Last Updated on 2025-09-03 by SolenoidFactory

As a device that converts electrical energy into magnetic energy, electromagnet plays a vital role in the history of human science and technology. From the discovery of the basic principles of electromagnetism to the birth of electromagnets and their wide application in various fields, this process has not only promoted the progress of science and technology, but also profoundly changed the way of life and production of human beings. This article will discuss the invention, history and development of electromagnets in detail.

1. Basic principles of electromagnetism and early exploration

The relationship between electricity and magnetism has attracted human attention since ancient times. As early as 600 BC, Thales, a natural philosopher in ancient Greece, recorded the phenomenon that amber attracted light and small objects and magnets attracted iron after friction. However, people at that time had a superficial understanding of magnetism and electricity and lacked a systematic theoretical explanation.

Ancient China had noticed the magnetic phenomenon and invented the compass. The compass used the natural magnetism of magnetite to make the spoon handle point south under the action of geomagnetism, becoming the world’s first compass. This invention played an important role in fields such as navigation and greatly promoted the progress of human civilization.

In the Middle Ages in Europe, magnetism was further studied, but the understanding of magnetic phenomena remained at the empirical and experimental stage. At the same time, electrical phenomena were gradually observed by people. For example, the Greeks discovered that rubbing amber could attract light and small objects, but they were also unable to explain this phenomenon.

In 1600, the Englishman William Gilbert published a monograph on magnetism, “The Magnet”, which systematically discussed that the earth is a large magnet and described many magnetic experiments. He corrected the misunderstanding of his predecessors that friction attracted light objects, proposed that this was not due to magnetic force, but the effect of electricity, and used the Greek word “amber” to create the word “electric”.

In the 18th century, with the advent of a series of important discoveries such as electric charge, the difference between conductors and insulators, the two types of electricity, and methods of storing electricity, the study of electricity gradually deepened. Among them, the invention of the Leyden jar made electricity store and useable, providing an important tool for later electrical research.

In the early 19th century, the study of electromagnetism ushered in a major breakthrough. In 1820, Danish physicist Hans Christian Oersted accidentally discovered the relationship between electric current and magnetic field during a classroom demonstration. He noticed that when current passed through a wire, a nearby compass would deflect. This phenomenon shows that electric current can generate magnetic field, revealing the deep connection between electricity and magnetism, marking the beginning of electromagnetic research.

2. The invention and early application of electromagnet

Based on Oersted’s discovery of the magnetic effect of electric current, scientists further explored the mechanism of electric current generating magnetic field and tried to use this phenomenon for application. Based on Oersted’s discovery, British scientist Michael Faraday discovered the phenomenon of electromagnetic induction through a series of experiments, that is, a changing magnetic field can generate electric current in a conductor. This discovery laid the foundation for the establishment of electromagnetic theory and provided theoretical support for the invention of electromagnet.

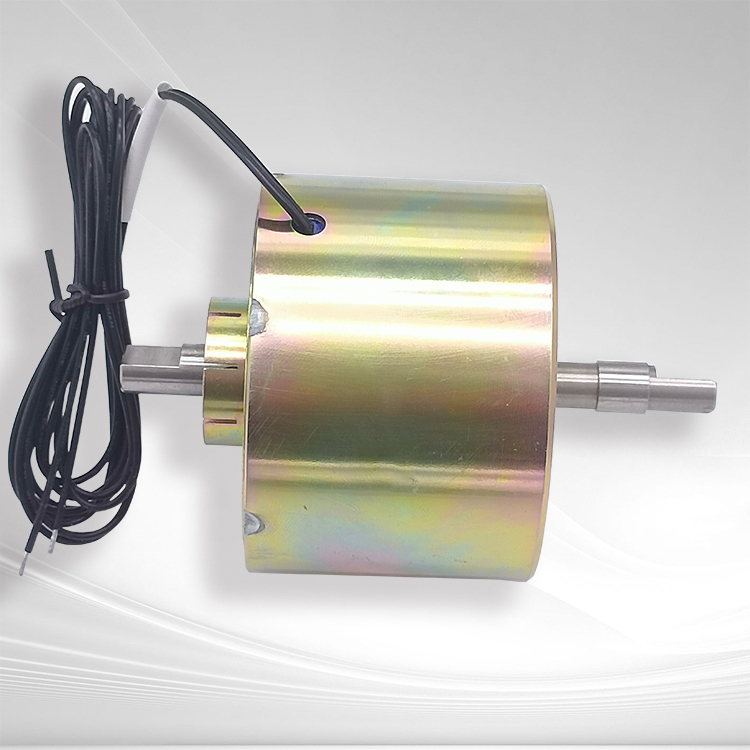

The principle of electromagnet is based on the fact that electric current generates magnetic field through a coil wound by a wire, and this magnetic field can be amplified by the iron core. By adjusting the current size and the number of turns of the coil, the magnetic field strength of the electromagnet can be controlled.

In 1823, British scientist William Sturgeon conducted a landmark experiment. He wound 18 turns of bare copper wire on a U-shaped iron rod. When the copper wire was connected to a voltaic battery, the copper coil wound on the U-shaped iron rod generated a dense magnetic field, turning the U-shaped iron rod into an “electromagnet”. The magnetic energy of this electromagnet is many times greater than that of a permanent magnet. It can absorb an iron block 20 times heavier than it. When the power is cut off, the U-shaped iron bar loses its magnetism and becomes an ordinary iron bar again.

Sturgeon’s invention made people see the bright prospects of converting electrical energy into magnetic energy. This invention quickly spread in Britain, the United States and some coastal countries in Western Europe. The invention of the electromagnet provided new tools for electromagnetic research and application, and also promoted the development of electromagnetic theory.

In 1829, American electrician Joseph Henry made some innovations to the Sturgeon electromagnet device. He replaced the bare copper wire with an insulated wire, so there was no need to worry about being short-circuited by the copper wire being too close. Because the wires have an insulating layer, they can be tightly wound together. Since the denser the coil, the stronger the magnetic field generated, this greatly improves the ability to convert electrical energy into magnetic energy.

3. The development and wide application of electromagnet

With the continuous improvement and innovation of electromagnet technology, its application field has gradually expanded. Electromagnets have been widely used in telegraph systems. In 1837, Samuel Morse invented the telegraph, which achieved long-distance information transmission through the telegraph key controlled by electromagnets. The invention and application of the telegraph greatly promoted the development of communication technology.

The application of electromagnets in motors and generators is an important practice of electromagnetic theory. Motors use the magnetic field generated by electromagnets to drive rotating machinery to convert electrical energy into mechanical energy. Generators induce current in conductors through rotating magnetic fields to convert mechanical energy into electrical energy. The invention and application of motors and generators marked the advent of the electrical age.

In addition, electromagnets also play an important role in magnetic levitation technology. Maglev trains achieve frictionless suspension and high-speed operation through the magnetic field generated by electromagnets. This technology has broad application prospects in the field of transportation.

In industrial production, electromagnets are widely used in lifting, traction, braking and other fields. Lifting electromagnets are used to lift magnetic materials such as steel and iron sand; traction electromagnets are used to pull mechanical devices to perform automatic control tasks; brake electromagnets are used as mechanical brakes for motors in electrical transmission devices.

In daily life and scientific research, electromagnets are also widely used. For example, electromagnetic relays use electromagnets to control the on and off of circuits; electronic door locks use electromagnets to realize the opening and closing of door locks; intelligent channel turns use electromagnets to control the passage of channels; and electromagnetic flowmeters use electromagnets to measure the flow of fluids.

4. Modern progress and future prospects of electromagnet technology

With the continuous development of science and technology, electromagnet technology is also constantly improving. Modern electromagnets use more advanced materials and manufacturing processes, with higher performance and a wider range of applications.

In terms of materials, modern electromagnets use high-performance soft magnetic materials and conductive materials. These materials have higher magnetic permeability and electrical conductivity, and can generate stronger magnetic fields and higher efficiency. At the same time, the use of these materials can also reduce the volume and weight of electromagnets, and improve their reliability and service life.

In terms of manufacturing technology, modern electromagnets use precision processing and assembly technologies. These technologies can ensure the precise control of parameters such as the number of turns, wire diameter, and insulation layer thickness of the electromagnet, thereby improving its performance and stability. In addition, the use of advanced packaging and heat dissipation technologies can also effectively reduce the temperature rise and noise of electromagnets.

In the future, with the continuous development of new energy, intelligent manufacturing and other fields, electromagnet technology will usher in more opportunities and challenges. For example, in new energy vehicles, electromagnets will be used to drive key components such as motors, braking systems and suspension systems; in intelligent manufacturing, electromagnets will be used to achieve more precise control and positioning functions. At the same time, with the continuous development of emerging technologies such as nanotechnology and quantum technology, electromagnet technology will continue to develop in the direction of miniaturization, intelligence and multifunctionality.

electromagnet changed human lifestyles and production methods

From the discovery of the basic principles of electromagnetism to the invention and application of electromagnets, mankind has gone through a long journey. This journey has not only promoted the progress of science and technology, but also profoundly changed human lifestyles and production methods. As an important electromagnetic device, electromagnets play an irreplaceable role in communications, electricity, transportation, industrial production and other fields. Looking to the future, with the continuous development of science and technology, electromagnet technology will usher in more opportunities and challenges, and make greater contributions to the progress of human civilization.

About SF electromagnet factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagne

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.