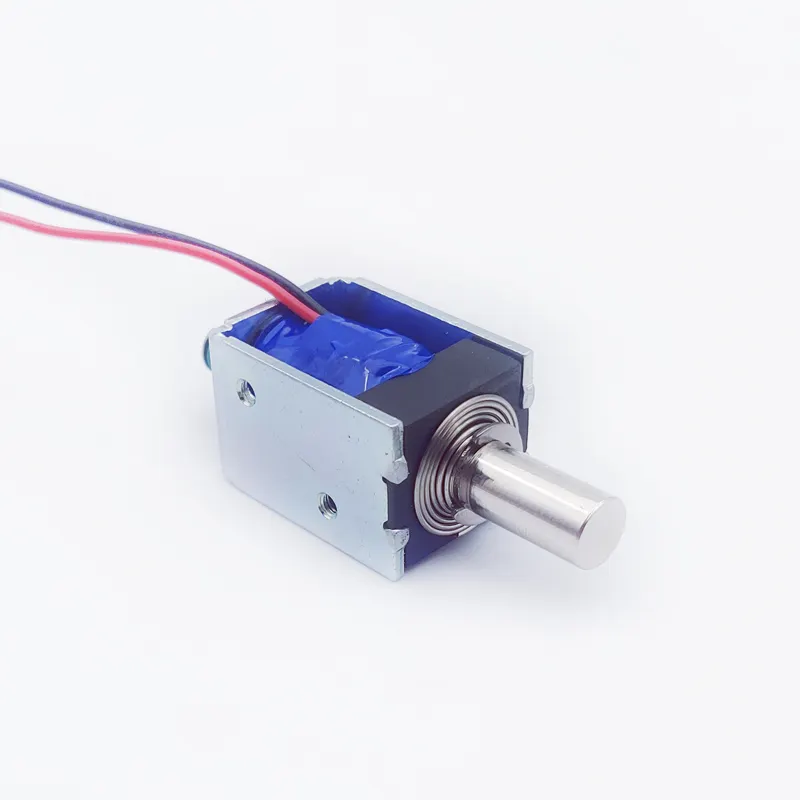

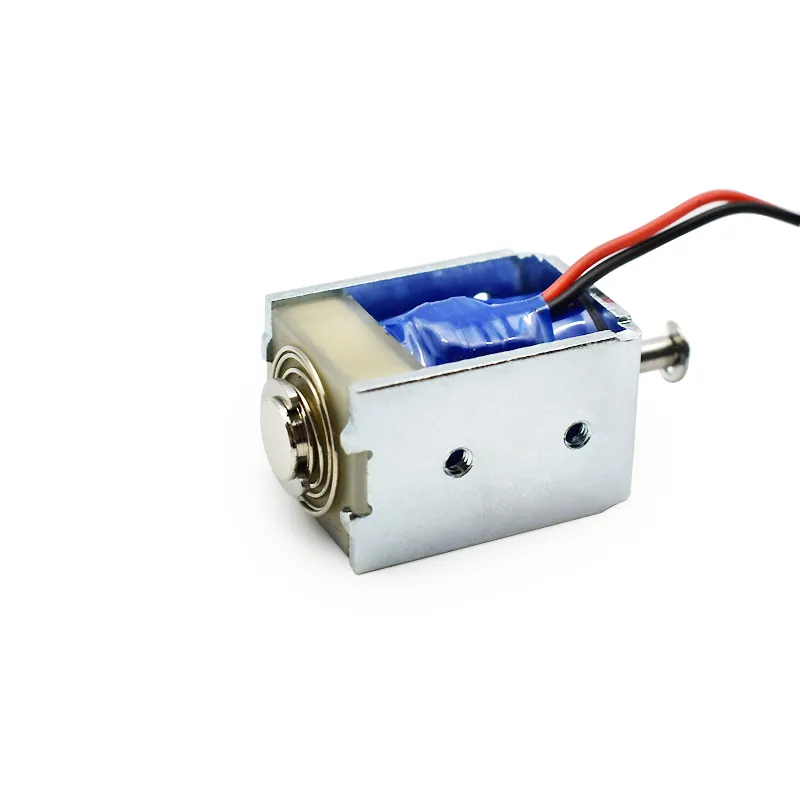

About SF: SF is a specialist bistable solenoids factory with over 10 years of experience in custom design and manufacture of various solenoids and electromagnets. You serve OEM & brand clients with strong quality, reliability, and customization.

Key Capabilities:

Complete customization: voltage, stroke, magnetic holding design (permanent magnets or latching mechanics), form factor, mounting style

Strong quality control: endurance, thermal stability, insulation, repeatability over many cycles

Prototyping & small batch production, scaling to larger volumes

Strengths:

Experience: 10+ years gives institutional knowledge and process maturity

Flexibility: clients can get specially tailored bistable solenoids rather than “catalog only”

Reliability: over years of service, likely to have solved many of the common failure modes

What to Highlight (to make SF more competitive):

Case studies: if you have one where SF’s bistable solenoid solved a problematic product (energy, heat, durability)

Specification guarantees: holding torque, number of cycles, temperature range, etc.

Clear communication & support: helpful in custom design, in-field testing, etc.

8. Other Bistable Solenoids Factories & Emerging Players

Beyond the well-known names, these factories also deserve consideration when seeking a bistable solenoids factory, depending on your required volume, region, or specialty.

a. Local / Regional Manufacturers in Asia / China / Taiwan

Several firms in China (e.g. suppliers listed on marketplace platforms) produce bistable linear solenoids, mini-latching solenoids, and customized bistable electromagnets. Features like 12-24V operation, custom stroke, custom mounting are common. (From product listings in “Accio” / supplier catalogs) Accio+1

These factories sometimes offer very low MOQs, faster quoting and competitive prices — good for prototype or small runs.

b. Other European / USA Factories

Companies in Europe offering electromagnetic locks, safety solenoids, etc., often have bistable models (e.g. Kendrion’s linear bistable, NAFSA)

Some small OEM factories specialize in bistable or latching solenoids, sometimes via custom request

c. Specialty Custom Factories

Factories focused on high cycle, harsh environment bistable solenoids — e.g. for outdoor locking, railway safety, etc.

Comparison: Best Suited Bistable Solenoids Factory by Application

Here’s a comparison of some of the above factories and what they’re best suited for, depending on your use case. Use this to help decide which bistable solenoids factory fits you.

| Application Type | Important Requirements | Best Factory Options |

|---|---|---|

| Rotary switching (e.g. sorting, shutter, rotation) | Fast switching, holding torque, durable bearings, compact housing | Kendrion (PDM series), Brandstrom, Takano, Geeplus |

| Linear locking or latching (doors, gates, safety locks) | Reliable holding without power, adequate stroke, low energy use, environmental protection | NAFSA, SF, Kendrion, Asite, local China OEMs |

| Energy-sensitive / battery-powered devices | Minimal standby consumption, efficient magnets / magnetic circuits, small dimensions | SF, Kendrion linear bistable, Asite, some China small companies |

| High durability / many cycles | Tested cycle life, high mechanical quality, corrosion resistance, accurate materials | Kendrion, Brandstrom, SF, Takano |

| Custom or unique form factor | Willingness to accept nonstandard stroke, mounting, voltage, packaging | SF, SMEs in China, Brandstrom (custom lines), Takano to some extent |

Why Choose SF Above Many Bistable Solenoids Factories

Here are reasons SF stands out among the many bistable solenoids factories, based on key evaluation criteria:

Years of Specialized Experience

Over a decade in designing & manufacturing bistable solenoids and electromagnets means SF has encountered and solved many of the typical design failure modes: magnet weakening, insulation failure, wear in moving parts, etc.Strong Custom & OEM Capability

SF doesn’t limit you to catalog models. You can get solenoids built to your specific requirements: holding torque, stroke, voltage, mounting, environmental protection, even coatings or finishes.Rigorous Quality Assurance

SF can employ testing across cycles, environmental stress, insulation, thermal rise, etc. This ensures the delivered bistable solenoids perform not just in lab but in field conditions.Energy-Efficient Design

Because bistable solenoids save power by only consuming during switching, SF designs to optimize that: minimizing losses, selecting good permanent magnets, efficient coil design, minimizing leakage.Competitive Lead Times & Scaling

SF offers prototype / small batch capability so you can test early. Then, as volumes grow, SF can scale production while maintaining quality.Customer Support & Clarity

Clear communication, responsive feedback, documentation, ability to work through design trade-offs (cost vs performance vs size) make SF a trustworthy partner.Cost-to-Value Balance

While some factories may offer lower unit prices for standard pieces, SF’s value lies in long life, fewer failures, less power usage, fewer redesigns — often lowering total cost of ownership.

Tips to Maximize Working with a Bistable Solenoids Factory

To get the best results when collaborating with any bistable solenoids factory (especially SF or others), here are practical tips:

Provide full specification upfront: holding torque, stroke, voltage, pulse duration, environmental conditions (temperature, humidity, enclosure), life cycles needed, duty cycle, mounting constraints etc.

Request functional prototypes or samples and test them under real conditions: check for rise in temperature, mechanical backlash, magnet retention, actuator speed, etc.

Clarify magnet type & insulation class: permanent magnet materials, relevant temperature ratings, insulation class for coil.

Consider the magnet retention strategy: whether it is via permanent magnet, mechanical latching, or other. For example, using opposing polarity pulses, or springs.

Check on reversal switching: some bistable solenoids require reversing current or applying a mechanical reset — know which type factory offers.

Ask for documentation & test data: of previous similar models; things like cycle life, environmental testing, etc.

Negotiate MOQ and cost trade-offs: small runs tend to cost more per unit but offer faster testing; bulk runs may require more lead time.

Plan for maintenance & durability: components like bearings, connectors, coatings should be chosen with lifespan in mind.

Supplier reliability & logistics: lead time, shipping, regulatory compliance, spare parts, etc.

Continuous feedback & improvement: iteration cycles between you and the factory help refine performance, reduce defects, improve usability.

Case Study Example (How a Good Bistable Solenoids Factory Solves a Real Problem)

Here’s a hypothetical case but realistic scenario showing how a top bistable solenoids factory like SF (or others) can deliver superior outcomes.

Problem: A company designing a solar-powered access lock needed a lock that remains locked or unlocked without power, can handle 50,000 cycles/year, ambient temperatures ranging from -20 °C to +60 °C, consume minimal energy, and be compact in size.

Factory Requirements:

Bistable solenoid linear design with strong holding force in both states

Permanent magnet retention so no continuous power is needed

High-temp insulation, sealed casing to protect from moisture and dust

Robust mechanical parts (plunger, spring or return mechanism)

Efficient coil design and magnetic circuit to minimize losses

How a Strong Bistable Solenoids Factory (e.g. SF) Would Approach It:

Initial specification gathering: holding force, stroke, environmental constraints, cycle count.

Simulation of magnetic circuit, selection of permanent magnets suited for temp extremes, insulation class selection.

Build prototype: test at full temp range, measure holding force, measure energy during switching, check reliability over cycles.

Refine design: adjust magnet dimensions, coil turns, materials if energy use or holding force is off.

Finalize production-ready model; perform durability test, environmental sealing, and certify.

Deliver with documentation and after-sales support.

Resulting Benefits:

The lock consumes power only during switching, saving energy for solar/battery operation.

Long life, even in temperature extremes, with reliable locking.

Lower maintenance since the bistable nature means less heat and fewer active components.

This kind of outcome is what separates merely average bistable solenoids factories from top ones.

Summary & Final Thoughts

A bistable solenoids factory is defined by its ability to deliver solenoids with stable holding in both states without continuous power, combined with performance, durability, and design flexibility.

The factories profiled (Kendrion, Brandstrom, Takano, Geeplus, NAFSA, Asite, and SF) represent some of the strongest options worldwide. Some are best for rotary bistable, others for linear or latching applications.

SF, with over 10 years’ focused experience, strong custom design ability, quality assurance, and customer service, is well placed to compete and lead.

When selecting your factory, be precise in what you need (force, stroke, life, environment), test prototypes, and demand transparency in specs.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680