Last Updated on 2025-09-03 by SolenoidFactory

In the vast universe of electromagnet technology, Rotary Solenoids is like a shining star. With its unique rotating action mechanism and wide application fields, it has become an indispensable part of modern industrial and electronic equipment. As a factory specializing in the production of electromagnets, we are well aware of the great potential of Rotary Solenoids in improving equipment performance, simplifying control logic, and realizing complex actions. This article will explore the working principle, structural composition, advantage analysis, customization process, application scope and specific application cases of Rotary Solenoids in depth, and take you to appreciate the unique charm of this technology.

1. What is the Working principle of Rotary Solenoids ?

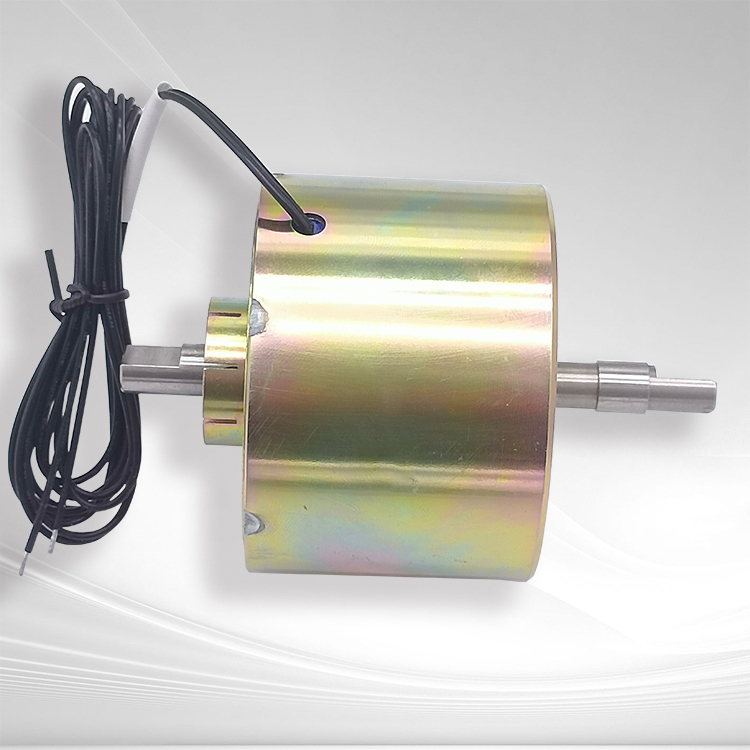

Rotary Solenoids, also known as rotary solenoids, is an electromagnetic device that can convert electrical energy into rotating mechanical energy. Its working principle is based on electromagnetic induction and magnetic field. When current passes through the coil wound on the iron core, a magnetic field will be generated around the iron core, causing the iron core and its moving parts (such as rotors or armatures) to rotate under the action of magnetic force.

Specifically, Rotary Solenoids usually contain a fixed iron core, a rotatable moving part (rotor), and a coil wound on the iron core. When the coil is energized, the magnetic field generated interacts with the permanent magnet or magnetic material on the rotor to generate a rotational torque, causing the rotor to start rotating. By controlling the on and off state of the coil and the direction and magnitude of the current, the direction and speed of the rotor rotation can be controlled.

2.What is the Structural composition of Rotary Solenoids ?

The structural design of Rotary Solenoids is precise and complex, and usually consists of the following key parts:

Iron core: The iron core is the core component of Rotary Solenoids, usually made of soft magnetic materials such as silicon steel sheets or ferrites. The function of the iron core is to enhance the magnetic field and improve the electromagnetic conversion efficiency.

Coil: The coil is a wire wound on the iron core, usually made of copper wire or aluminum wire. The number of turns and wire diameter of the coil affect the strength of the magnetic field and the magnitude of the electromagnetic force. In Rotary Solenoids, the coil is usually precisely wound on the iron core to produce a uniform magnetic field distribution.

Rotor: The rotor is the key component for realizing the rotational action in Rotary Solenoids. It can be a disk or cylinder made of permanent magnet, ferrite or other magnetic materials. The rotor rotates under the action of the rotational torque under the action of the magnetic field.

Bearing: The bearing is used to support the rotor and reduce the friction and wear during its rotation. The selection and design of the bearing are crucial to the rotation performance and life of the Rotary Solenoids.

Housing: The housing is used to protect the internal structure of the Rotary Solenoids from interference and damage from the external environment. The housing is usually made of metal or plastic and has a certain strength and sealing.

Control circuit: The control circuit is used to control the on and off state of the Rotary Solenoids and the direction and size of the current, so as to realize the control of the rotation direction and speed of the rotor. The control circuit can be customized according to customer needs to adapt to different application scenarios and control logic.

3. What are Advantages of Rotary Solenoids ?

Compared with traditional electromagnets, Rotary Solenoids has many advantages, which make it stand out in many application fields:

Rotational action capability: Rotary Solenoids can achieve rotational action, which makes it unique in application scenarios that require rotational drive. For example, in automation equipment, Rotary Solenoids can be used to drive rotating mechanisms, valves and other components.

High efficiency: Rotary Solenoids uses precise coil winding technology and optimized magnetic field design, which enables it to fully utilize magnetic field energy during rotational action and improve electromagnetic conversion efficiency. At the same time, its compact structure and excellent heat dissipation performance help reduce energy consumption and extend service life.

Flexible control: The control circuit of Rotary Solenoids can be customized according to customer needs to achieve different control logic and functions. For example, complex timing control, position feedback and other functions can be implemented through programming to meet the needs of specific application scenarios.

Strong adaptability: The shell design and sealing performance of Rotary Solenoids enable it to adapt to various harsh environments, such as high temperature, low temperature, humidity, dust, etc. This makes Rotary Solenoids have a wide range of application prospects in industrial automation, automotive electronics, medical equipment and other fields.

Easy maintenance: The structural design of Rotary Solenoids is concise and easy to install and maintain. Customers can easily disassemble and replace parts as needed, reducing maintenance costs and downtime.

4. How to customize Rotary Solenoids

In order to meet the needs of different customers, we provide customized services for Rotary Solenoids. The following are several key steps in the customization process:

Demand communication: First, we will communicate with customers in detail to understand their specific application scenarios, performance requirements, installation environment and other information. This will help us provide customers with the most suitable customized solutions.

Scheme design: According to customer needs, our engineers will carry out scheme design. This includes selecting suitable core materials, determining the number of coil turns and wire diameter, designing the size and structure of components such as rotors and bearings, etc. At the same time, we will also consider the customization needs of the control circuit to achieve specific control logic and functions. After the scheme design is completed, we will confirm with the customer and adjust and optimize according to the feedback.

Manufacturing: After the solution is confirmed, we will enter the manufacturing stage. We will use advanced production equipment and processes to ensure that the quality and performance of the product meet the design requirements. At the same time, we will conduct strict quality inspection and control to ensure that each Rotary Solenoids can meet customer expectations.

Testing and debugging: After the manufacturing is completed, we will test and debug the Rotary Solenoids. This includes performance testing, functional testing, reliability testing, etc. Through testing and debugging, we can ensure that the product can operate stably and reliably in actual applications.

Delivery and after-sales: After testing and debugging, we will package and deliver according to customer requirements. At the same time, we provide comprehensive after-sales service and technical support to ensure that customers can get timely and effective help and support during use.

5. what is Application scope of Rotary Solenoids

Rotary Solenoids has been widely used in many fields due to its unique performance and advantages:

Industrial automation: In automated production lines, Rotary Solenoids are often used to drive rotating mechanisms, valves and other components. Its rotational motion capability and high efficiency enable automated production lines to operate more flexibly and efficiently.

Automotive electronics: In the field of automotive electronics, Rotary Solenoids are widely used in seat adjustment, window lifting, sunroof switches and other components. Its flexible control and strong adaptability make automotive electronic systems more intelligent and humanized.

Medical equipment: In medical equipment, Rotary Solenoids are often used to drive surgical instruments, bed lifting and other components. Its precise control and stable performance ensure the safety and reliability of medical equipment.

Aerospace: In the field of aerospace, Rotary Solenoids are used to drive the control surfaces, doors and other components of various aircraft. Its small size, light weight and high reliability enable aerospace equipment to operate more flexibly and efficiently.

Consumer electronics: In the field of consumer electronics, Rotary Solenoids are used in the automatic rotation of cameras and automatic flipping of screens in mobile phones, tablets and other devices. Its fast response and easy installation and maintenance make consumer electronic devices more intelligent and convenient.

6.What are Application Cases of Rotary Solenoids ?

The following are some examples of Rotary Solenoids in specific applications:

Valve control in industrial automation: In automated production lines, Rotary Solenoids are used to control the opening and closing of rotary valves. When the valve needs to be opened or closed, the control system sends a signal to the Rotary Solenoids to generate a rotational torque and drive the valve to perform the corresponding opening and closing operations. This application not only improves the automation level of the production line, but also reduces the need and cost of manual intervention.

Seat adjustment in automotive electronics: In modern cars, Rotary Solenoids are widely used in seat adjustment systems. When the driver or passenger needs to adjust the seat position, just press the corresponding button to trigger the Rotary Solenoids to rotate and drive the seat to adjust accordingly. This application not only improves driving and riding comfort, but also makes seat adjustment more intelligent and convenient.

Surgical instrument drive in medical equipment: In medical equipment, Rotary Solenoids are used to drive surgical instruments for rotational operations. For example, in minimally invasive surgery, doctors can control Rotary Solenoids to achieve precise rotation and cutting of surgical instruments. This application not only improves the success rate and safety of surgery, but also reduces the doctor’s operating burden.

Automatic rotation of cameras in consumer electronics: Rotary Solenoids are used to achieve automatic rotation of cameras in devices such as smartphones and tablets. When the user needs to switch between the front and rear cameras, the device triggers the Rotary Solenoids to rotate and drive the camera to move accordingly. This application not only improves the convenience of taking photos and videos, but also makes consumer electronic devices more intelligent and user-friendly.

7. Future Outlook

With the advancement of science and technology and the continuous changes in application needs, Rotary Solenoids will be applied and developed in more fields. In the future, we can expect progress in the following aspects:

Technological innovation: With the continuous emergence of new materials, new processes and new technologies, the performance of Rotary Solenoids will be further improved. For example, the use of high-performance permanent magnetic materials can increase the magnetic field strength and electromagnetic force; the use of advanced winding technology can reduce resistance and heat generation; the use of intelligent control technology can achieve more precise control and monitoring, etc.

Application expansion: With the rapid development of industrial automation, automotive electronics, medical equipment and other fields, the application scope of Rotary Solenoids will be further expanded. For example, in the field of industrial automation, Rotary Solenoids can be used for more complex control systems and harsher working environments; in the field of automotive electronics, Rotary Solenoids can be used for more advanced driver assistance systems and autonomous driving systems; in the field of medical equipment, Rotary Solenoids can be used for more sophisticated surgical robots and rehabilitation equipment, etc.

Environmental protection and energy saving: With the increasing global attention to environmental protection and energy saving, Rotary Solenoids will play a greater role in energy saving and consumption reduction. For example, by optimizing the design and adopting new energy technologies, the energy consumption and emissions of Rotary Solenoids can be reduced; by recycling and reusing the parts and materials of waste Rotary Solenoids, resource waste and environmental pollution can be reduced.

As a factory focusing on the production of electromagnets, we will continue to be committed to the research and development and innovation of Rotary Solenoids technology to provide customers with better products and services. We believe that in the near future, Rotary Solenoids will demonstrate its unique charm and huge potential in more fields and make greater contributions to promoting scientific and technological progress and social development.

About SF electromagnet factory

Shengfeng Electromagnet Co., Ltd. was established in 2015 and is located in the Xiansha Industrial Park with beautiful scenery and convenient transportation. The company covers an area of 16000 square meters and has modern production plants, advanced production equipment and a high-quality technical team. Since its establishment, we have always adhered to the corporate philosophy of “innovation, quality, and service”, focusing on the research and development and production of electromagnets, constantly promoting product upgrades and technological progress, and providing customers with the best quality products and services.

Why choose SF electromagne

HIGH END QUALITY:As the best solenoid electromagnet manufacturer in china, our QC team will ensure every single product you receive are best quality. We have professional quality testing machine.

PRODUCT DESIGN:Our sampling department has complete process of making drawings into reality. We also improve your product design based on our years of working experience.Tell us what you think.

STABLE DELIVERY TIME:As the best electromagnet manufacturer & supplier,we have sufficient manufacturing capacity, big orders won’t beat us, we can still deliver the order for you in time.

BEST PRICE:We are source factory of electromagnet and the best solenoid manufacturer in China, that’s why we can provide high quality bags with best price.

PRECISE MANAGEMENT:Nothing can be achieved if we don’t implement precise management. We are a company with complete management system.

7-24 SERVICE:As the best solenoid manufacturer, 24-7 immediate response: We’ll receive your feedback to make us a better supplier.

FAQs of electromagnet

We are a Chinese top electromagnet manufacturer and our factory is located in Dongguan. Welcome to visit our factory!

We pecialize in the design and production of high quality electromagnet,solenoid valve,such as rotary solenoid, bistable solenoids, latching solenoids, open frame solenoids, tubular solenoids, self-holding solenoid

•Of course, usually we will provide free samples, and you only need to cover the freight. For custom electromagnet samples, pls send your requirements to us for checking the sample cost.

• It takes about 7 days for sample production.

Yes, we provide free design services, structural design and simple graphic design.

Sure. We can do any electromagnet with your design. Now we open a ODM solenoid which is for small quantity from 100pc to 500pc,but you can still have your own logo.

Depending on the order quantity and production details, it will take about 15 to 20 days.

Always a pre-production sample before mass production; Always final Inspection before shipment

• Power,usage,size, material, quantity, shipping destination, etc.

• You can also just tell us your requirements and we will recommend products to you.

• By sea, by air or by express.

• If you have your own freight forwarder in China, it is the ex-factory or FOB price.

•CFR or CIF, etc., if you need us to ship on your behalf.

• DDP and DDU can also be used.

• More choices, we will consider your choices.

• The price is determined by the quantity, material, processing method, size and other factors. In addition, due to our continuous

technological innovation, the prices of some of our products are extremely competitive, please contact us to quote.