Last Updated on 2025-09-03 by SolenoidFactory

Electromagnet has revolutionized numerous industries, particularly in the realm of precision instruments. Their ability to generate controlled magnetic fields with high precision and reliability makes them indispensable in a wide range of applications, from scientific research to industrial manufacturing. This blog explores the various applications of electromagnets in precision instruments, highlighting their critical role in enhancing accuracy, efficiency, and reliability.

The Role of Electromagnet in Precision Instruments

Electromagnets are devices that produce magnetic fields when an electric current passes through them. These fields can be precisely controlled by varying the current’s strength, direction, and duration. This control is essential in precision instruments, where minute changes in magnetic force can significantly impact performance.

In precision instruments, electromagnets are often used in combination with other components, such as sensors, actuators, and microcontrollers, to create complex and highly accurate systems. They enable functions such as positioning, sensing, and actuation with unparalleled precision, making them crucial in applications where even the smallest errors can have significant consequences.

Electromagnet Applications in Scientific Research

Electromagnet play a pivotal role in scientific research, particularly in fields such as physics, chemistry, and biology. Here are some notable applications:

Mass Spectrometers: Electromagnets are central to mass spectrometers, which are used to analyze the chemical composition of samples. By creating a strong magnetic field, they separate ions based on their mass-to-charge ratio, enabling precise identification and quantification of compounds.

NMR Spectrometers: Nuclear Magnetic Resonance (NMR) spectrometers rely on electromagnets to generate the magnetic field necessary for aligning nuclear spins and measuring their resonance frequencies. This technology is crucial in fields like structural biology and materials science, providing insights into molecular structures and interactions.

Particle Accelerators: Electromagnets are essential in particle accelerators, such as those used in high-energy physics research. They guide and accelerate particles to near-light speeds, enabling experiments that probe the fundamental nature of matter and energy.

Applications in Industrial Manufacturing

In industrial manufacturing, electromagnets are used in a variety of precision instruments to enhance production processes and ensure product quality. Here are some examples:

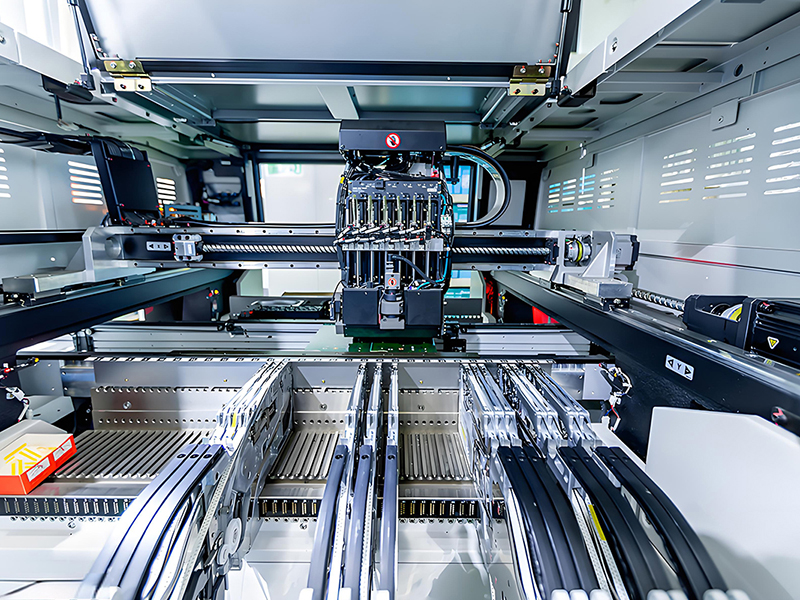

Precision Assembly Machines: Electromagnets are often incorporated into precision assembly machines, enabling the accurate placement and alignment of components. This is particularly important in industries such as electronics and aerospace, where tolerance levels are extremely tight.

Magnetic Levitation (Maglev) Systems: Maglev systems use electromagnets to levitate and propel objects with minimal friction. They are employed in high-speed trains and precision manufacturing equipment, offering increased efficiency and reduced wear and tear.

Non-Destructive Testing (NDT) Equipment: Electromagnets are used in NDT equipment, such as eddy current testers, to detect defects in materials without damaging them. This is essential in industries like aerospace and automotive, where component integrity is critical.

Advancements and Innovations

The application of electromagnets in precision instruments continues to evolve, driven by advancements in materials science, electronics, and computational technologies. Here are some notable trends:

High-Temperature Superconducting Electromagnets: The development of high-temperature superconducting materials has led to the creation of more efficient and powerful electromagnets. These materials enable the generation of stronger magnetic fields with lower energy consumption, which is beneficial in applications requiring high precision and sensitivity.

Miniaturization and Integration: The trend towards miniaturization and integration of precision instruments has led to the development of compact and lightweight electromagnets. These devices enable the creation of portable and handheld precision instruments, expanding their use in various fields.

Smart Electromagnets: The integration of sensors, microcontrollers, and advanced algorithms has given rise to smart electromagnets that can adapt and optimize their performance in real-time. This capability enhances precision and reliability, particularly in dynamic and unpredictable environments.

Electromagnet is indispensable in precision instruments

Electromagnets are indispensable in precision instruments, enabling functions such as positioning, sensing, and actuation with unparalleled accuracy and reliability. Their applications span scientific research, industrial manufacturing, and beyond, contributing to advancements in numerous fields. As technology continues to evolve, we can expect to see further refinements and innovations in electromagnet design and application, driving even greater precision and efficiency in precision instruments. Understanding and leveraging the capabilities of electromagnets is crucial for harnessing their full potential and unlocking new possibilities in scientific research and industrial manufacturing.

About SF electromagnets factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagnet

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.