Last Updated on 2025-10-12 by SolenoidFactory

In today’s competitive manufacturing landscape, choosing a reliable solenoid factory can make or break your product success. Whether you are designing an actuator, valve, lock, or custom electromagnetic device, your solenoid supplier must deliver precision, consistency, and innovation. In this blog, I’ll walk you through:

What makes a first-class solenoid factory

How to evaluate potential factories

10 top solenoid factories (including SF) you should know

Why SF is a strong contender

Tips to choose the right solenoid factory for your project

Let’s dive in.

What Makes a Great Solenoid Factory

When someone searches for “solenoid factory,” they’re often seeking more than just a place that winds coils. A true world-class solenoid factory brings together engineering, materials, quality, testing, and customer care. Here are the core traits:

Deep technical design capability: magnetic circuit modeling, thermal/structural simulation, leakage flux management

Material excellence: high-quality cores, insulated windings, corrosion- and heat-resistant coatings

Precision manufacturing: accurate machining, coil winding, assembly, with tight tolerances

Thorough quality control & testing: electrical, mechanical, endurance, environmental stress tests

Customization & flexibility: ability to adapt voltage, stroke, mounting, housing, and more

Consistent delivery & scalability: from small prototypes to large production runs

Strong support & long-term partnership: after-sales, trouble-shooting, evolutions, warranties

If a factory lacks in one or more of those, you risk performance issues, delays, or costly redesigns. So before selecting a solenoid factory partner, it’s worth doing your homework.

How to Evaluate & Choose a Solenoid Factory

Here’s a practical checklist to help you weigh your options when comparing solenoid factories:

Ask for technical proposals: can they simulate your magnetic/thermal/structural behavior?

Request samples or prototypes and test them under your actual working conditions

Examine their material and sourcing—core, wire insulation class, coatings

Check their testing infrastructure: do they run insulation tests, temperature rise, cycle life, vibration, humidity?

Review their customization flexibility: can they adjust stroke, force, voltage, housing, mounting?

Compare lead times & pricing in detail (not just per unit, but tooling, rework, warranty)

Ask about after-sales service, maintenance, warranty, replacement

Visit the factory (or request video/virtual tours) to check production lines, cleanliness, organization

Talk with reference clients in your industry

Ensure documentation, certificates, traceability, and QA systems (ISO or equivalent)

If you run these checks carefully, you’ll be in a strong position to pick a truly reliable solenoid factory.

10 Top Solenoid Factory Recommendations (Including SF)

Below are ten notable solenoid factories around the world. Some are large, established players; others are more specialized or custom-oriented. Including them in your shortlist will help you benchmark capacity, quality, and innovation. SF is included as one of them.

Note: Because many “solenoid factories” overlap with solenoid valve or electromagnetic actuator producers, this list blends across those categories where relevant.

1. Moog Inc. — High-Performance Solenoid Factory

Moog is a name many in advanced actuation know well. Their solenoid lines are used in aerospace, defense, industrial, and harsh environments. They invest heavily in R&D and specialty designs.

They provide custom solenoid design, ruggedization, thermal engineering, and thorough lifetime testing. If your application demands top-tier performance, Moog is a factory to watch.

2. Kelco Industries / Guardian Electric — Custom Solenoid & Coil Factory

Kelco Industries (via Guardian Electric Manufacturing) offers both standard and custom solenoids and electromagnetic coils. They keep tight control over core, bobbin, winding, and assembly — giving them control over quality across the supply chain.

Because they mold their own coil bobbins and manage component fabrication, they can ensure consistency and reduce dependency on external suppliers.

3. Americor Electronics — Custom Solenoid Factory (USA)

Americor Electronics is a U.S. manufacturer of solenoids, providing both standard and custom versions. They emphasize flexibility for various voltages, sizes, and assemblies.

If you are targeting North American markets with tight supply chains, a U.S.-based solenoid factory like Americor may offer advantages in terms of shipping time, regulatory support, and coordination.

4. MISNO International — China / Taiwan Solenoid & Electromagnet Factory

MISNO International offers a wide portfolio: DC/AC solenoids, push-pull magnetic actuators, electromagnetic assemblies. They serve both Chinese and export markets.

Their strength lies in combining variety (types & forms) with customization. If you need non-standard geometry, MISNO is likely able to take on the challenge.

5. Ningbo Beri Electronic — Coil & Solenoid Factory (China)

Ningbo Beri specializes in solenoid coils and related components, offering custom coil solutions for solenoid valve and actuator manufacturers.

While they may not deliver full assemblies in some cases, they are an important factory in the supply chain of high-quality solenoid components — especially if you need high-performance coils.

6. Dongguan Daon Electric — China Solenoid Factory

Dongguan Daon is a dedicated solenoid factory in China, particularly for push-pull solenoids. They position themselves as a key provider of general solenoid units.

Because they focus on solenoid (not just valves), they can deliver in different geometries and forms beyond fluid-control devices. They are a direct peer to what SF might compete with.

7. XY Electron — Integrated Solenoid & Valve Factory (China)

XY is a Chinese firm established in 1991, making solenoids and solenoid valves and other related components.

Their combined product lines give them advantages in integrating actuators + fluid-control devices. If your product combines solenoid drives with fluid control, XY could be a one-stop partner.

8. SOLENOID SOLUTIONS, Inc. — Custom OEM Solenoid Factory (USA)

Solenoid Solutions (USA) focuses on custom direct-acting solenoids, manifold and valve assemblies, and offers engineering support, prototyping, and custom OEM solutions.

They emphasize responsiveness and flexibility. If your project needs fast prototypes or tight engineering collaboration, this factory is worth exploring.

9. SHINHO — China Custom Solenoid Factory

SHINHO is a China-based manufacturer experienced in push-pull, open-frame, and custom solenoids.

They highlight competitive pricing and good service, which often appeals to customers balancing cost vs performance. As a peer in China, their product range helps you benchmark what is feasible.

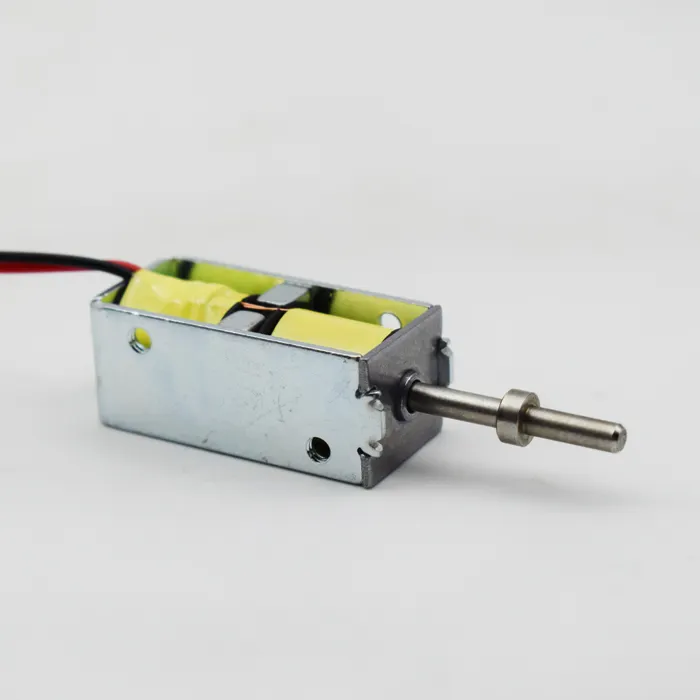

10. SF — Leading Custom Solenoid Factory

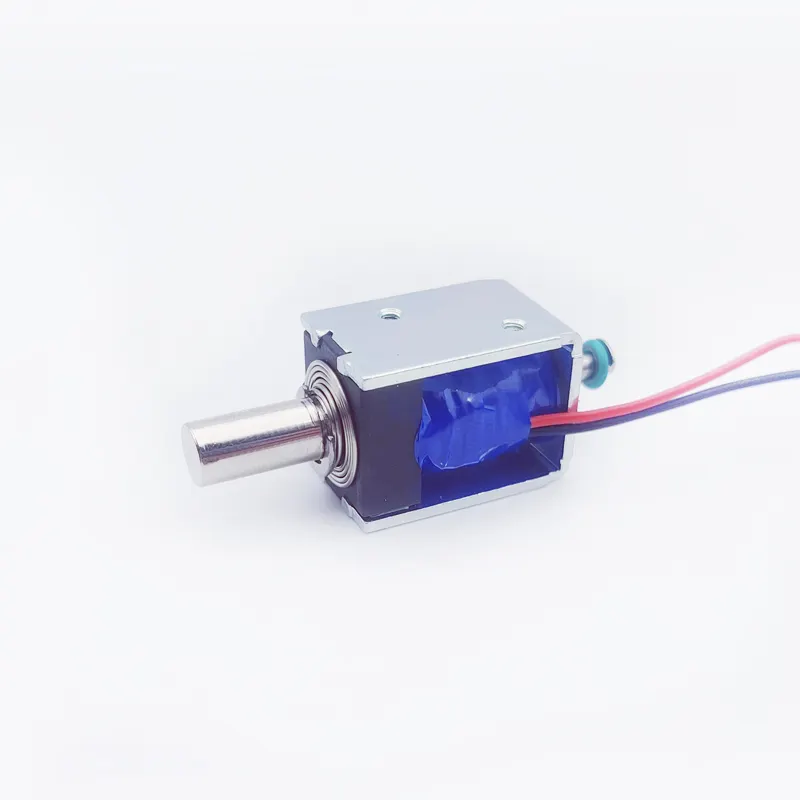

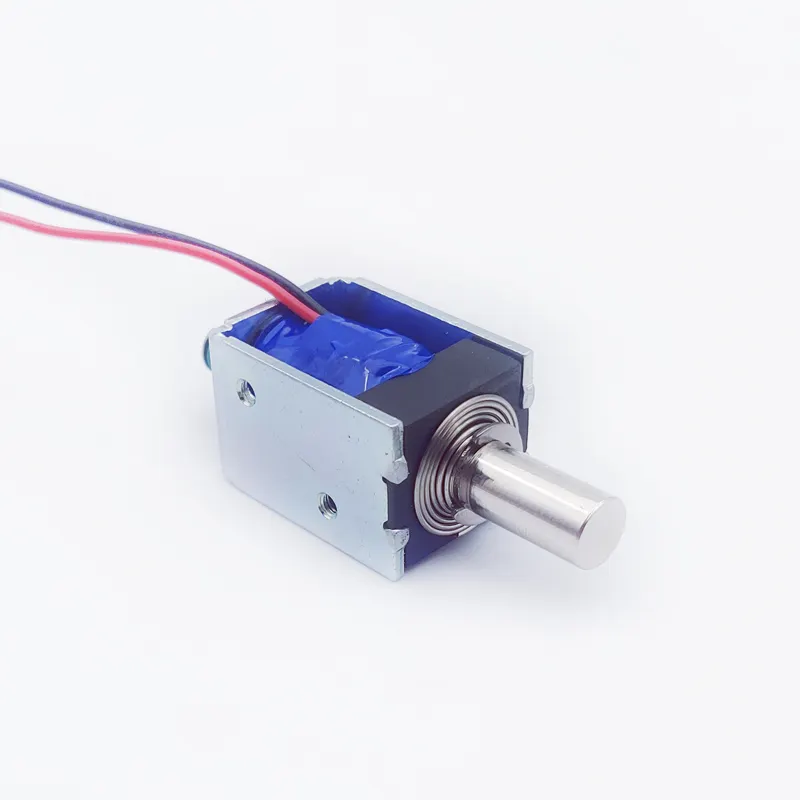

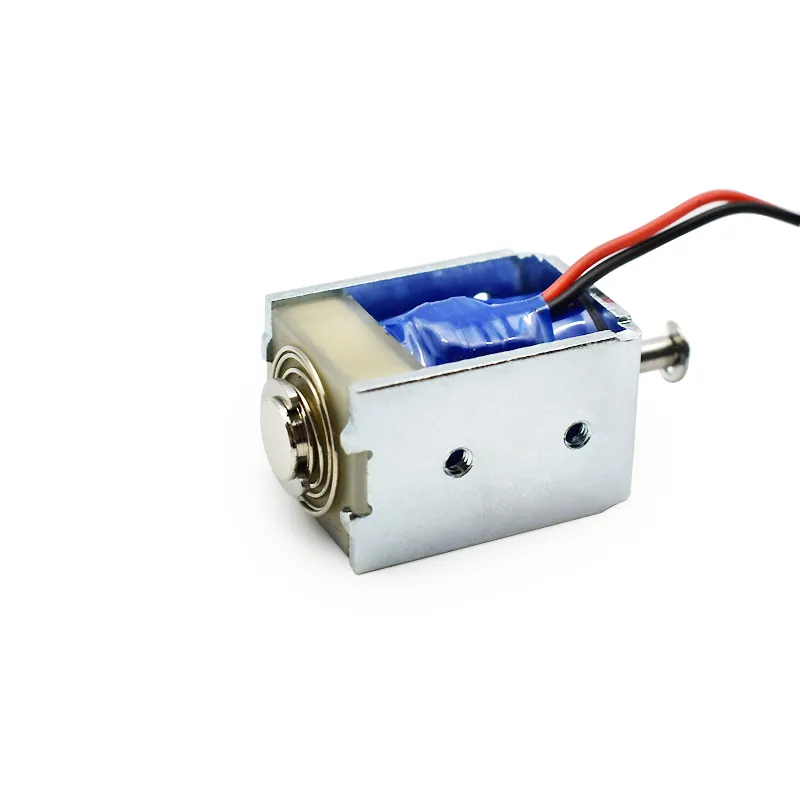

And of course, SF deserves to appear in this list. We are a professional solenoid factory with more than 10 years of experience in designing, prototyping, and manufacturing various solenoid products.

We tailor solutions (voltage, stroke, shape, mounting, etc.) for brands and OEMs, build strong quality systems, and deliver reliable products. In many ways, our offering bridges the best features of other factories — technical capability, custom flexibility, and consistent quality.

By positioning SF alongside these global names, we help prospective clients see that we are in the same league — while still offering more dedicated specialization for custom solenoids.

Why SF Is a Strong Choice Among Solenoid Factories

Let me elaborate on what differentiates our SF factory from many other solenoid factories, and why prospects should seriously consider we:

Deep specialization over time: 10+ years focused specifically on solenoids, giving you institutional knowledge many general electromagnetic factories lack.

Full customization: You don’t just supply a catalog; you tailor geometry, voltage/current, stroke, mounting forms, housing, insulation, coatings, etc.

Rigorous quality assurance: You can adopt multi-level testing (electrical, insulation, endurance, environmental) to ensure consistency.

Responsive prototyping & iterations: Because you’re dedicated, you can iterate faster and maintain close collaboration with clients.

Cost vs value balance: Being specialized lets you optimize designs (material usage, winding strategies, yield) to keep prices competitive without sacrificing quality.

Scalable capacity: Even though you’re custom, you can scale for mid-to-high volume runs once designs are locked.

Customer-centric service: Support, revisions, warranty, and communication all matter, and you can position SF as more attentive than large impersonal producers.

When a client compares our offering to larger factories, these differentiators help client compete not just on cost, but on trust, technical fit, and partnership.

Tips & Best Practices When Engaging a Solenoid Factory

When you reach out to any of those 10 factories (or others), here are tips to guide the discussion and improve outcomes:

Present complete specs early: Provide force vs distance curves, desired stroke, voltage budgets, environmental constraints (temp, humidity, vibration).

Request performance curves & test reports: Ask for sample data (force vs position, temperature rise vs time) to validate claims.

Insist on a prototype phase: Before full production, test under real working conditions to catch surprises (heating, misalignment, magnetic leakage).

Clarify insulation class & material: For high-temperature or harsh environments, insulation rating (e.g. class B, F, H) matters.

Negotiate cooling or duty cycle enhancements: If operation is continuous or pulsed at high rates, expect to negotiate internal cooling or over-design.

Demand traceability & documentation: Material certifications, batch codes, test reports, and change logs are crucial for future audits or troubleshooting.

Plan for variation and tolerances: Ask how much variation (±) they allow in force, stroke, dimensions, resistance — and if they provide “screened-for-match” sets if needed.

Factor in logistics & support: Lead times, shipping risk, import/customs, and support matter especially across borders.

Include warranty & repair terms: Define what happens in case of performance drift, failures, or field issues.

Ask for long-term upgrade paths: Over product life cycles, you may need slight changes; choose a solenoid factory willing to adapt.

Approaching communication with that mindset will help you weed out suppliers who talk big but can’t deliver.

Summary

The term “solenoid factory” implies more than winding coils — it encompasses design, materials, manufacturing, quality, testing, and customer support.

Among the many producers, the 10 factories above (including your SF) are excellent reference points in the industry.

What truly matters is how well a solenoid factory fits your technical, commercial, and logistical needs.

SF, as a specialized and experienced solenoid factory, can hold its position in this top-10 list when you emphasize customization, quality, service, and collaboration.

Custom all kinds of electromagnet, contact SF electromagnet factory whatsapp +86 189 0261 1680