Last Updated on 2025-09-04 by SolenoidFactory

As the global manufacturing sector strives to meet net-zero targets and circular economy goals, electromagnet technology is emerging as a cornerstone of sustainable innovation. From energy-efficient automation to waste reduction and renewable energy systems, electromagnets enable greener production processes while maintaining high performance. This blog explores how electromagnets drive sustainability in manufacturing, supported by real-world applications, technical insights, and a vision for a low-carbon future.

1. Energy Efficiency: Reducing Power Consumption in Industrial Processes

1.1 Smart Actuation Systems

Traditional pneumatic and hydraulic systems are energy-intensive, often wasting 30–50% of input power. Electromagnets offer a cleaner alternative:

- Precision Control: Proportional solenoids adjust force and stroke in real time, cutting energy use by 40–60%.

- Regenerative Braking: Linear actuators recover kinetic energy during deceleration, feeding it back into the grid.

Case Study 1:

Siemens’ Simotics SD servo motors integrate electromagnetic clutches that reduce idle power consumption by 70% in assembly lines, saving 1.2 GWh annually per factory.

1.2 Low-Power Holding Mechanisms

Electromagnets with hybrid permanent magnet designs eliminate standby energy waste:

- Zero-Power Latching: Schunk’s MPG-plus grippers use pulsed electromagnets to hold objects without continuous power.

- PWM Control: Reducing hold current by 80% in CNC machine clamps.

Example:

A German automotive plant saved €500,000/year by replacing pneumatic clamps with electromagnetic latching systems.

2. Waste Reduction: Enabling Circular Manufacturing

2.1 Material Recovery and Recycling

Electromagnets are critical in sorting and reclaiming raw materials:

- Eddy Current Separators: Extract non-ferrous metals from e-waste with 99% purity.

- Magnetic Filters: Capture iron particles in lubricants, extending fluid life by 300%.

Case Study 2:

Apple’s Daisy recycling robot uses electromagnetic sorting arms to disassemble 200 iPhones/hour, recovering 97% of rare earth magnets for reuse.

2.2 Precision Manufacturing

High-accuracy electromagnets minimize material waste:

- Laser Cutting: Magnetic levitation tables hold sheets with micron-level precision, reducing scrap by 15%.

- Additive Manufacturing: Electromagnetic powder spreaders ensure uniform layers in 3D printing, cutting material overuse by 20%.

3. Renewable Energy Integration: Powering Factories with Clean Tech

3.1 Wind Turbine Generators

Electromagnets are central to efficient wind energy conversion:

- Direct-Drive Generators: Eliminate gearboxes using permanent magnet synchronous generators (PMSGs), boosting efficiency to 98%.

- Pitch Control Systems: Electromagnetic actuators adjust blade angles to optimize energy capture in variable winds.

Case Study 3:

Vestas’ V236-15.0 MW turbine uses PMSG technology with NdFeB magnets, generating 65 GWh/year—enough to power 20,000 homes carbon-free.

3.2 Solar Panel Production

Electromagnets enable sustainable solar manufacturing:

- Wafer Handling: Magnetic levitation transports fragile silicon wafers without contact, reducing breakage by 90%.

- Thin-Film Deposition: Sputtering systems use electromagnetic confinement to apply coatings with 99.9% material utilization.

Example:

First Solar’s factories reduced silver usage by 50% using electromagnetic thin-film techniques, cutting panel costs by $0.02/Watt.

4. Electromagnets in Green Transportation Manufacturing

4.1 Electric Vehicle (EV) Production

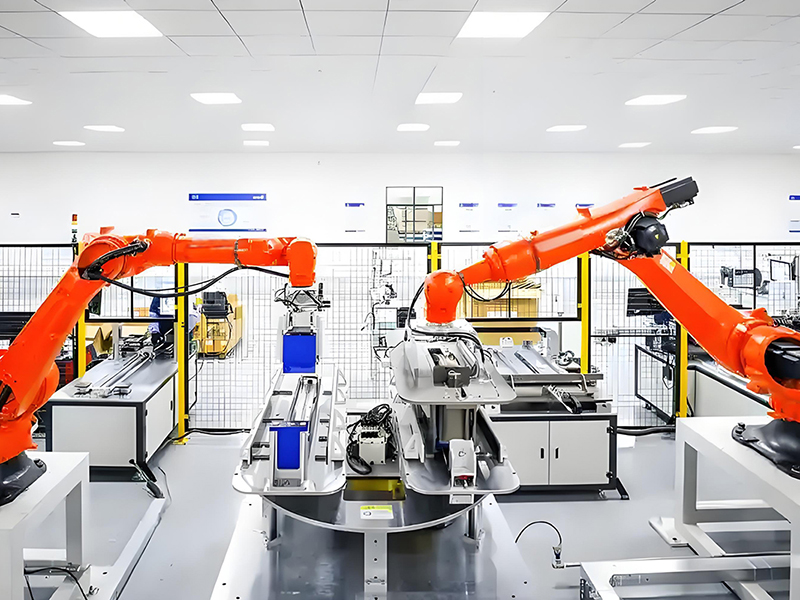

- Battery Assembly: Electromagnetic robots place cells with 0.1mm accuracy, minimizing defects.

- Motor Manufacturing: Magnetizing coils align NdFeB rotor magnets, improving motor efficiency by 5%.

Case Study 4:

Tesla’s Gigafactory Berlin employs electromagnetic grippers to assemble 4680 battery cells at 10,000 units/hour, reducing energy use by 30% vs. hydraulic systems.

4.2 Lightweighting Innovations

Electromagnets help reduce vehicle weight for lower emissions:

- Magnetic Fasteners: Replace bolts in composite frames, cutting weight by 15%.

- Active Suspension: Electromagnetic dampers adjust stiffness in real time, enabling lighter chassis designs.

Breakthrough:

BMW’s iX SUV uses electromagnetic riveting to join aluminum and carbon fiber, shedding 200 kg vs. traditional welding.

5. Sustainable Material Innovations

5.1 Rare Earth-Free Magnets

To reduce reliance on mined rare earths, manufacturers are adopting:

- Ferrite Magnets: Used in 60% of global electromagnets, fully recyclable.

- Manganese-Aluminum-Carbon (MnAlC) Alloys: Deliver 70% of NdFeB strength without rare earths.

Case Study 5:

Hitachi’s Eco-Magnets, made from recycled ferrite and MnAlC, cut CO₂ emissions by 50% in elevator motor production.

5.2 Recyclable Coils

- Bio-Based Insulation: Polyhydroxyalkanoate (PHA) coatings replace petroleum-derived enamels.

- Modular Designs: ABB’s EcoDry transformers use easily disassembled coils, achieving 95% material recovery.

6. Electromagnets in Smart, Low-Carbon Factories

6.1 IoT-Driven Energy Management

Smart electromagnets with embedded sensors optimize resource use:

- Predictive Maintenance: Vibration sensors detect coil degradation, cutting downtime by 40%.

- Load Balancing: AI adjusts electromagnetic actuator schedules to off-peak energy periods.

Case Study 6:

Schneider Electric’s Le Vaudreuil Factory reduced energy consumption by 25% using IoT-connected electromagnetic systems.

6.2 Digital Twins and Simulation

Virtual models refine electromagnet efficiency before production:

- COMSOL Multiphysics: Simulates thermal and electromagnetic behavior to minimize prototyping waste.

- ANSYS Maxwell: Optimizes coil geometries for 20% lower losses.

7. Challenges and Solutions in Sustainable Electromagnet Design

7.1 Material Sourcing Ethics

- Conflict Minerals: Ensure cobalt and rare earths are sourced from certified mines.

- Solution: Blockchain tracking via platforms like IBM’s Responsible Sourcing.

7.2 End-of-Life Recycling

- Challenge: Only 5% of electromagnets are recycled today due to complex material mixes.

- Solution: Design for disassembly (DfD) standards and hydrometallurgical recovery processes.

7.3 Energy-Intensive Production

- Challenge: Magnet sintering consumes 50–100 kWh/kg.

- Solution: Microwave sintering cuts energy use by 60% and time by 70%.

8. Future Trends: Electromagnets in a Net-Zero World

- Self-Powered Electromagnets: Harvest energy from vibrations or thermal gradients.

- AI-Optimized Magnets: Machine learning designs coils with 90% lower losses.

- Carbon-Neutral Factories: Renewable-powered production with closed-loop material flows.

Electromagnets—Forging a Sustainable Industrial Future

Electromagnets are not just components; they are enablers of a cleaner, more efficient manufacturing paradigm. By embracing energy-efficient designs, circular material flows, and renewable integration, industries can slash emissions while boosting competitiveness.

As a leader in custom electromagnet solutions, we’re committed to advancing technologies that align profit with planetary health. Whether you’re retrofitting legacy systems or building a greenfield factory, the future of manufacturing is magnetic—and sustainably so.

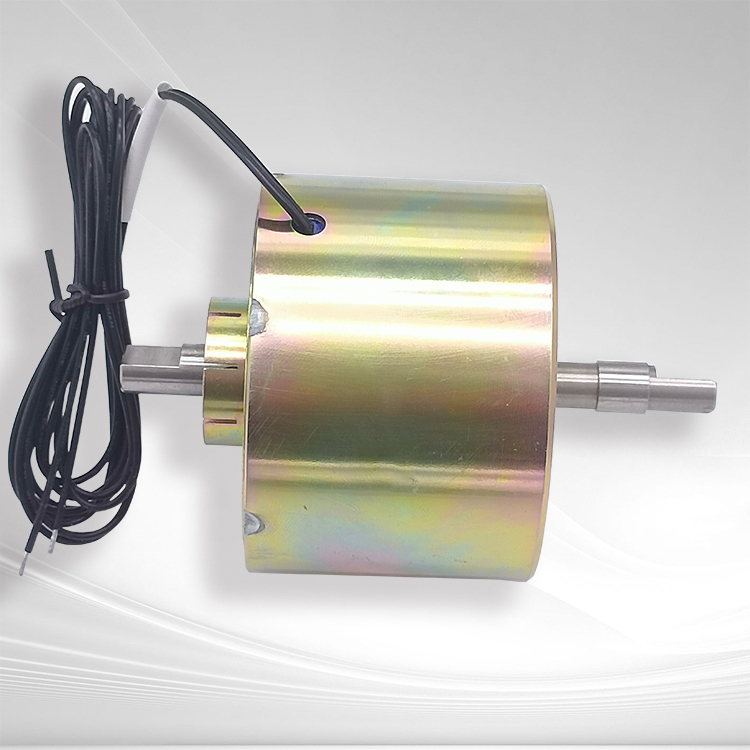

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier. Contact WhatsApp +86 18902611680

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.