Application of electromagnet in manufacturing industry

Electromagnet have been widely used in modern household appliances

Working Principle of Electromagnet

An electromagnet is a device that uses electric current to pass through a wire to generate a magnetic field, thereby attracting ferromagnetic materials. Its core components include a coil, an iron core, and an armature. When the coil is energized, the magnetic field generated magnetizes the iron core, which in turn attracts the armature to achieve mechanical movement or position control. Depending on the purpose and structure, electromagnets can be divided into many types, such as DC electromagnets, AC electromagnets, suction cup electromagnets, push-pull electromagnets, etc.

Application scope of electromagnet in manufacturing industry

The application of electromagnets in manufacturing industry is mainly reflected in the following aspects:

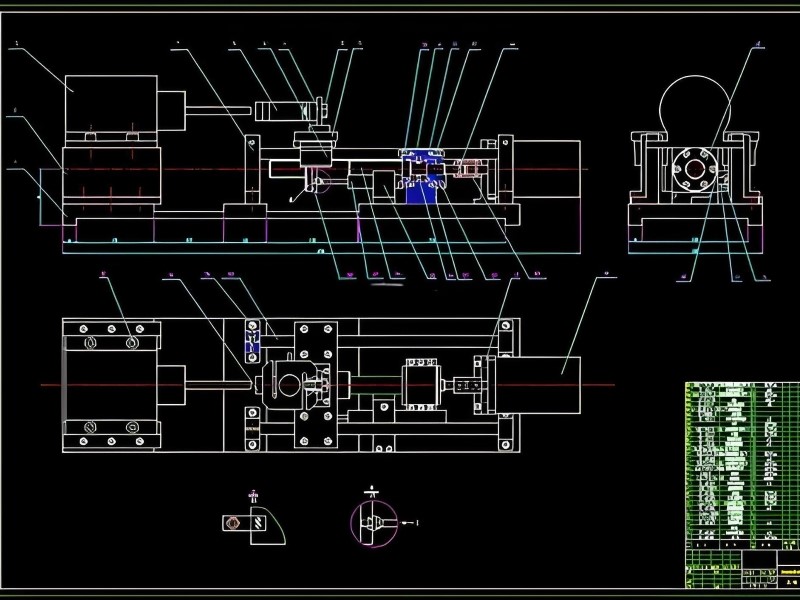

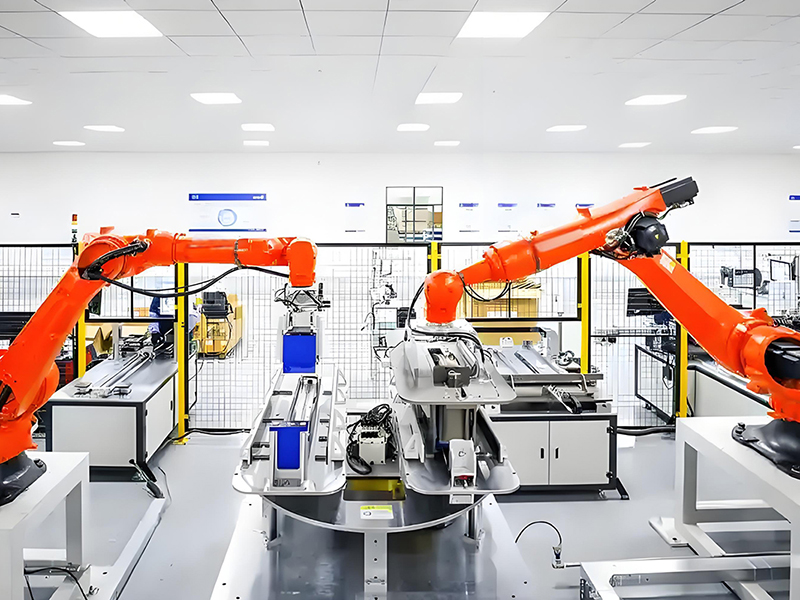

Automated production line

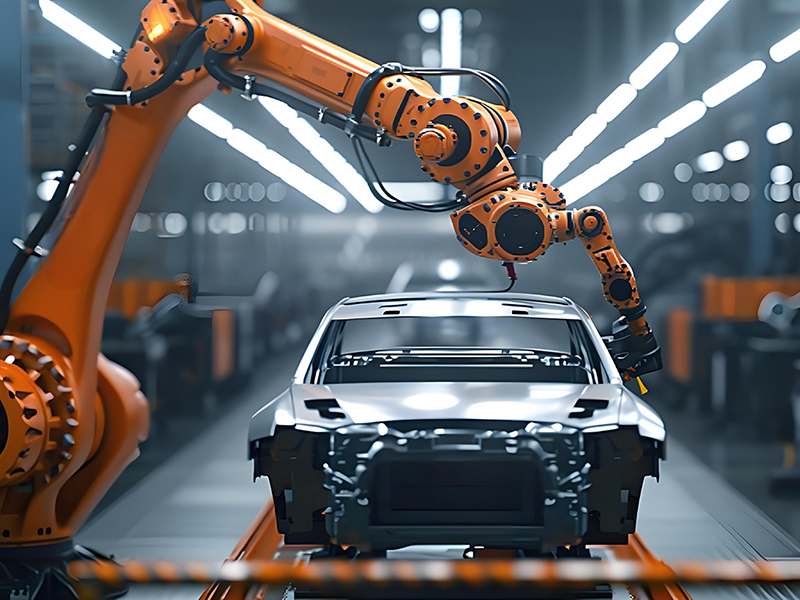

Automobile manufacturing

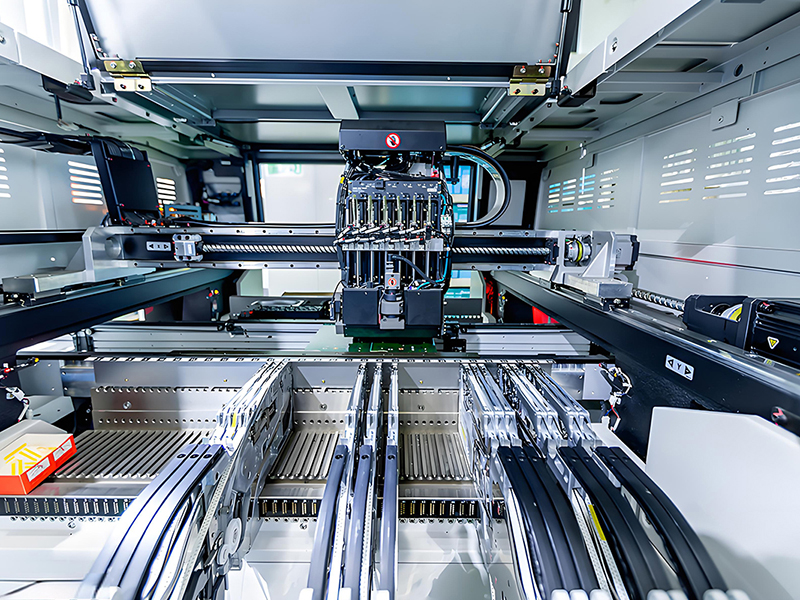

Precision instruments and medical equipment

Home appliances and office equipment

Application cases of electromagnets in home appliances

The application of electromagnets makes home appliances more intelligent, energy-saving and efficient

Electromagnet for Auto door lock system

In modern cars, automatic door lock systems have become standard. The system automatically locks and unlocks the doors by means of electromagnets. When the driver presses the door lock button or remote control, the electromagnet generates a magnetic force and drives the lock tongue to expand and expand, so as to realize the lock and unlock the door. This system not only improves the safety of driving, but also enhances the convenience of users.

Electromagnetic suckers on automated production lines

In automated production lines, electromagnetic suckers are widely used in material handling. Taking the steel plate processing production line as an example, the electromagnetic sucker absorbs the steel plate through the electromagnetic force to achieve rapid and accurate handling of the steel plate. The system can adjust the suction force according to the production demand to ensure the stable handling of the steel plate. At the same time, the electromagnetic chuck also has the automatic demagnetization function, when the steel plate reaches the designated position, the electromagnet power off, the steel plate automatically falls off, to achieve efficient production.

Electromagnet for MRI machine

Nuclear magnetic resonance imaging (MRI) is an important tool in modern medical diagnosis. One of its core components is a superconducting magnet, which uses electromagnets to generate a strong static magnetic field. When the human body enters the magnetic field, the hydrogen nucleus in the body resonates under the excitation of the radio frequency pulse, producing a weak signal. These signals are picked up and amplified by a receiver and processed by a computer to form high-resolution medical images. The electromagnet in MRI equipment requires not only high magnetic field strength and good uniformity, but also long-term stable operation to ensure the accuracy of diagnosis.

Electromagnet applications in precision instruments

In precision instruments, the characteristics of high precision and high stability of electromagnets have been fully applied. In electron microscopy, for example, the sample table is controlled and moved precisely by electromagnets. When a specific area of the sample needs to be observed, the electromagnet is energized to create a magnetic force that drives the sample table to the specified position. This process requires the electromagnet to have extremely high control accuracy and response speed to ensure the accuracy and efficiency of the observation.

Electromagnets improve the automation of home appliances

As an important component in the manufacturing industry, electromagnets play an irreplaceable role in many fields with their unique electromagnetic conversion characteristics. From automated production lines to automobile manufacturing, from precision instruments to medical equipment, the application cases of electromagnets are endless, showing their important role in improving production efficiency, ensuring product quality, and realizing automatic control. In the future, with the continuous progress of technology and the continuous expansion of application fields, electromagnets will play a more important role in the manufacturing industry, providing strong support for the transformation and upgrading of the manufacturing industry and sustainable development.

Products